Patents

Literature

34 results about "Normal fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

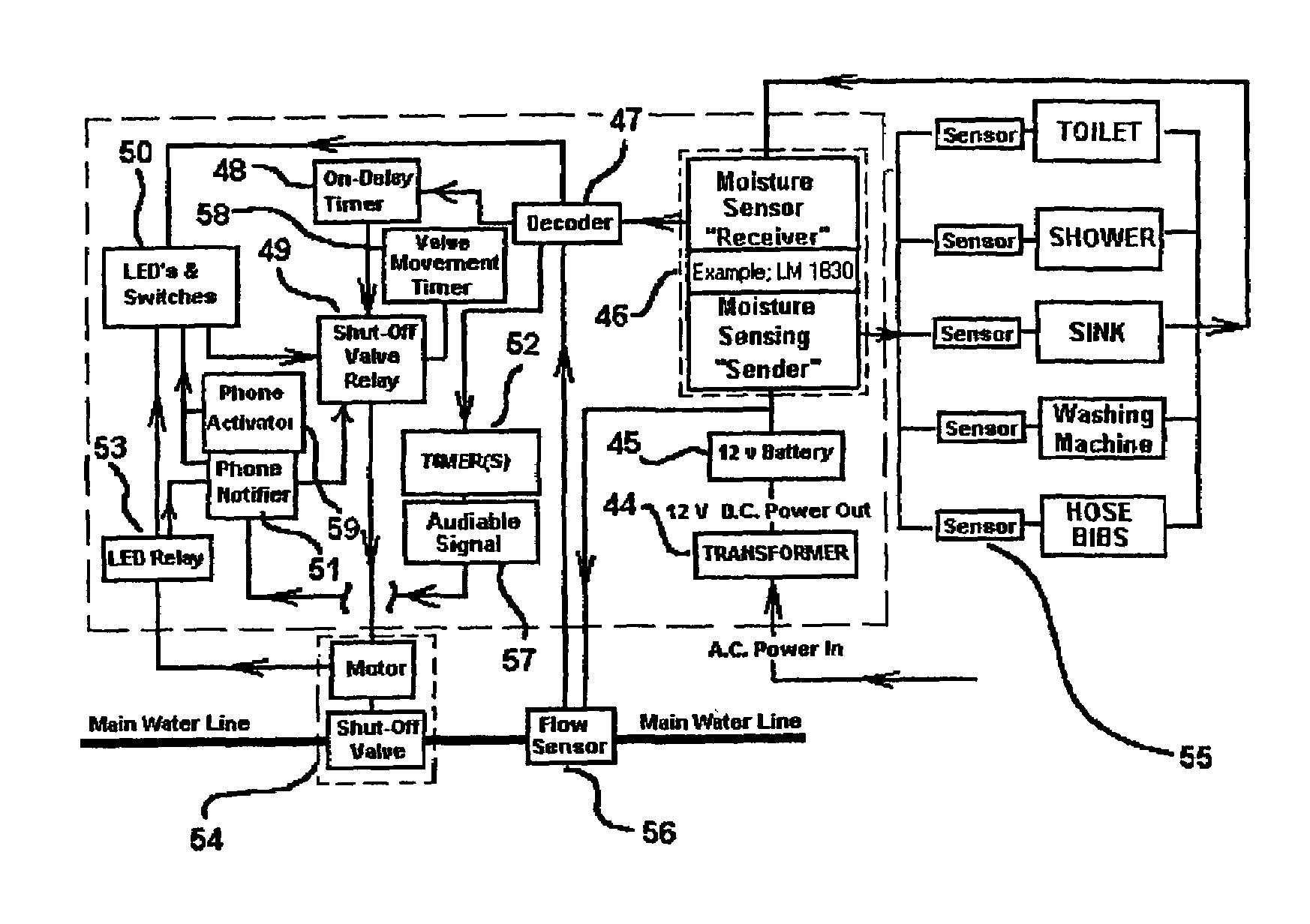

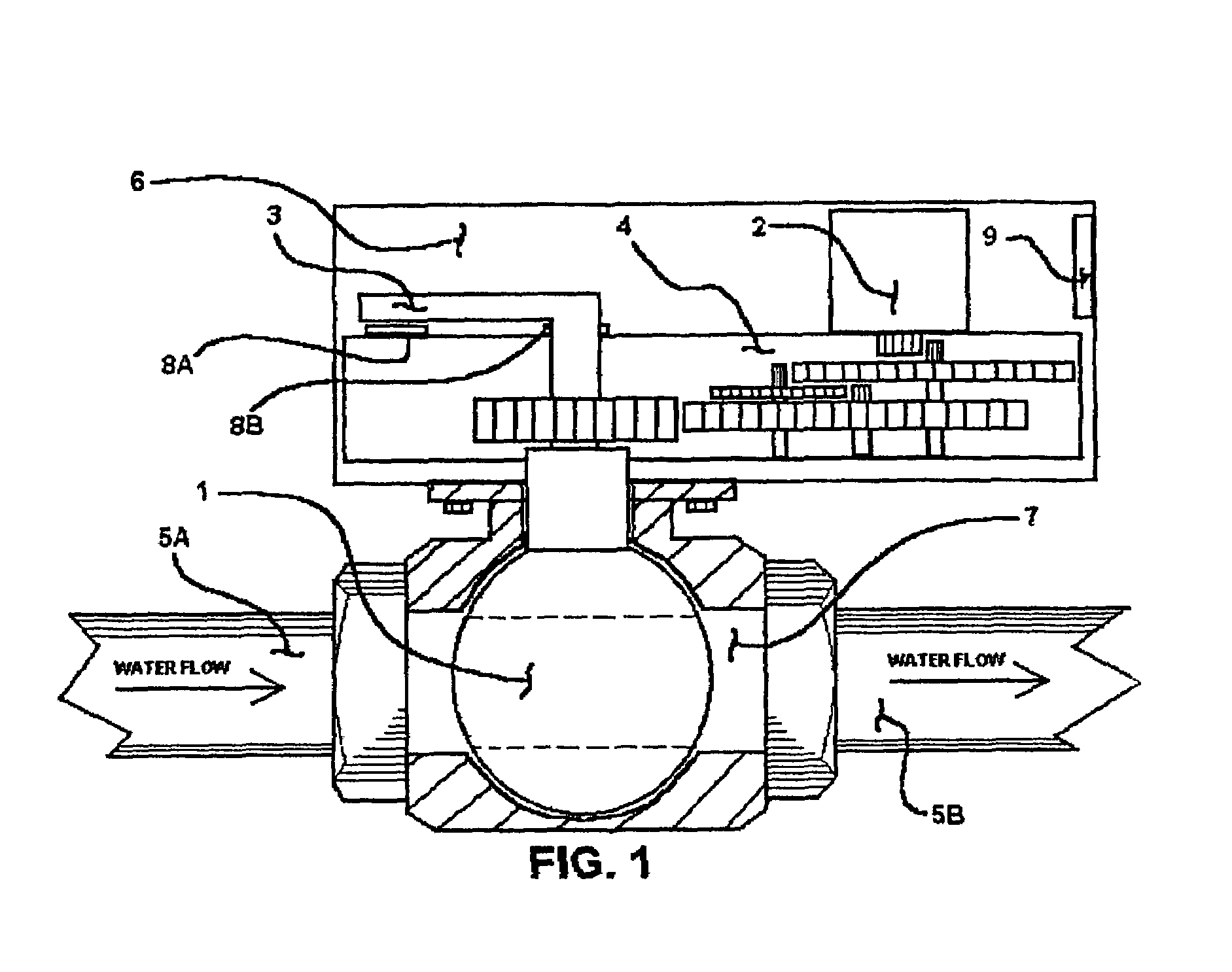

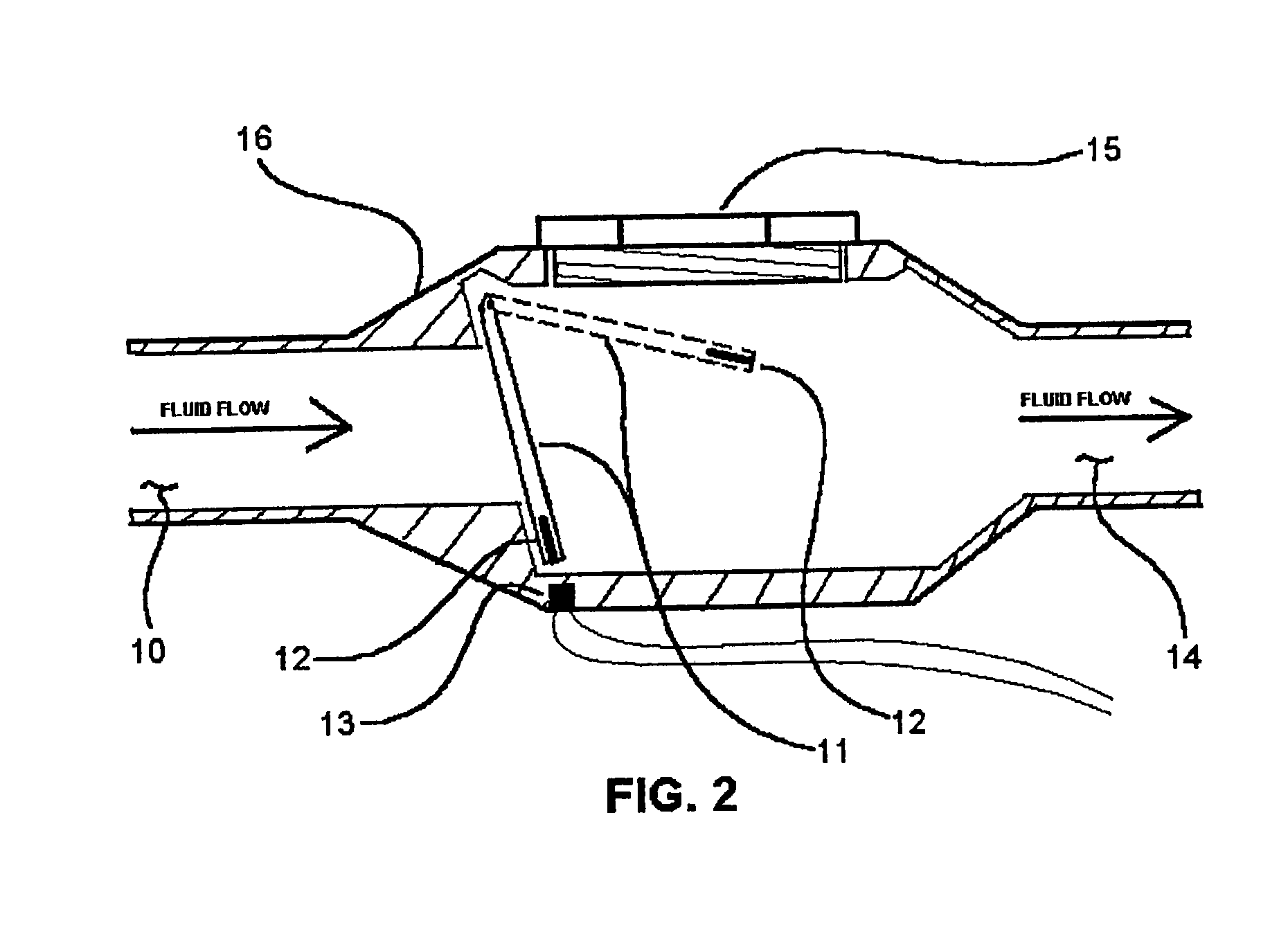

Liquid leak detector and automatic shutoff system

InactiveUS7032435B2Reduce leakageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateCatheterGuide tube

Owner:HASSENFLUG BRIAN EDWARD

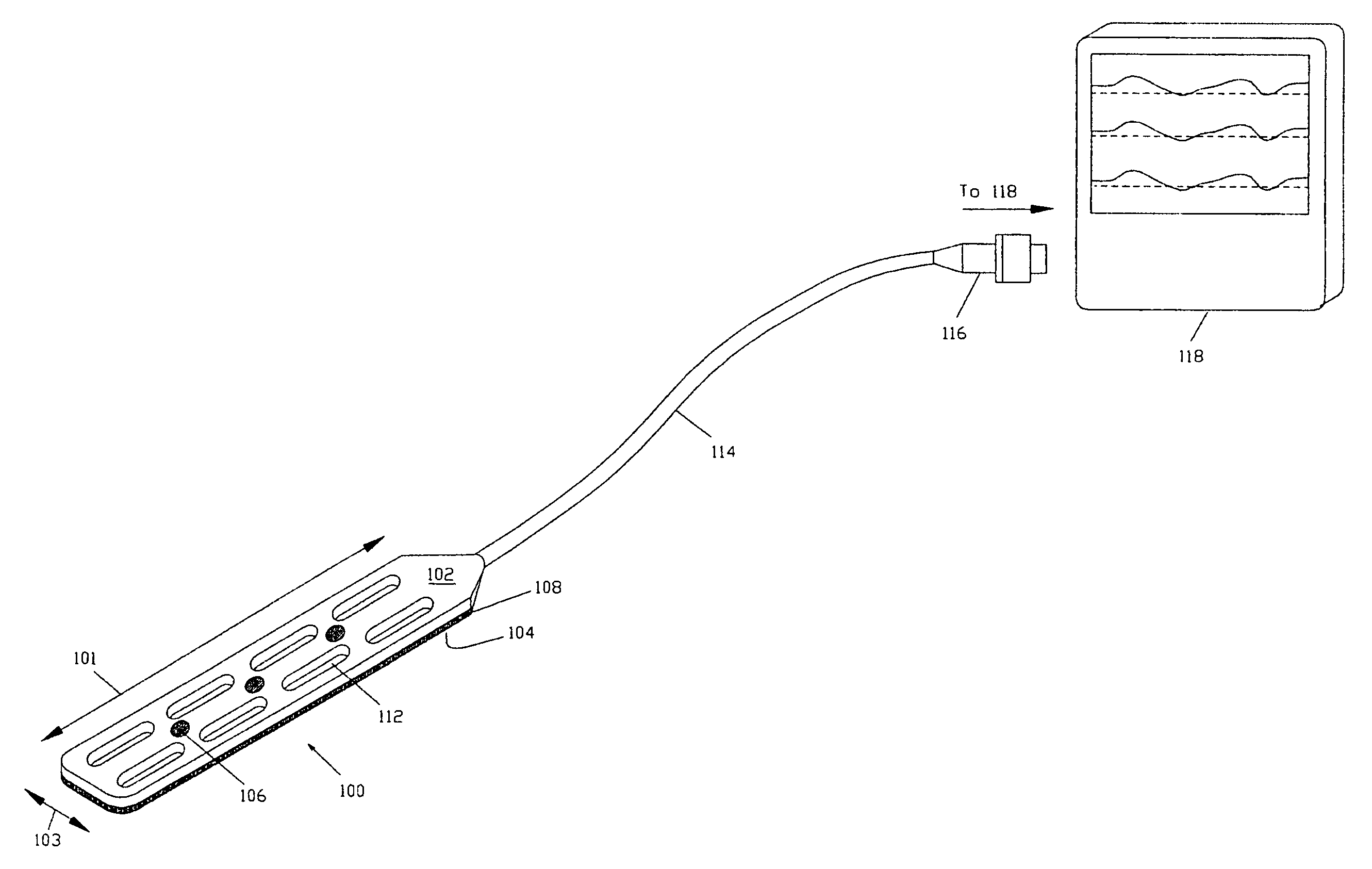

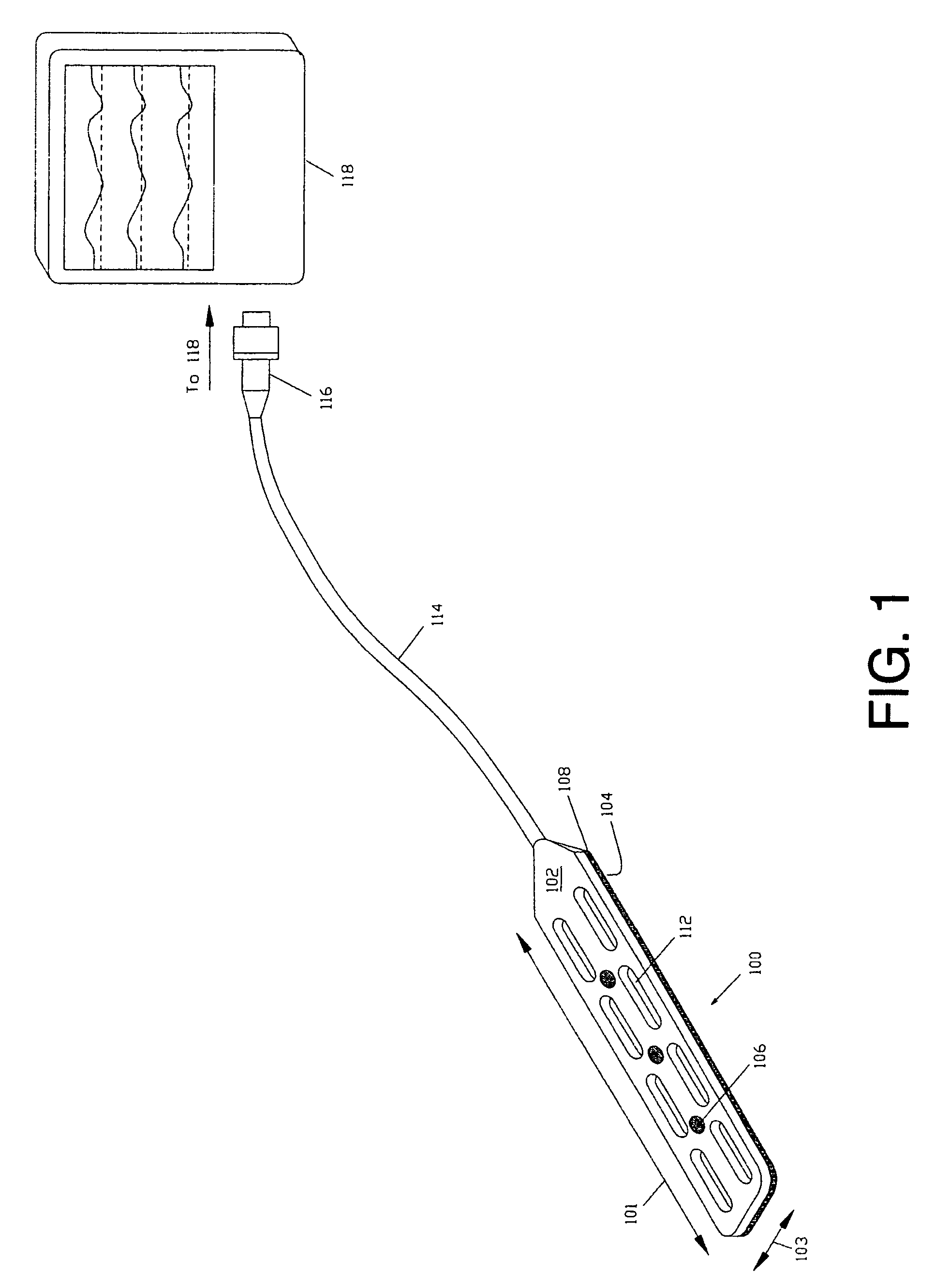

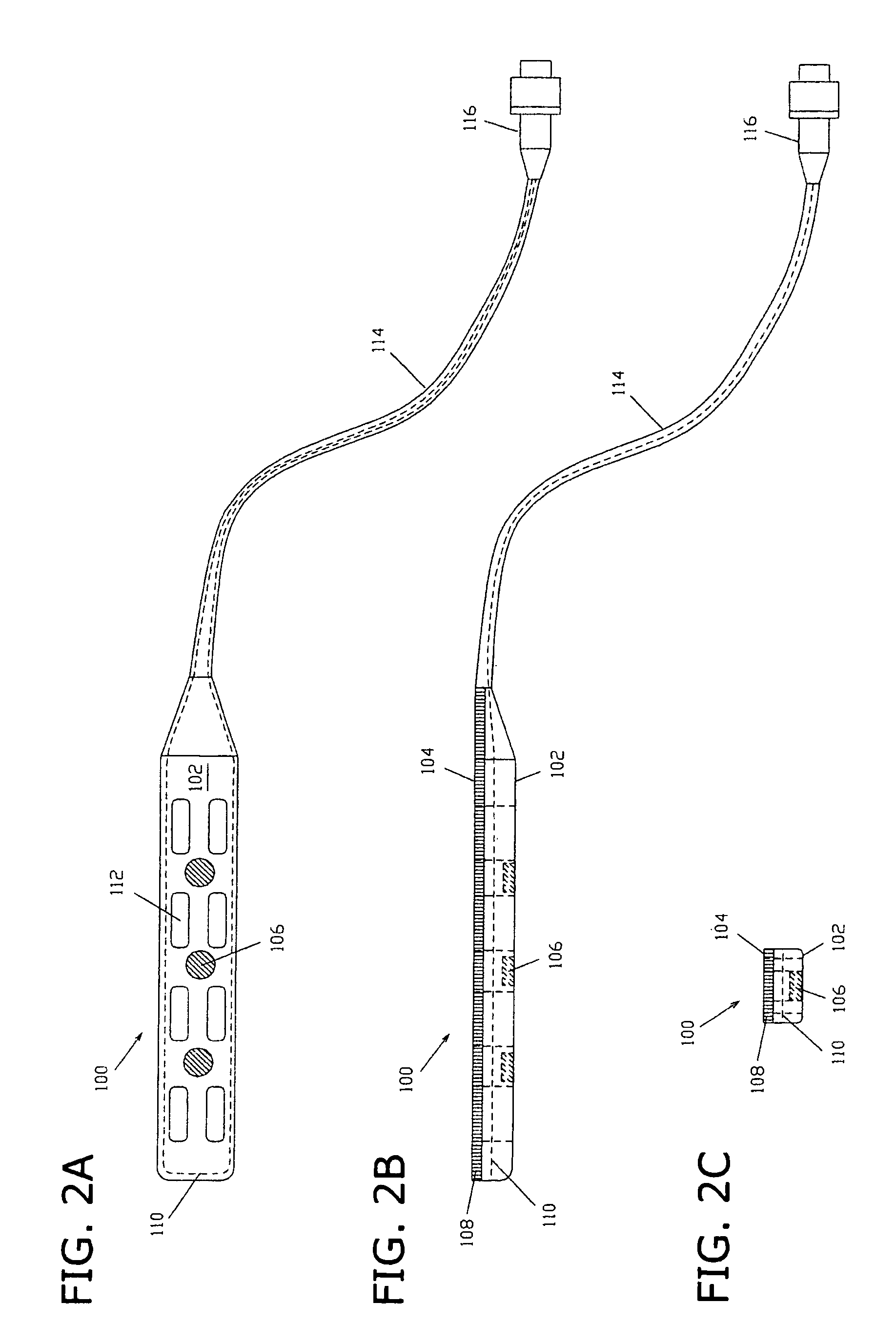

Methods and devices for tissue monitoring

InactiveUS7753902B1Increase contactEasy to manufactureWound drainsCatheterVascular thrombosisMedicine

The present invention is directed to a system and method for monitoring the physiological parameters of an organ or tissue during and after surgery. The system has a probe and a monitoring unit. In one embodiment the probe includes features for convenient, fixed and releasable attachment to surgical drains without interfering with their normal fluid-draining function while utilizing their suction to enhance the probe-to-tissue interface for improved sensing. An applicator is provided to facilitate such attachment. The monitoring unit which controls the sensors of the probe includes a processor to process, record and display the sensor data. This system may be valuable for monitoring transplanted organs and tissue grafts during the critical postoperative period when most of the clinical complications, such as vascular thrombosis, may occur.

Owner:MANSOUR HEBAH NOSHY +1

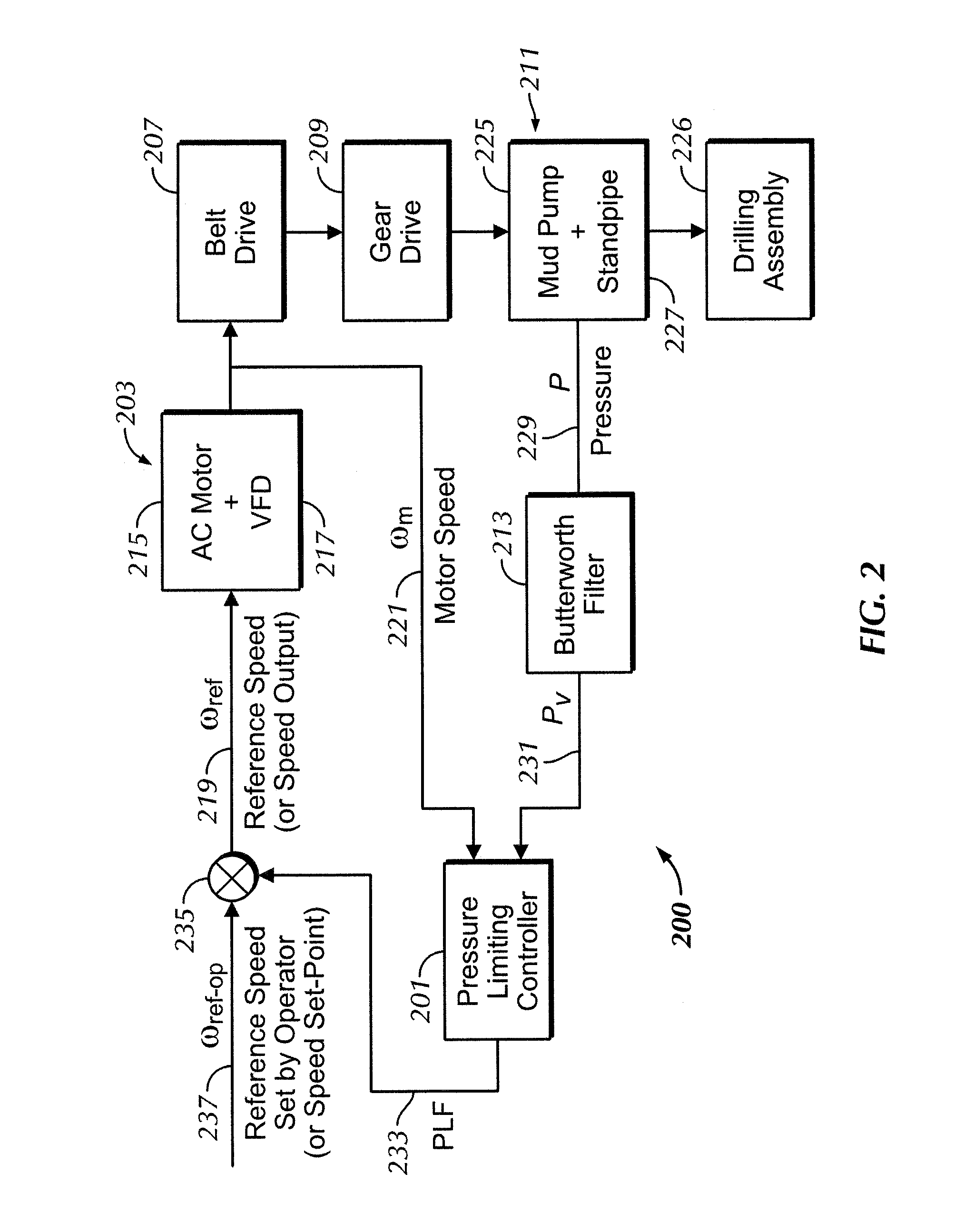

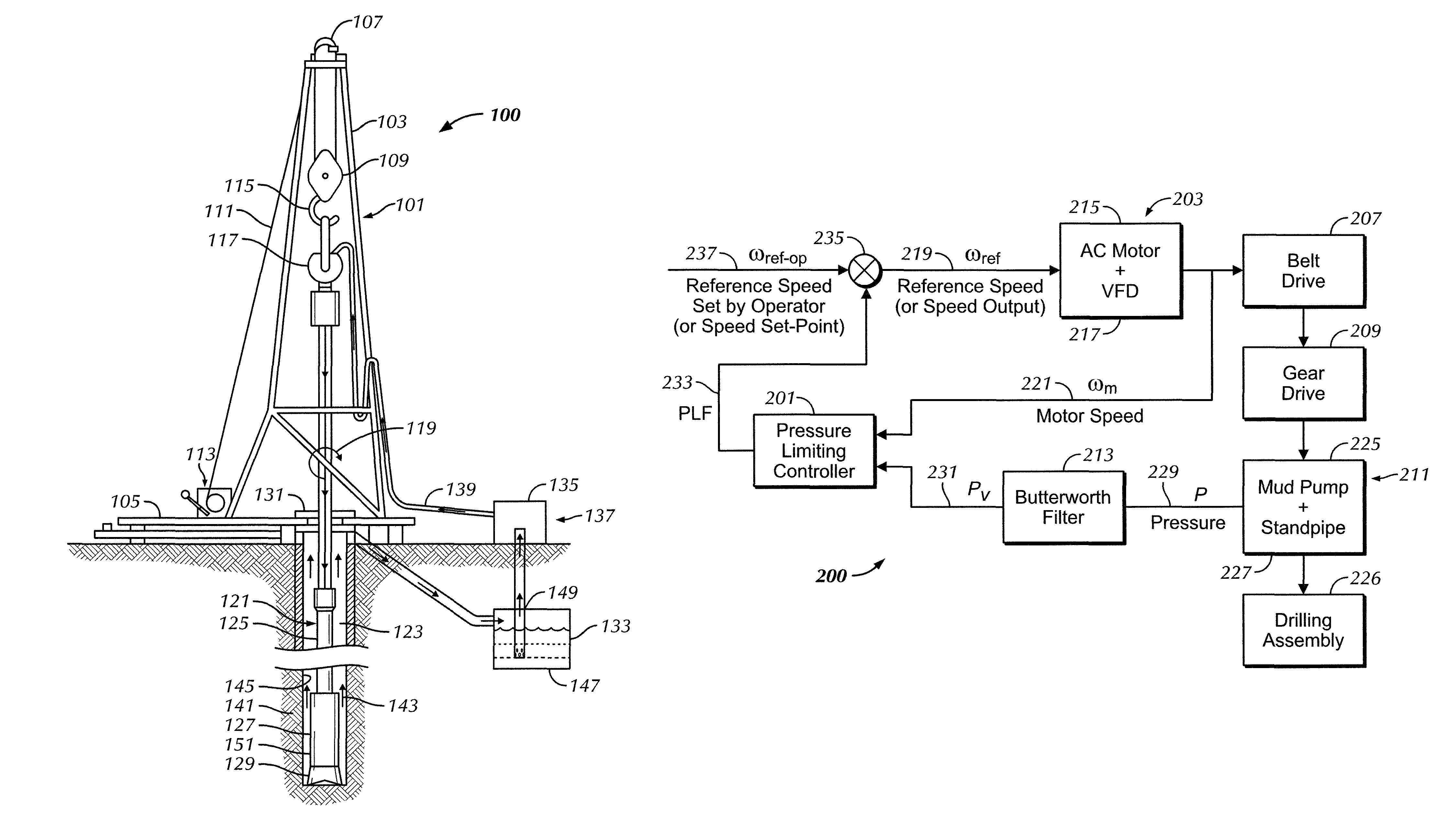

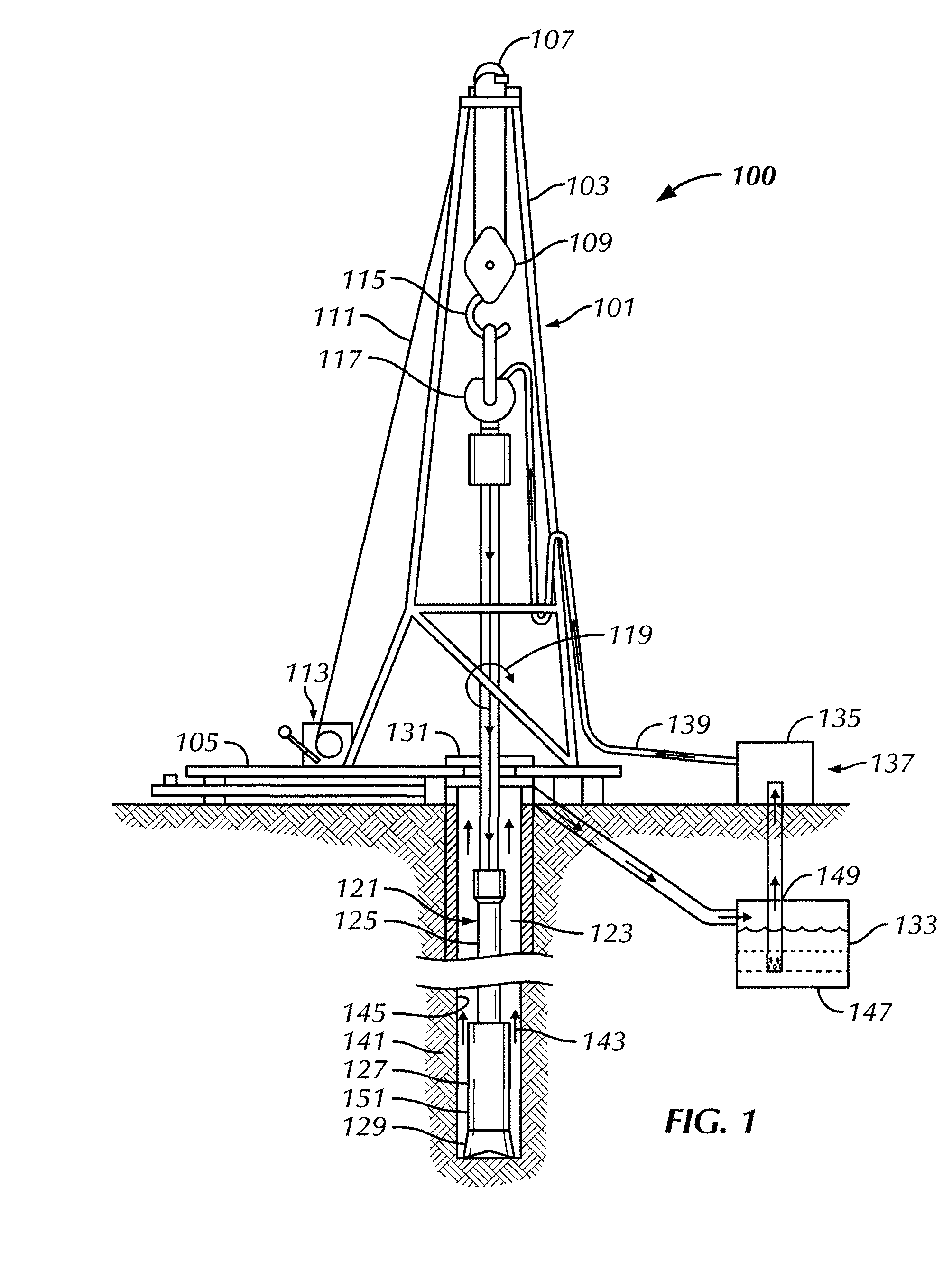

Pressure limiting controller

A method of controlling pressure in a mud pump system includes generating a pressure limiting factor output using a pressure feedback input and a motor speed input to calculate a fluid conductance estimate, maintaining the pressure limiting factor output at a maximum value based on a pressure set-point, continuously updating a normal fluid conductance value based on the fluid conductance estimate while the pressure limiting factor output remains at the maximum value, freezing the normal fluid conductance value, if the pressure limiting factor output is less than the maximum value, calculating a change in fluid conductance based on the normal fluid conductance value and the fluid conductance estimate, generating at least one adaptive gain based on the change in fluid conductance, and controlling a motor speed of a pump in the mud pump system based on the at least one adaptive gain.

