Pressure-difference-activated sealant and preparation method thereof

A sealant and activator technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of expensive, time-consuming, easy-to-damage pipe fittings, etc., and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

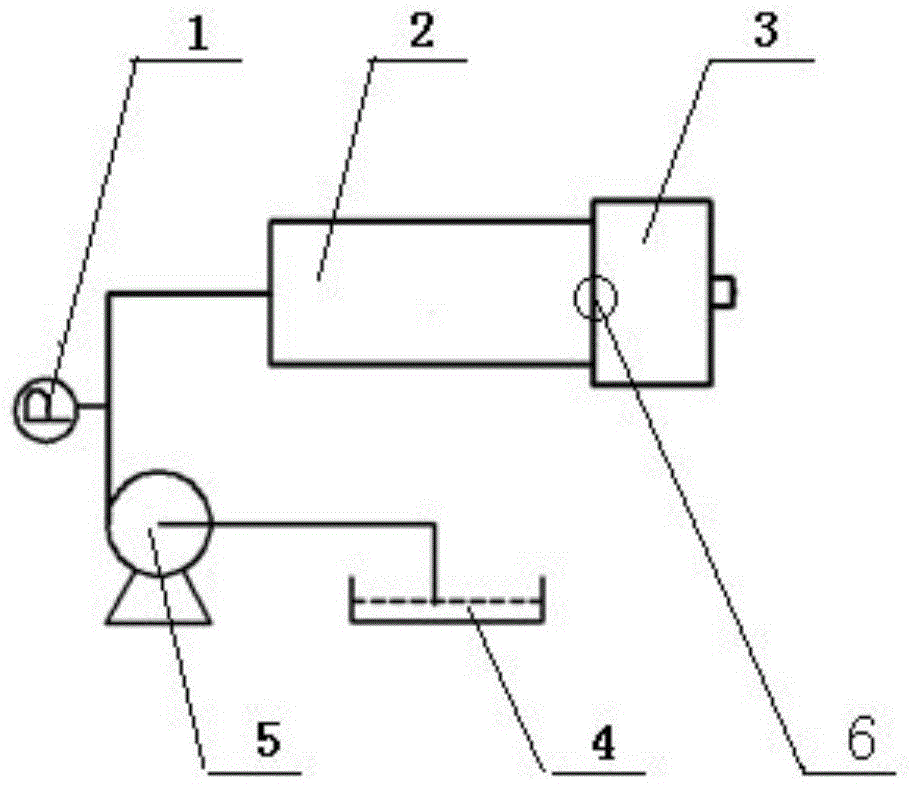

Method used

Image

Examples

Embodiment 1

[0025] A differential pressure activated sealant, the composition and quality of its raw materials are:

[0026] The mass of styrene-butadiene latex is 15g; sodium chloride 1.5g; butadiene and styrene prepolymer 10g (polymerization degree 80-120); styrene 1g; butadiene 0,5g; Gemini1231 surfactant 6g; water 66g .

[0027] The preparation method of the present invention is as follows: add styrene-butadiene latex into water under stirring, control the stirring speed at 1500 rpm and add sodium chloride dropwise. Polymer, styrene and butadiene monomer, stirred for 30min.

Embodiment 2

[0029] There is no latex monomer in this embodiment, because the molecular weight distribution of natural latex is wide, and it is also possible without latex monomer.

[0030] A differential pressure activated sealant, the composition and quality of its raw materials are:

[0031] The quality of natural rubber latex is 15g; sodium chloride 2g; isoprene prepolymer 8g (polymerization degree 80-120); 25% Gemini1631 and OP-40 surfactant compound system 8g; water 68g.

[0032] The preparation method of the present invention is: add natural rubber latex into water under stirring, control the stirring speed at 1500 rpm to add sodium chloride dropwise, after the dropwise addition, add OP-10 with a mass concentration of 25% and cationic Gemini1631 compounded after 15 minutes of reaction After the surfactant terminates the reaction, after the addition is completed, the prepolymer is added and stirred for 30 minutes to obtain the present invention.

[0033] The weight ratio of OP-10:ca...

Embodiment 3

[0035] A differential pressure activated sealant, the composition and quality of its raw materials are:

[0036] The quality of polyacrylate latex is 12g; magnesium sulfate 0.3g; acrylate prepolymer 10g (polymerization degree 150-200); butyl acrylate 1g; ethyl acrylate 1.2g; mass concentration 10wt% didodecanyl disulfate Sodium 8g solution; water 67.5g.

[0037] The preparation method of the present invention is: add polyacrylate latex into water under stirring, control the stirring speed at 2500 rpm to add magnesium sulfate dropwise, after the dropwise addition is completed, add 10% sodium didodecyl disulfate in mass concentration after 15 minutes of reaction After the reaction is terminated, after the addition is complete, the prepolymer, butyl acrylate and ethyl acrylate monomers are added and stirred for 30 minutes to obtain the present invention.

