Method for recycling spent lithium-ion batteries to manufacture NCM salt

A lithium-ion battery and waste technology, which is applied in the field of recycling and making NCM salt, can solve the problems of flammability and explosion of organic solvents, potential safety hazards, etc., and achieve the effect of simplifying the process, avoiding waste water and waste gas, and realizing zero discharge of waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

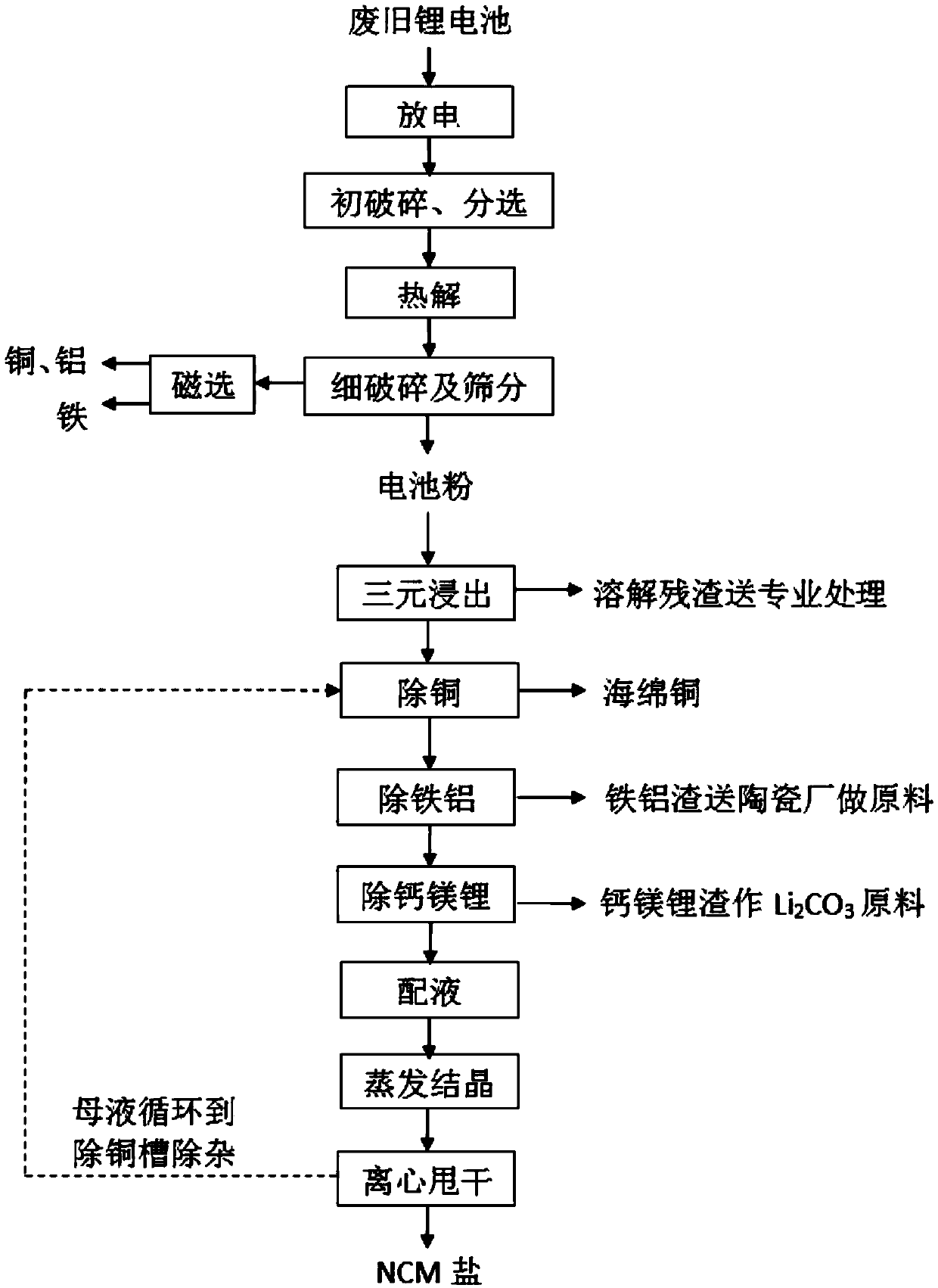

[0026] see figure 1 Shown, the specific embodiment that the present invention provides is as follows:

[0027] A kind of method of waste lithium ion battery of the present embodiment reclaims and makes NCM salt, and the steps are as follows:

[0028] (1) The waste lithium-ion battery is subjected to primary crushing and sorting, pyrolysis, fine crushing and screening to obtain battery powder; the purpose of the primary crushing process is to simply and roughly decompose the battery to make its volume smaller, which is used for subsequent In the pyrolysis process, each component in the battery is fully destroyed and pyrolyzed;

[0029] (2) The battery powder described in step (1) is subjected to a pulping treatment, and the pulped battery powder is leached in an acid leaching tank, and the leachate is subjected to solid-liquid separation to obtain a filtrate;

[0030] (3) The filtrate in step (2) obtains the impurity removal liquid through the impurity removal process;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com