Owner:SCHLUMBERGER TECH CORP

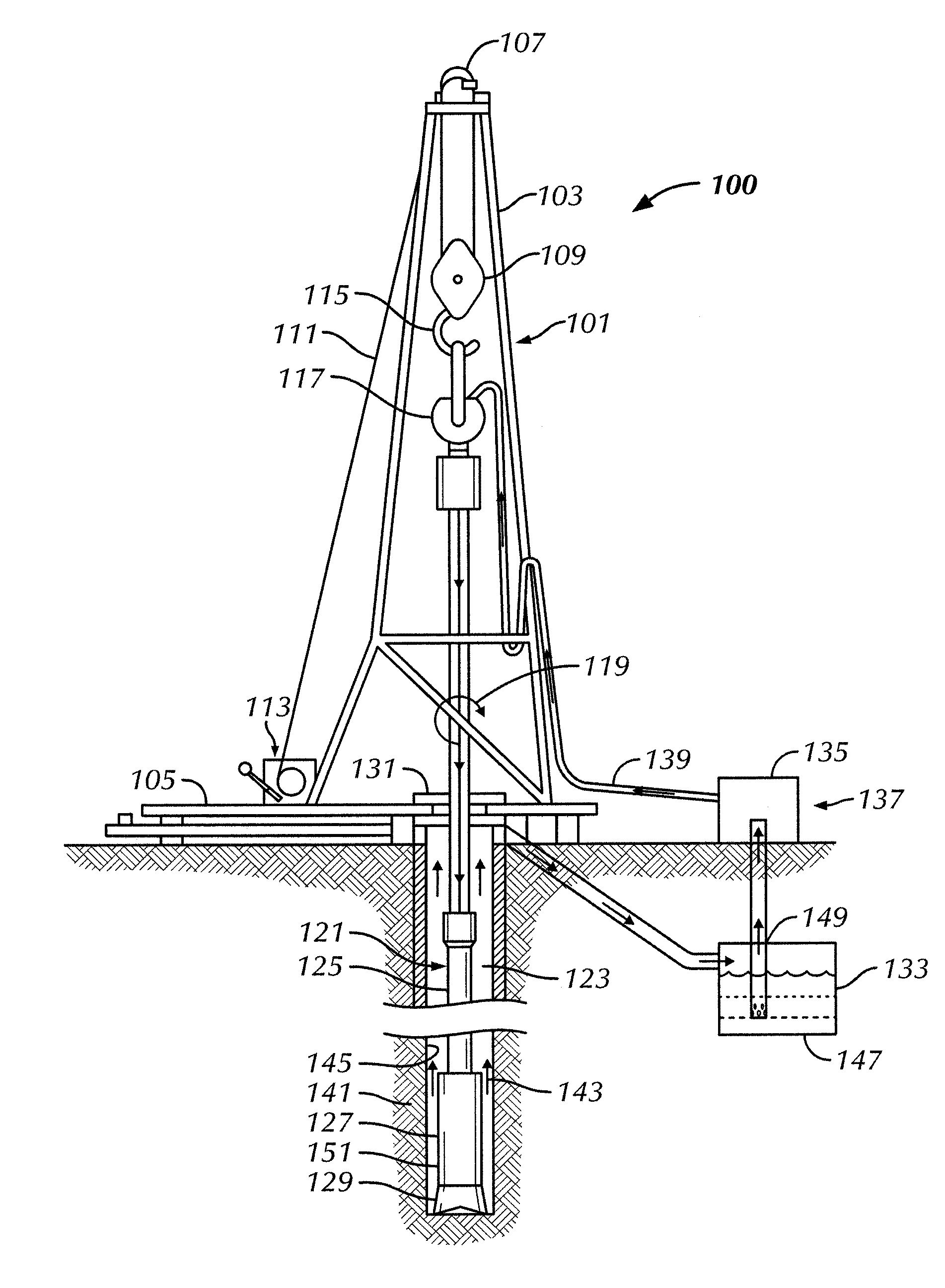

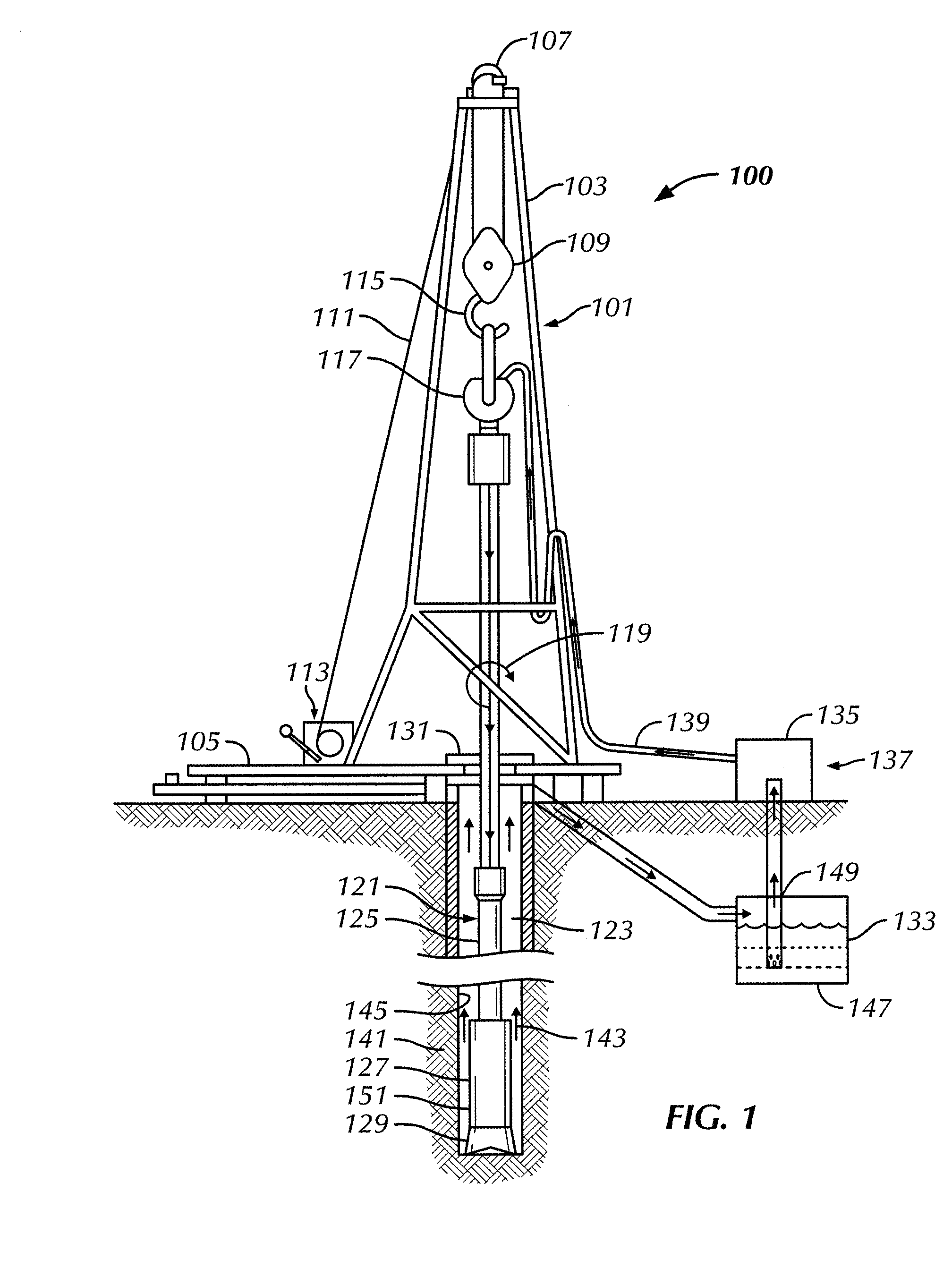

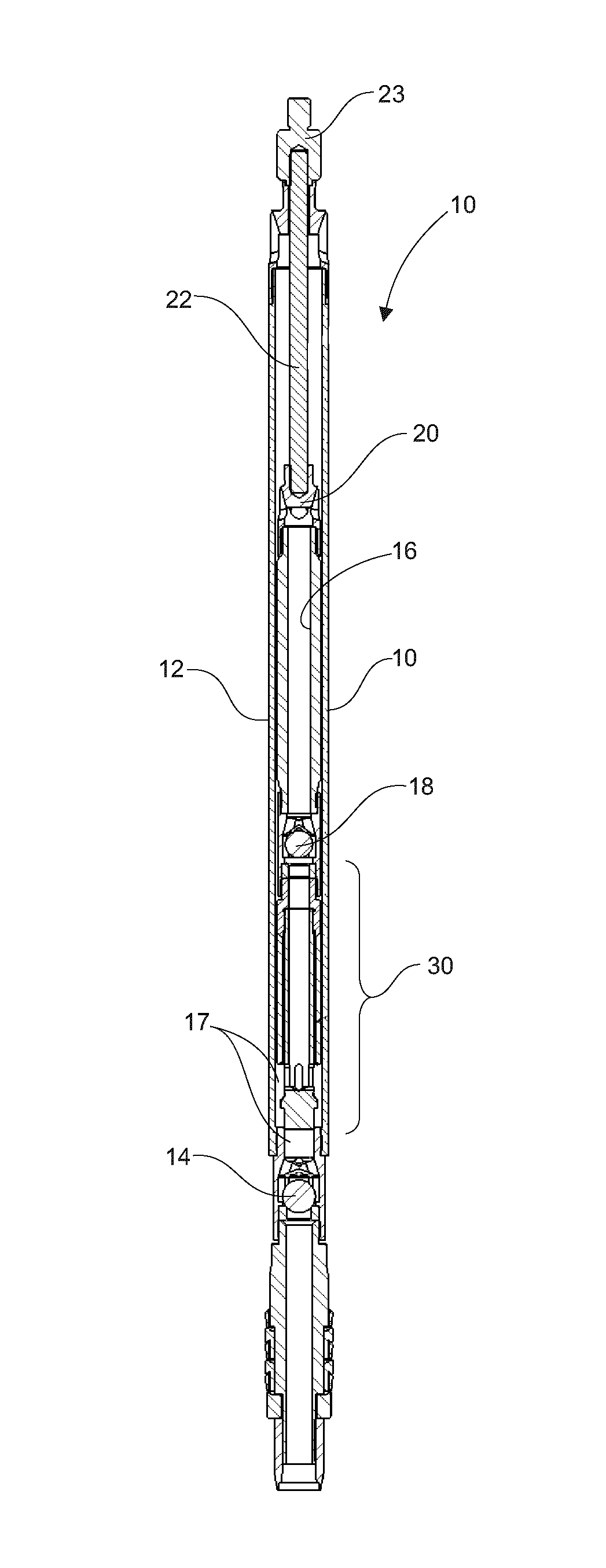

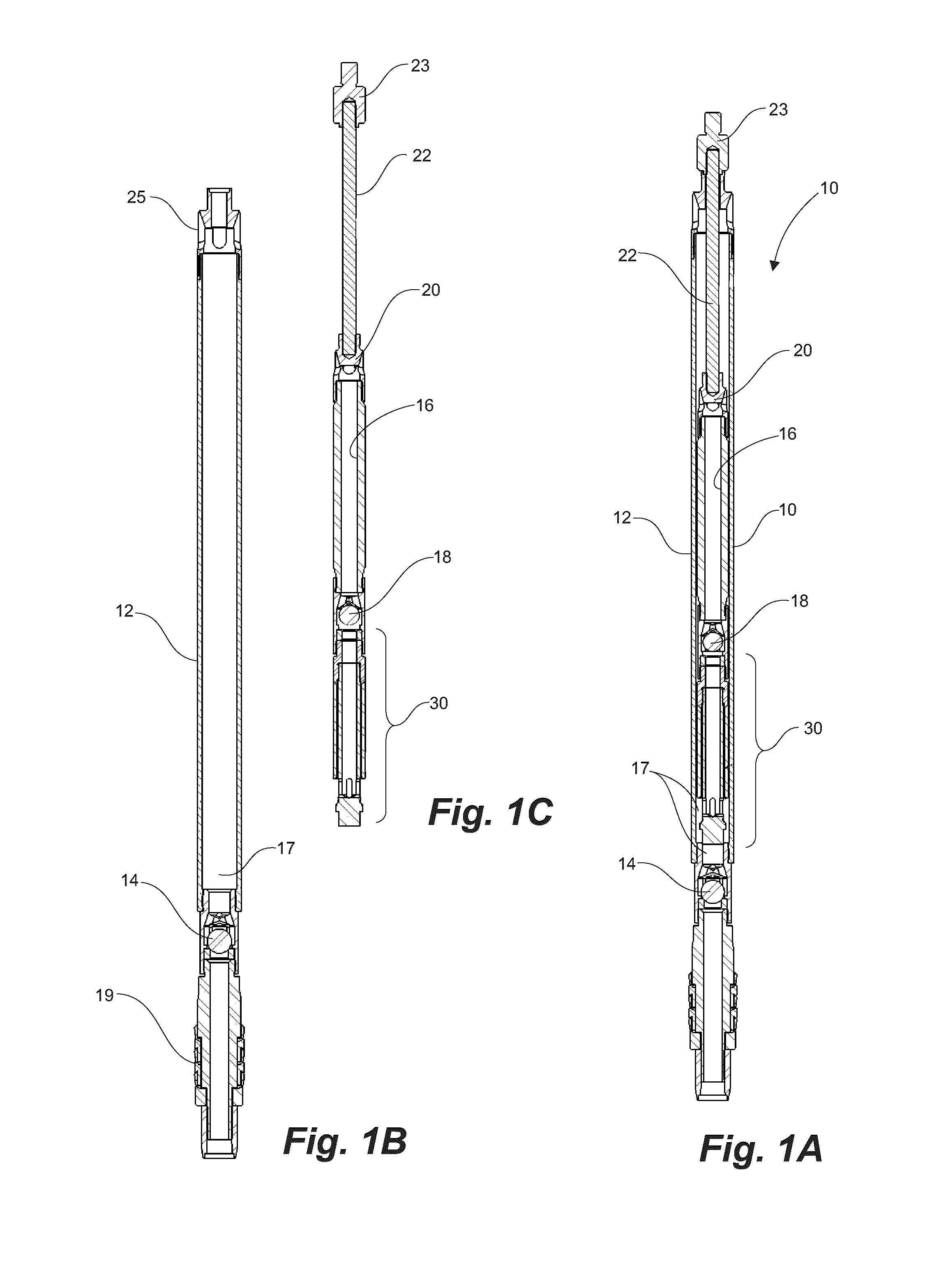

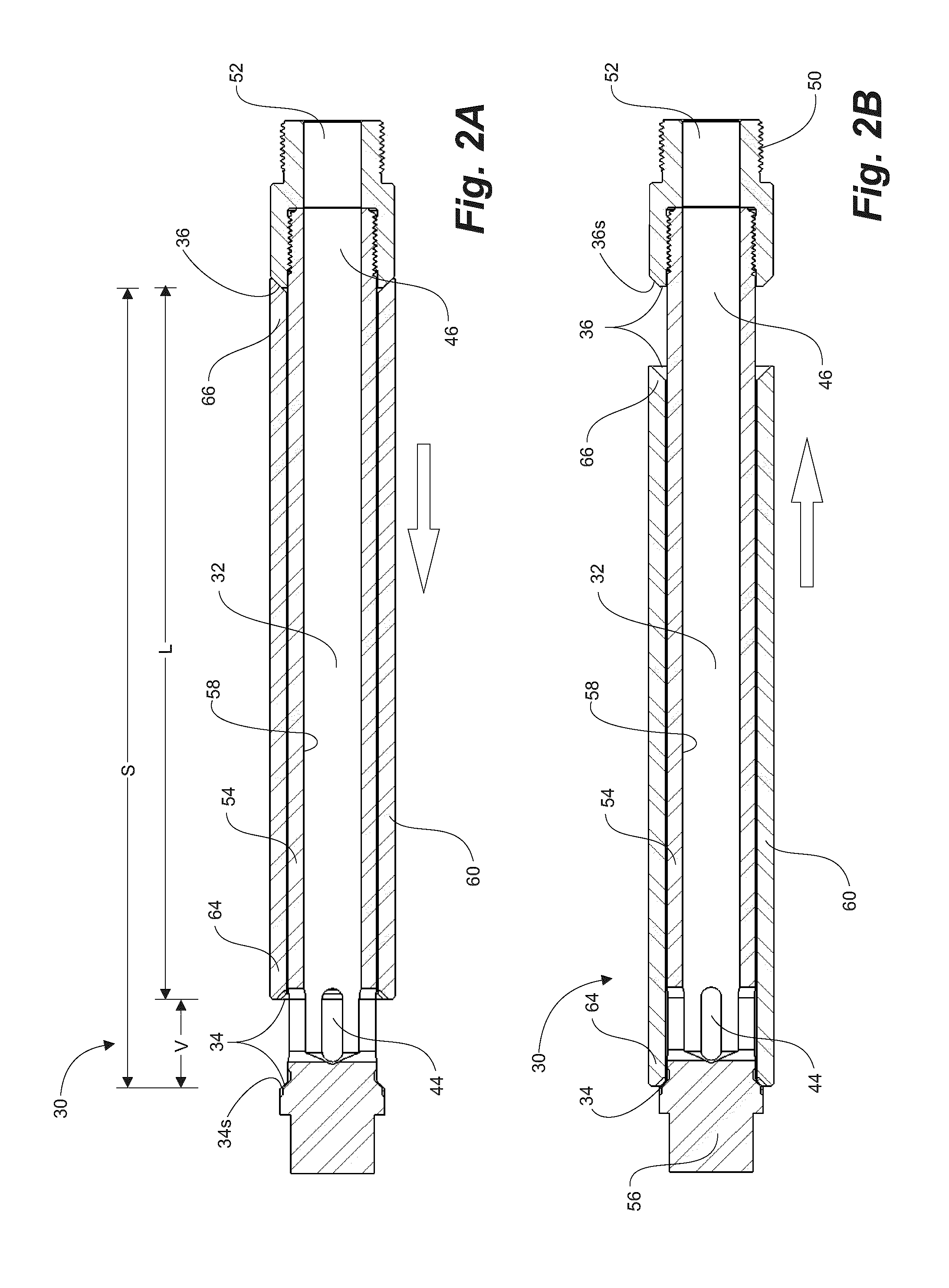

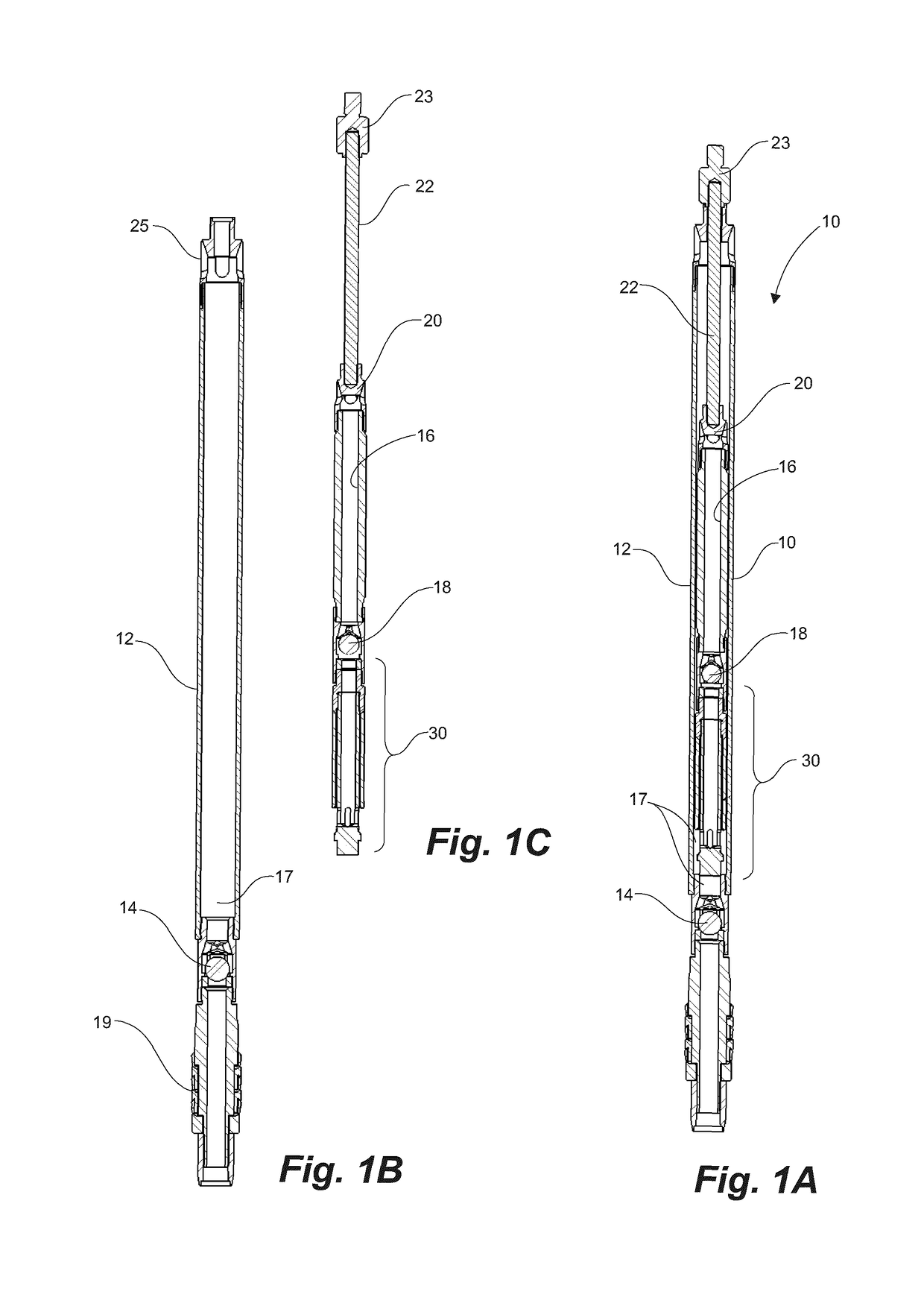

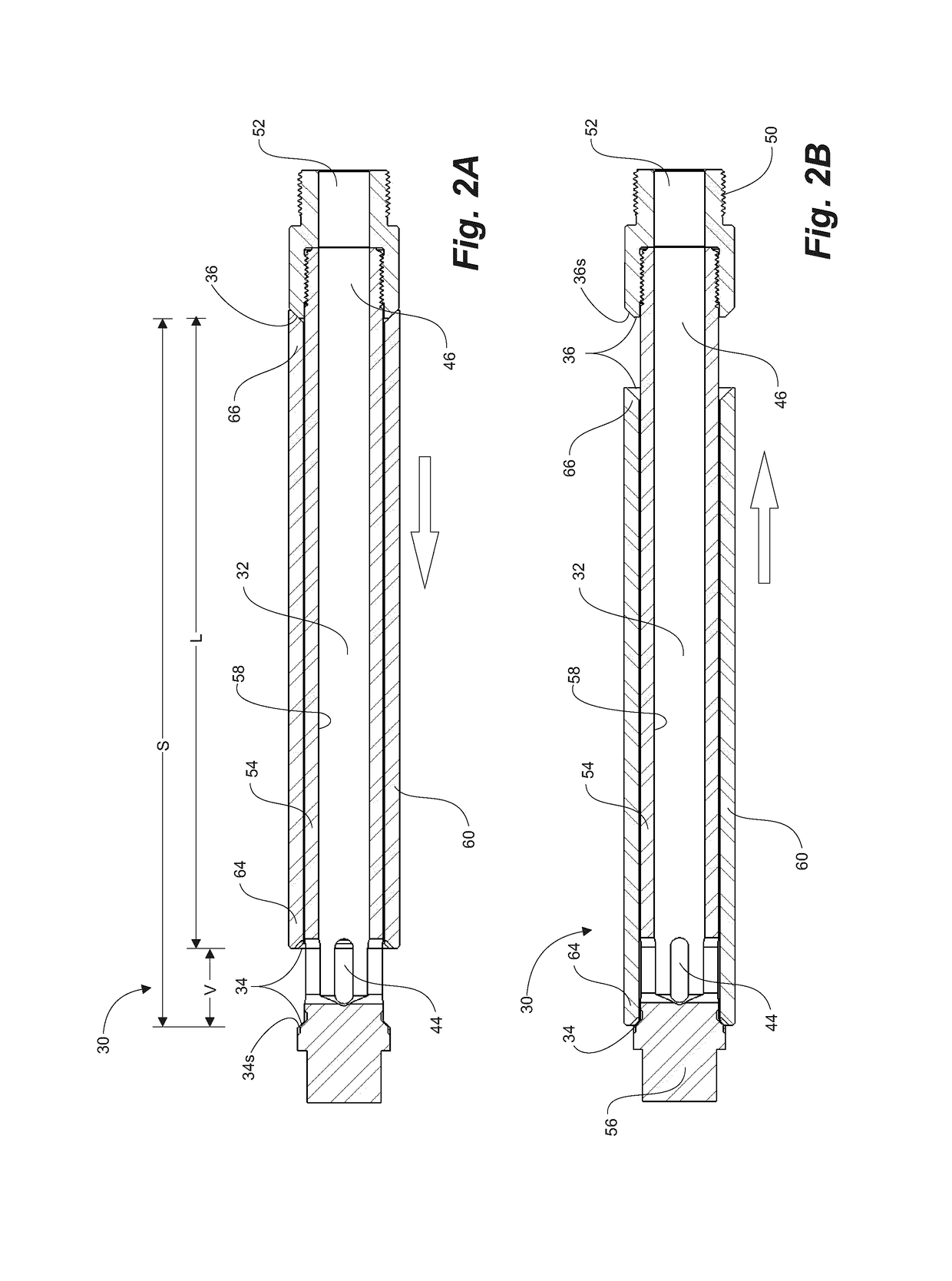

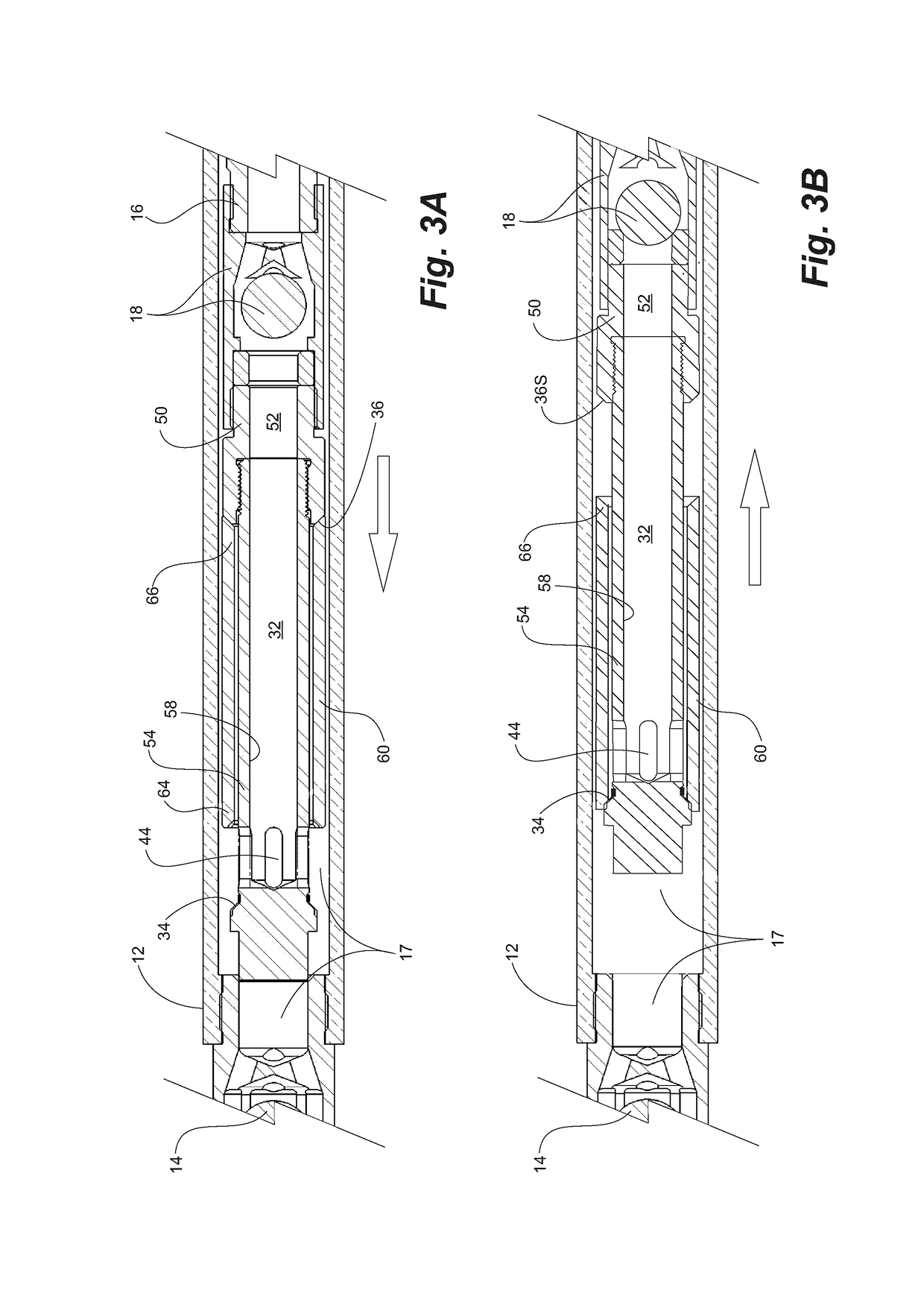

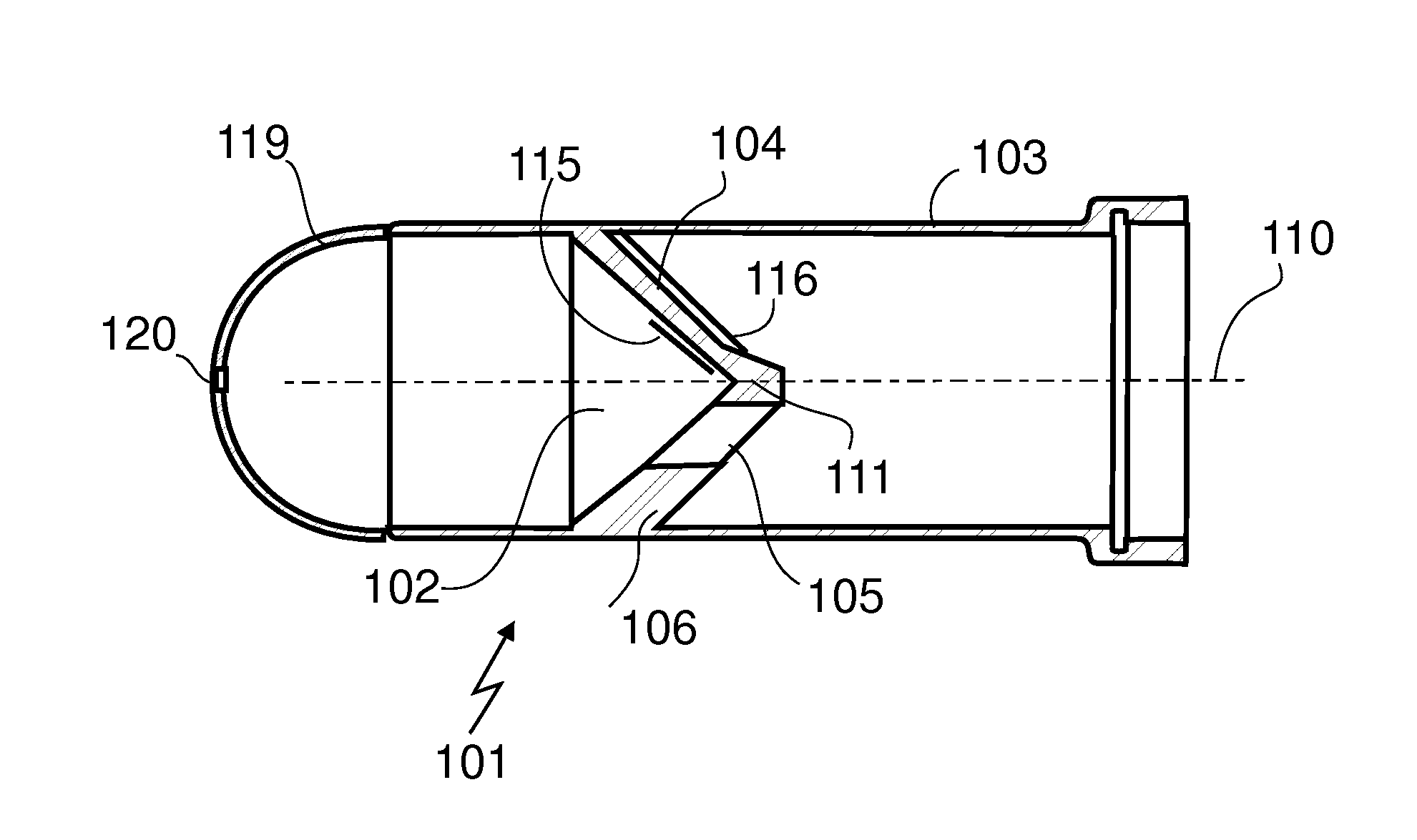

Anti-gas lock valve for a reciprocating downhole pump

ActiveUS20150376996A1Increase productionReduce maintenanceFluid parameterConstructionsPump chamberHydrostatic head

Method and apparatus overcoming gas-lock in reciprocating downhole pumps. On the downstroke of a plunger in a barrel, gassy fluid is compressed in the pump chamber between standing and travelling valves. Downhole plunger movement drags a sleeve over a mandrel for opening a chamber valve to a staging chamber located at a downhole end of the travelling valve for receiving at least a portion of the compressed and gassy fluid therein. On the upstroke, the chamber valve is dragged closed for sealably retaining the compressed gassy fluid therein while drawing an additional increment of fluid through the standing valve into the pump chamber. Continued downstroke and upstroke cycles increases pressure of the compressed gassy fluid in the pump chamber until it exceeds the hydrostatic head above the travelling valve for resumption of normal fluid pumping.

