Synchronous machining mechanism for workpieces in flushing holes for EDM

A forming processing and synchronous processing technology, applied in the field of mechanical processing, can solve the problems that the workpiece cannot be processed and affects the processing quality of the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

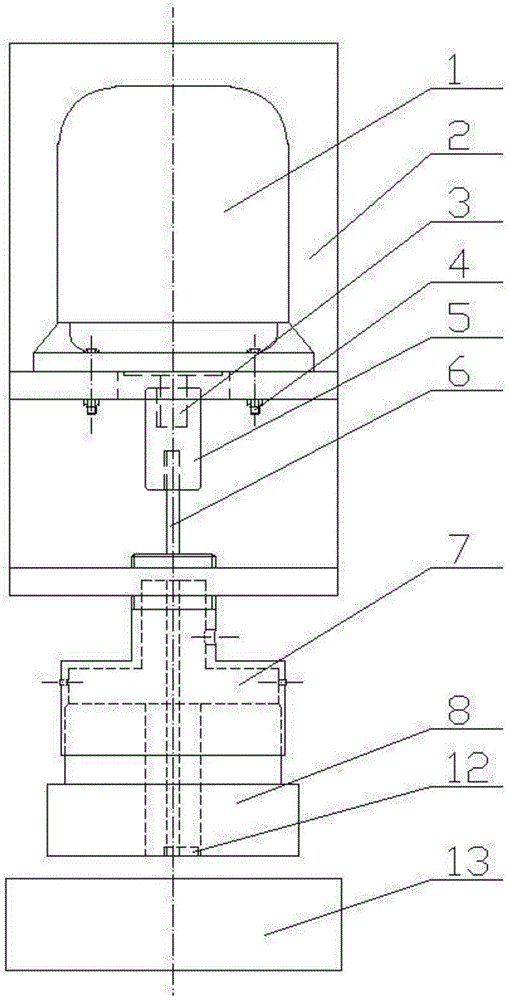

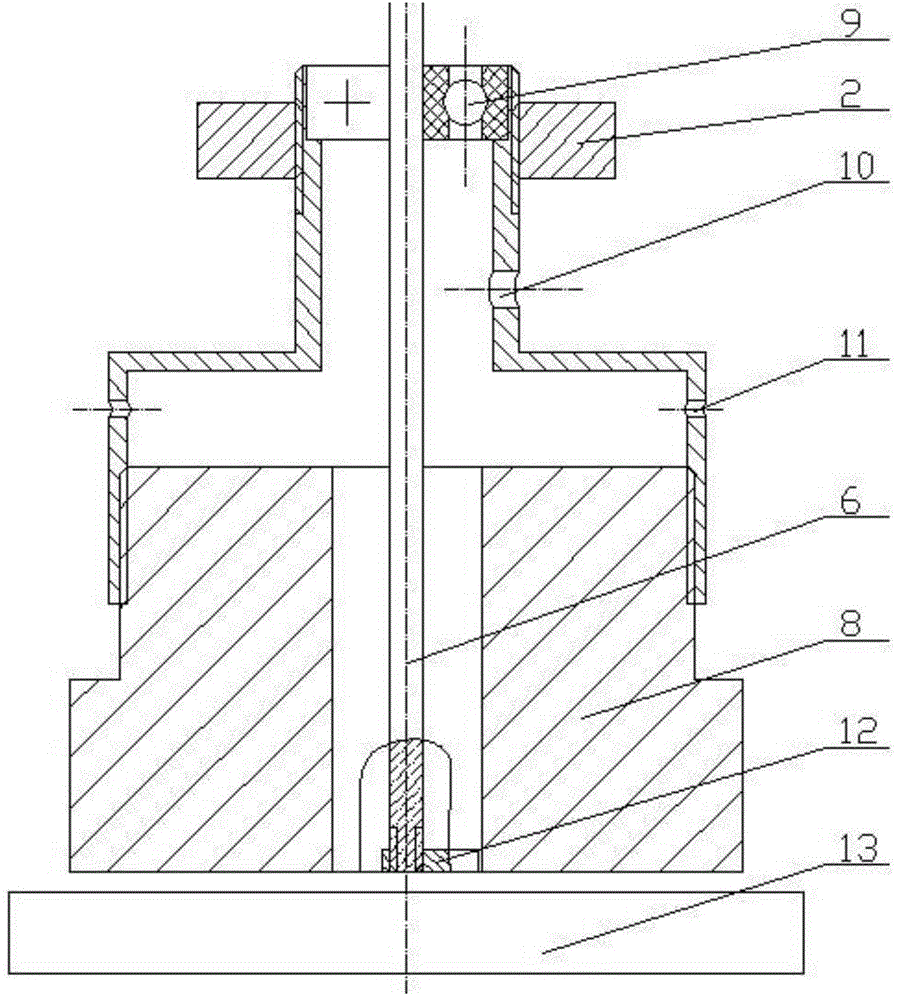

[0010] See figure 1 ,2. The present invention is mainly composed of a motor 1, a supporting frame 2, a coupling 5, an elongated shaft 6, an electrode mounting seat 7, an electrode 8, and a rectangular copper block 12.

[0011] During EDM processing, the working fluid enters through the inner punching hole 10 on the electrode mounting seat 7, flows through the inner punching hole on the electrode 8, and then flows out through the surface of the workpiece 13 to complete the punching. The elongated shaft 6 is driven to rotate by the electric motor 1, the elongated shaft 6 and the electric motor 1 are connected by a coupling 5, and the elongated shaft 6 is radially positioned by a bearing 9. The end of the elongated shaft 6 is connected to the rectangular parallelepiped copper block 12 through threads, and the bottom of the rectangular parallelepiped copper block 12 is flush with the bottom of the electrode 8. In addition, there are two symmetrical brush holes 11 on the electrode mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com