Reflow backwashing mechanism for automatic filtration of fluid

An automatic filtration and fluid technology, which is applied in the direction of filtration separation, dispersed particle filtration, fixed filter element filter, etc., can solve the problems that affect the stability of the rotation frequency of the fluid replacement, the low speed of the fluid replacement, and insufficient stability, etc., to achieve Improve the effect of automatic filtering, improve the rotation frequency and work stability and reliability, and the effect of stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

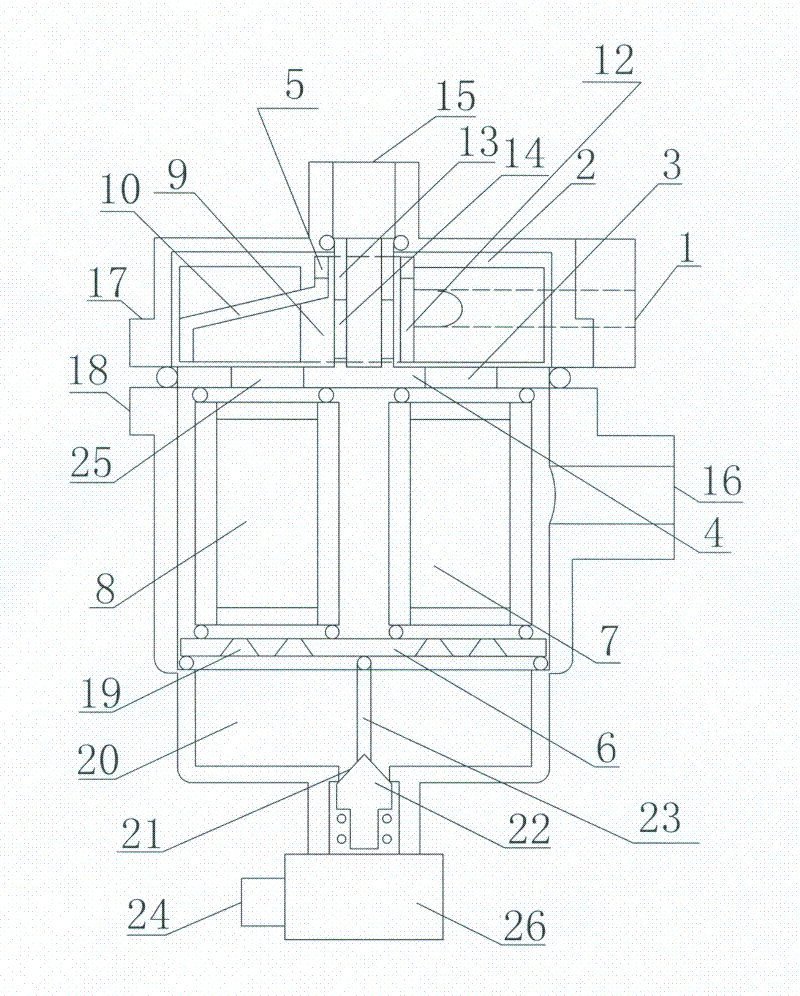

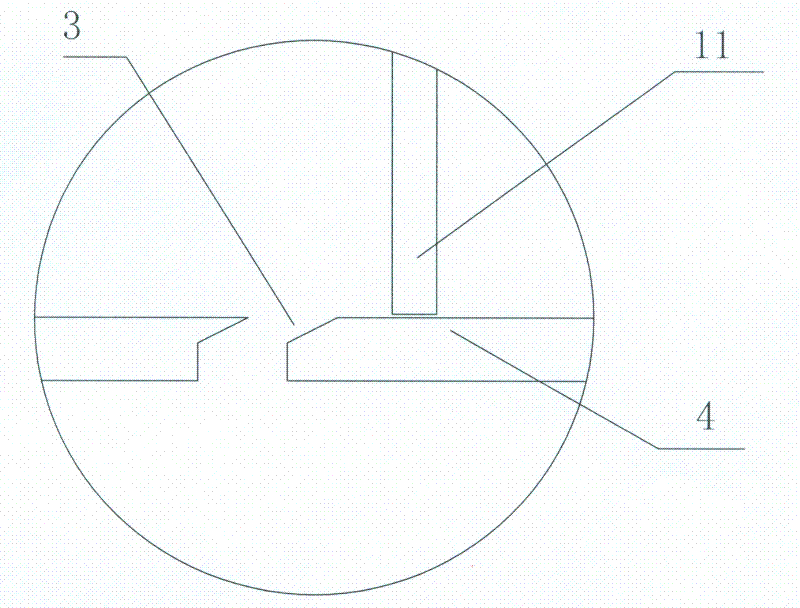

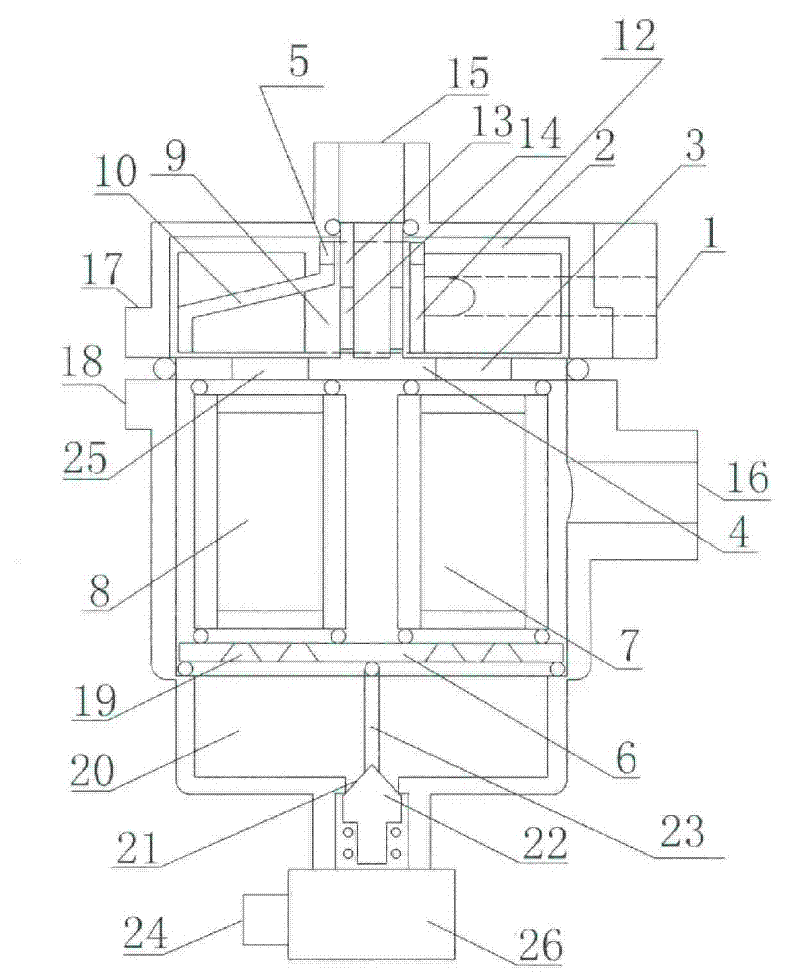

[0013] When the transfer pump pumps the fuel tangentially from the fluid inlet 1, the fluid will tangentially impact the paddles, causing the paddles to rotate, so that the switching fluid in the switching chamber 2 rotates in a directional direction. At this time, the fuel passes through the upper partition 4 After the right guide hole 3 enters the right filter element 7 and is filtered, the remaining fuel oil directly enters the left filter element 8, except that part passes through the oil outlet port 16 for diesel engine combustion, and the filter screen of the left filter element 8 is backwashed, and enters the left filter element 8 The fuel oil enters the inner cavity of the fluid exchange chamber 2 through the left guide through hole 25. At this time, the fuel oil will directionally impact the paddle 11 and pass through the through hole 14 of the hollow mandrel 13 to the delivery pump from the oil return interface 15. It is combined with the diesel oil from the fuel tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com