Owner:INNOVATIVE OILFIELD CONSULTANTS

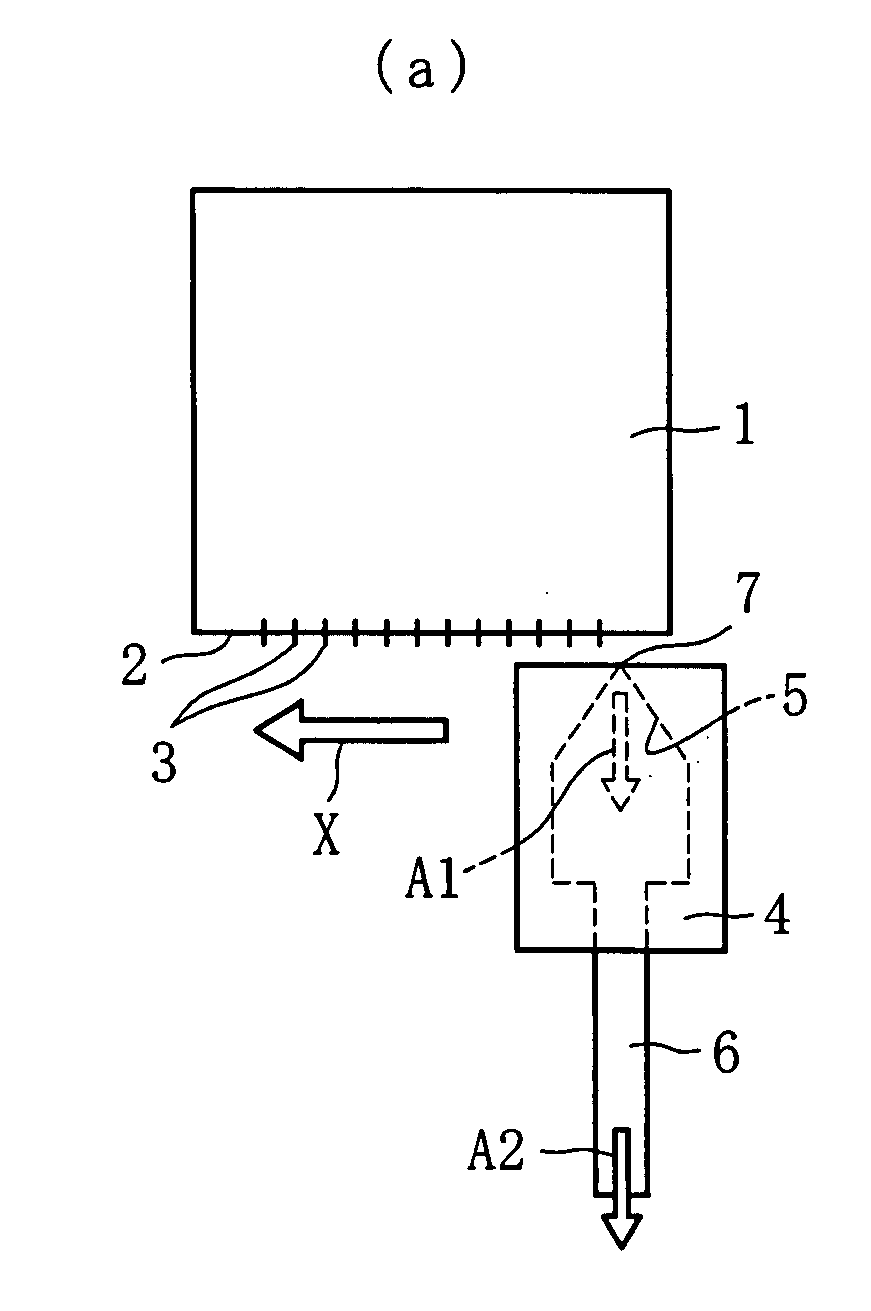

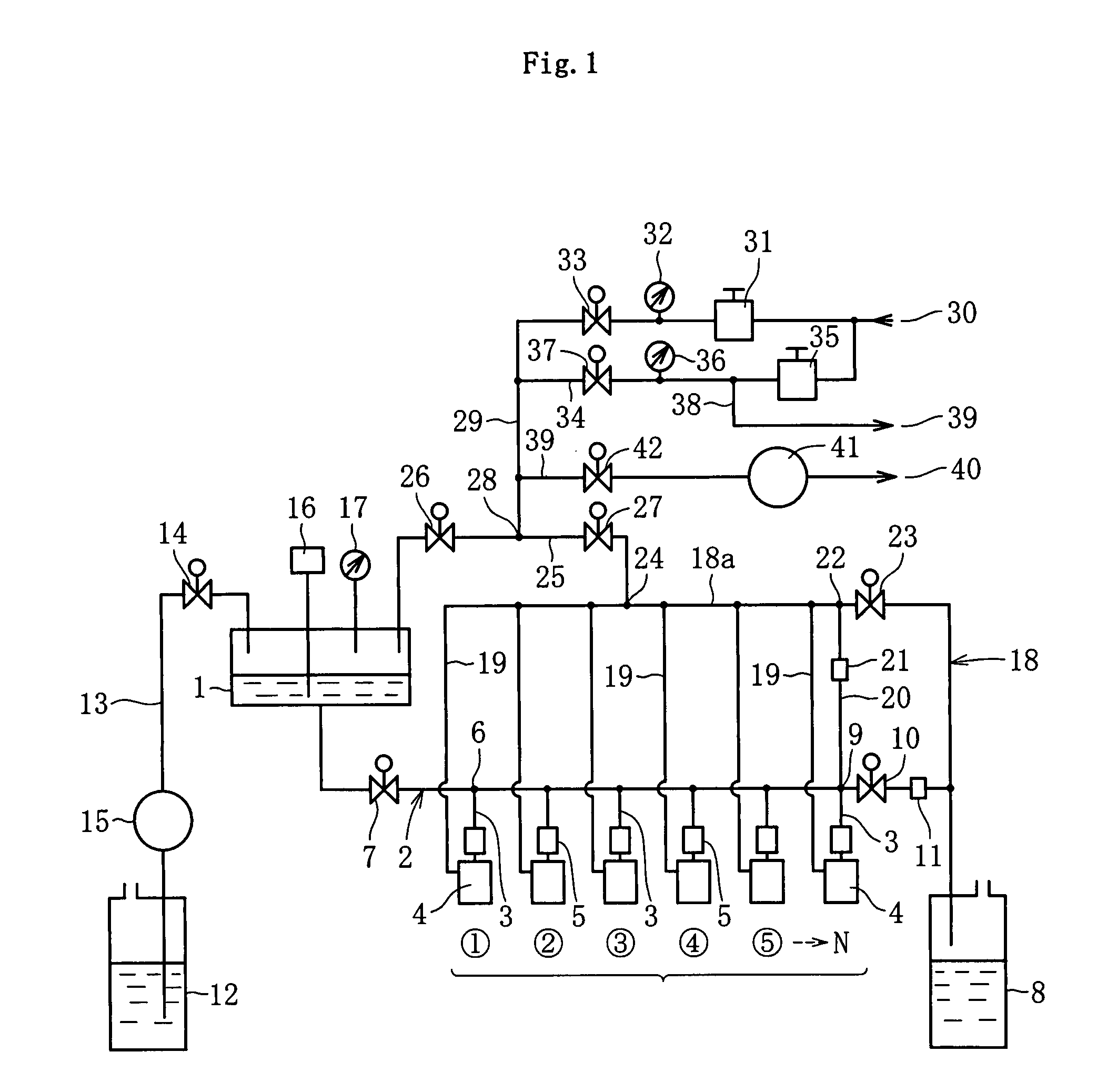

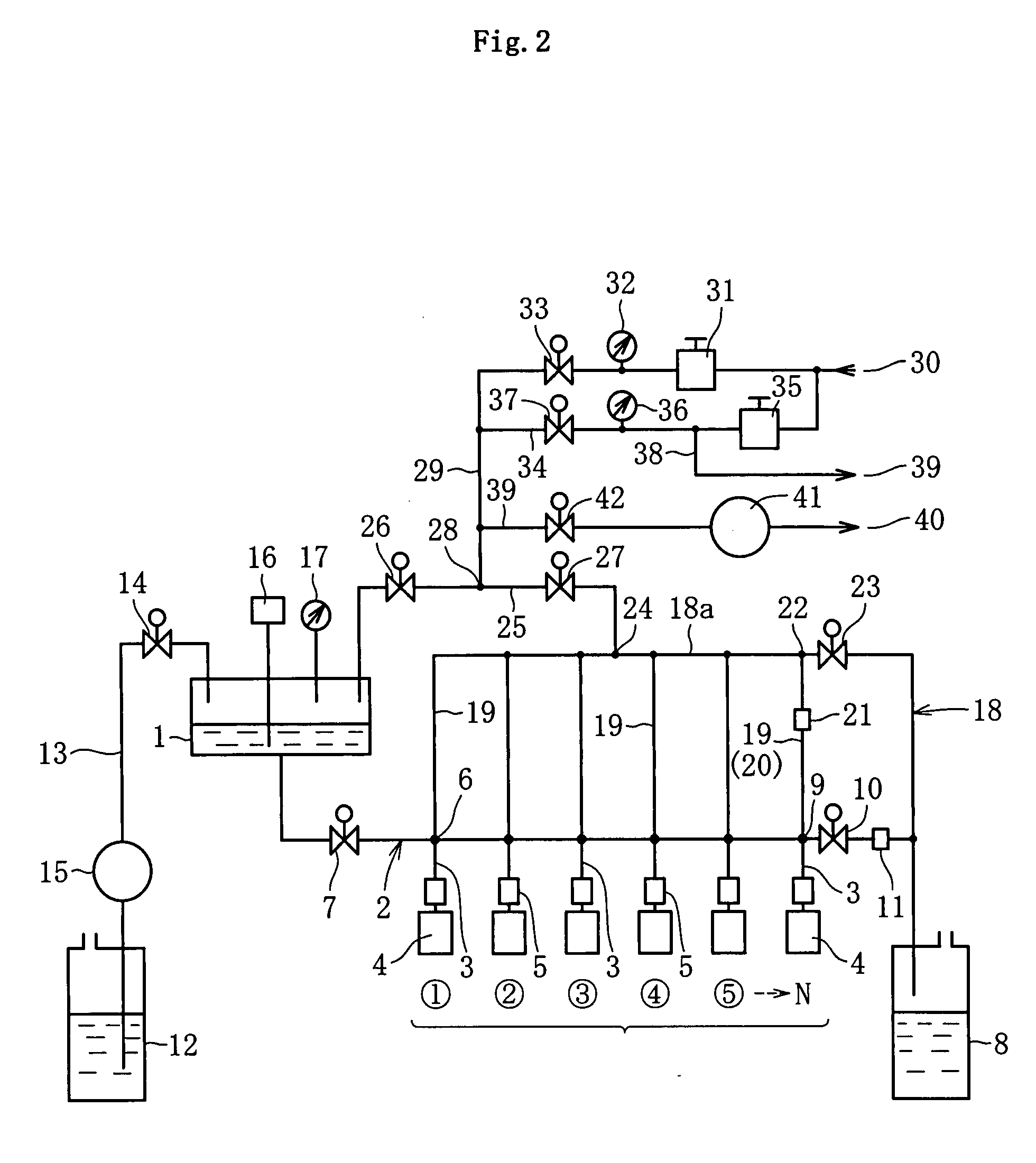

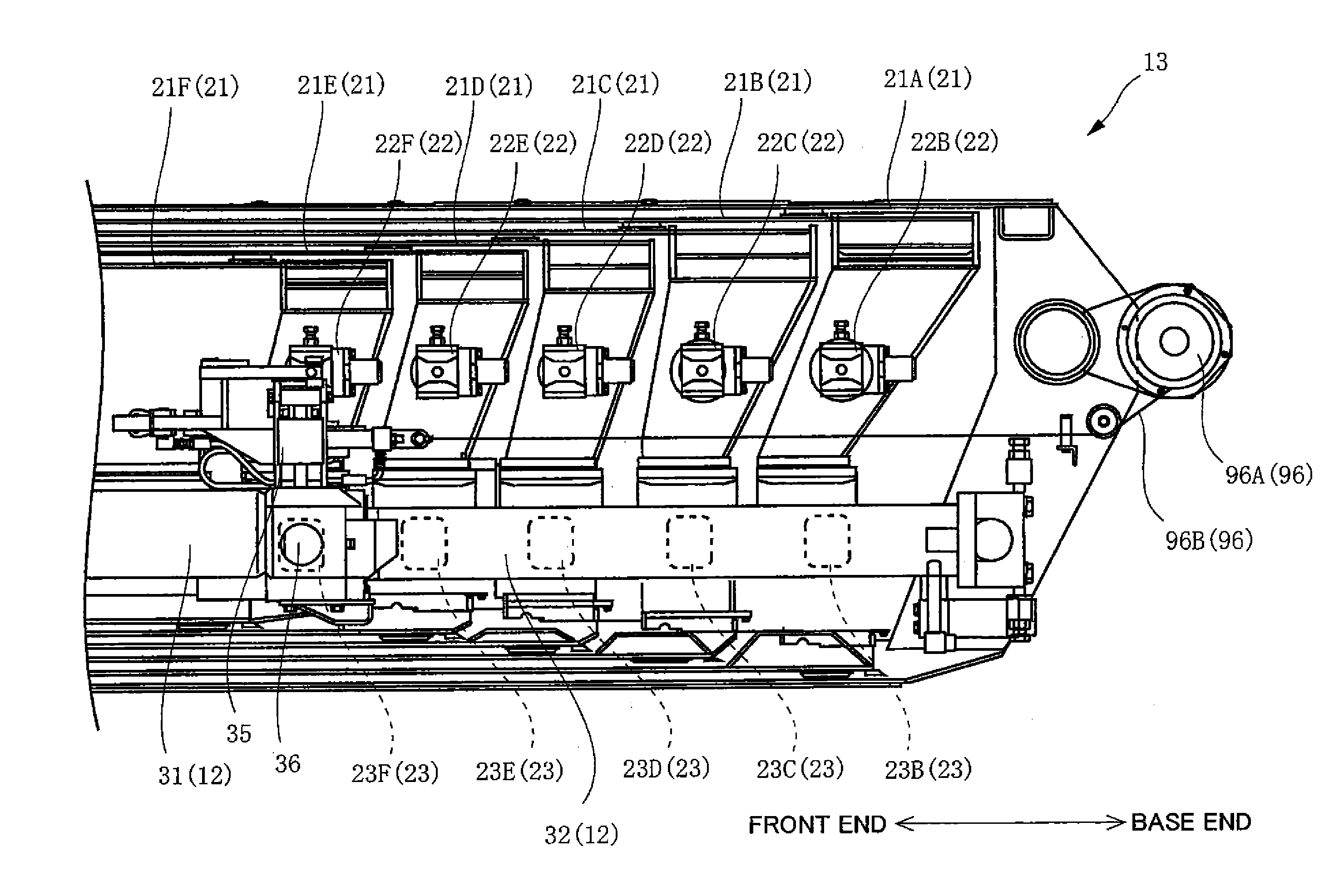

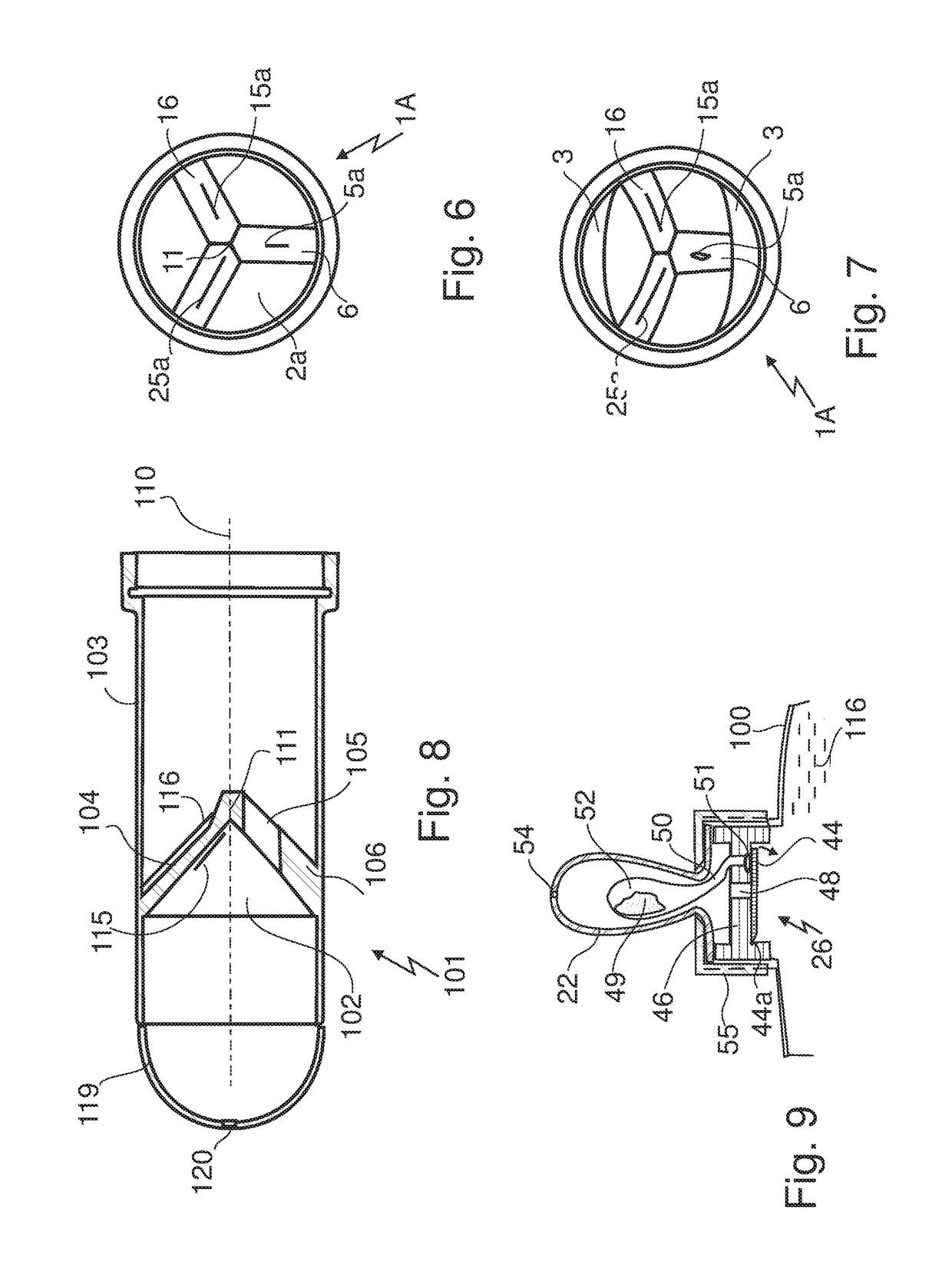

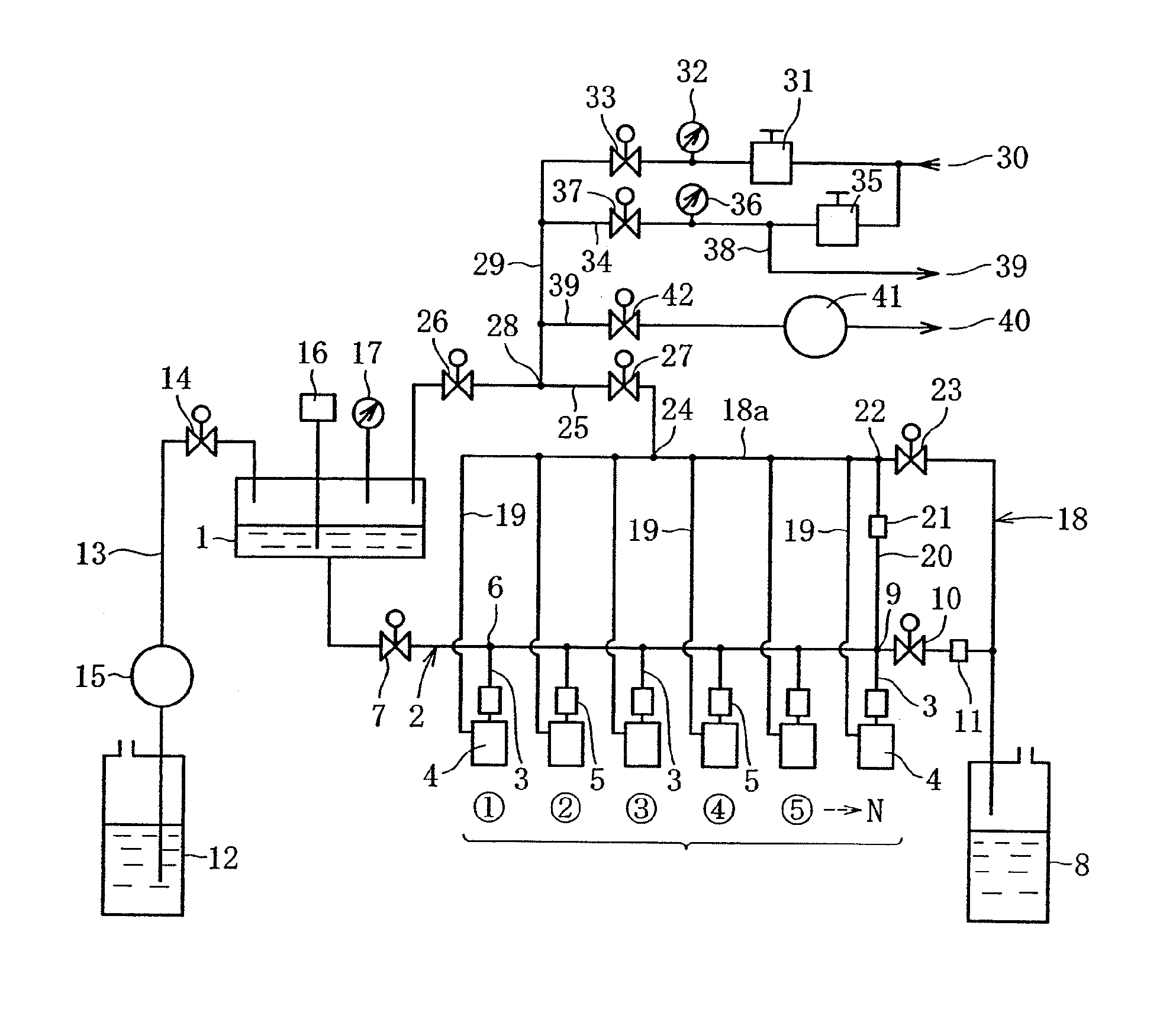

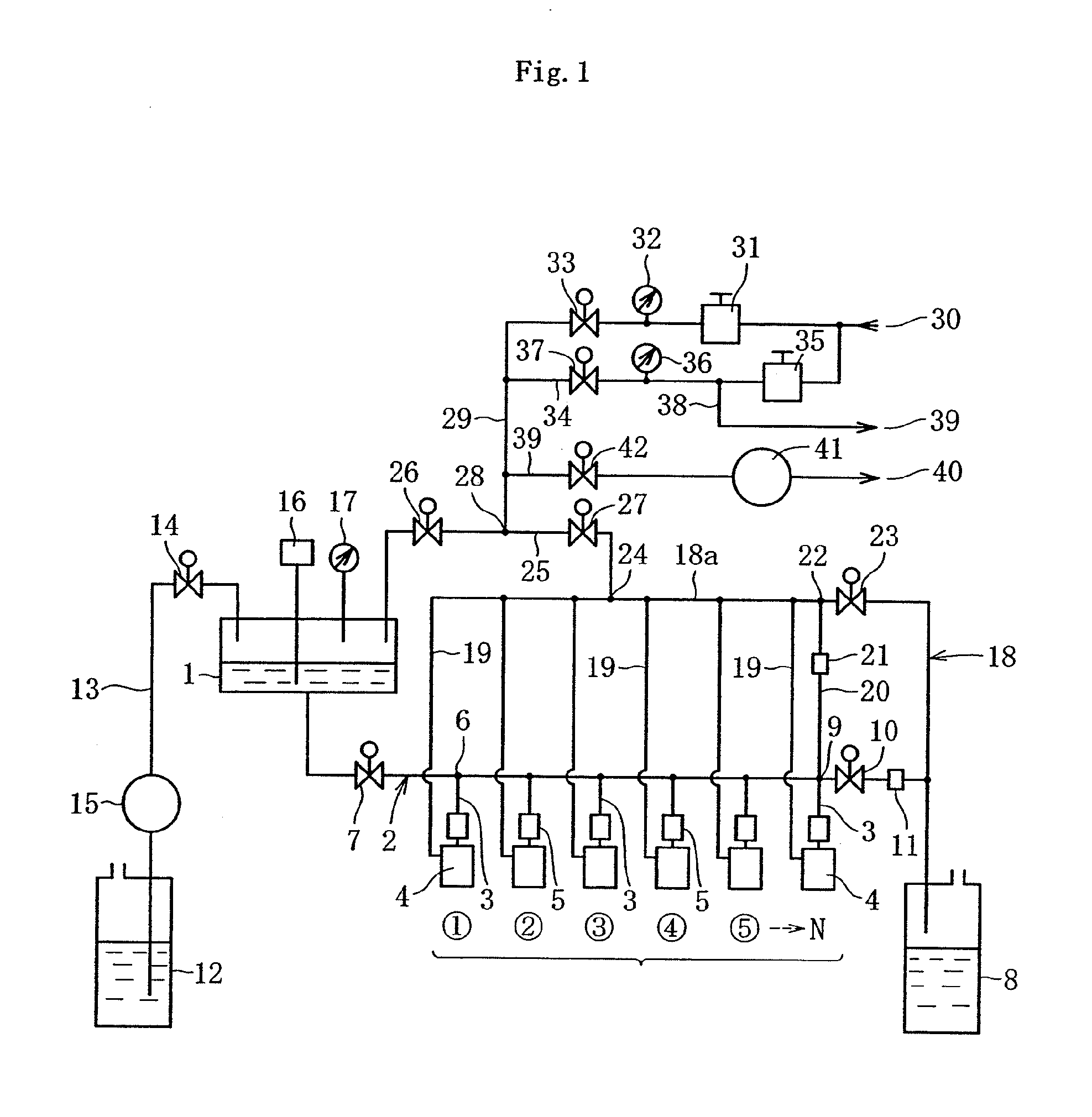

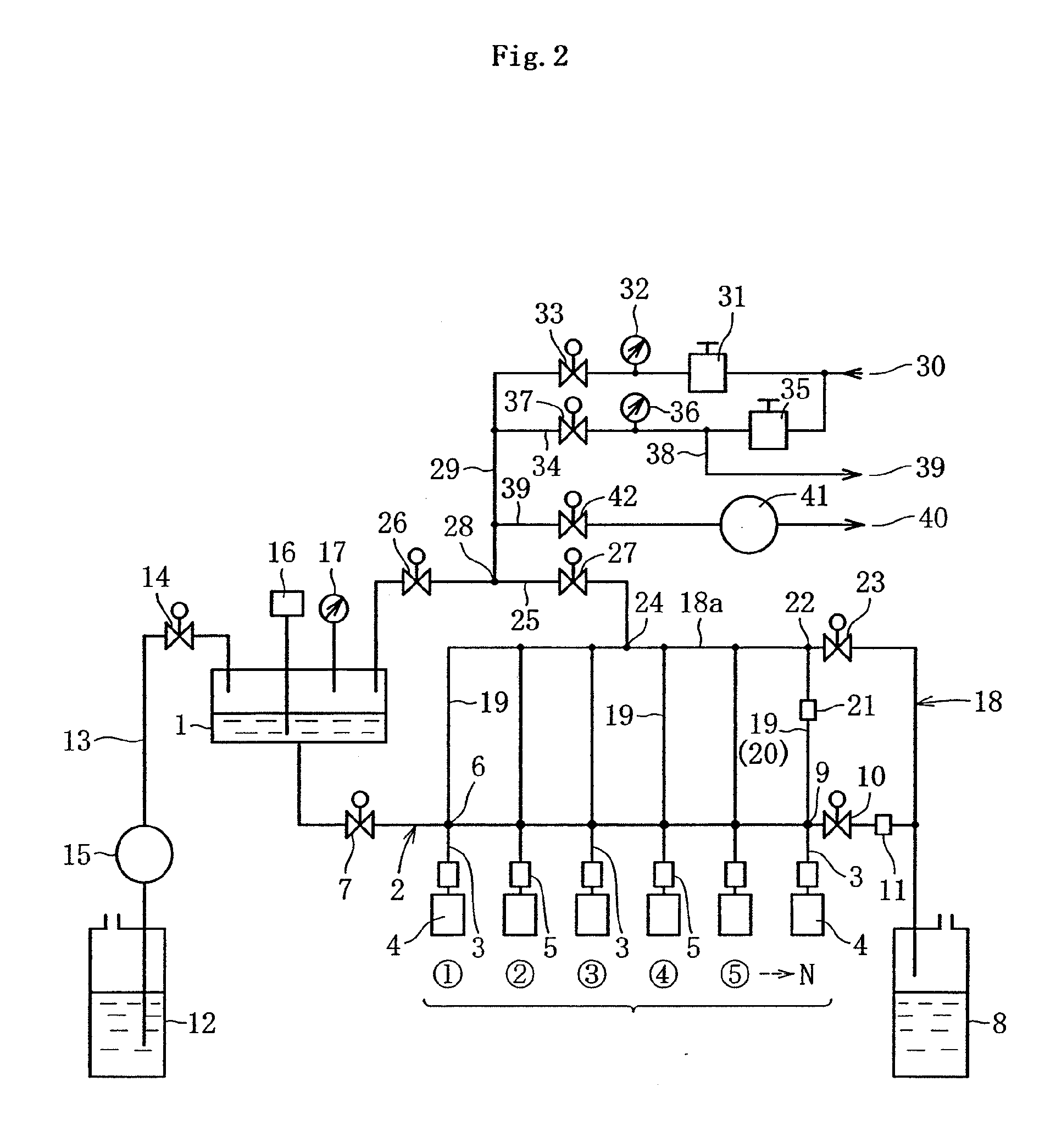

Device for feeding liquid to inkjet heads and device for wiping inkjet heads

When liquid materials are fed to inkjet heads, fluid pressures of liquid materials to be fed to inkjet heads are equalized so that a gas does not remain in liquid feed pipe lines without causing structures of the liquid feed pipe lines to be complicated. Separate liquid feed pipe lines (3) for feeding the liquid material, each of which communicates with each of a plurality of inkjet heads (4), are each connected to a common liquid feed pipe line (2) which stores one kind of the liquid material and communicates with an ink tank (1). Separate gas flow pipe lines (19), each of which is capable of feeding a gas and communicates with a connection portion between the common liquid feed pipe line (2) and each of the separate liquid feed pipe lines (3), with each of the inkjet heads (4), or with both the connection portion and each of the inkjet heads (4), are each connected to a bypass pipe line (18a) (common gas flow pipe line (18)) capable of being opened and closed with respect to the atmosphere.

