Method for preparing self-suspended hydraulic fracturing proppant

A clean water fracturing and proppant technology, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of high density and poor suspension of fracturing proppant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a self-suspending clear water fracturing proppant, comprising the following steps:

[0041] (1) Prepare the following raw materials in parts by mass: 100 parts of aggregate, 2 parts of resin, 1 part of curing agent, 0.01 part of catalyst, and 0.3 part of amine additive. The aggregate is 20 / 40 quartz sand, the resin is glycerol polymer, the curing agent is toluene diisocyanate, the catalyst is dibutyltin dilaurate, and the amine additive is diethylenetriamine.

[0042] (2) After heating the aggregate to 88°C, add resin and catalyst, and mix and stir;

[0043] (3) When the temperature drops to 78°C, add amine additives and stir to mix;

[0044] (4) When the temperature drops to 72°C, add a curing agent and mix and stir; when the temperature drops to 46°C, take it out of the pot to prepare a self-suspending clear water fracturing proppant.

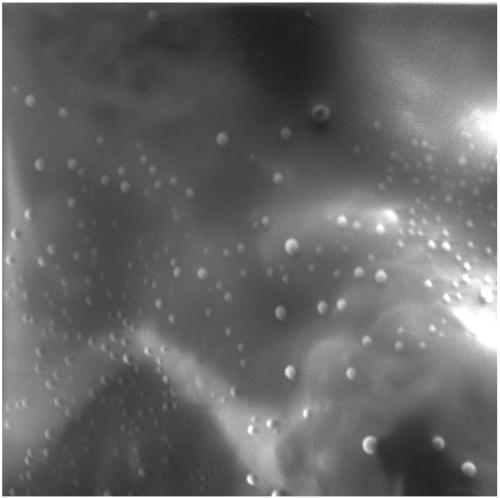

[0045] The surface of the self-suspending clear water fracturing proppant prepared by this method has bulges...

Embodiment 2

[0047] A method for preparing a self-suspending clear water fracturing proppant, comprising the following steps:

[0048] (1) Prepare the following raw materials in parts by mass: 100 parts of aggregate, 2.5 parts of resin, 1 part of curing agent, 0.015 part of catalyst, and 0.4 part of amine additive. The aggregate is 30 / 50 quartz sand, the resin is propylene glycol polymer, the curing agent isophorone diisocyanate, the catalyst is tributyltin, and the amine additive is ethylenediamine.

[0049] (2) After heating the aggregate to 82°C, add resin and catalyst, and mix and stir;

[0050] (3) When the temperature drops to 72°C, add amine additives and stir to mix;

[0051] (4) When the temperature drops to 67°C, add a curing agent and mix and stir; when the temperature drops to 45°C, take it out of the pot to prepare a self-suspending clear water fracturing proppant.

[0052] The surface of the self-suspension clear water fracturing proppant prepared by this method has bulges ...

Embodiment 3

[0054] A method for preparing a self-suspending clear water fracturing proppant, comprising the following steps:

[0055] (1) Prepare the following raw materials in parts by mass: 100 parts of aggregate, 3 parts of resin, 2 parts of curing agent, 0.02 part of catalyst, and 0.4 part of amine additive. The aggregate is 40 / 70 quartz sand, the resin is propanol polymer, the curing agent is diphenylmethane diisocyanate, the catalyst is lead isooctanoate, and the amine additive is diethylenetriamine.

[0056] (2) After heating the aggregate to 82°C, add resin and catalyst, and mix and stir;

[0057] (3) When the temperature drops to 72°C, add amine additives and stir to mix;

[0058] (4) When the temperature drops to 66°C, add a curing agent and mix and stir; when the temperature drops to 48°C, take it out of the pot to prepare a self-suspending clean water fracturing proppant.

[0059] The surface of the self-suspended clear water fracturing proppant prepared by this method has b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com