A method for arsenic-containing arsenic dust removal and distribution crystallization to synthesize arsenic-fixed minerals

A technology for distributing crystallization and arsenic fume, which is applied in the field of metallurgy, can solve the problems of no further research on the recovery of valuable metal powder, incomplete separation of arsenic and other elements, and low purity of arsenic trioxide, so as to achieve a wide range of raw materials and high stability , the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

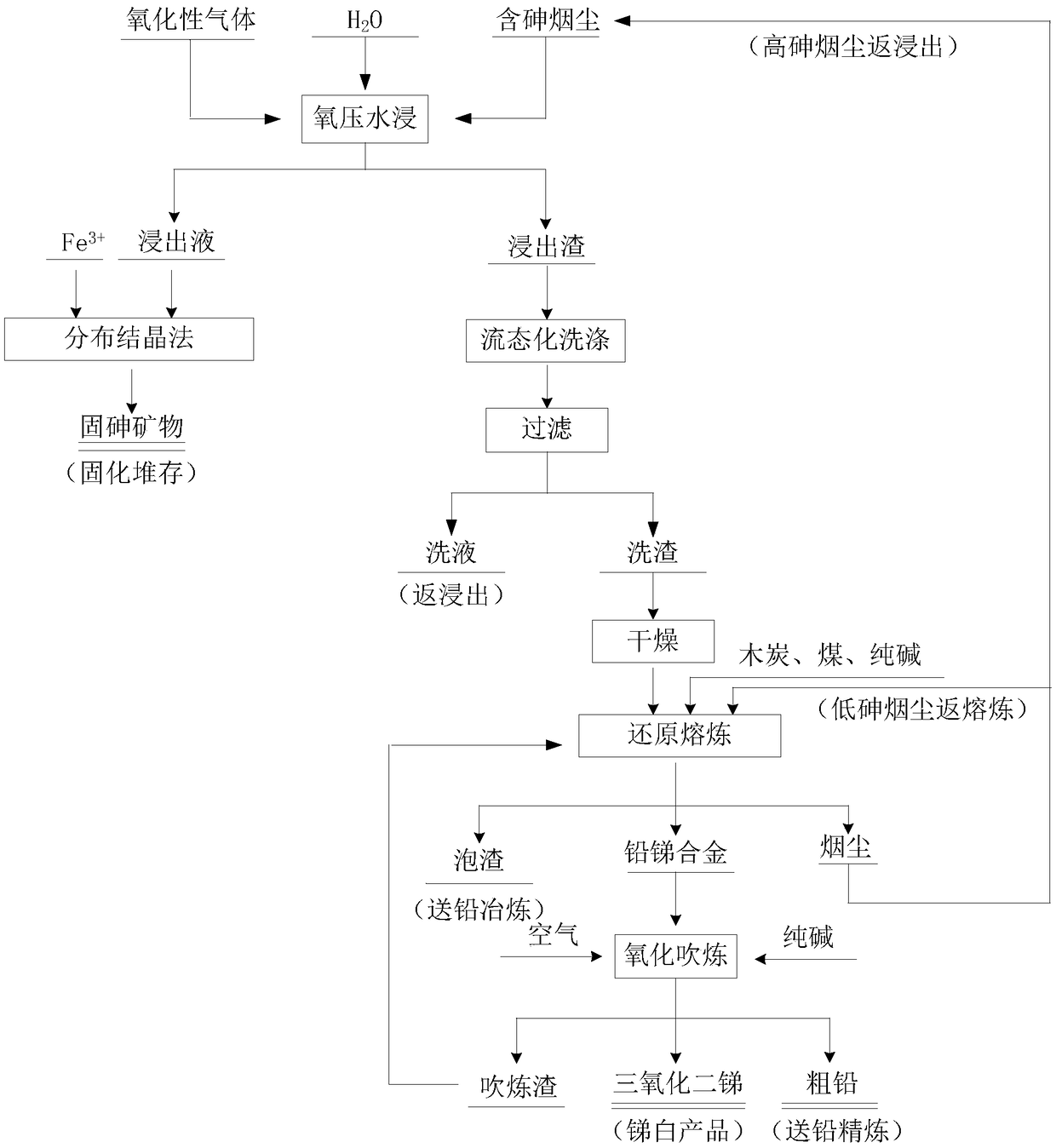

Method used

Image

Examples

Embodiment 1

[0043] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, the main components of the raw materials are Pb 1.57%, As 48.56%, Sn 0.51%, Sb 21.24%, Zn 0.73%, Te 0.35%, Se 0.25%. Take the following steps to deal with:

[0044] (1) Oxygen pressure water immersion: Weigh a certain quality of high arsenic and antimony fumes into the reactor, the control conditions are liquid-solid volume mass ratio 10:1, stirring speed 300r / min, leaching temperature 160°C, oxygen partial pressure 2Mpa, The leaching time is 2 hours. After the leaching is completed, the slurry is removed, filtered and separated to obtain the arsenic-containing leach solution and leach residue;

[0045] After testing: the arsenic leaching rate is 61.53%, and the concentration of each element in the leach solution is Pb 709.60ppm, Se 31.02ppm, Sb 1.26g / L, Te 123.28ppm, As 29.88g / L.

[0046] (2) Fixing arsenic in the leach solution: the leach solution obtained in step (1) is synthesized with ...

Embodiment 2

[0053] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, the main components of the raw materials are Pb 6.88%, As 36.51%, Sn 1.11%, Sb 29.77%, Zn 0.54%, Te 0.24%, Se 0.05%. Take the following steps to deal with:

[0054] (1) Oxygen pressure water immersion: Weigh a certain quality of high arsenic and antimony fumes into the reactor, the control conditions are liquid-solid volume mass ratio 20:1, stirring speed 300r / min, leaching temperature 160°C, oxygen partial pressure 0.5Mpa , the leaching time is 2h, after the leaching is finished, remove the slurry and filter and separate to obtain the arsenic-containing leach solution and leach residue;

[0055] After testing: the arsenic leaching rate is 51.29%, and the concentration of each element in the leach solution is 515.20ppm Pb, 31.56ppm Se, 0.88g / L Sb, 122.26ppm Te, and 9.36g / L As.

[0056] (2) Arsenic fixation in the leach solution: the leach solution obtained in step (1) is synthesized by the ...

Embodiment 3

[0063] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, the main components of the raw materials are Pb 5.46%, As 30.29%, Sn 0.98%, Sb 29.58%, Zn 0.68%, Te 0.26%, Se 0.07%. Take the following steps to deal with:

[0064] (1) Oxygen pressure water immersion: Weigh a certain quality of high arsenic and antimony fume in the reaction kettle, the control conditions are liquid-solid volume mass ratio 10:1, stirring speed 300r / min, leaching temperature 200℃, oxygen partial pressure 2.5Mpa , the leaching time is 4h, after the leaching is over, remove the slurry and filter and separate to obtain the arsenic-containing leach solution and leach residue;

[0065] After testing: the arsenic leaching rate is 64.52%, and the concentration of each element in the leach solution is Pb 956.35ppm, Se 18.91ppm, Sb 0.93g / L, Te 144.92ppm, As 19.54g / L.

[0066] (2) Fixing arsenic in the leach solution: the leach solution obtained in step (1) adopts the distributed crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com