Owner:ISHII HYOKI

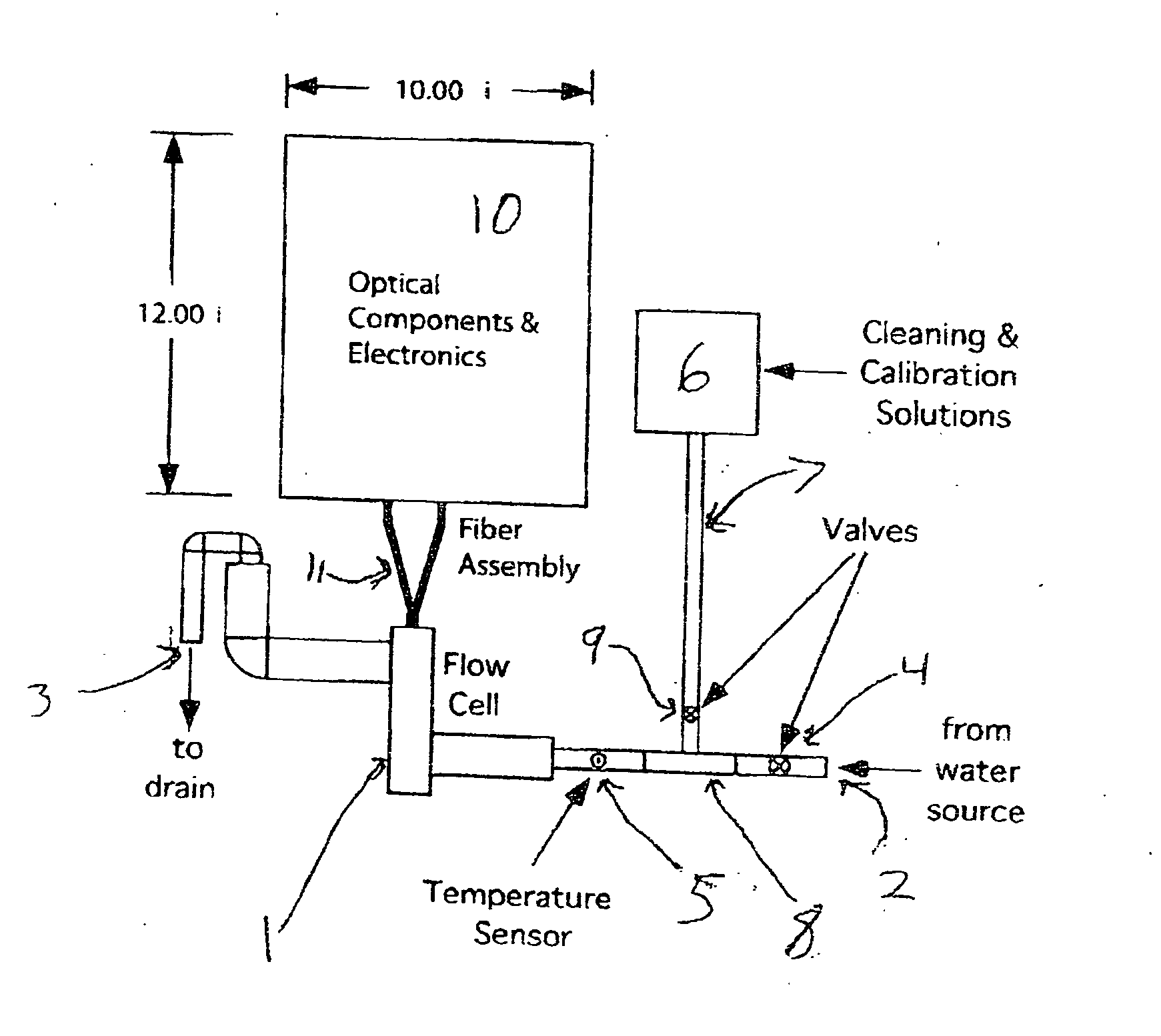

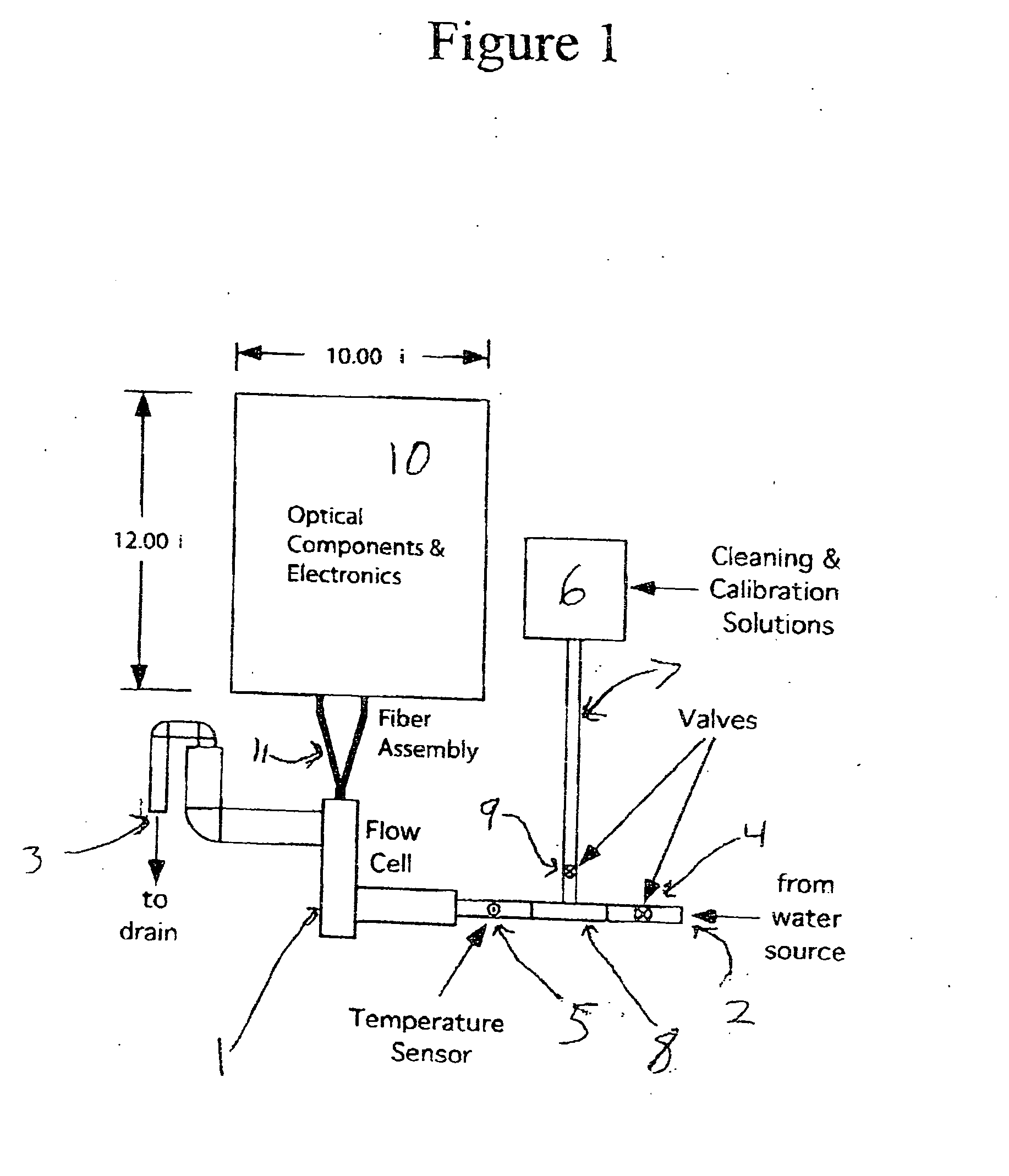

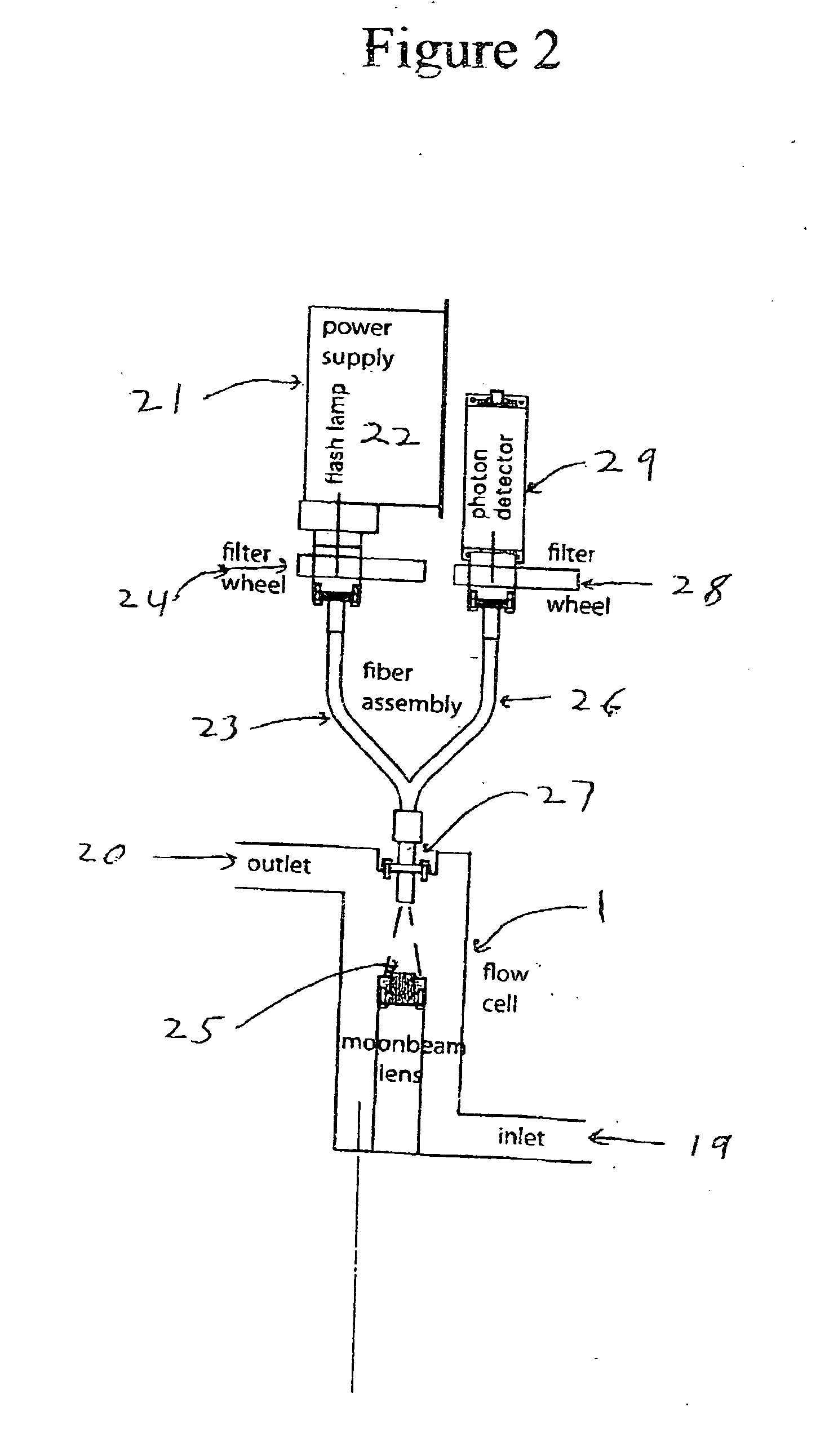

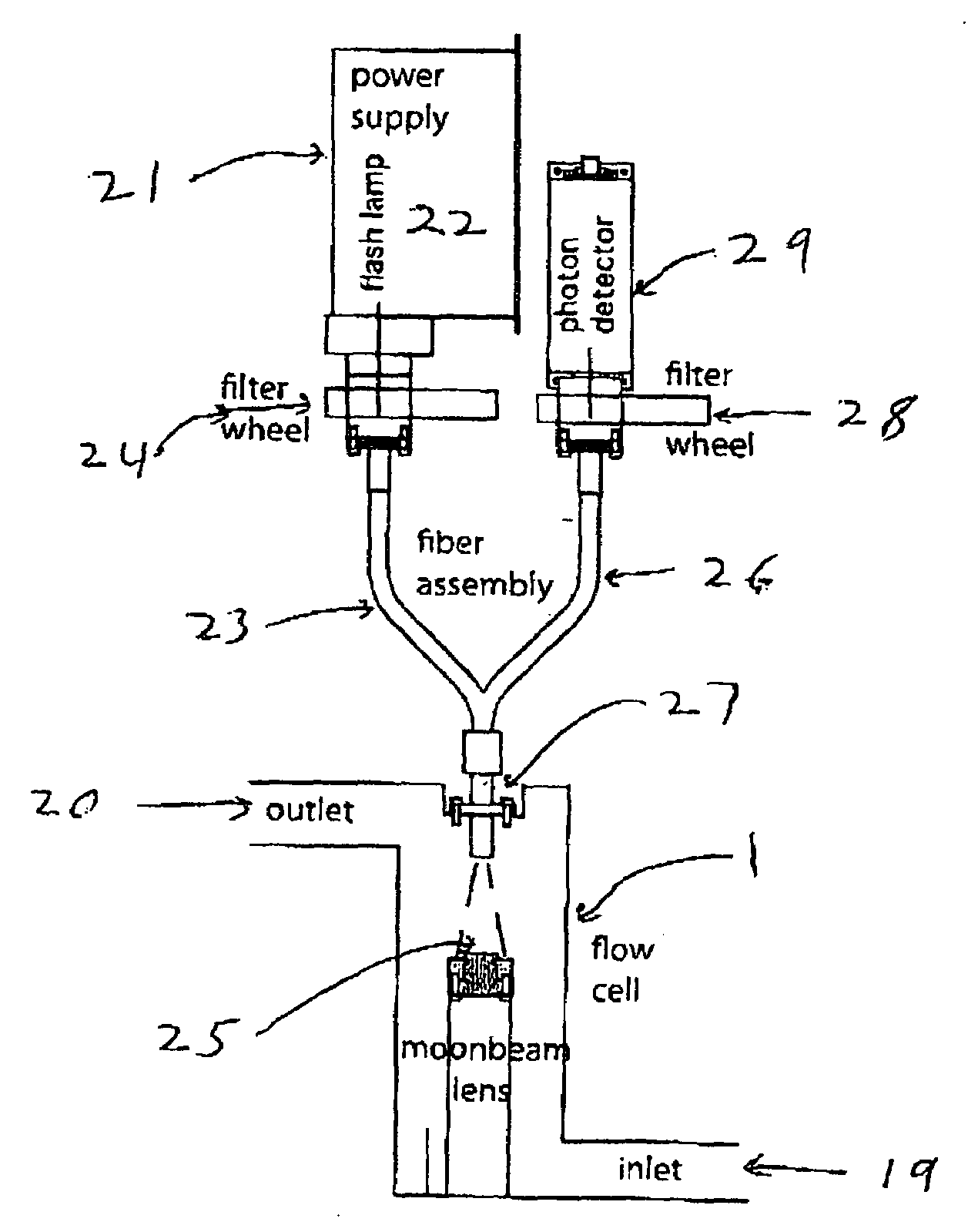

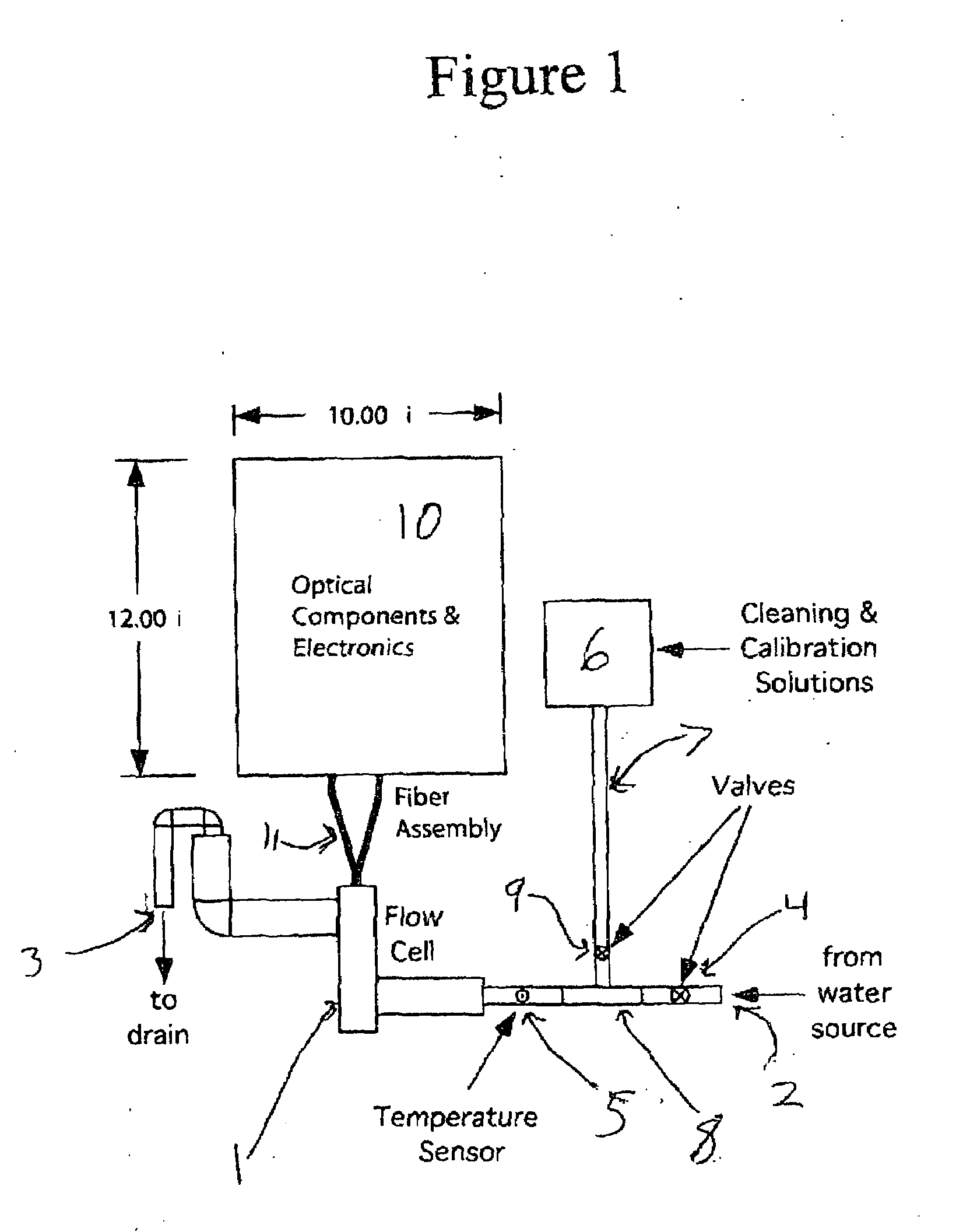

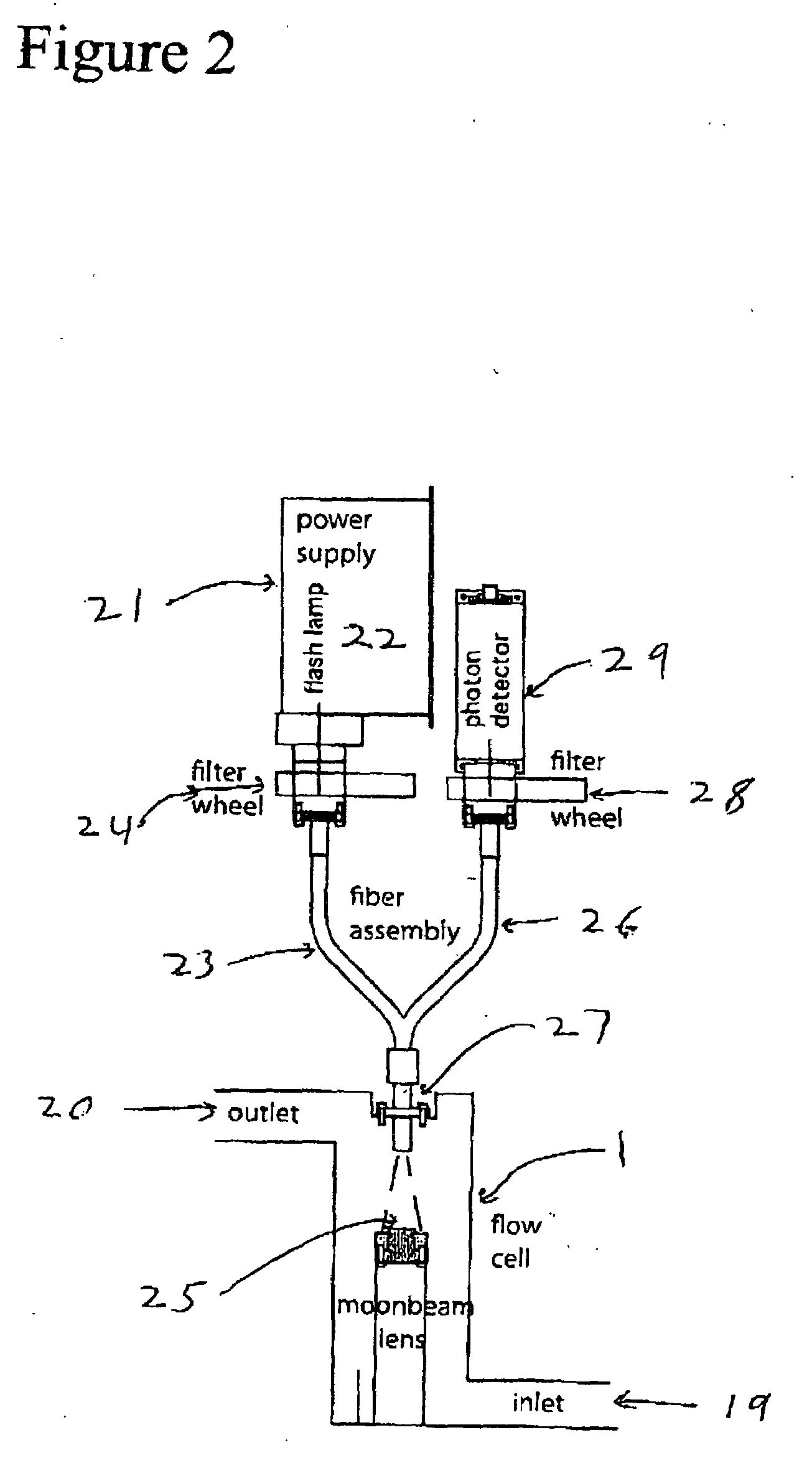

Zero angle photon spectrophotometer for monitoring of water systems

A method and apparatus for monitoring water and other fluid systems is described. The fluid is continually monitored spectrophotometrically by measuring many optical parameters in an in-line, on-line system, which compensates for normal fluid changes while detecting abnormalities.

Owner:G6NINE LLC

Zero angle photo spectrophotometer for monitoring of water systems

InactiveUS20090046287A1Radiation pyrometryAbsorption/flicker/reflection spectroscopyNormal fluidFluid system

A method and apparatus for monitoring water and other fluid systems is described. The fluid is continually monitored spectrophotometrically by measuring many optical parameters in an in-line, on-line system, which compensates for normal fluid changes while detecting abnormalities.

Owner:U S GOVERNMENT BY THE ENVIRONMENTAL PROTECTION AGENCY

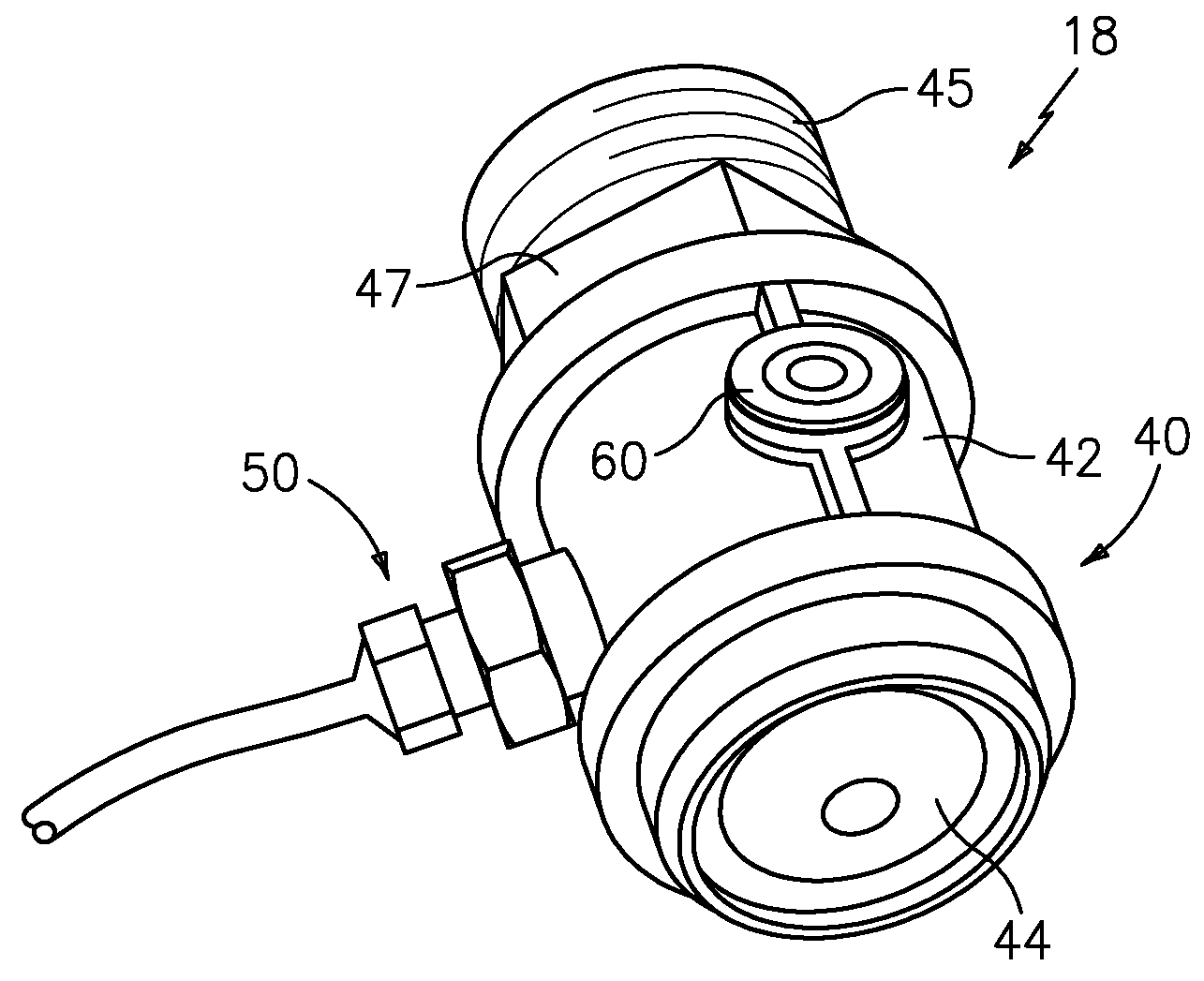

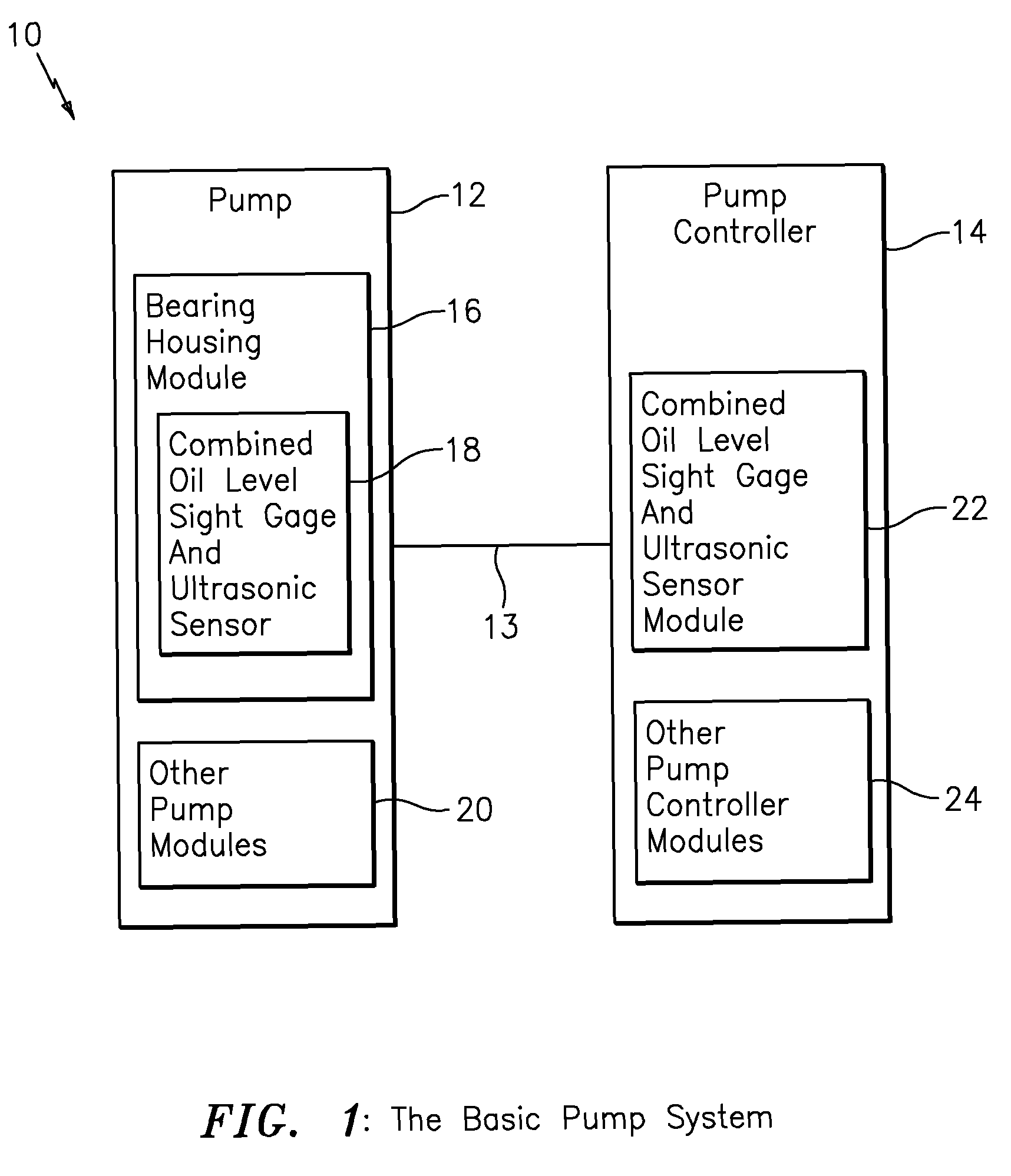

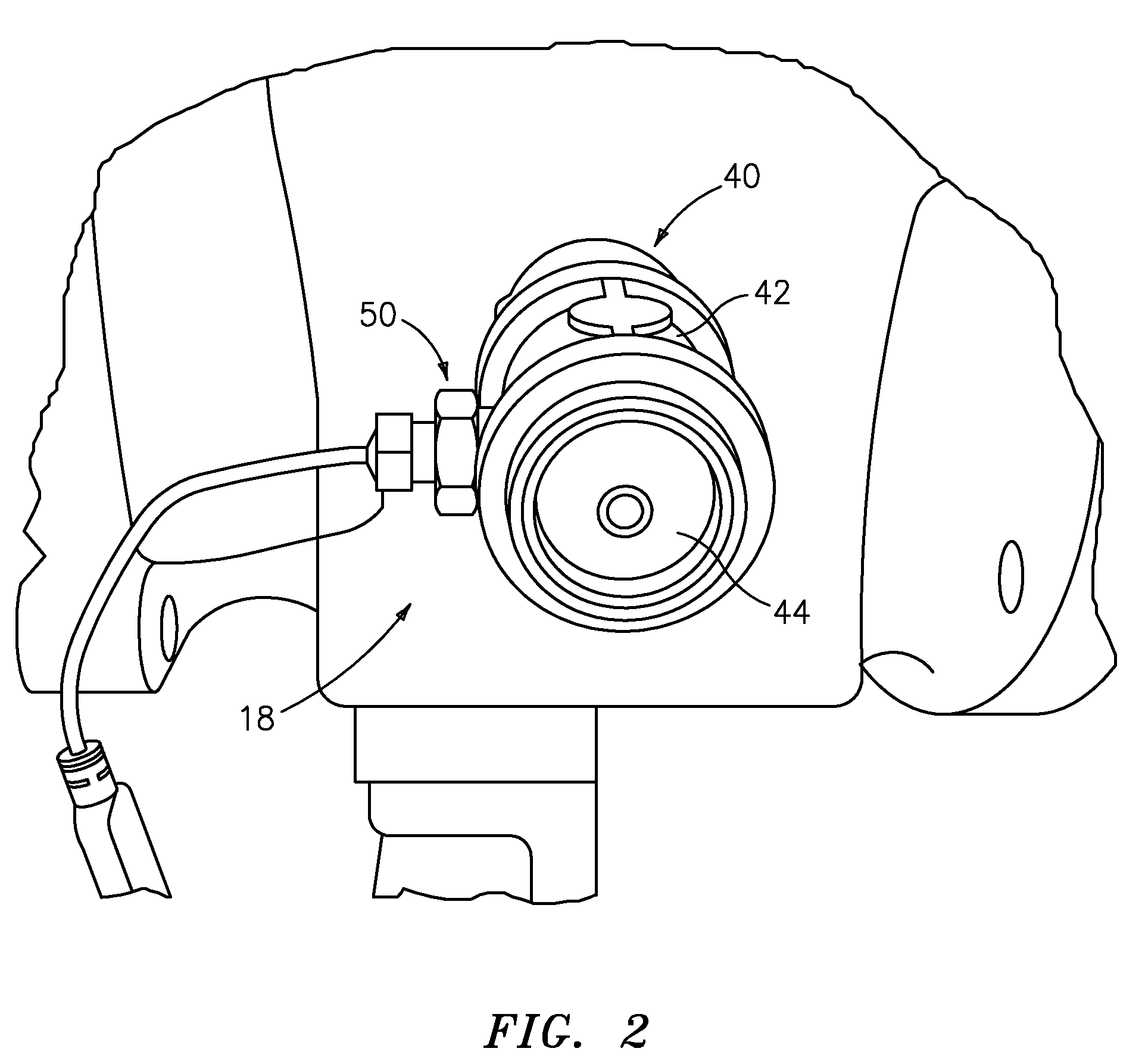

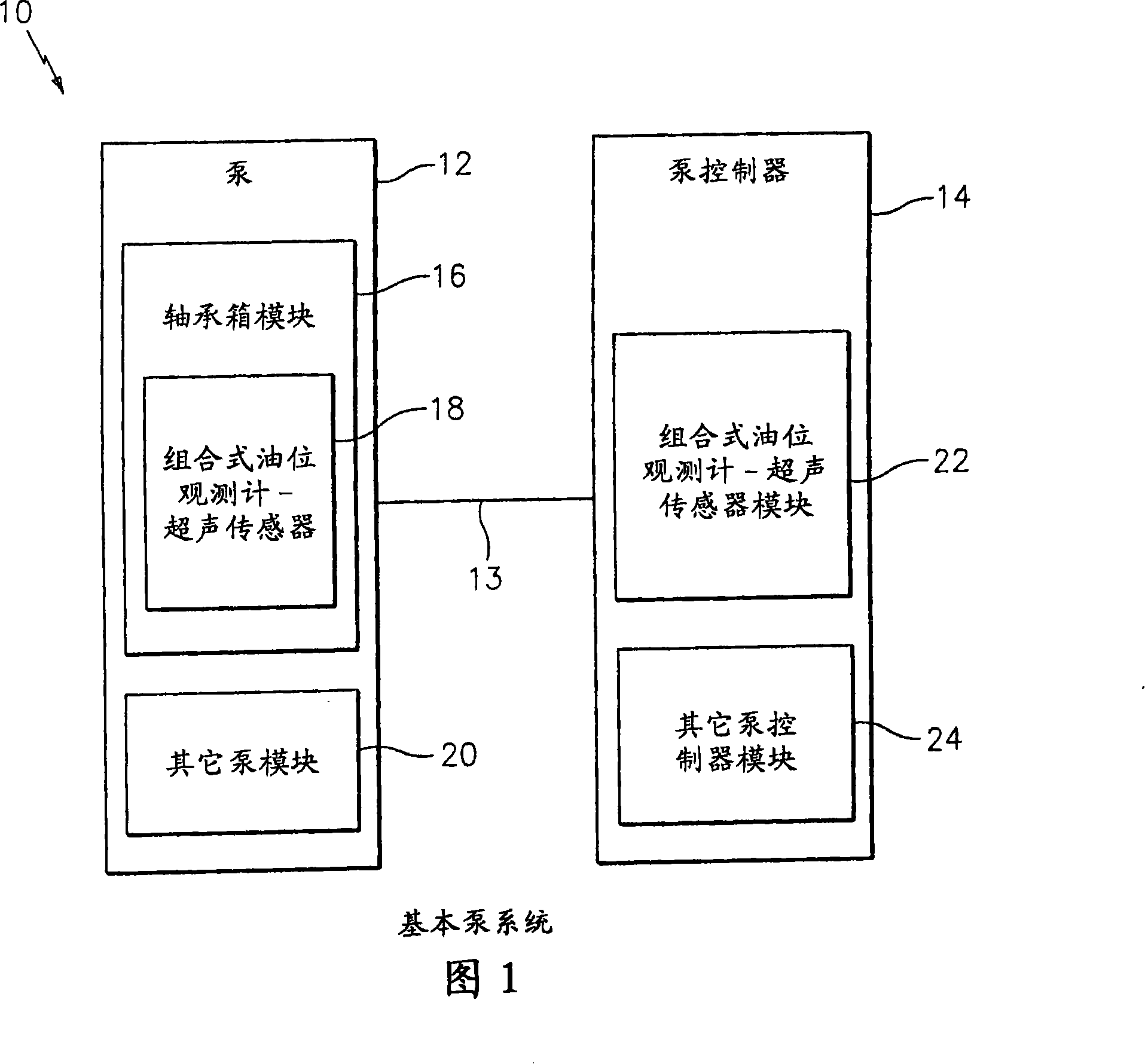

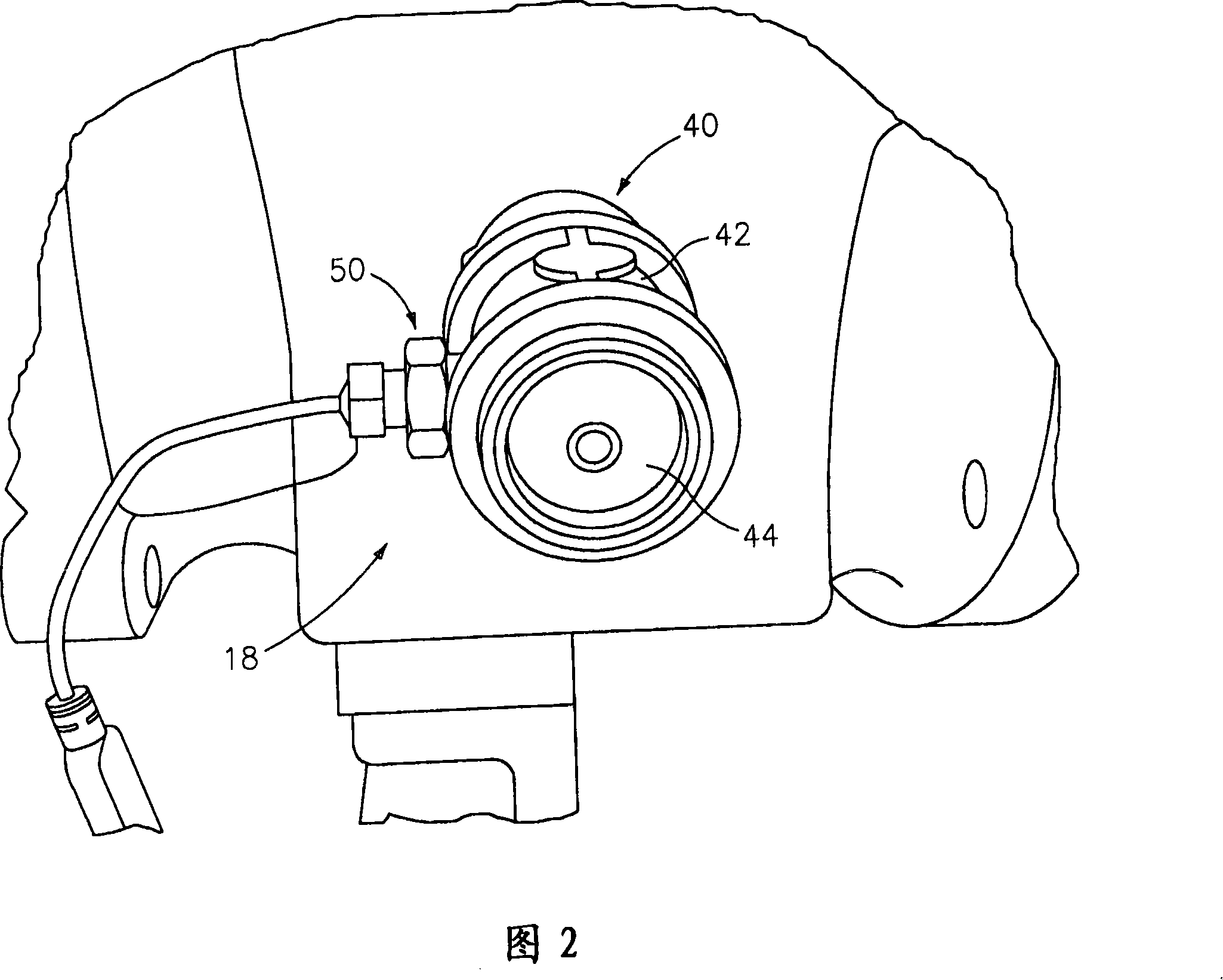

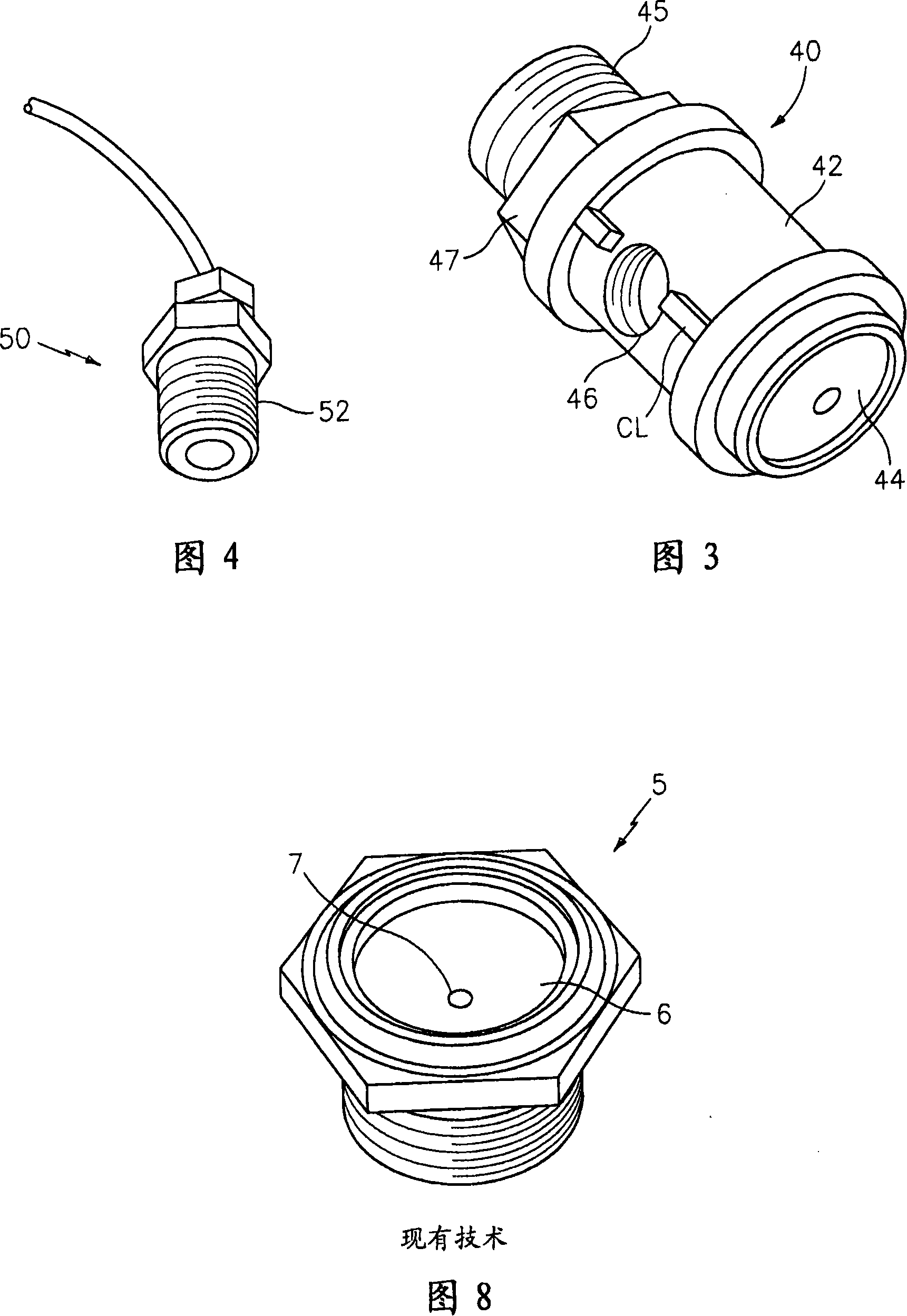

Combined sight oil level gage and ultrasonic sensor

The invention provides a combined fluid level sight gage and ultrasonic sensor featuring a fluid level sight gage having a housing for containing a fluid and having a sight glass for viewing the level of the fluid therein, and an ultrasonic sensor coupled to the housing, responsive to the level of fluid in the housing, for providing an ultrasonic sensor signal containing information about the level of fluid in the housing. In operation, the sight glass provides a visual verification that the ultrasonic sensor is working correctly in relation to the fluid visible in the sight glass. The ultrasonic sensor signal may be used to automatically annunciate alarms or warnings either locally at the equipment or by wired or wireless electronic means. In some embodiments according to the present invention, the housing has a centerline for indicating a normal fluid level therein. The ultrasonic sensor may be arranged in the housing on the centerline, or slightly below the centerline, or slightly above the centerline.