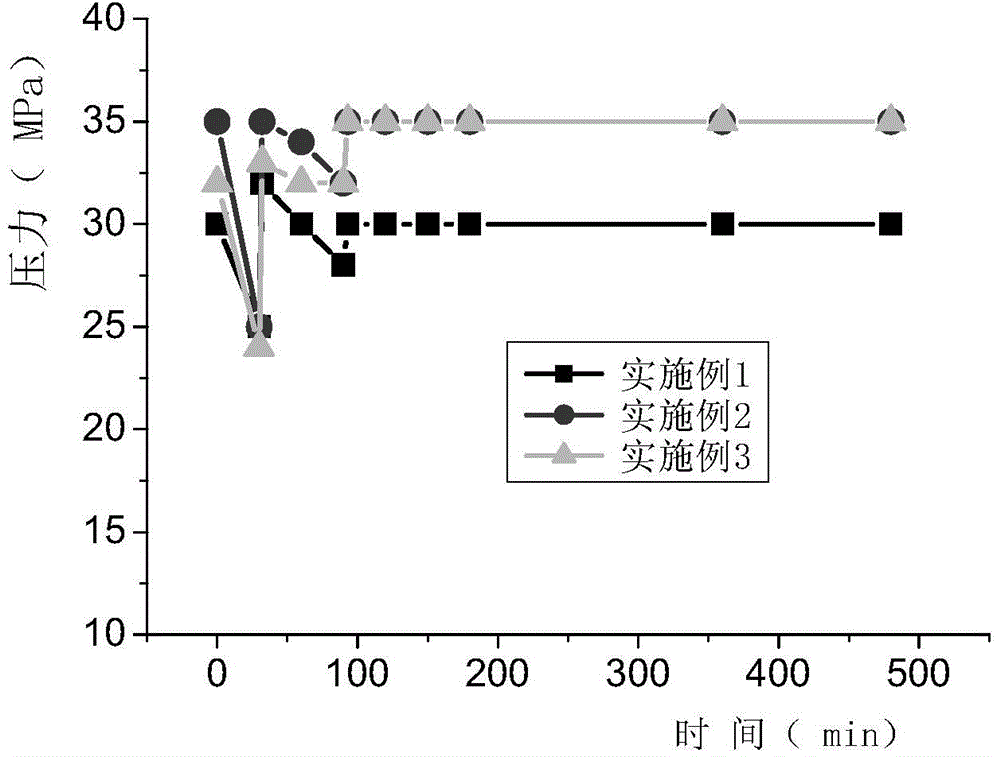

[0038] Verify the use effect of the present invention by comparative example below:

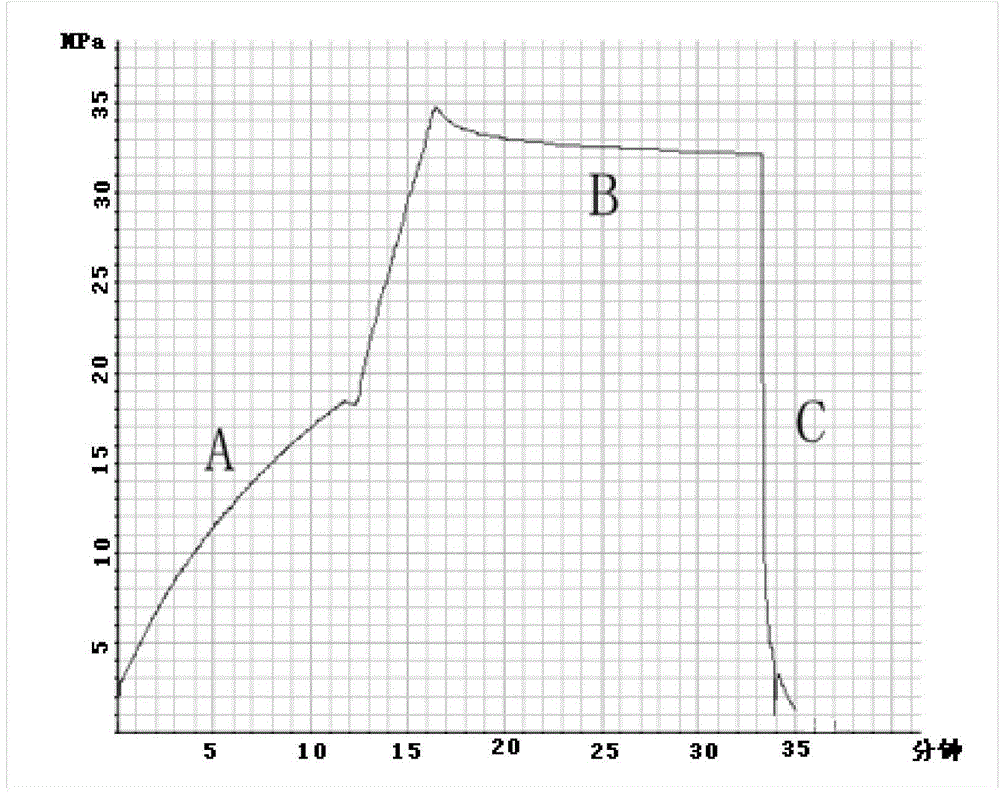

[0039] Use 9-5 / 8"casing thread to des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com