Method for treating isobutyrate-containing wastewater by alcohol etherification

A technology of esterification of isobutyrate and alcohol, which is applied in chemical instruments and methods, natural water treatment, preparation of organic compounds, etc., can solve the problem of difficult methods, and no alcohol ester isobutyric acid metal salt wastewater treatment method has been found. and other problems, to achieve the effect of easy separation and low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

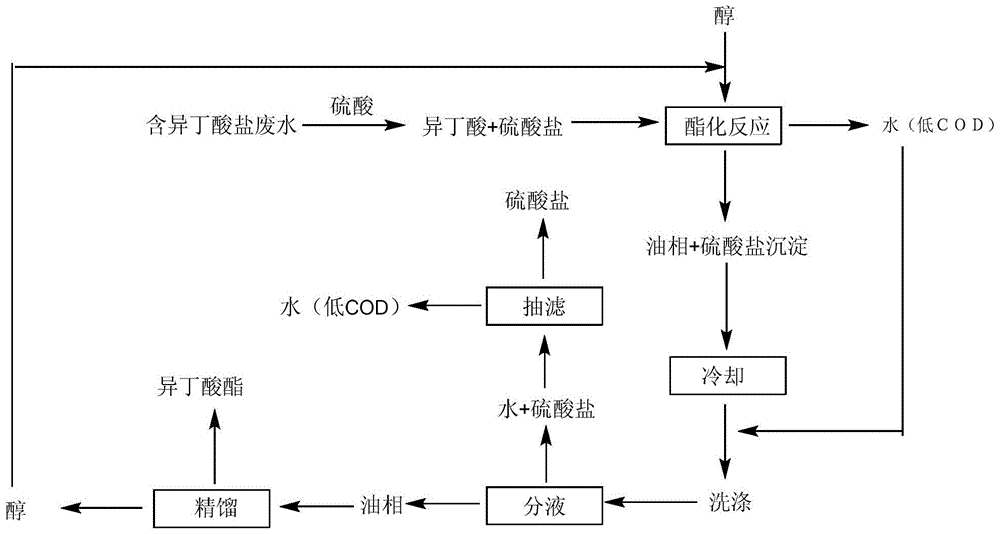

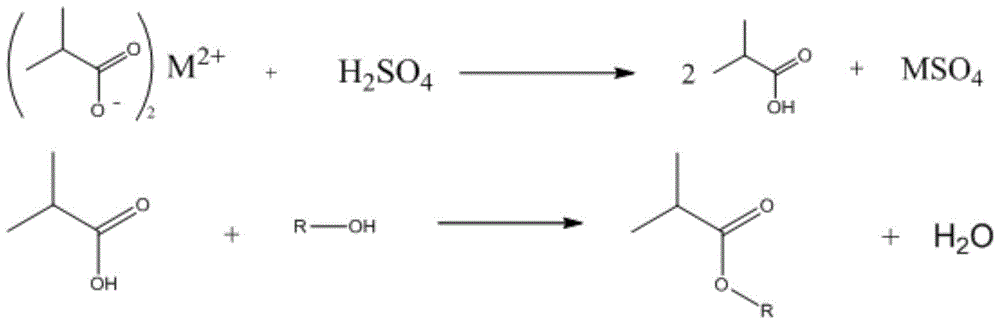

Method used

Image

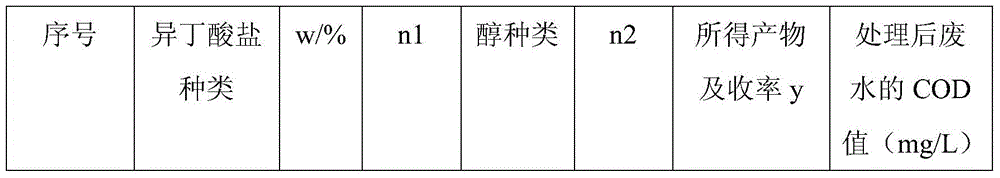

Examples

Embodiment 1

[0033] Embodiment 1, a kind of method that alcohol esterification process contains isobutyrate waste water, carry out following steps successively:

[0034] 1), 273g barium isobutyrate mass fraction is 64% waste water (isobutyrate radical 1.12mol), 62g concentrated sulfuric acid (0.62mol), 166g isobutanol (2.24mol) is added in the flask. Heat up to reflux under stirring, the azeotropic temperature of isobutanol and water is about 90°C, and the temperature of the reaction system in the flask is controlled at 90-107°C. During the reaction process, the water in the reaction system was continuously separated, and when no water was separated, the reaction was stopped, and a total of 92 g of water was separated.

[0035] That is, the molar ratio of isobutyrate to isobutanol is 1:2; the molar ratio of isobutyrate to concentrated sulfuric acid is 1:0.55.

[0036] 2), after the reaction solution obtained in step 1) was cooled to room temperature, 92 g of separated water was poured bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com