Owner:GERBER LIONEL +1

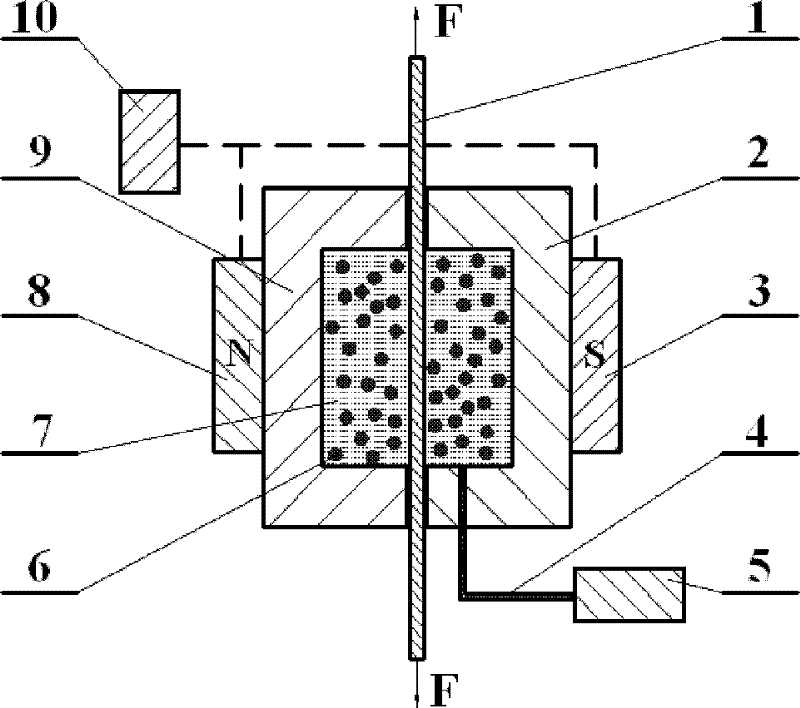

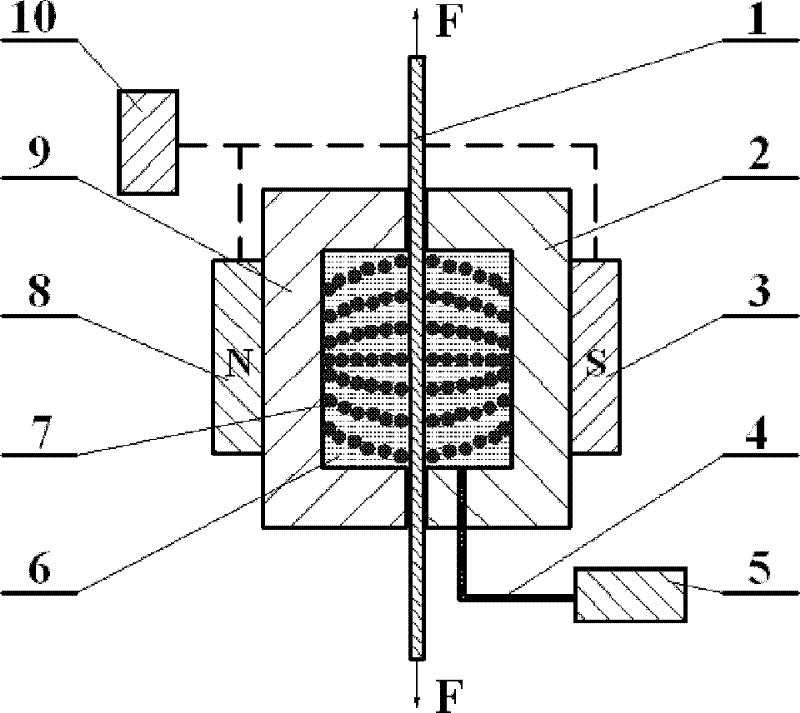

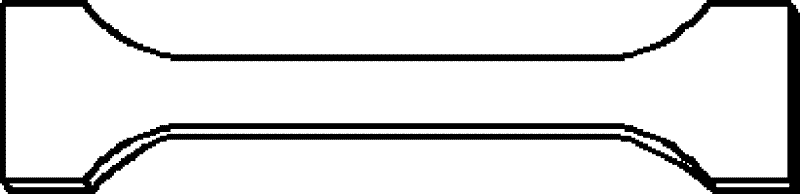

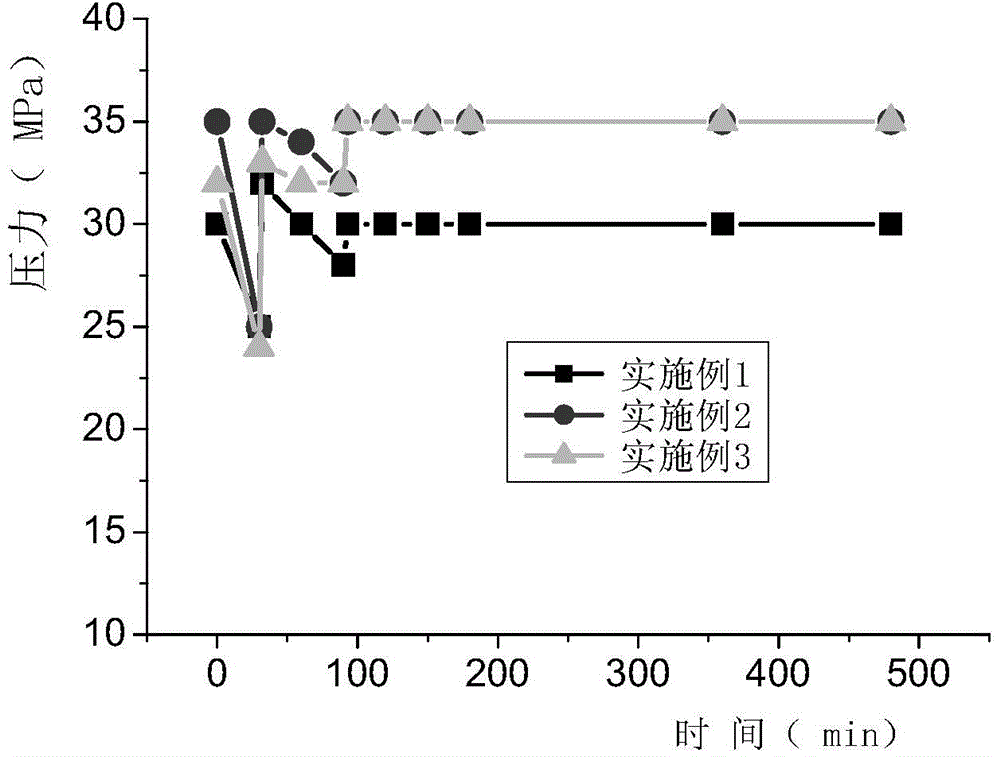

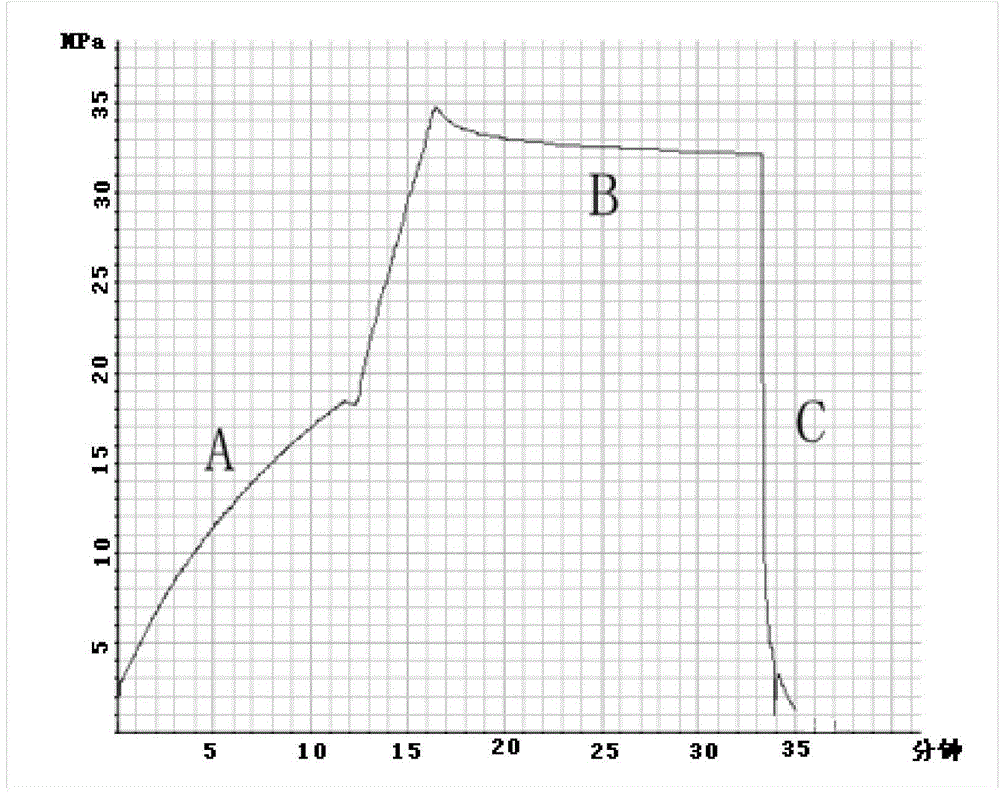

Material mechanical property testing method under three-dimensional stress state

ActiveCN102645375AHigh yield strengthHigh elongationMaterial strength using tensile/compressive forcesMagnetic mediaEngineering

The invention provides a material mechanical property testing method under a three-dimensional stress state, relating to a material mechanical property testing method. When common liquid is used as a force transfer medium to apply normal pressure, a high pressure can hardly be provided and dynamic seal and other bottleneck problems can be caused during a plate stretching process; and the problems can be solved through adoption of the method provided by the invention. The method provided by the invention comprises a left die cavity, a right die cavity, an S pole, an N pole, a high-pressure oil pipe, a hydraulic control system, magnetic particles, base liquid and a magnetic control unit; a magnetic medium is used as an intelligent material and has directional arrangement under the action of a controllable magnetic field so as to apply normal pressure to a plate, and the size of the normal pressure can be changed through the regulation on the magnetic field, so as to test the one-way stretch forming property of the plate under the actions of different normal forces; compared with the common liquid, the magnetic medium can realize sealing more easily; therefore, a technical means is provided for testing the high-pressure forming property of plate (tube) fluid. The method requires simple equipment and few test steps, has high controllability and can be easily implemented, popularized and applied to production.

Owner:HARBIN INST OF TECH

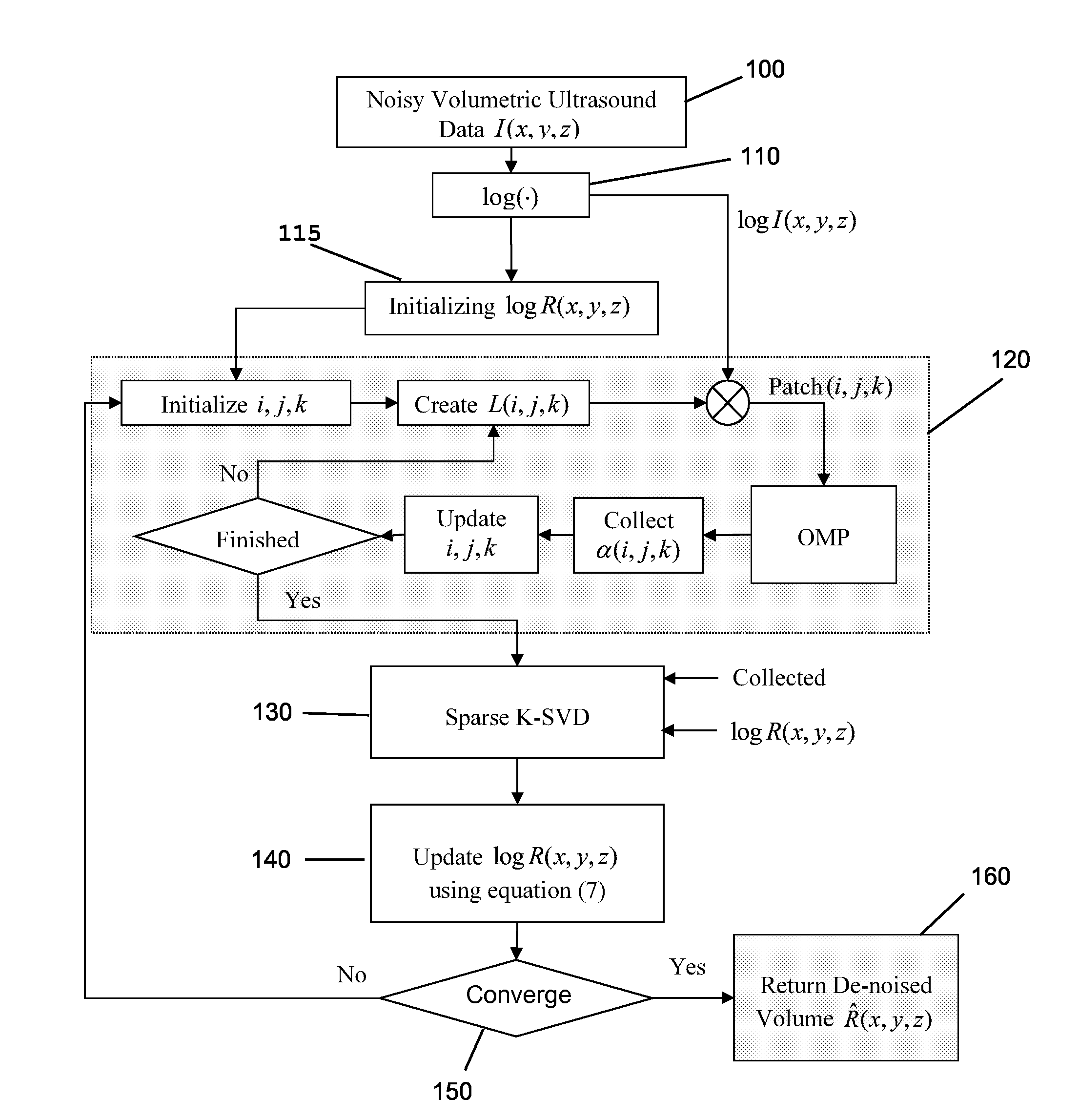

Computer aided diagnosis for detecting abdominal bleeding with 3D ultrasound imaging

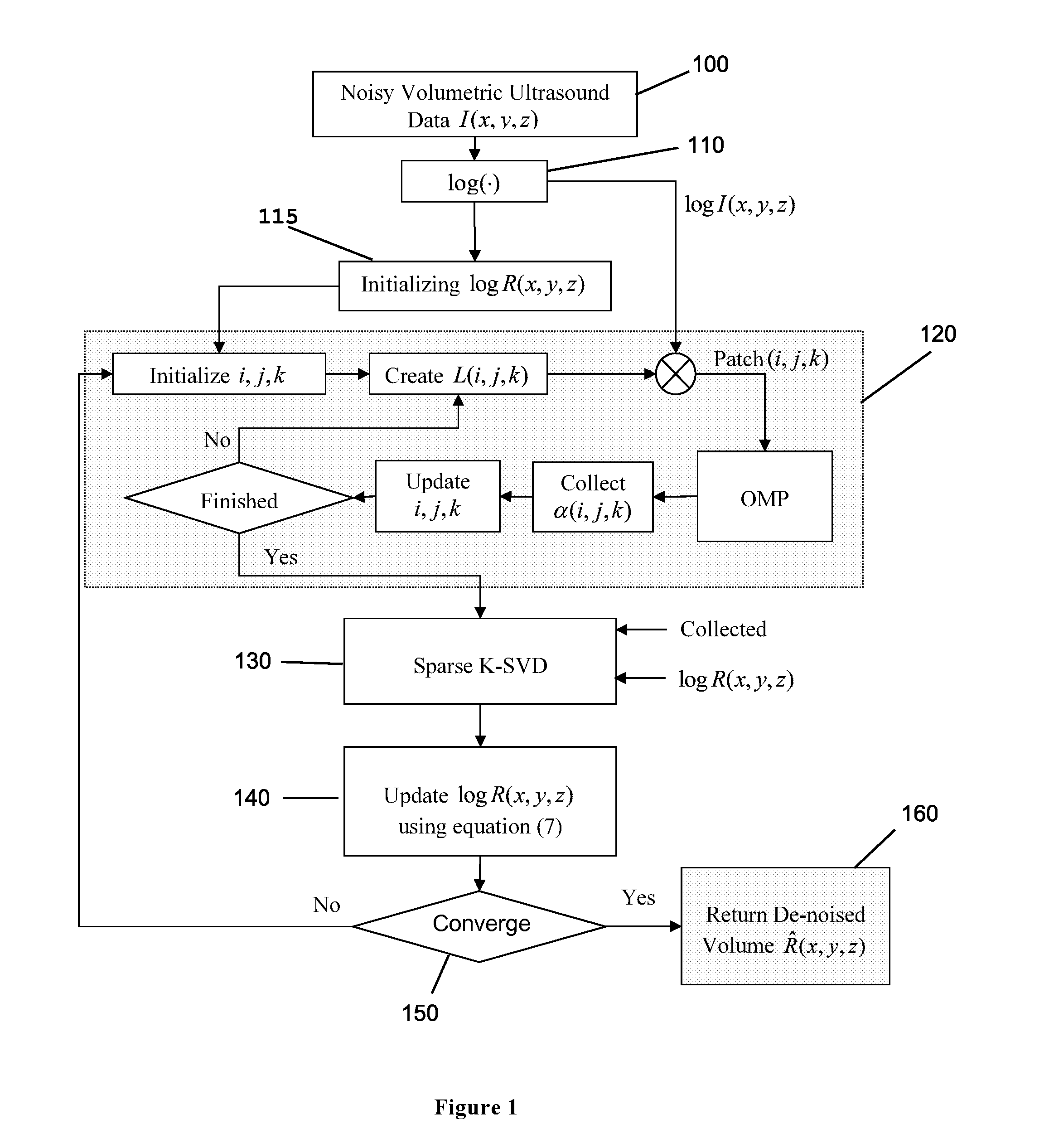

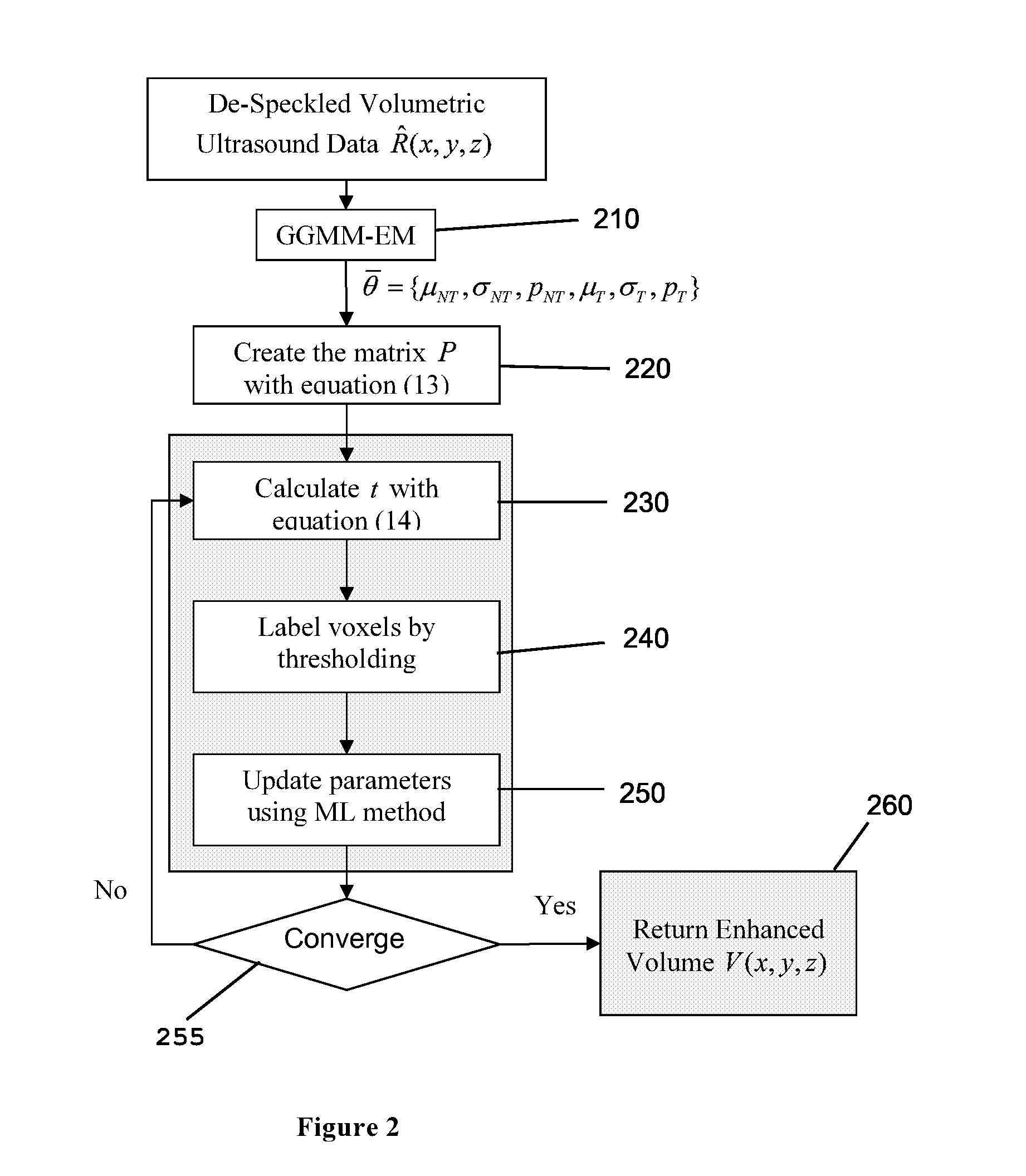

The presented invention provides a detection method for free fluid in the human body. The preprocessing procedure is applied to reduce the speckle noise and enhance tissue volumetric pixels (voxels) intensity levels to make tissue and non-tissue voxels more distinguishable from each other. An initial surface selection step provides flexibility to either manually or automatically selecting a seed point to segment fluid regions in the volumetric data. A kidney and liver organ detection procedure provides a method for determining whether the detected fluid region is a normal fluid-carrying body organ or if it is due to a medical condition as a free fluid region. A combinational approach using a 3-dimensional Snake and Level-Set is utilized to accurately detect fluid regions in the volumetric ultrasound data.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

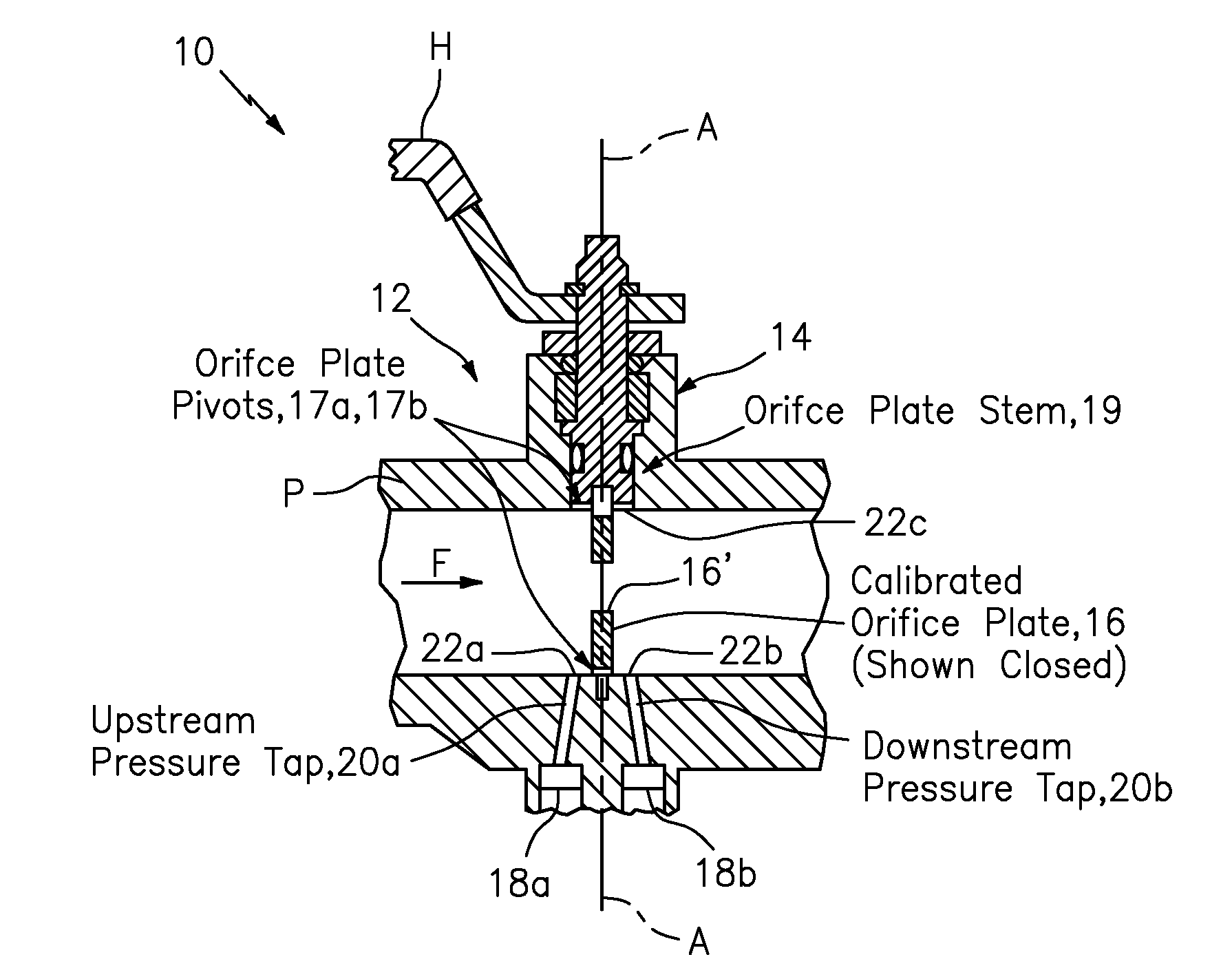

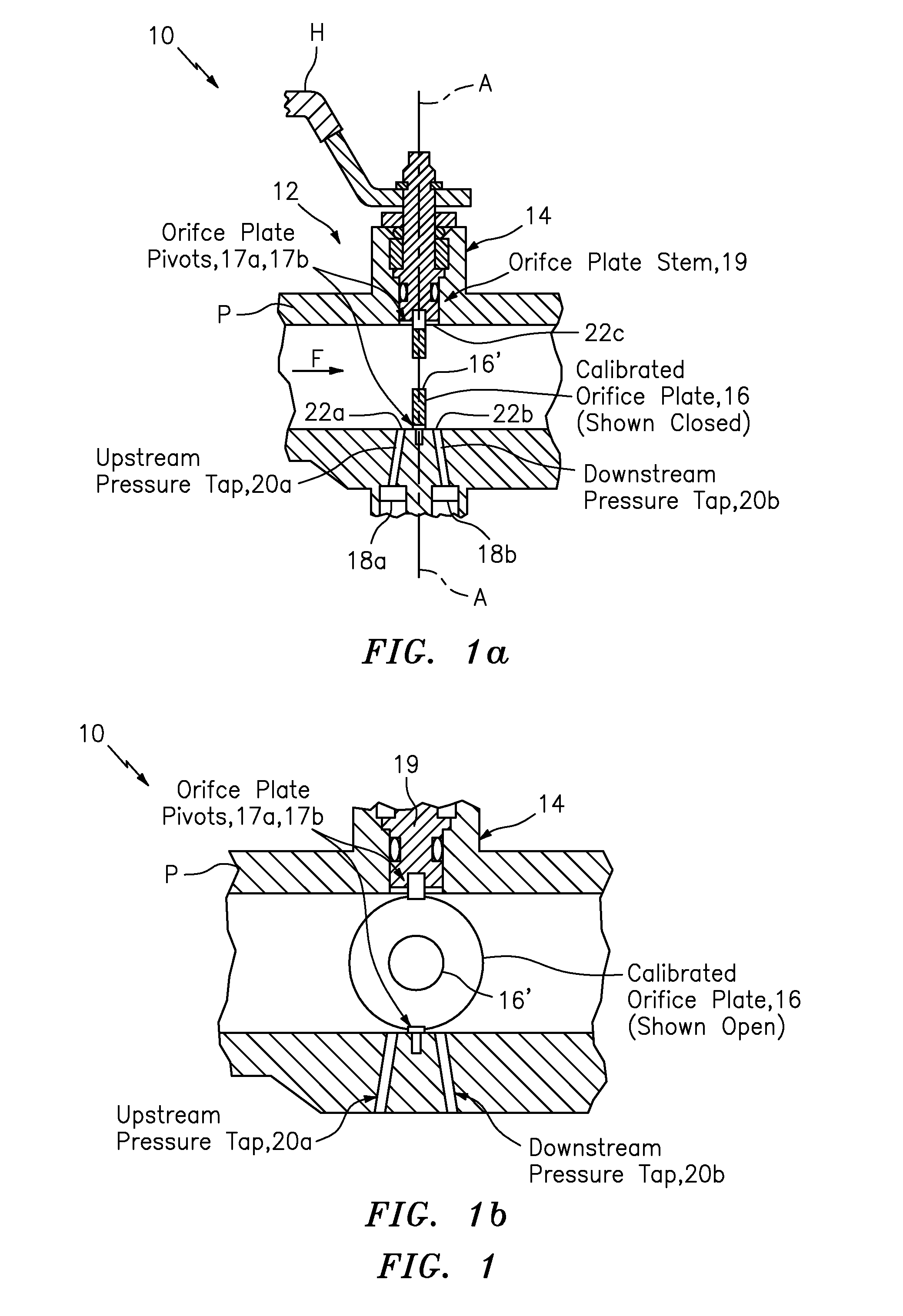

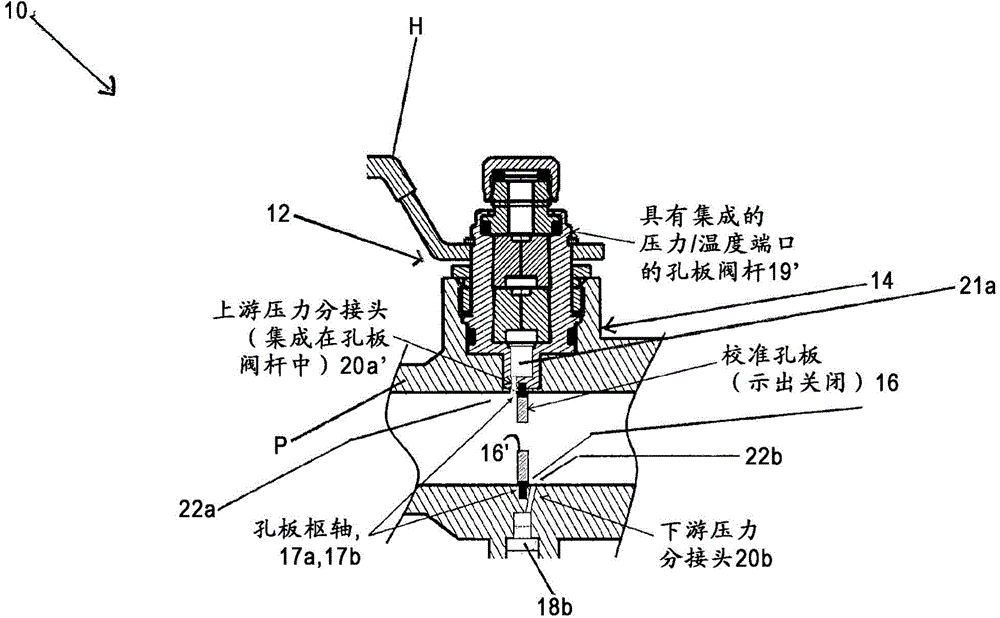

Rotatable Orifice Plate for Direct Flow Measurement

Owner:FLUID HANDLING

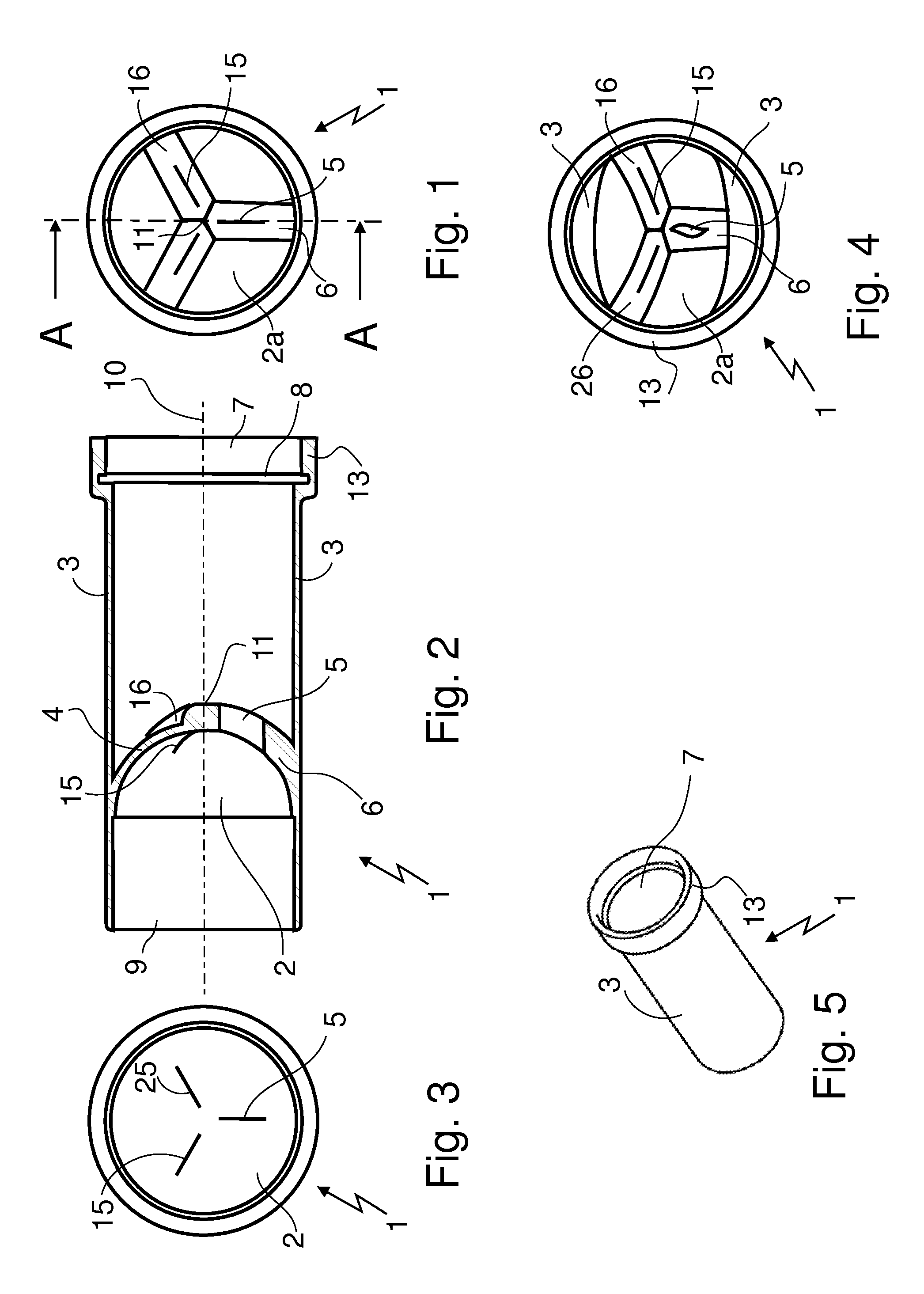

Washing machine brake cam actuator with interrupted ring

InactiveUS6860124B1Improve toleranceInstances of unacceptable knocking noise are reducedOther washing machinesTextiles and paperCamActuator

A brake cam actuator assembly for a washing machine includes an actuator having a cylindrical body that is drivingly coupled to a transmission pulley hub through a wrap spring clutch circumscribing the transmission pulley hub and brake cam actuator body. A first end of the brake cam actuator includes a segmented ring that reduces knocking noises due to imperfections and manufacturing defects in the transmission pulley hub and brake cam actuator first end which interface one another. The segmented ring also forms controlled flow path for normal fluid leaks and prevents contamination of a ramped cam surface on a second end of brake cam actuator and contamination of a friction brake surface that may produce friction material squeaking noises.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Anti-gas lock valve for a reciprocating downhole pump

ActiveUS10174752B2Reduce harmIncrease productionFluid parameterPositive displacement pump componentsHydrostatic headPump chamber

Method and apparatus overcoming gas-lock in reciprocating downhole pumps. On the downstroke of a plunger in a barrel, gassy fluid is compressed in the pump chamber between standing and travelling valves. Downhole plunger movement drags a sleeve over a mandrel for opening a chamber valve to a staging chamber located at a downhole end of the travelling valve for receiving at least a portion of the compressed and gassy fluid therein. On the upstroke, the chamber valve is dragged closed for sealably retaining the compressed gassy fluid therein while drawing an additional increment of fluid through the standing valve into the pump chamber. Continued downstroke and upstroke cycles increases pressure of the compressed gassy fluid in the pump chamber until it exceeds the hydrostatic head above the travelling valve for resumption of normal fluid pumping.

