Determining method of amount of shale oil deposit hydrofracture propping agent

A technology for hydraulic fracturing and shale oil, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of increasing the economic cost of fracturing and the unsatisfactory effect of fracturing stimulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Further illustrate the specific embodiment of the present invention below in conjunction with accompanying drawing and field application example, specifically as follows:

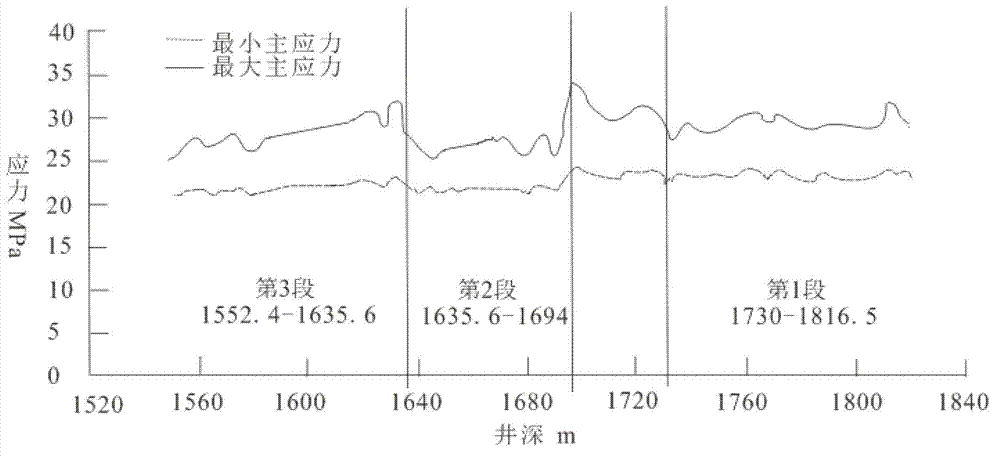

[0049] The drilling depth of a horizontal well in a shale reservoir is 1850m, the length of the horizontal section is 264.1m, and the vertical thickness is 95.7m; according to the reservoir conditions of the well, lithological characteristics, stress difference in the horizontal section, cementing quality and other factors, it is divided into 3 sections fracture( image 3 ). The target interval of fracturing is 1552.4-1816.5m, and it is planned to obtain shale oil production capacity through fracturing.

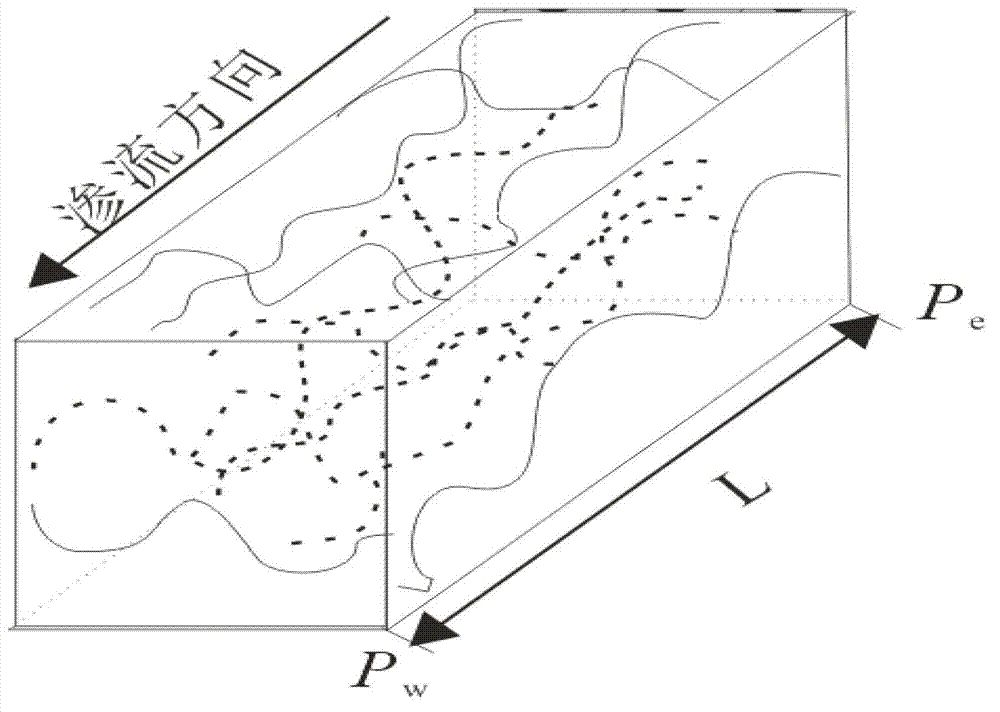

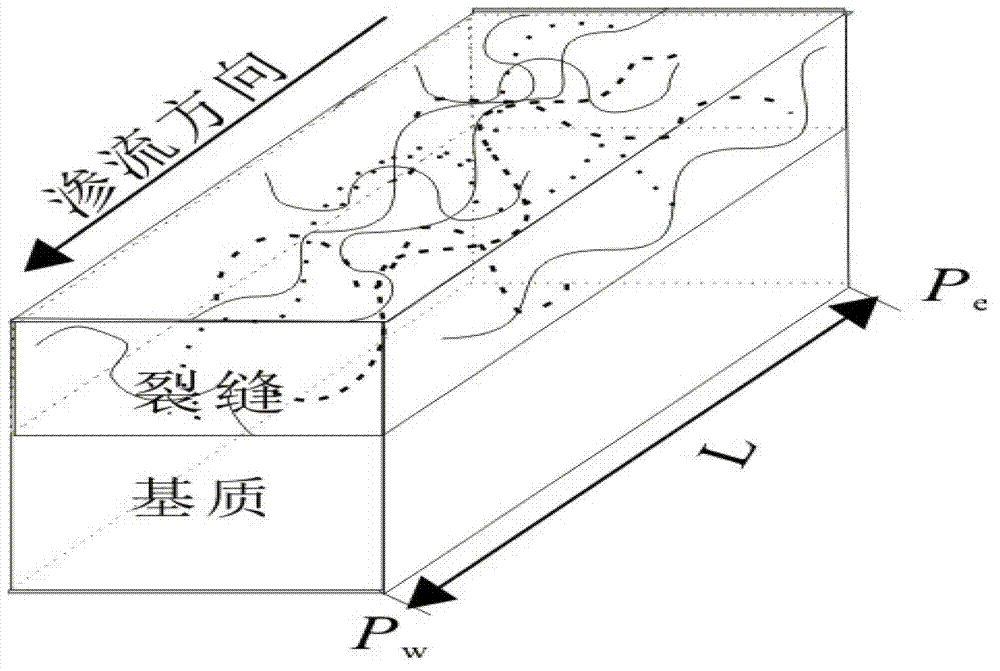

[0050] (1) According to the principle of equivalent seepage, establish a quantitative model of the relationship between the fracture network system and the propping dose (see figure 1 , figure 2 , formula 8, formula 9);

[0051] (2) Based on the reservoir fluid high-pressure physical property d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com