Hydraulic fracturing proppant as well as preparation method and application thereof

A hydraulic fracturing and proppant technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of repeated operation procedures, complex matching, short action time, etc., and achieve long-term uniform release , Simple construction and operation, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

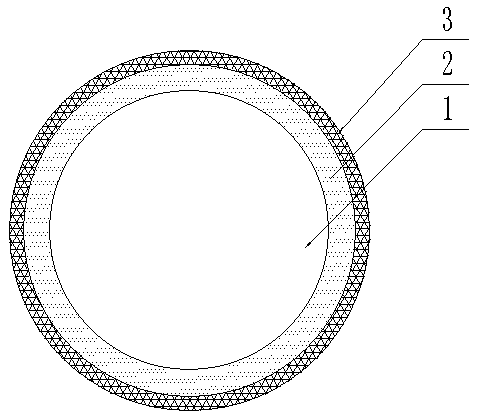

[0044] This embodiment relates to a hydraulic fracturing proppant, such as figure 1 As shown, it includes a proppant inner core 1 and a solid anti-wax layer 2 and a protective layer 3 that are wrapped sequentially outside the proppant inner core from the inside to the outside; specifically, the proppant inner core 1 is ceramic treated with a silane coupling agent. grains or quartz sand; the solid anti-wax layer 2 is composed of a main anti-wax agent, a dissolution rate control agent, a dispersant, and a binder; the protective layer 3 is a degradable nano material.

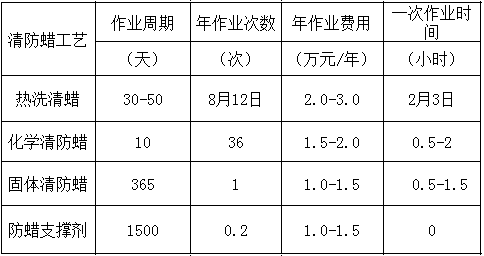

[0045] After the hydraulic fracturing pre-fluid stage is completed, the hydraulic fracturing proppant described in the present invention is injected into the formation instead of the conventional proppant, and then the fracturing operation is continued (the fracturing operation procedure is the same as that of the conventional fracturing), the The proppant is added at the initial stage of hydraulic fracturing and s...

Embodiment 2

[0047] This embodiment provides a hydraulic fracturing proppant, which consists of the following components in parts by weight:

[0048] 70-75 parts of ceramsite or quartz sand treated with silane coupling agent;

[0049] 15-20 parts of main anti-wax agent, 4-6 parts of dissolution rate controller, 3-4 parts of dispersant, 3-4 parts of binder;

[0050] 1-2 parts of degradable nanomaterials.

[0051] Further, the degradable nanomaterial is composed of the following components by weight percentage: 35%-45% of starch, 30%-40% of nanopowder, 15%-20% of plasticizer, 10%-15% of polyvinyl alcohol %.

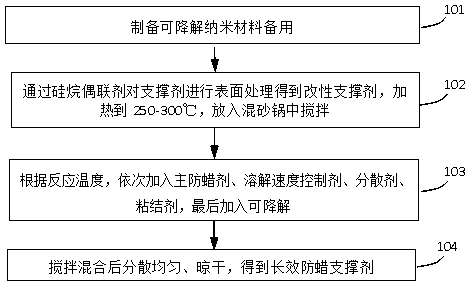

[0052] Further, this embodiment further discloses the preparation method of the proppant, such as figure 2 shown, including the following steps:

[0053]S101, preparing degradable nanomaterials, the specific method is: melt-blending the formulated amount of starch, nanopowder (with a particle size of 15-30 nanometers), plasticizer, and polyvinyl alcohol at 140-160°C, namely Obtain...

Embodiment 3

[0062] On the basis of the foregoing examples, as a preference, the silane coupling agent is vinyltriethoxysilane, vinyltrimethoxysilane, vinyltris(2-methoxyethoxy)silane, One or a mixture of γ-aminopropyltrimethoxysilane and γ-aminopropyltriethoxysilane.

[0063] Further, the main anti-wax agent is vinyl acetate-maleic anhydride-acrylamide terpolymer or higher alcohol polyacrylate; specifically, the vinyl acetate-maleic anhydride-acrylamide tripolymer The molar ratio of the monomers in the copolymer is vinyl acetate:maleic anhydride:acrylamide=1:(0.5~1):(0.3~0.5), and the molecular weight of the terpolymer is 2000-10000kDa; Higher alcohol polyacrylate is preferably tetradecyl polyacrylate, hexadecyl polyacrylate or octadecyl polyacrylate.

[0064] The preferred vinyl acetate-maleic anhydride copolymer of the dissolution rate control agent, the monomer molar ratio of this binary copolymer is vinyl acetate: maleic anhydride=1:2~2:1; The vinyl acetate-maleic anhydride=1:2~2:1; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com