Owner:INNOVATIVE OILFIELD CONSULTANTS

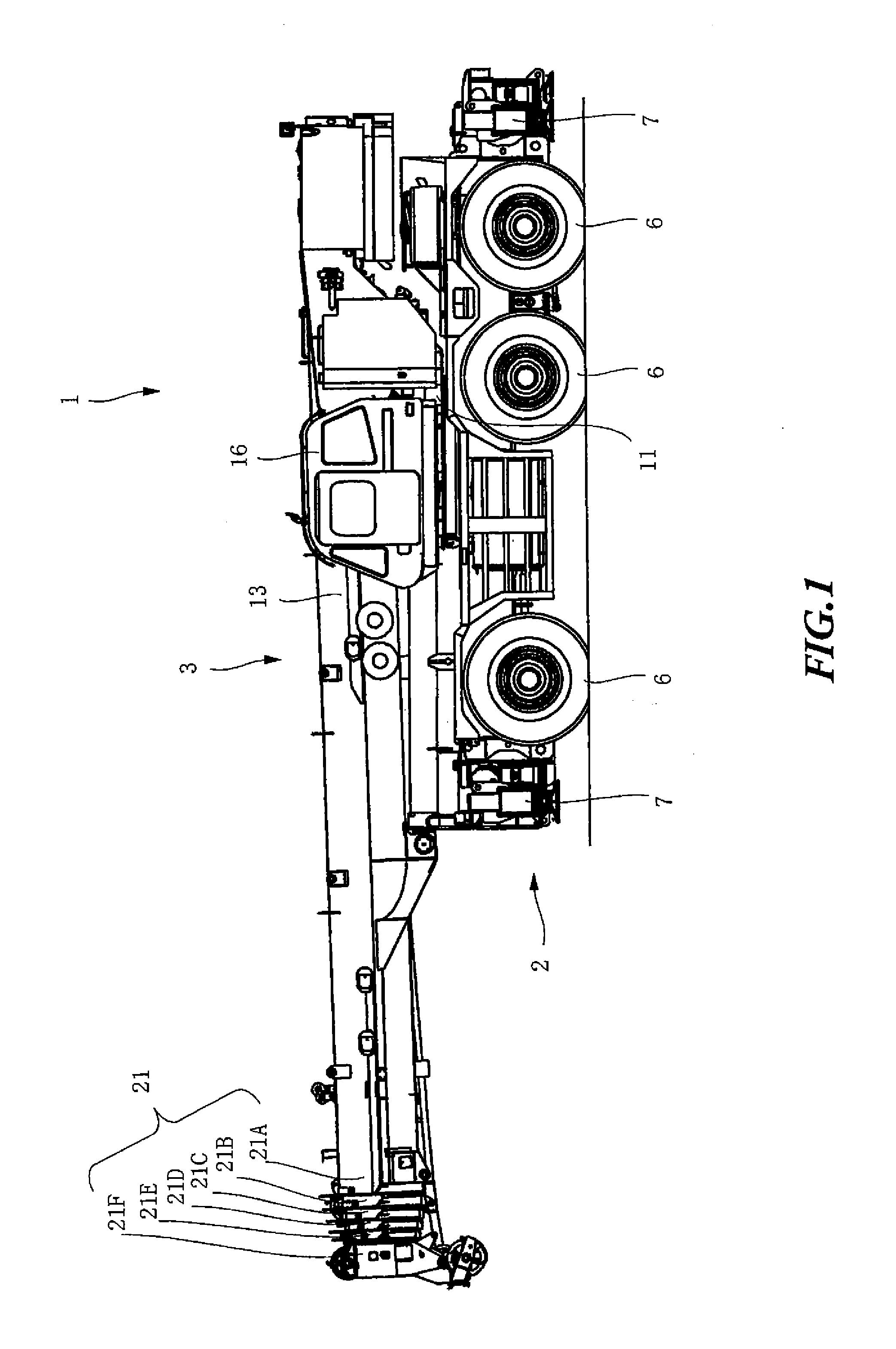

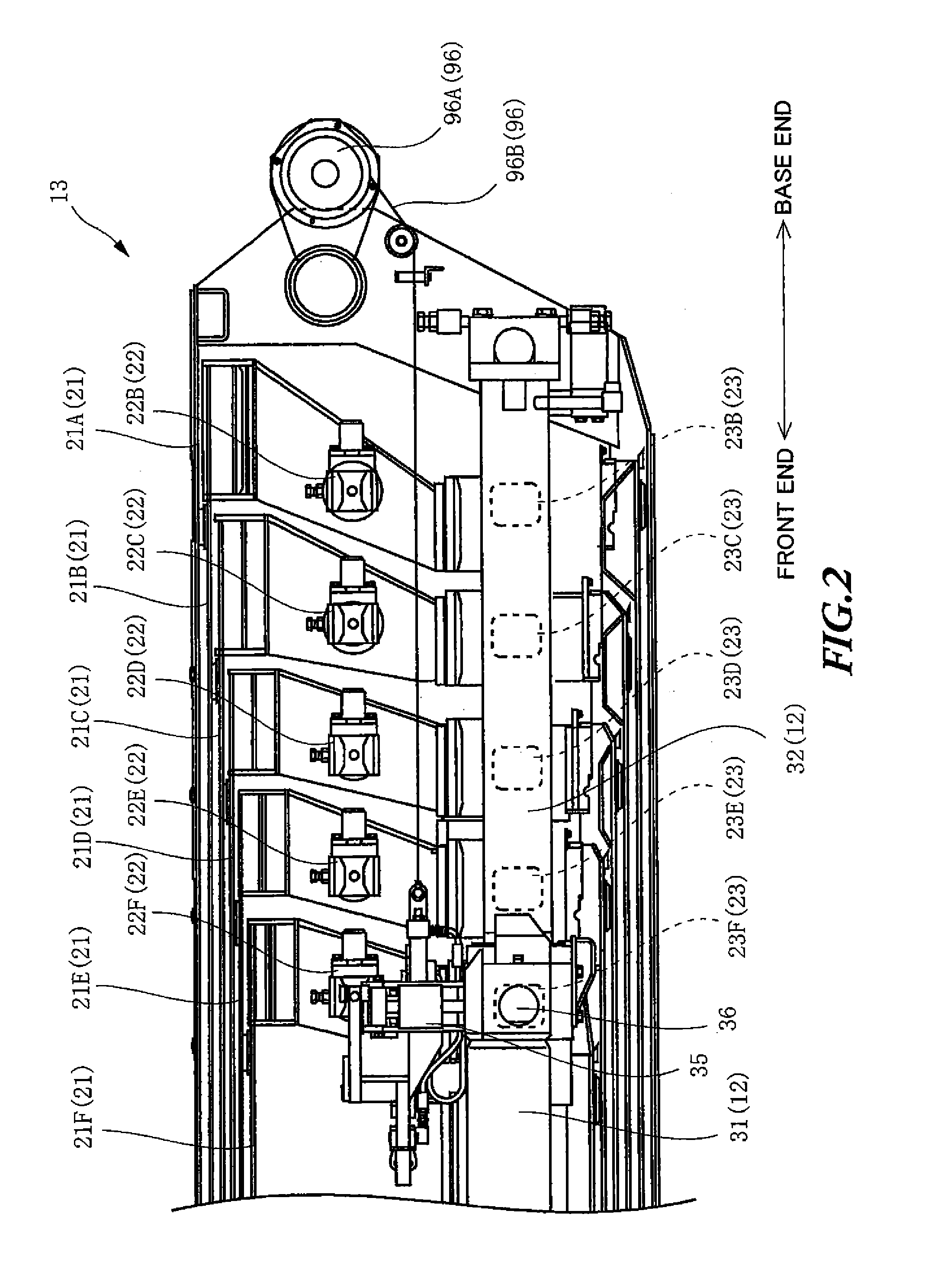

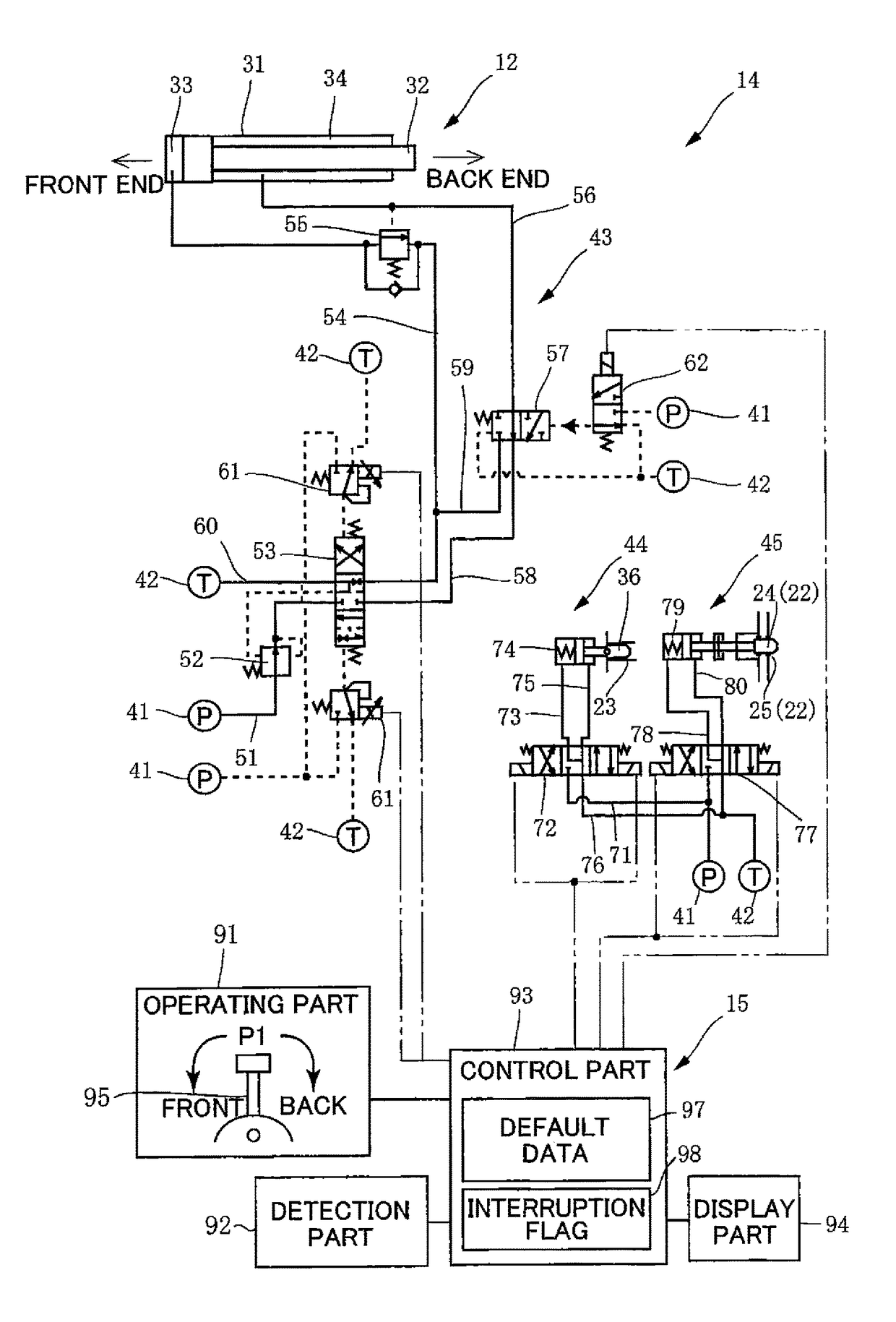

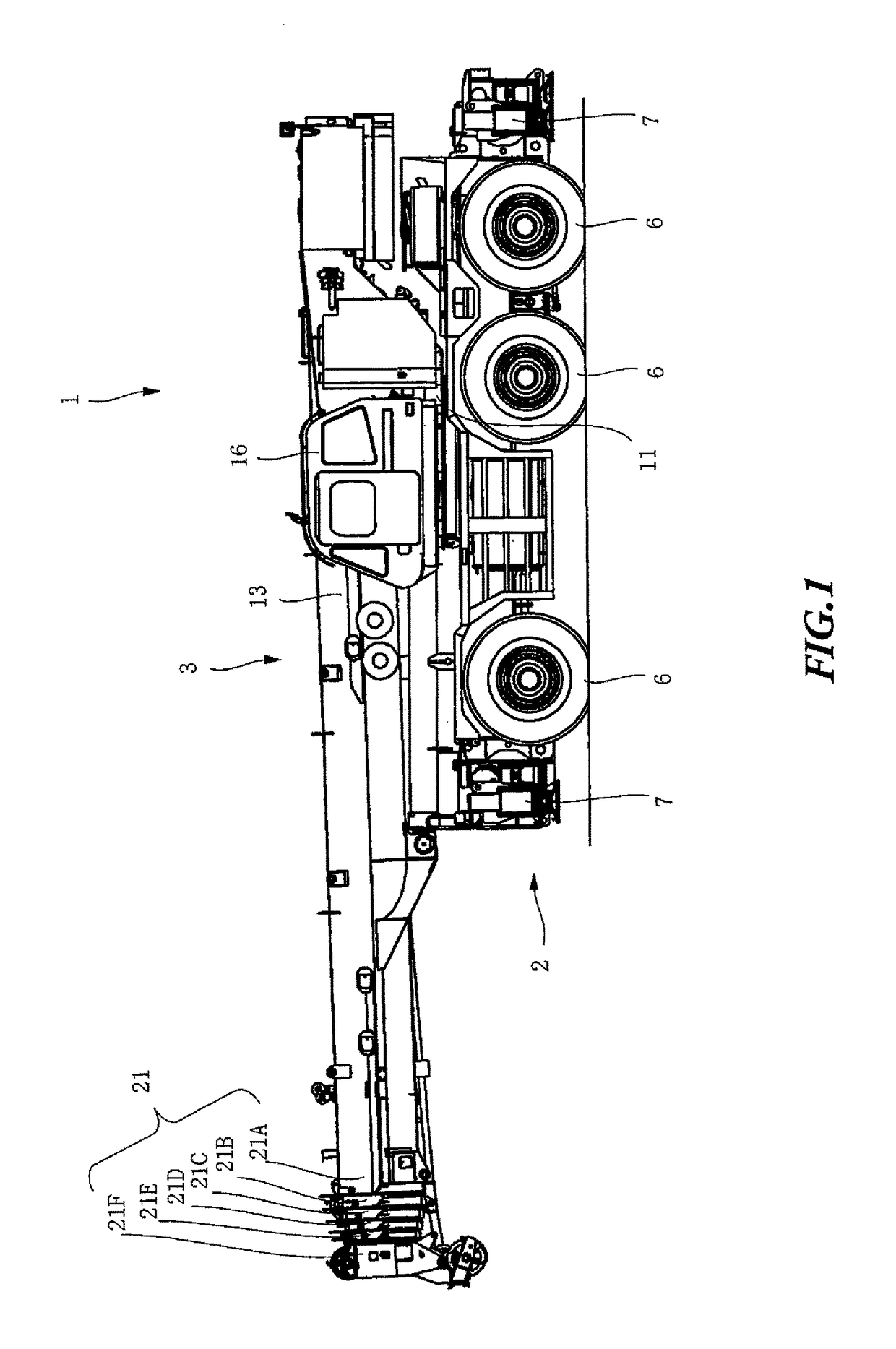

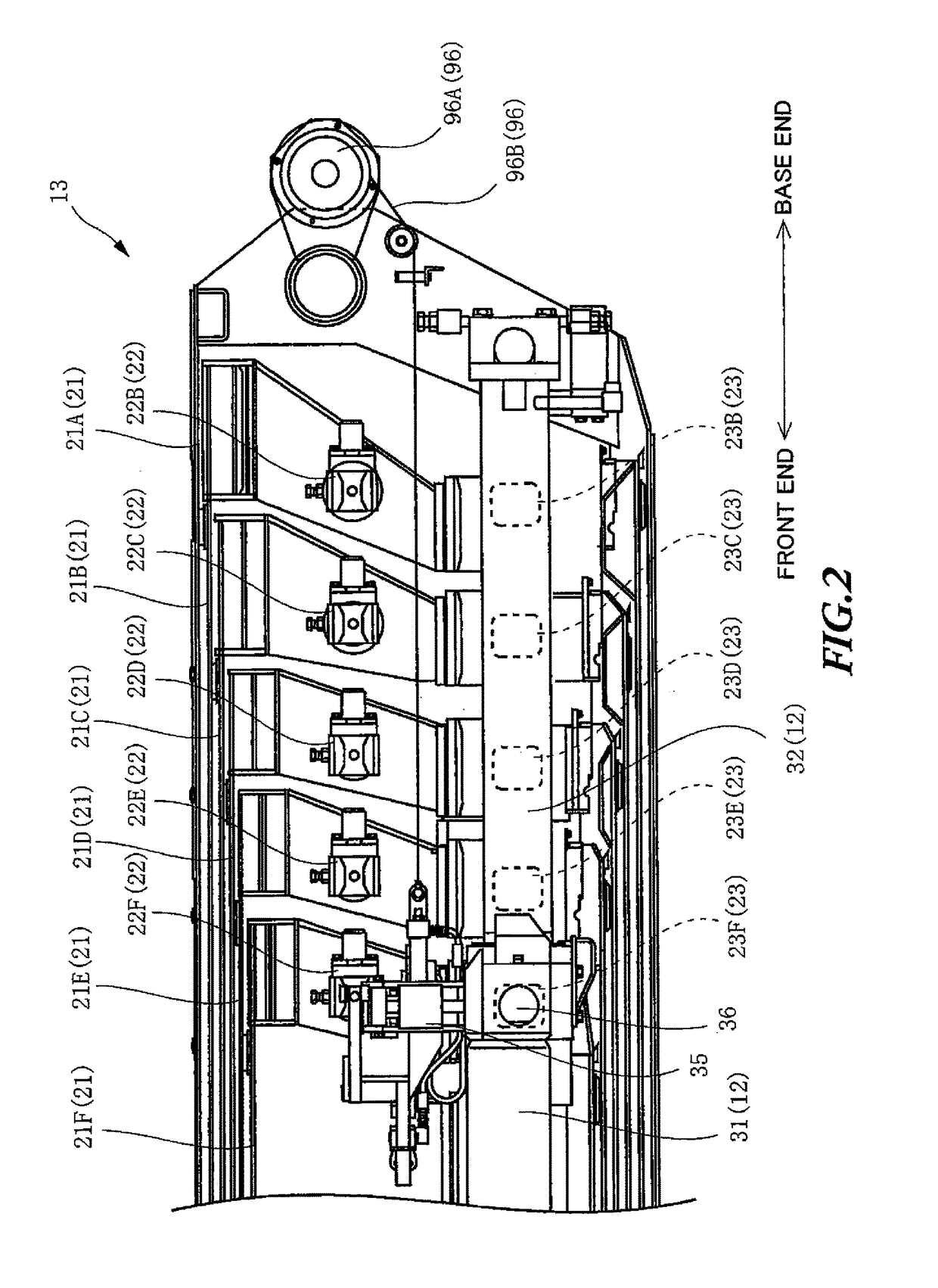

Boom extending and retracting apparatus of a crane

There is provided a boom extending and retracting apparatus that can improve the convenience of the telescopic boom while reducing the burden on the operator. The boom extending and retracting apparatus of the crane chooses the mode of the fluid circuit between the normal fluid circuit and the differential fluid circuit to slide a plurality of boom members by one telescopic cylinder. After the operating lever is turned to an extension side and the controller starts extending the telescopic boom using the differential fluid circuit, when the operating lever is turned to the extension side again via the neutral position, the controller chooses the normal fluid circuit to extend the telescopic boom using the normal fluid circuit.

Owner:TADANO LTD

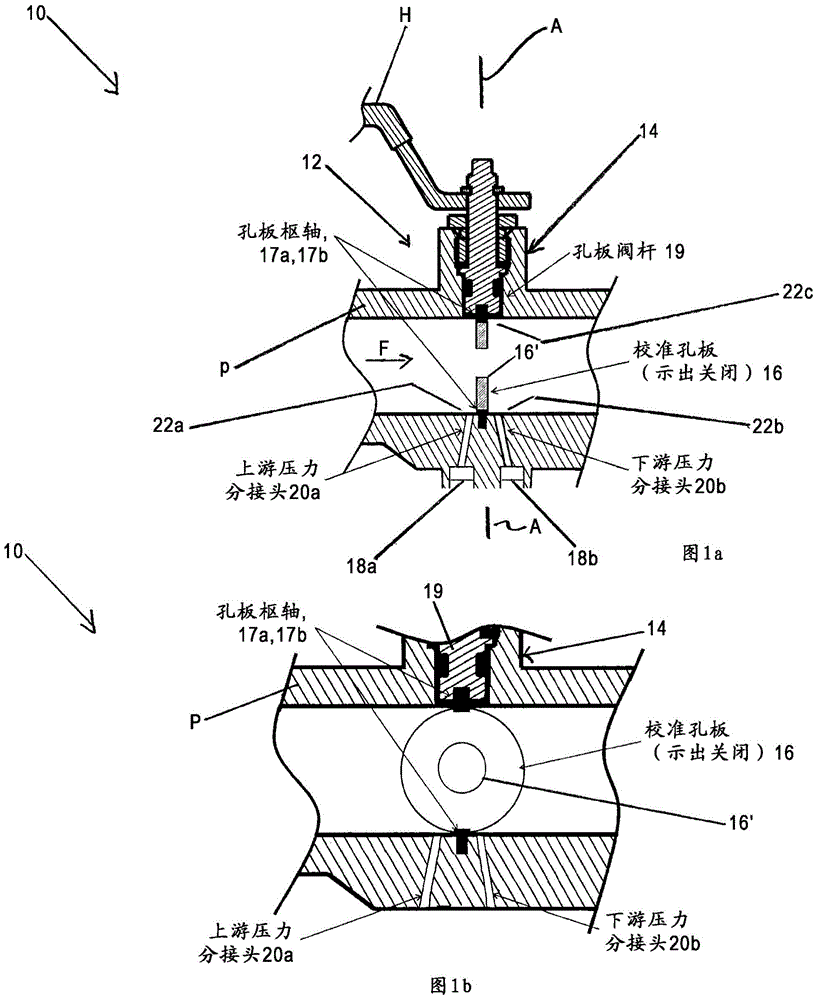

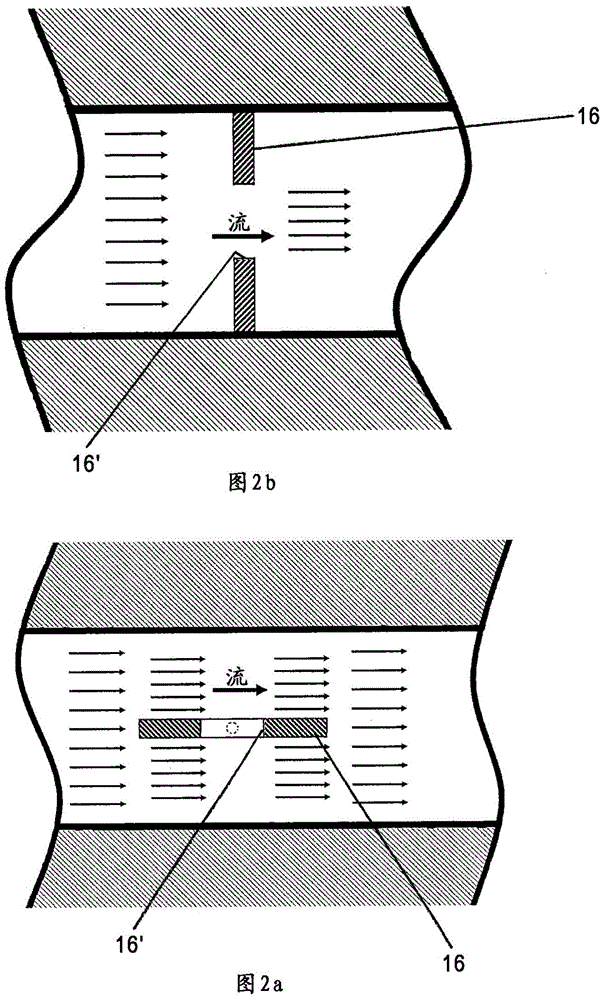

Rotatable orifice plate for direct flow measurement

ActiveCN104956189AReduce the amount requiredAvoid gatheringVolume/mass flow by differential pressureLift valveRotational axisEngineering

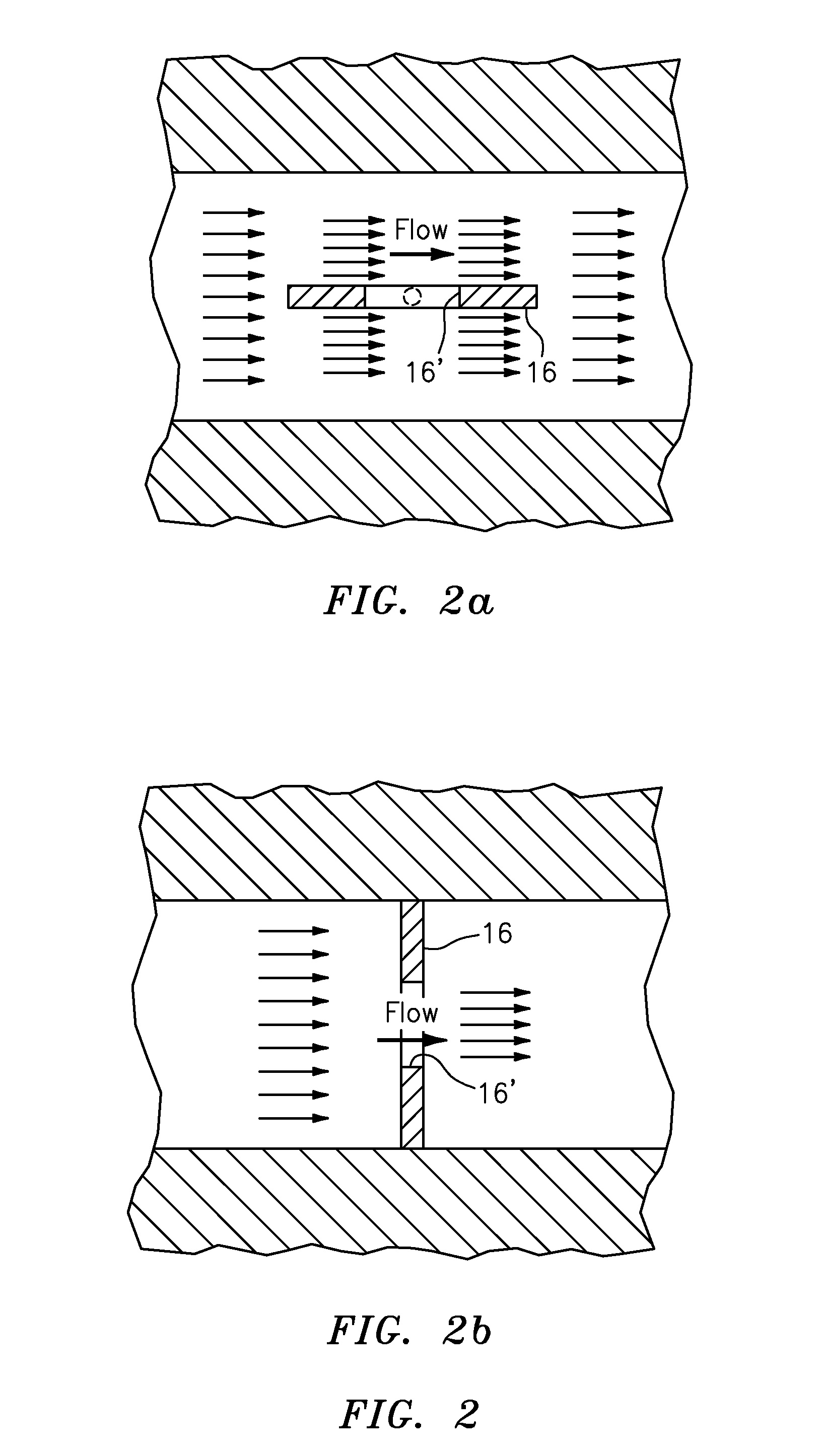

A valve is provided having a valve housing / body configured to be arranged in, or form part of, a piping having a fluid flow, and configured with a pressure tap arranged at a location along the piping to allow pressure of the fluid flow of the piping to be measured, and also having a rotatable orifice plate configured to rotate in the valve body / housing on an axis of rotation positioned at a different location along the piping than the pressure tap for rotating between a first rotatable position for providing a normal fluid flow operation and a second rotatable position substantially perpendicular to the fluid flow for providing a direct flow measurement of the fluid flow determined based on signalling sensed by the pressure tap sensor containing information about a measured pressure at the pressure tap when the orifice plate is in the second rotatable position.

Owner:FLUID HANDLING

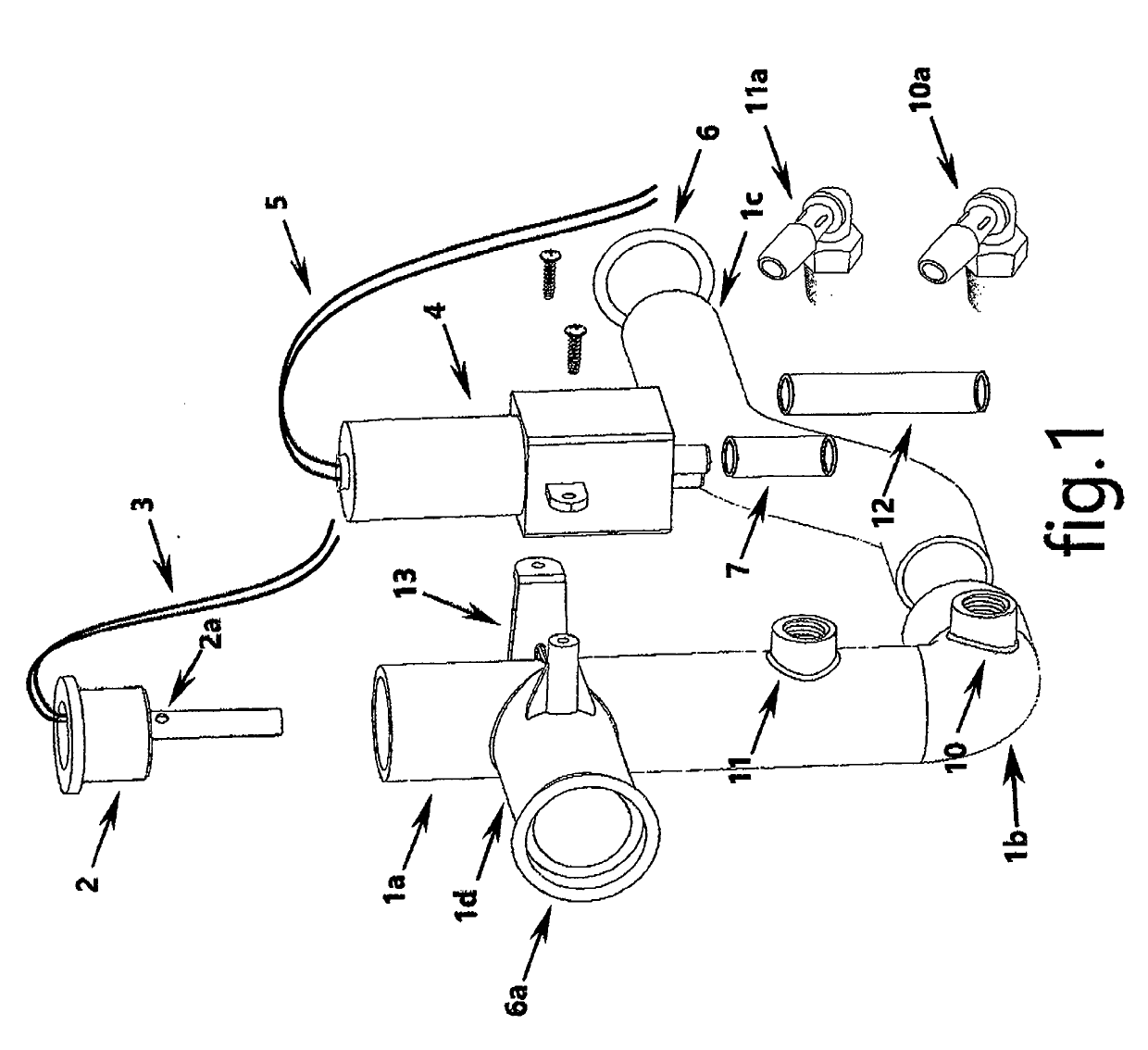

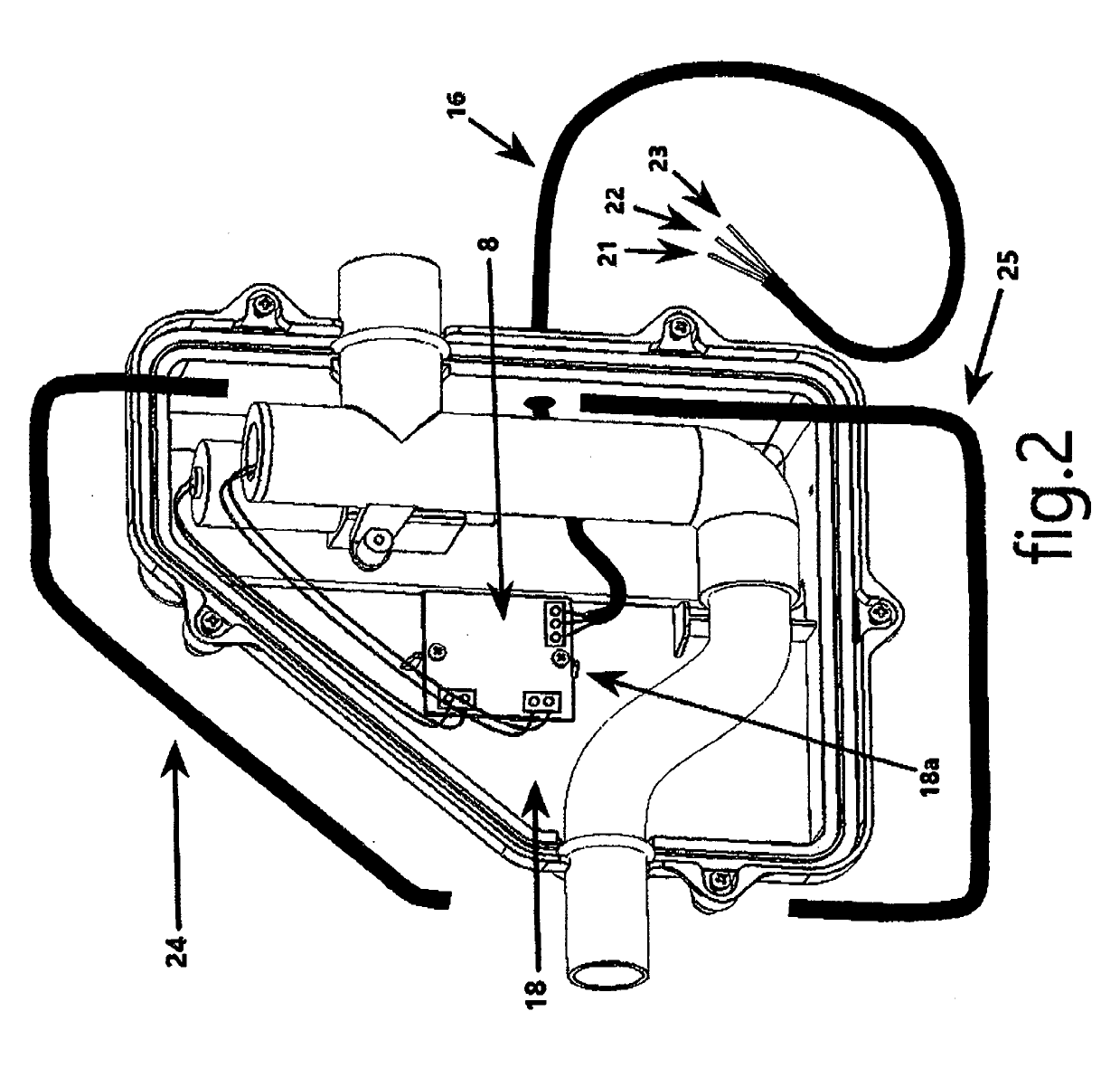

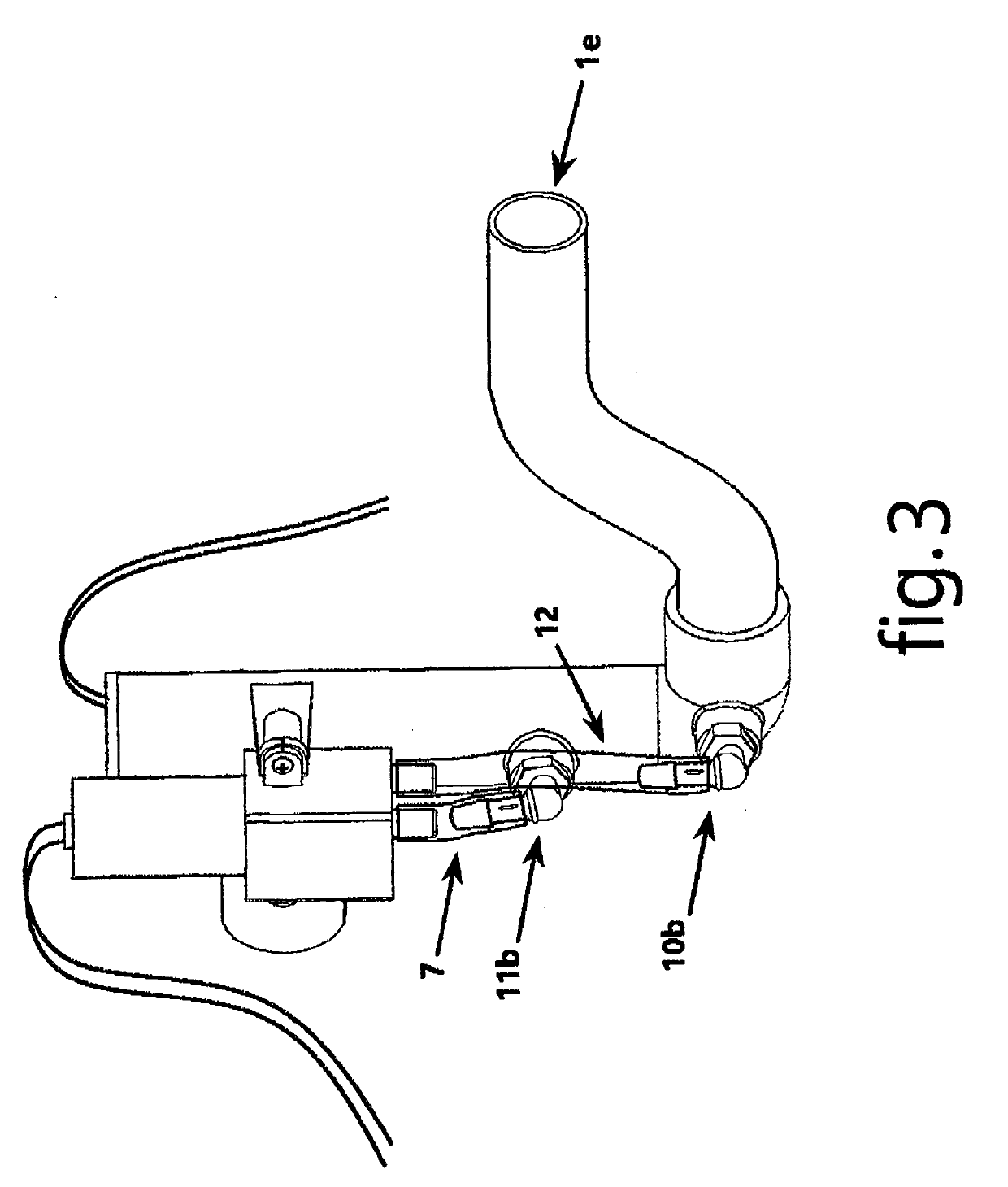

Self cleaning condensate drain pressure trap

The present invention comprises a self-cleaning condensate drain fluid pressure trap for air conditioning. Particulates present in the air which pass through an air conditioner adhere to moister (condensation) which is present on the internal evaporator coil. Condensation drips off the evaporator coil along with the particulates which has mixed in with it. Air-conditioning condensate fluid and particulates, or debris, accumulate inside an air-conditioner evaporator coil drain pan and are drained outward through the condensate fluid drain opening. Condensate fluid pressure traps, necessary accessories of a condensate drain line, are normally secured to the drain pan right outside of the air conditioners drain opening. Since condensate fluid is slow flowing, and not pressurized, debris that drains out of the air conditioner tends to settle in the bottom of the condensate fluid pressure trap. The debris will build up until a clog or restriction to drainage flow occurs. This description of events is based on my experience as an HVAC service technician and from cases gathered from other HVAC professionals.This device, a self-cleaning condensate drain pressure trap for air conditioning, can prevent air conditioning condensate drain pan fluid overflows due to debris restrictions which occur in the condensate drain fluid pressure trap or elsewhere in the condensate drain line. In preferred embodiments a printed circuit board (PCB) is an incorporated part in the self-cleaning condensate drain pressure trap assembly. The PCB is designed to sense condensate fluid in the sensor cap at the high level of section 1a of the fluid pressure trap. Once the positive presence of fluid is sensed a relay on the PCB breaks the control voltage to the air-conditioners controls or thermostat. The invention then utilizes the incorporated fluid pump to circulate condensate drain fluid from section 1a of the pressure trap into section 1b of the pressure trap in a manner which is perpendicular to the normal fluid drainage flow through the fluid trap. This fluid pumping action loosens debris in section 1b and allows the drain fluid accumulated in the drain pan of the A / C unit to push the debris restriction out of the pressure trap by kinetic gravitational fluid force. After the debris is broken down and pushed through the fluid trap condensate drainage will resume. Unless there is another fluid restriction elsewhere in the drain line. When the PCB senses a negative presence of fluid at the sensor cap air-conditioner operations will be restored. If fluid drainage restrictions persist and a positive fluid presence at the sensor cap continues the PCB will continue to prevent the air conditioners operations. This will halt further production of condensate fluid to prevent condensate drain pan fluid overflow.The (self-cleaning condensate drain pressure trap) is not intended to remedy all causes of condensate fluid drainage restriction. Nor is it designed to clean out the entire condensate drain line. The varied reasons for this this are listed in the ‘background of the invention’ section of this application. In short, problems that occur within condensate fluid drain lines are too varied in nature and the construction methods of said drain lines are vast as well. In my professional opinion, any attempt to solve all relative drainage issues with a single device is not practical. That is why this device merely intends to resolve condensate fluid drainage issues which occur due to the restriction of the condensate fluid through the condensate fluid pressure trap.A device like (The self-cleaning condensate drain pressure trap) has been designed for the purpose of cleaning out entire condensate drain lines. The related patent (U.S. PG-Pub 2014 / 0130529), is flawed in certain embodiments where it is to be used. The device requires additional fluid trapping and / or elaborate external piping for it to function as a cleaning tool. It will experience failure(s) and / or cause damages when applied in condensate drain lines where more than one air conditioners share a common drain line or where drain line sections are not properly secured. The reasoning for these failures is laid out in the ‘background of the invention’ part of this application, sections (0004 thru 0007). These observations are based on my professional HVAC experience and the conclusions gathered by interview of other HVAC professionals.Another patent (U.S. PG-PUB 2005 / 0138939) is shown to incorporate a fluid sensor, actuated by ‘electrode’. The patent in not unlike the engineered function of the PCB's fluid sensing ability described herein the (self-cleaning condensate drain pressure trap for air conditioning). However, it is laid out in the ‘background of the invention’ part of this application section (0012 & 0013) why the patent (U.S. PG-PUB 2005 / 0138939) is flawed in its design and is prone to failure. In short, the electrodes described therein are unshielded or unprotected from the moisture rich environment in which they are applied. This will cause failure of the device in a variety of manners from short cycling of the control systems to simple failure due to corrosion and / or retarded conductivity of the electrodes by surface contamination. The improved designs made herein the (self-cleaning condensate pressure trap for air-conditioning) are a method for fluid detection in condensate systems which functions in a superior manner. This method is a replacement to the use of fluid float controls and has been manufactured and tested to function in a superior manner as a fluid sensor. The sensor cap of (The self-cleaning condensate pressure trap for air-conditioning) is a fluid splash-guard for the wires, which are contained therein, that convey the presence of fluid to the PCB. The wires have a plastic coating as well to protect them from surface contamination. The sensor cap and wire designs were engineered after observations while testing fluid sensing models determined that these elements were required to ensure proper operation. These elements also enable the fluid sensing capabilities to continue in a prolonged state of usage in a moisture rich environment.Finally, the engineering of the device (self cleaning condensate drain pressure trap for air conditioning) was kept as ergonomic as possible with as little parts as were necessary to perform the functions listed herein. In particular embodiments the device is constructed with materials that allow it to be used in indoor as well outdoor application. The device is resistant to U.V. rays, high ambient temperatures, debris and moisture. The device is light weight and can be supported merely by connection to the condensate drain line. The Installation method of (self cleaning condensate drain pressure trap for air conditioning) is the same as standard condensate fluid pressure traps, apart from the control wiring which must be connected to the air conditioner for cleaning and safety functions. Although, the device will function as a condensate fluid pressure trap whether power is applied or not.

Owner:RAYNES II JACK W

Pressure limiting controller

A method of controlling pressure in a mud pump system includes generating a pressure limiting factor output using a pressure feedback input and a motor speed input to calculate a fluid conductance estimate, maintaining the pressure limiting factor output at a maximum value based on a pressure set-point, continuously updating a normal fluid conductance value based on the fluid conductance estimate while the pressure limiting factor output remains at the maximum value, freezing the normal fluid conductance value, if the pressure limiting factor output is less than the maximum value, calculating a change in fluid conductance based on the normal fluid conductance value and the fluid conductance estimate, generating at least one adaptive gain based on the change in fluid conductance, and controlling a motor speed of a pump in the mud pump system based on the at least one adaptive gain.

Owner:SCHLUMBERGER TECH CORP

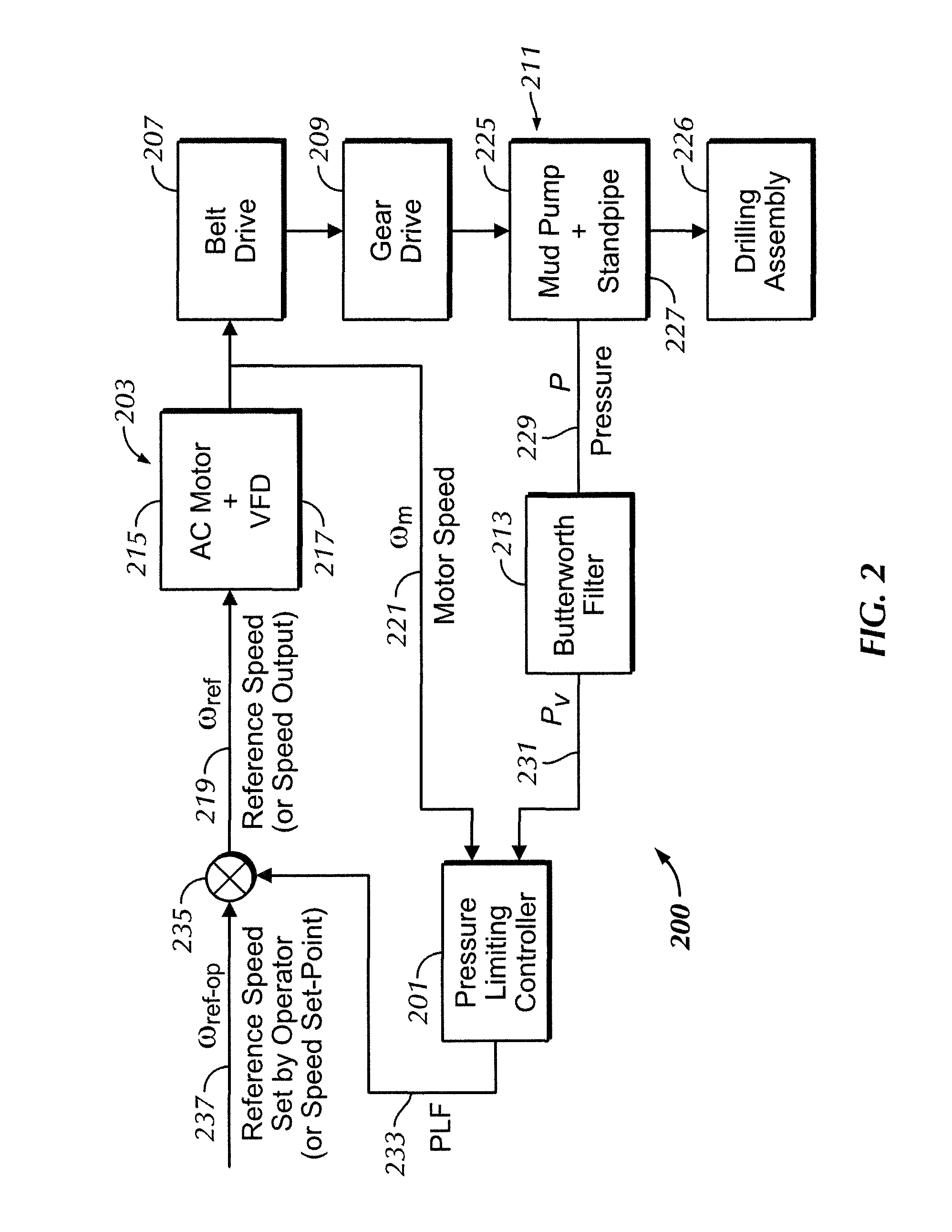

Method and device for measuring trace matter in liquid by micro suspension arm sensor

InactiveCN1987416AContamination detection is fast and real-timePrecise measurement of trace ion contentSurface/boundary effectMaterial analysis by optical meansPhotovoltaic detectorsIon density

The method includes steps: through channels, water pump drives samples of liquid to be tested and normal fluid into liquid pools respectively; placing micro cantilevers to liquid pools; using laser to hit reflection face, and using 2D photo detector to detect reflected light in order to know displacements of micro cantilevers; turning off, on channel of liquid to be detected, and turning on channel of normal fluid, when liquid to be detected passes, there will be fluctuation of micro cantilevers since sorption of matter in liquid, thus fluctuation of reflection of laser beam follows; position sensitive photo detector receives reflected laser signal; after calculation, magnification, and process, the method compares signal from the fluid to be tested with signal from normal fluid under same process mode so as to obtain information of ion density. By applying AFM technique to water contamination detection the invention measures content of ion in minute quantities in water in real time.

Owner:ZHEJIANG UNIV

Pressure-difference-activated sealant and preparation method thereof

ActiveCN104151652AWon't clogNormal flow stateOther chemical processesChemical reactionElectronic component

The invention relates to a pressure-difference-activated sealant and a preparation method thereof. The sealant is composed of rubber latex, a rubber latex prepolymer, a latex monomer, an activator, a terminating agent, and water. With the sealant, sealing can only be realized under a condition with pressure difference. The main components of the sealant are rubber latex, the rubber latex prepolymer, the monomer, an initiator, and the activator. The sealant only solidifies at a leak point with a pressure difference, and can maintain a normal fluid status at any other conditions. When sealing is finished, superfluous sealant is returned to the ground. The sealant does not block pipelines and liquid delivery systems. The sealant does not harm electronic component systems and metal seals, and does not react with them. Because the sealant only begins to polymerize into a tough solid under the condition with enough pressure difference, the polymerization reaction is not caused by sealant injection time, in-well temperature, and in-well environmental pressure factors.

Owner:古莱特科技股份有限公司

Combined sight oil level gage and ultrasonic sensor

The invention provides a combined fluid level sight gage and ultrasonic sensor featuring a fluid level sight gage having a housing for containing a fluid and having a sight glass for viewing the level of the fluid therein, and an ultrasonic sensor coupled to the housing, responsive to the level of fluid in the housing, for providing an ultrasonic sensor signal containing information about the level of fluid in the housing. In operation, the sight glass provides a visual verification that the ultrasonic sensor is working correctly in relation to the fluid visible in the sight glass. The ultrasonic sensor signal may be used to automatically annunciate alarms or warnings either locally at the equipment or by wired or wireless electronic means. In some embodiments according to the present invention, the housing has a centerline for indicating a normal fluid level therein. The ultrasonic sensor may be arranged in the housing on the centerline, or slightly below the centerline, or slightly above the centerline.

Owner:ITT MFG ENTERPRISES LLC

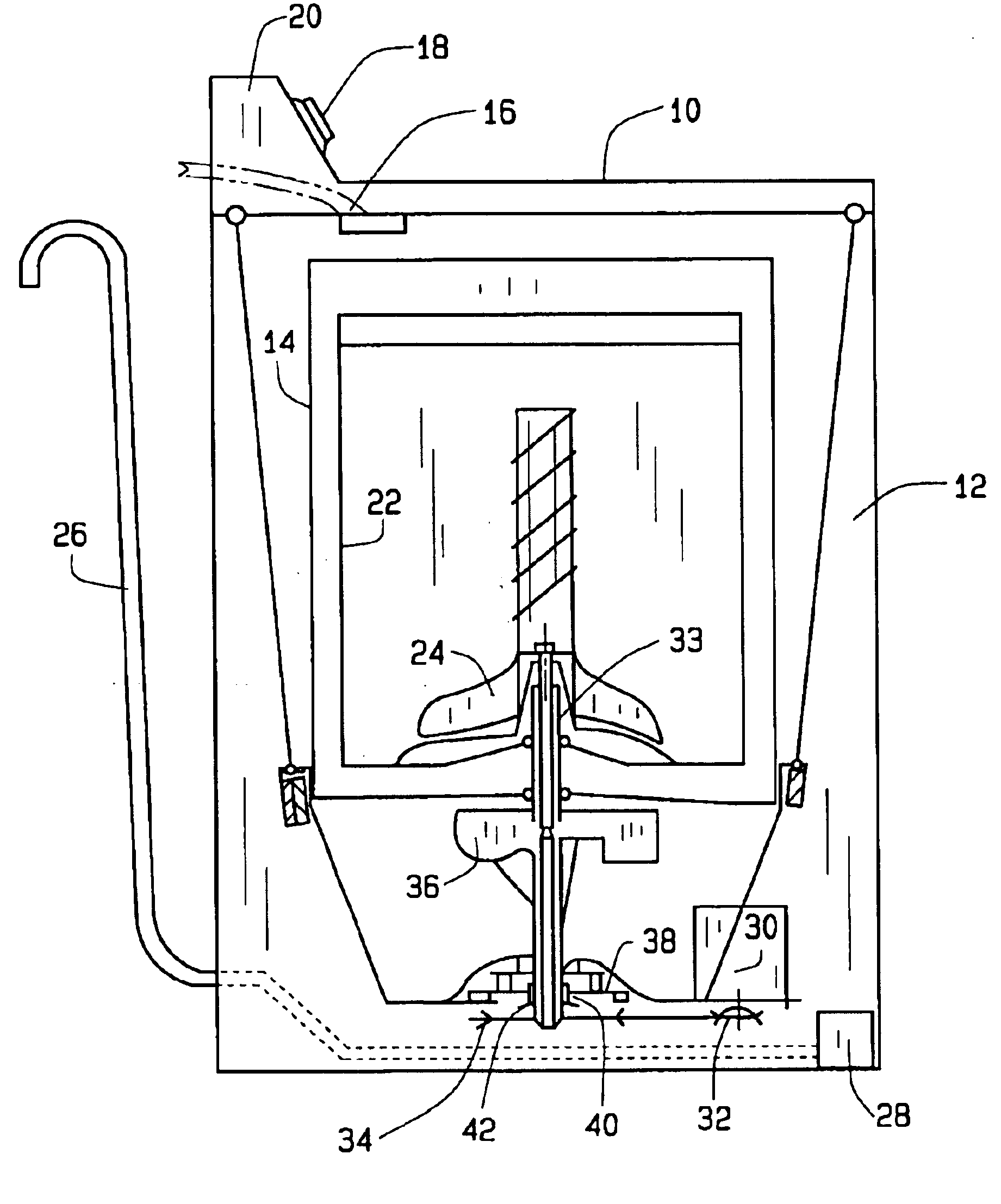

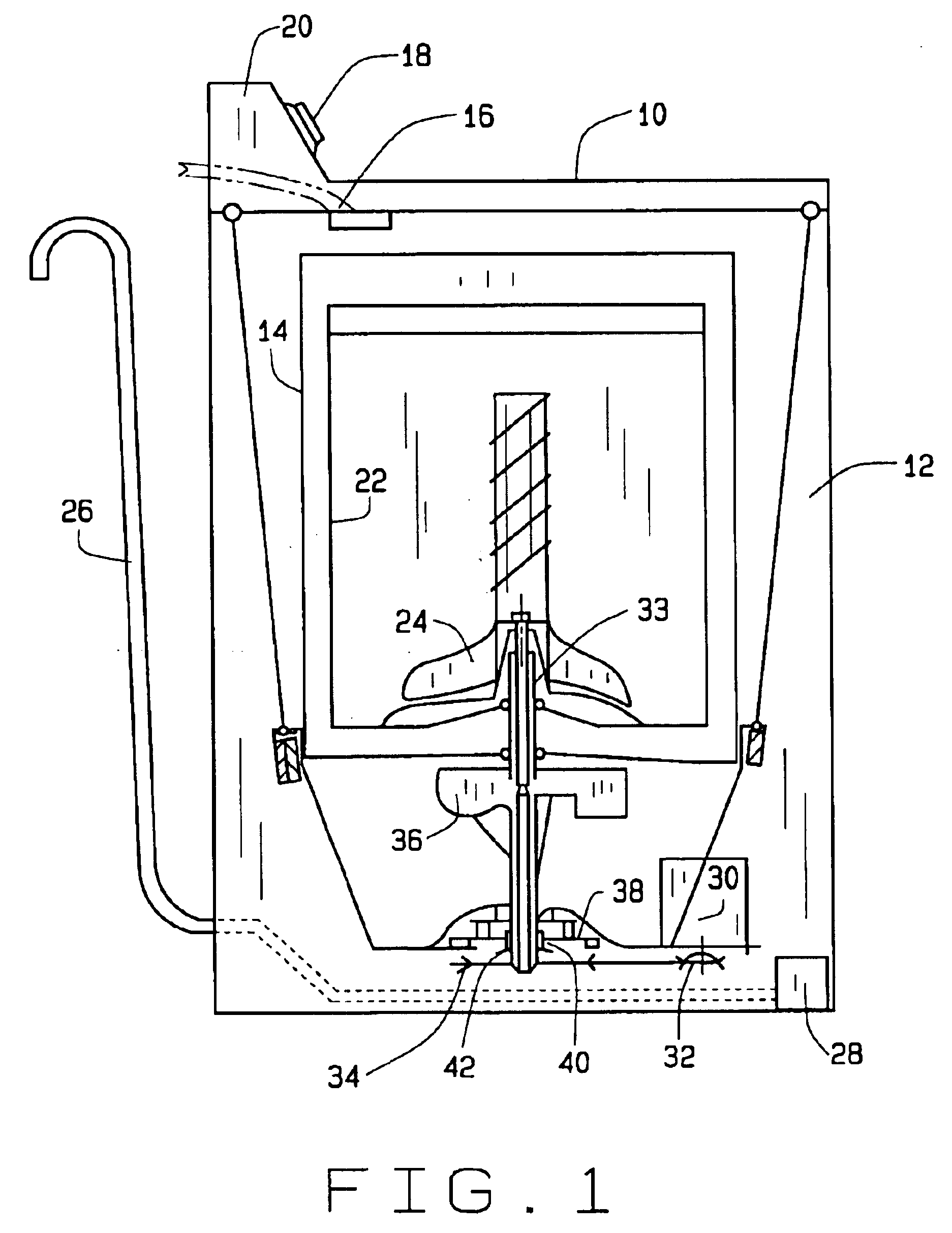

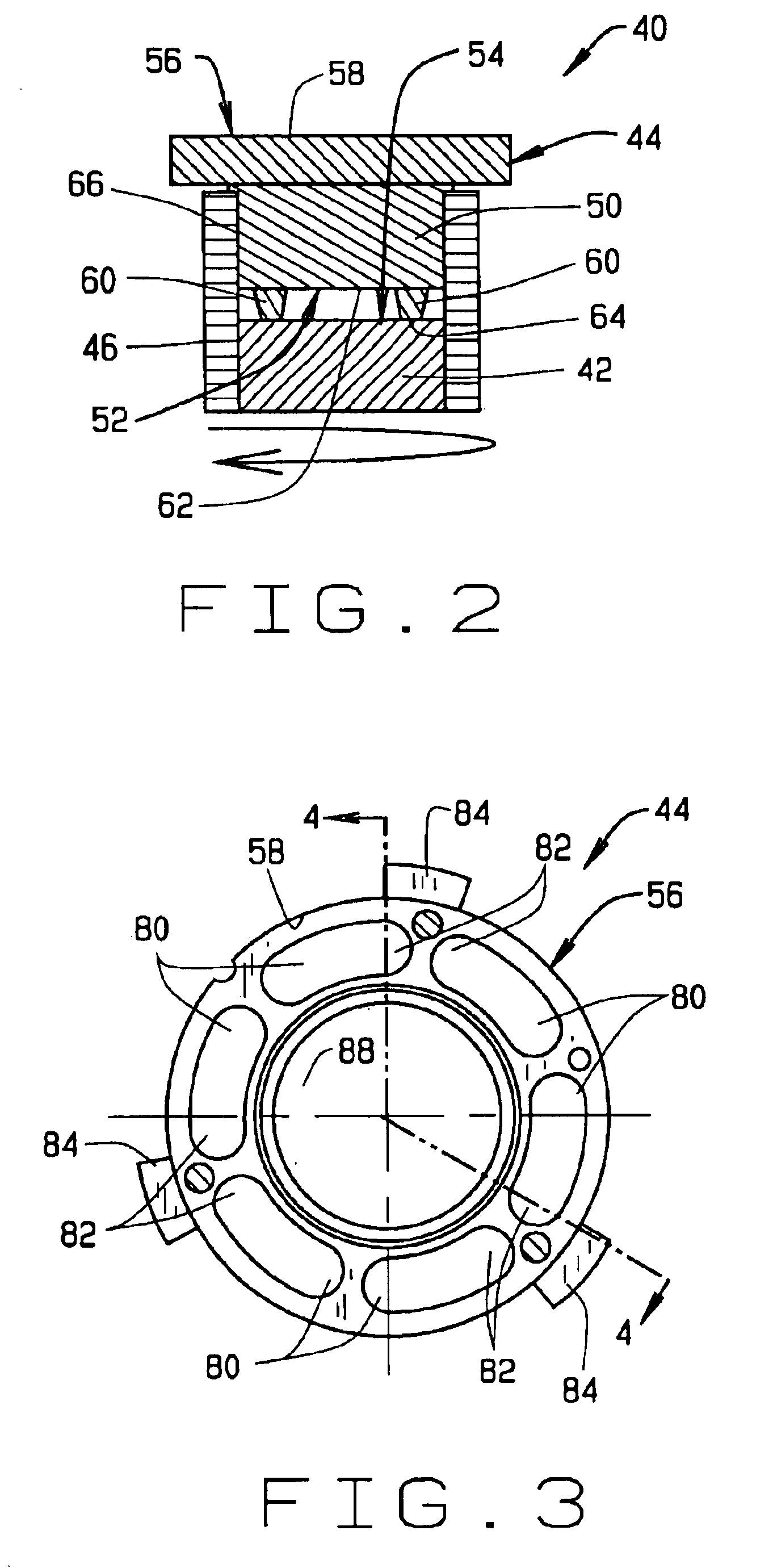

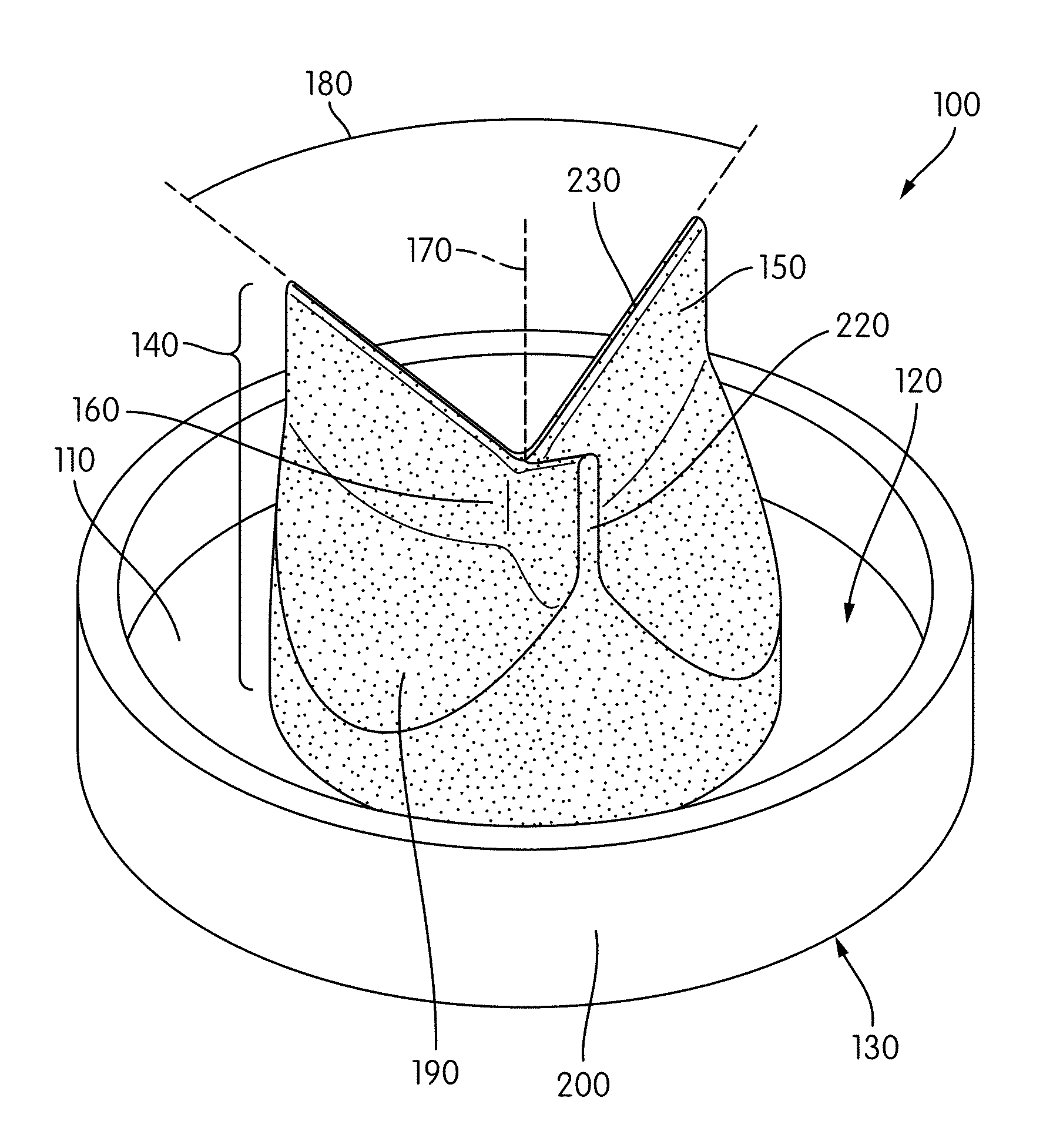

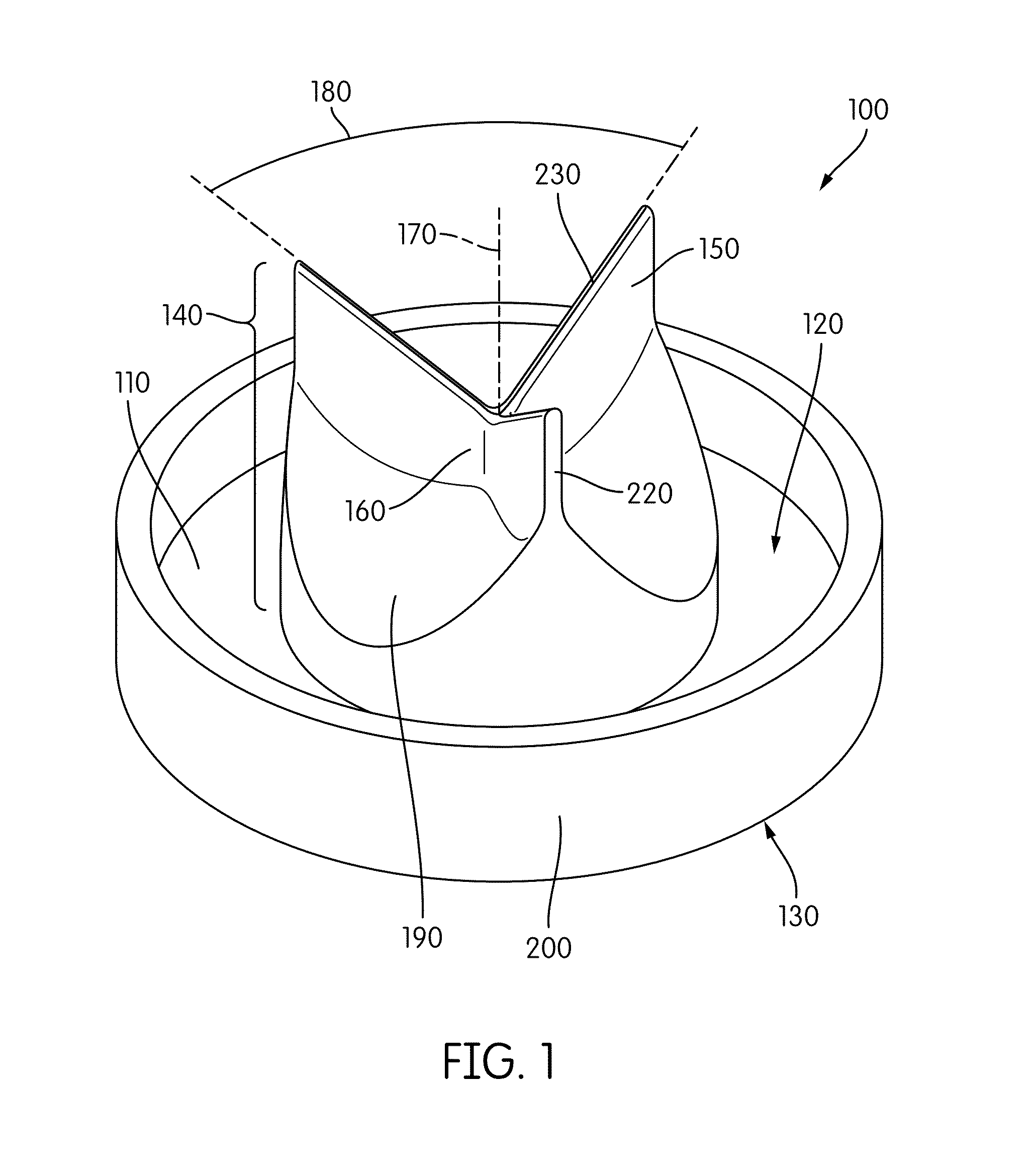

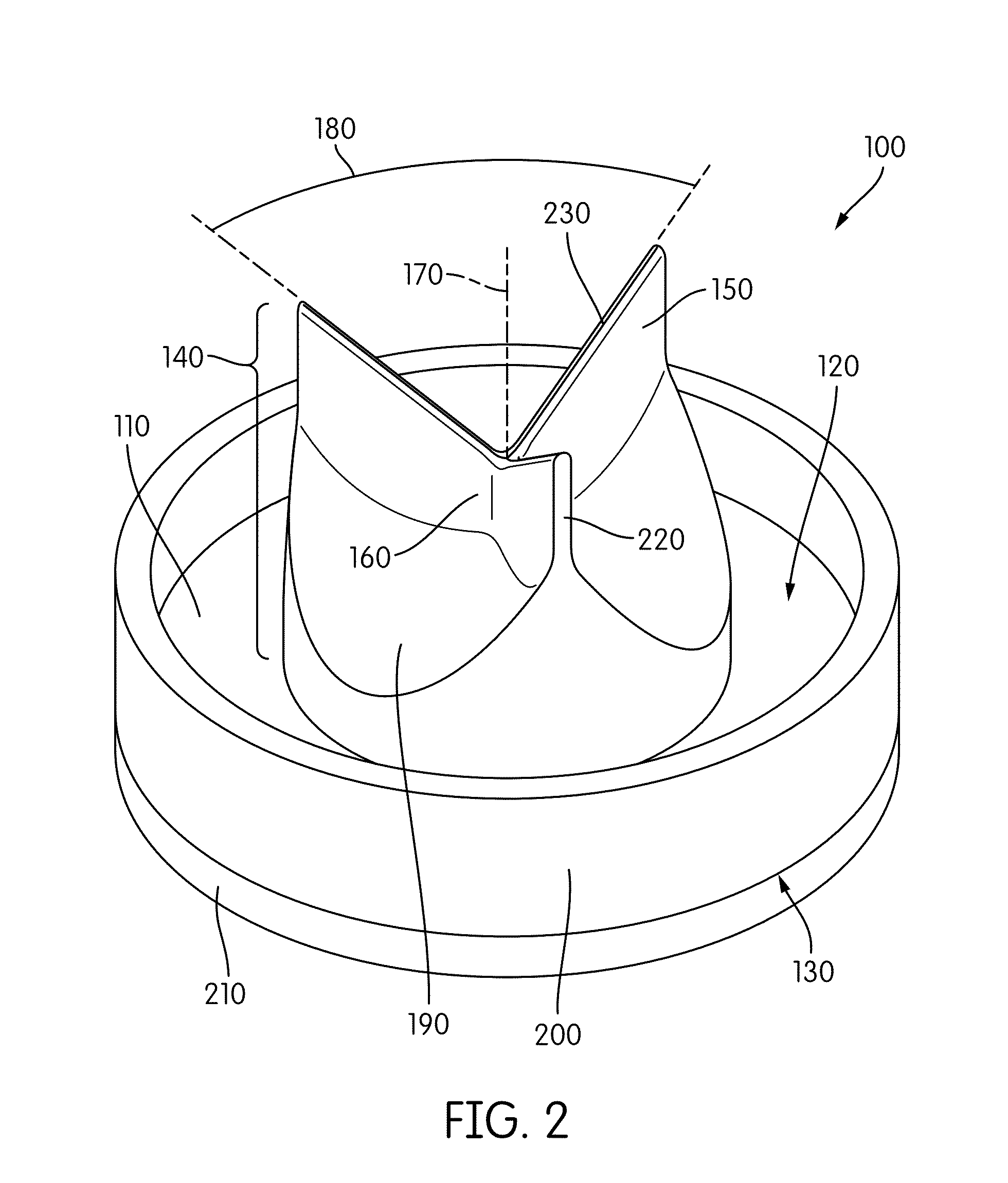

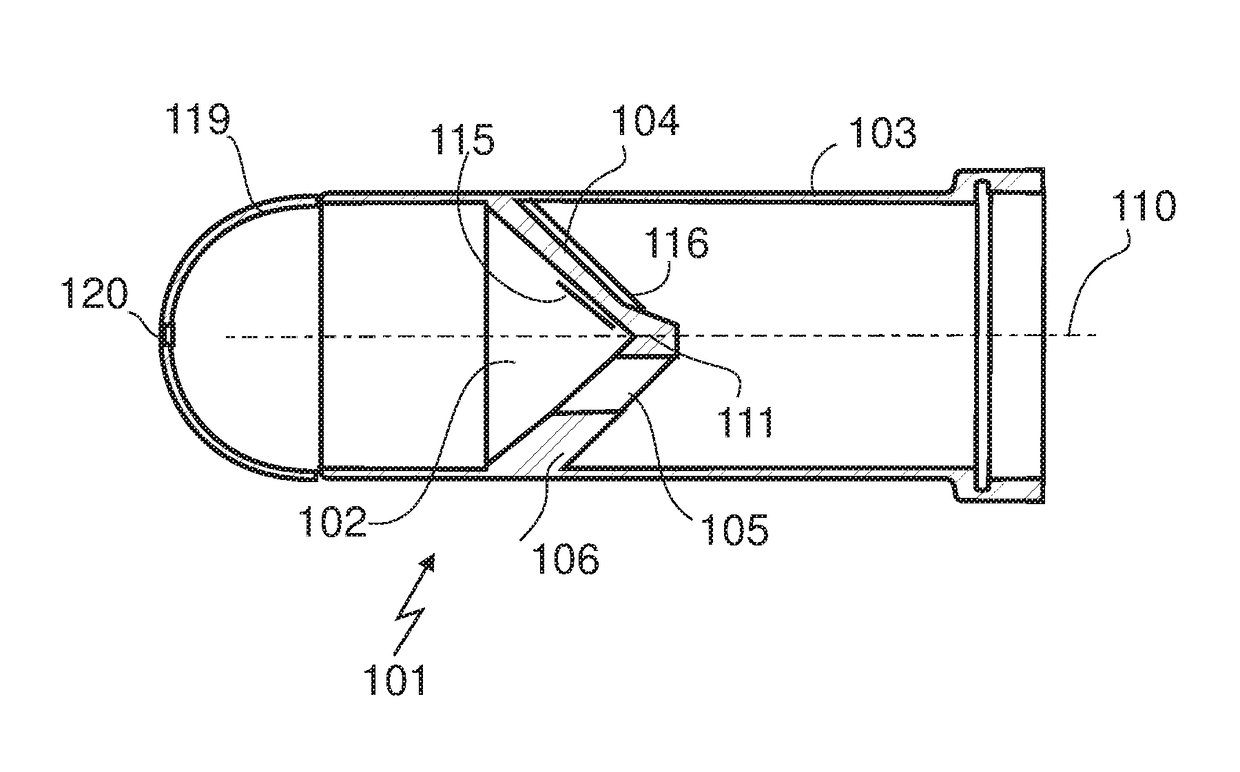

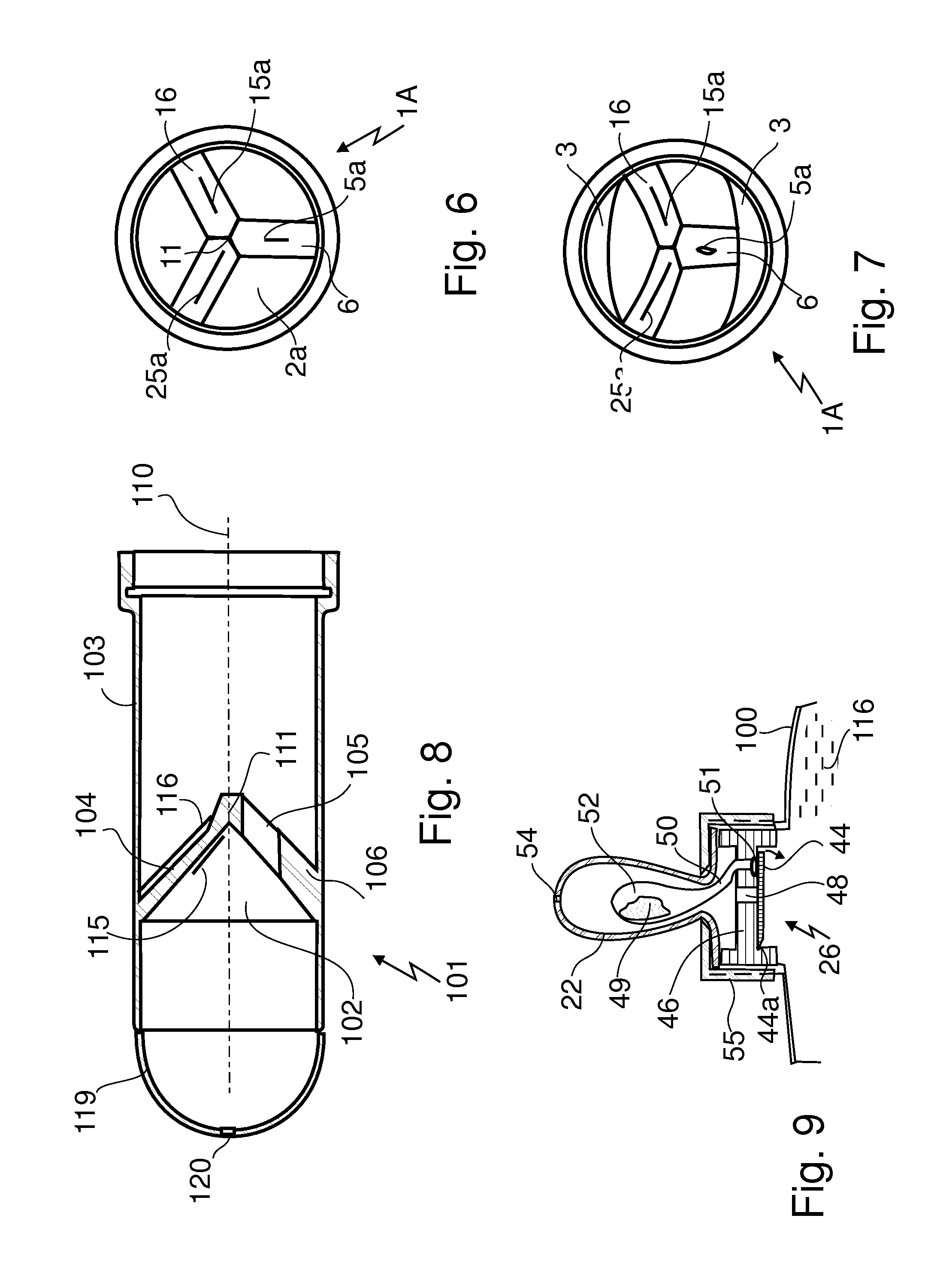

Cardiac valve prosthesis

InactiveUS20150088251A1Reduce thrombosisReduce formationIntravenous devicesBlood pumpThrombusAortic root

Provided herein is a prosthetic device in patients with ventricular assist device (VAD) support and a closed off aortic valve orifice, which reestablishes the formation of normal fluid flow patterns in the aortic root. The prosthesis includes a circular body having a first surface and a second surface and a projection disposed on the first surface of the body, wherein the projection includes a plurality of walls extending away from the first surface of the body, each wall being positioned such that a first side edge contacts a center of the body, thereby forming a plurality of intercepted arcs, each located between adjacent walls; and a plurality of concave parabolic surfaces, each disposed within an intercepted arc. Also provided are methods of using the prosthetic device to reduce thrombosis formation in patients with VAD support.

Owner:SAN DIEGO STATE UNIV RES FOUND

Chinese medicine method for curing fatty liver and erosion symptom and traditional Chinese medicine composition

InactiveCN102526692APrevent acid damageThe process of "acid erosion" is slowed down or stoppedDigestive systemUnknown materialsHematopoietic TissueNormal fluid

The invention relates to a Chinese medicine method for curing fatty liver and erosion symptom and a traditional Chinese medicine composition which is formed by decoction pieces prepared through Chinese traditional medicine and based on the cognition of natural change law of 'east promotes wind, wind promotes wood, wood promotes sour and sour promotes liver' in the traditional Chinese medicine. The traditional Chinese medicine composition can improve the meta-acid environment of body fluid so as to eliminate a series of acidization-caused abnormal representation of living matter, change the state that fat is accumulated and can not be metabolized and ablated, and repair the normal fluid combination in hematopoietic tissue organ cell, or the Chinese medicine method can also serve as life environment adjustment therapeutic agent for immunologic abnormality and body fluid acidization, inflammatory diseases manifested by liver pimelosis, fibrosis and cirrhosis, hypertension, atherosclerosis, pulmonary fibrosis and cancers.

Owner:张克杰

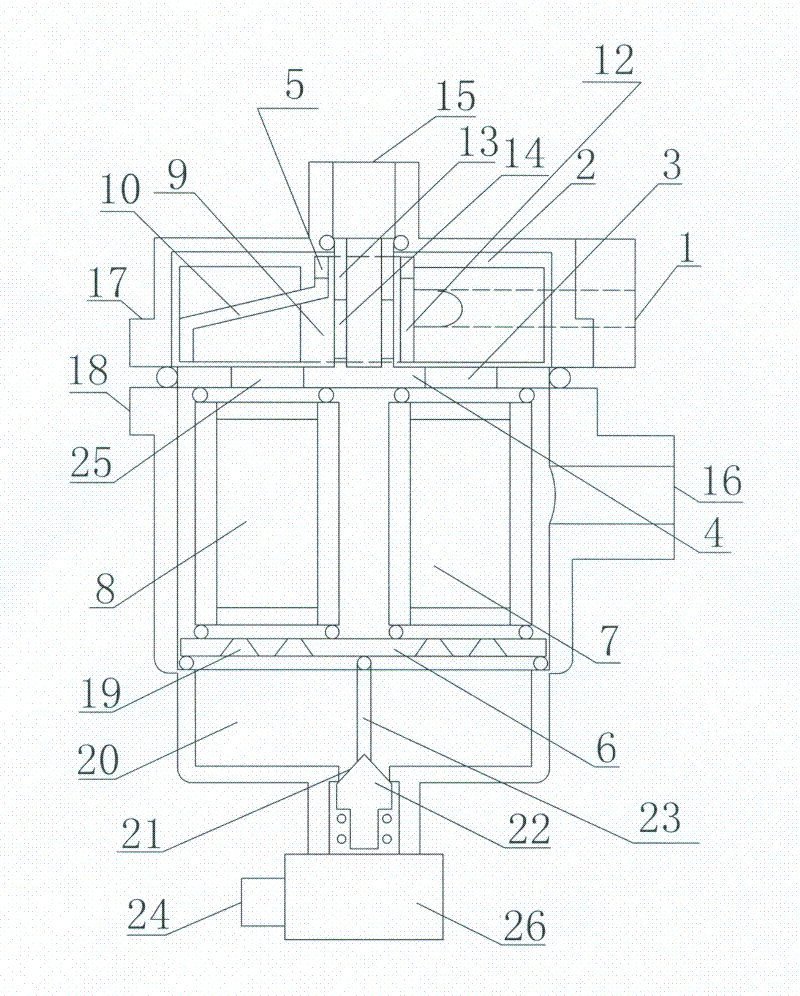

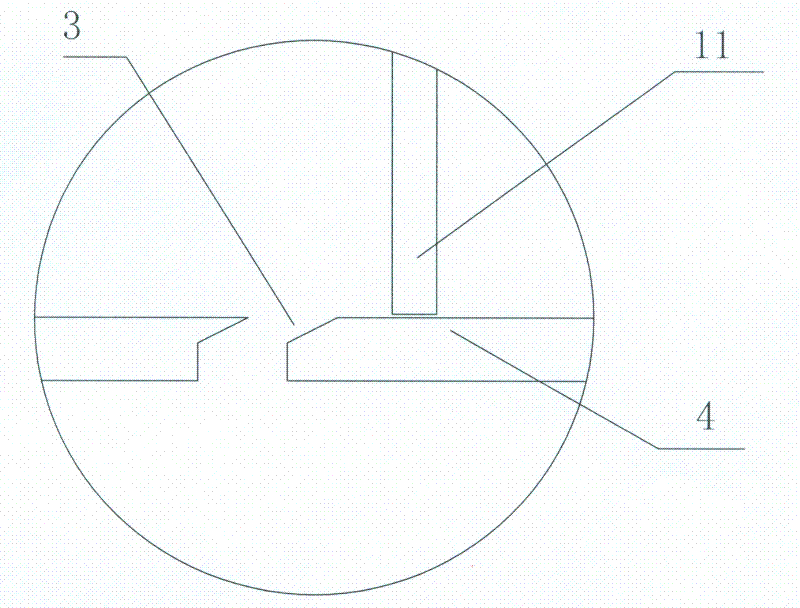

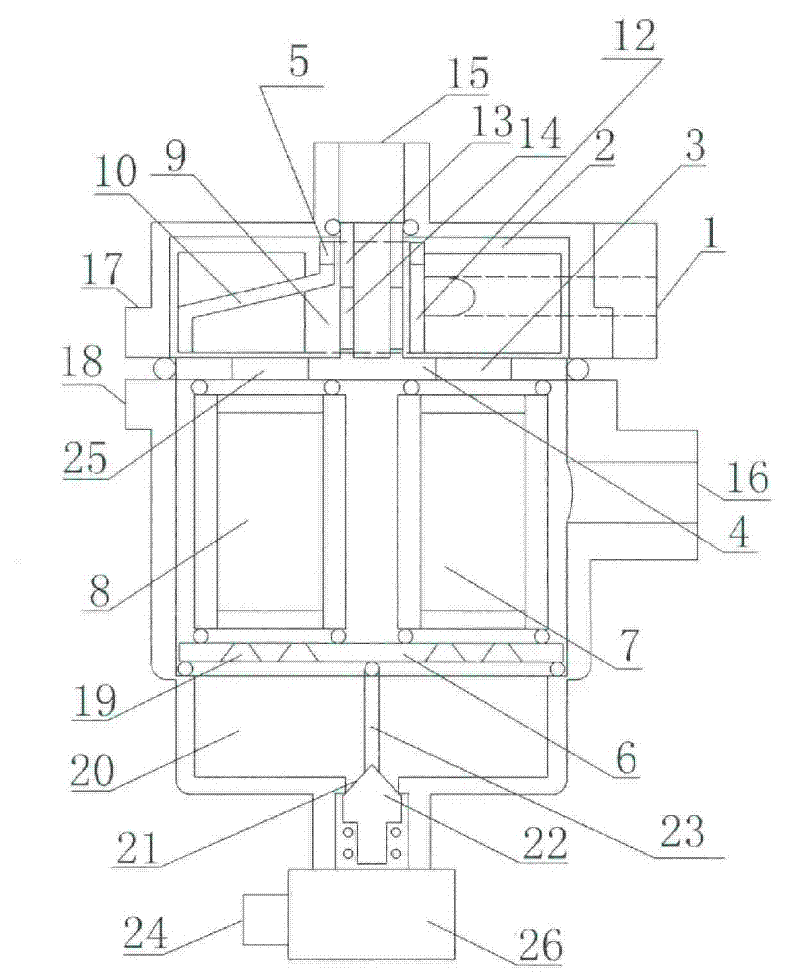

Reflow backwashing mechanism for automatic filtration of fluid

ActiveCN101658741BIncrease the rotation frequencyImprove frequency stabilityDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

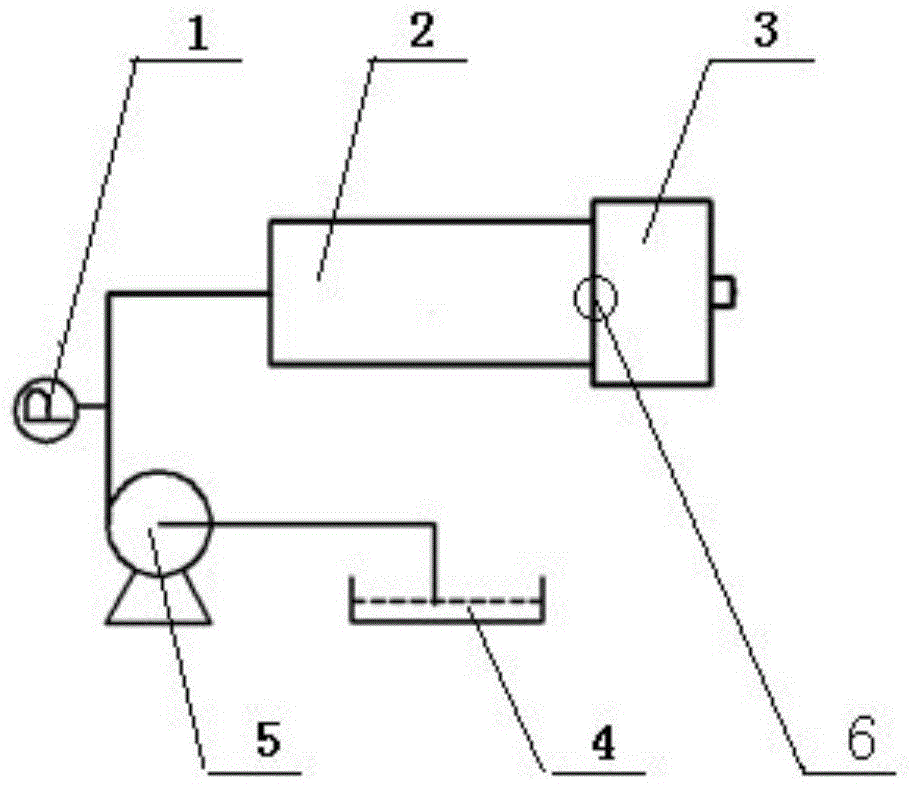

The invention discloses a reflow backwashing mechanism for automatic filtration of fluid. The reflow backwashing mechanism is characterized in that: a fluid inversion chamber (2) is internally provided with a hollow shaft sleeve (12), a blade and a baffle plate are connected with the hollow shaft sleeve (12) which is provided with an opening at a position of the lower part of the baffle plate of the hollow shaft sleeve (12), the hollow shaft sleeve (12) is internally provided with a hollow core shaft (13) with an upward opening, and a shaft wall of the hollow core shaft (13) is distributed with a through hole (14). The reflow backwashing mechanism is provided with a guide through hole with obliquity, thus being capable of fully utilizing composite force of reflow backwashing produced by normal fluid flow and fluid flow out of the oblique guide through hole to quicken rotation frequency of the inversed fluid. The inversed fluid is more stable due to dependence on the core shaft for rotation and arrangement of a counterweight balance, thus the reflow backwashing mechanism has advantages of causing the whole system to have safe and reliable operation and greatly improving automatic filtration effect.

Owner:浙江瑞孚电气有限公司

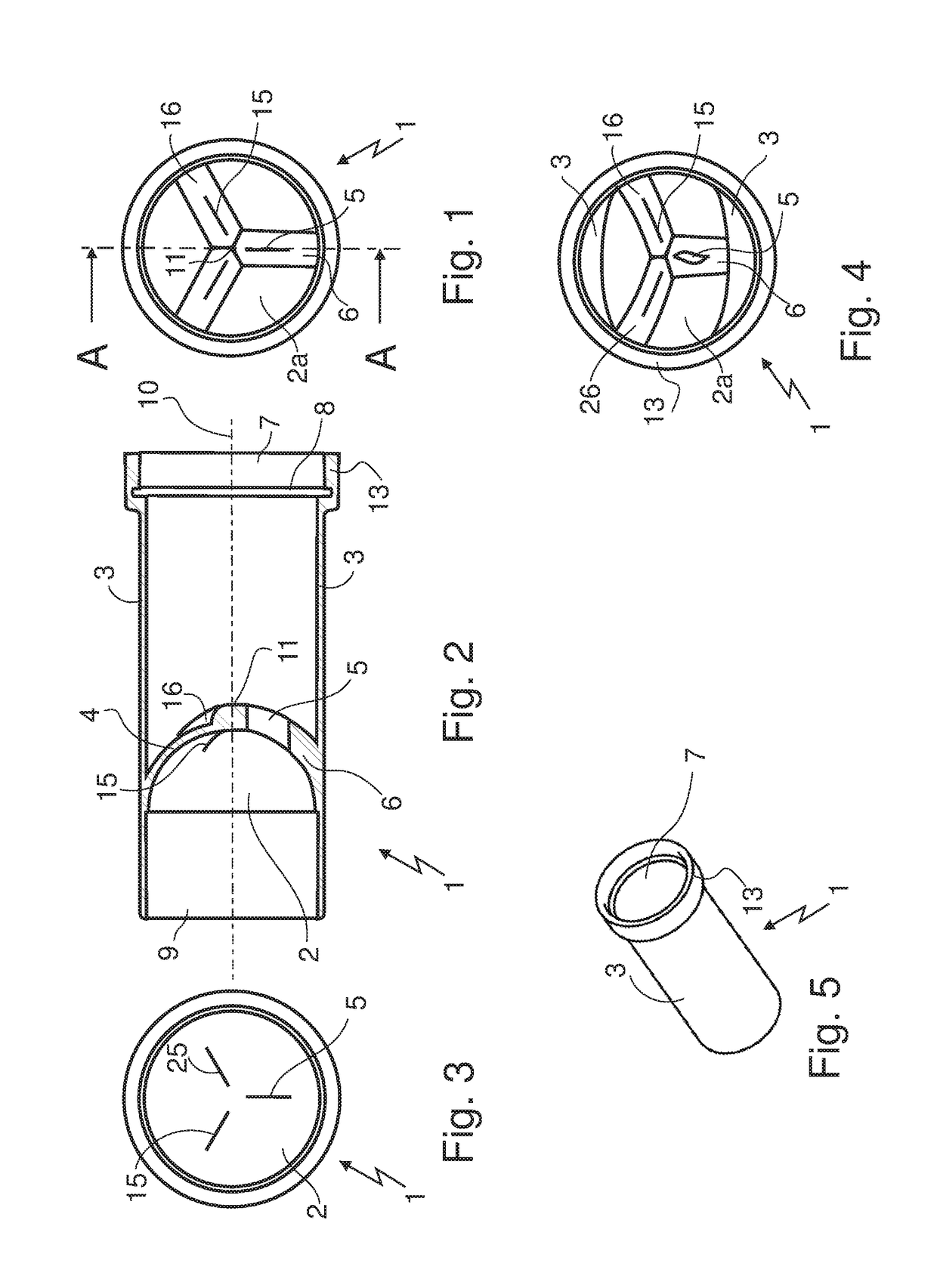

Unidirectional valve for presurized containers

InactiveUS20180280247A1Preventing undesired leaks from the containerAvoid interferenceFeeding-bottlesTeatsEngineeringLiquid content

Owner:VASERMAN ELCHANAN

Unidirectional valve for pressurized containers

InactiveUS20150342833A1Preventing undesired leaks from the containerAvoid interferenceFeeding-bottlesTeatsEngineeringLiquid content

In a nipple for a baby feeding container, a valve part is disclosed, comprising a unidirectional valve formed of a pliable material and oppositely oriented such that when attached to the container a normal fluid flow through the valve is into the container while a flow from the container to the outside is normally blocked, the valve is characterized by a plurality of normally closed non intersecting slits formed in a deformable wall which blocks the flow of liquid from the container to the outside unless when the slits become temporarily distorted by the natural mouth maneuverings of a baby. The valve is especially advantageous for use in baby feeding containers of inflatable type in which the liquid content is pressurized under the pressure exerted by the stretched elastomeric walls of the container.

Owner:VASERMAN ELCHANAN

Method for reducing content of sulphur in gasoline

ActiveCN1958730BImprove stabilityImprove desulfurization effectCatalytic crackingRare-earth elementMolecular sieve

This invention discloses a method for lowering sulfur content of gasoline. The method comprises: contacting sulfur-containing crude oil with a desulfurization composition. The desulfurization composition comprises molecular sieves as desulfurization elements. The skeleton of each molecular sieve contains vanadium and a second metallic element M, which is selected from IIA, IIB, IVB, VIIB and VIIIBof the period table of elements or one of lanthanide rare earth elements. The method can effectively lower the sulfur content of gasoline in normal fluid cracking (FCC) condition, and improve the hydrothermal stability of FCC catalyst.

Owner:CHINA PETROLEUM & CHEM CORP

Device for feeding liquid to inkjet heads and device for wiping inkjet heads

When liquid materials are fed to inkjet heads, fluid pressures of liquid materials to be fed to inkjet heads are equalized so that a gas does not remain in liquid feed pipe lines without causing structures of the liquid feed pipe lines to be complicated. Separate liquid feed pipe lines (3) for feeding the liquid material, each of which communicates with each of a plurality of inkjet heads (4), are each connected to a common liquid feed pipe line (2) which stores one kind of the liquid material and communicates with an ink tank (1). Separate gas flow pipe lines (19), each of which is capable of feeding a gas and communicates with a connection portion between the common liquid feed pipe line (2) and each of the separate liquid feed pipe lines (3), with each of the inkjet heads (4), or with both the connection portion and each of the inkjet heads (4), are each connected to a bypass pipe line (18a) (common gas flow pipe line (18)) capable of being opened and closed with respect to the atmosphere.

Owner:ISHII HYOKI

Boom extending and retracting apparatus of a crane

There is provided a boom extending and retracting apparatus that can improve the convenience of the telescopic boom while reducing the burden on the operator. The boom extending and retracting apparatus of the crane chooses the mode of the fluid circuit between the normal fluid circuit and the differential fluid circuit to slide a plurality of boom members by one telescopic cylinder. After the operating lever is turned to an extension side and the controller starts extending the telescopic boom using the differential fluid circuit, when the operating lever is turned to the extension side again via the neutral position, the controller chooses the normal fluid circuit to extend the telescopic boom using the normal fluid circuit.

Owner:TADANO LTD

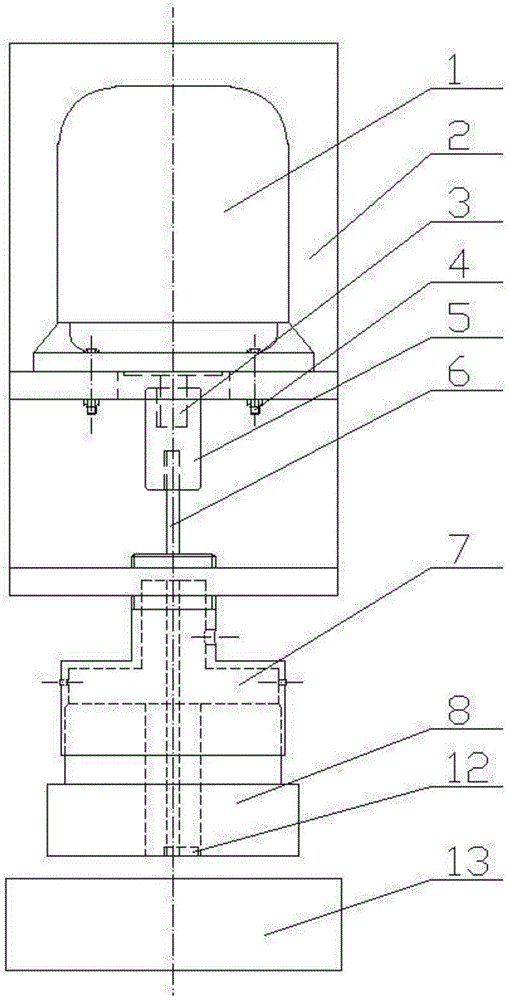

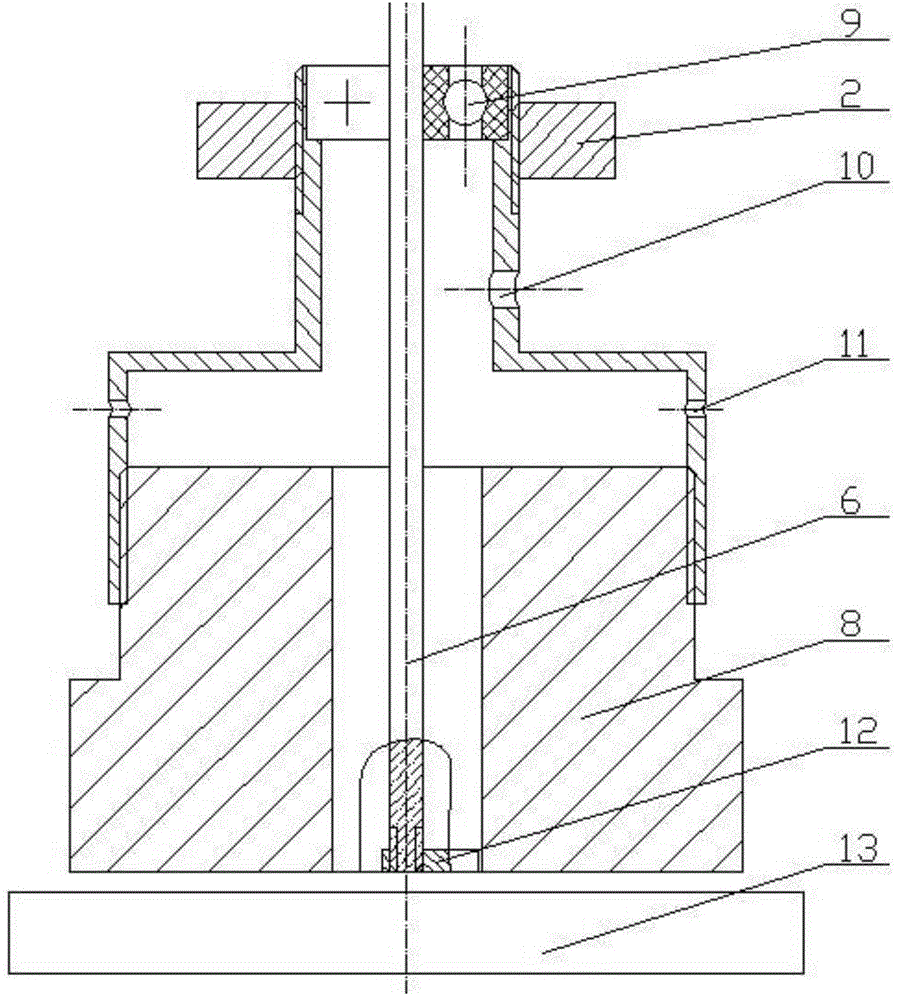

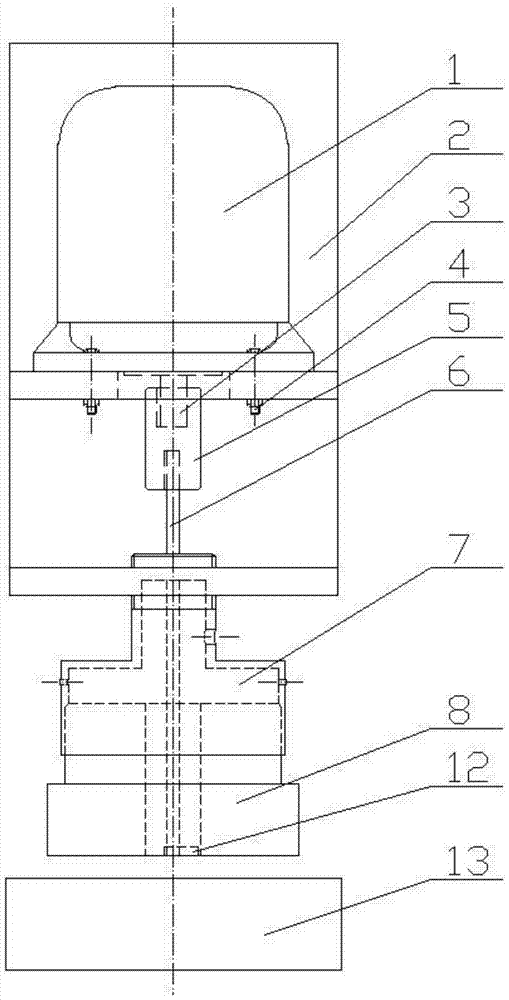

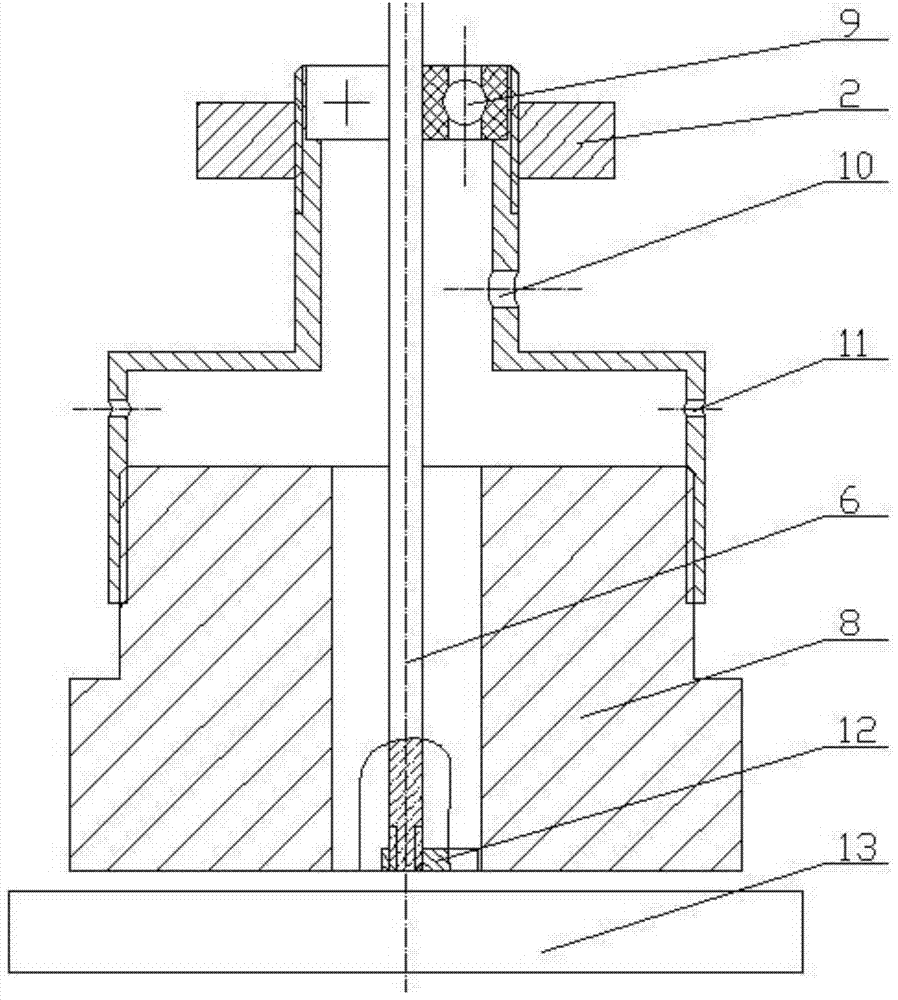

Synchronous machining mechanism for workpieces in flushing holes for EDM

ActiveCN104325202BSync removalElectrical-based machining electrodesElectrical-based auxillary apparatusCouplingCopper

The invention belongs to the field of machining, and relates to a synchronous processing mechanism for parts at fluid filling hole positions for electrical discharge machining. The synchronous processing mechanism mainly comprises a motor 1, a support frame 2, couplings 5, a spindly shaft 6, an electrode mounting base 7, an electrode 8 and a cuboid copper block 12. During electrical discharge machining, the motor 1 drives the spindly shaft 6 to rotate so as to drive the cuboid copper block 12 on the end part to rotate, the cuboid copper block 12 and the electrode 8 are isopotential, and the cuboid copper block 12 participates in electrical discharge machining of a workpiece 13 at a fluid filling hole position, and the normal fluid filling for the electrical discharge machining is not influenced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Synchronous processing mechanism for parts at fluid filling hole positions for electrical discharge machining

ActiveCN104325202ASync removalElectrical-based machining electrodesElectrical-based auxillary apparatusCouplingEngineering

The invention belongs to the field of machining, and relates to a synchronous processing mechanism for parts at fluid filling hole positions for electrical discharge machining. The synchronous processing mechanism mainly comprises a motor 1, a support frame 2, couplings 5, a spindly shaft 6, an electrode mounting base 7, an electrode 8 and a cuboid copper block 12. During electrical discharge machining, the motor 1 drives the spindly shaft 6 to rotate so as to drive the cuboid copper block 12 on the end part to rotate, the cuboid copper block 12 and the electrode 8 are isopotential, and the cuboid copper block 12 participates in electrical discharge machining of a workpiece 13 at a fluid filling hole position, and the normal fluid filling for the electrical discharge machining is not influenced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com