Low-density coated ceramsite proppant and preparation method thereof

A low-density, proppant technology, applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve problems such as high density, increased energy consumption and production costs, and limited reduction in proppant density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the low-density film-coated ceramsite proppant described in the above technical solution, comprising the following steps:

[0033] (1) Active carbon is mixed with resin to obtain membrane material;

[0034] (2) under the action of a coupling agent, the membrane material is used to coat the ceramsite to obtain a coating mixture;

[0035] (3) Adding a curing agent and a lubricant in sequence to the coating mixture, and obtaining a low-density coated ceramsite proppant after complete curing.

[0036] The invention mixes activated carbon with resin to obtain membrane material. In the present invention, the mixing is preferably carried out under stirring conditions; the present invention has no special requirements on the speed and time of the stirring, as long as the activated carbon and the resin can be mixed evenly. In the present invention, the equipment used for mixing is preferably a sand mixer.

[0037] Aft...

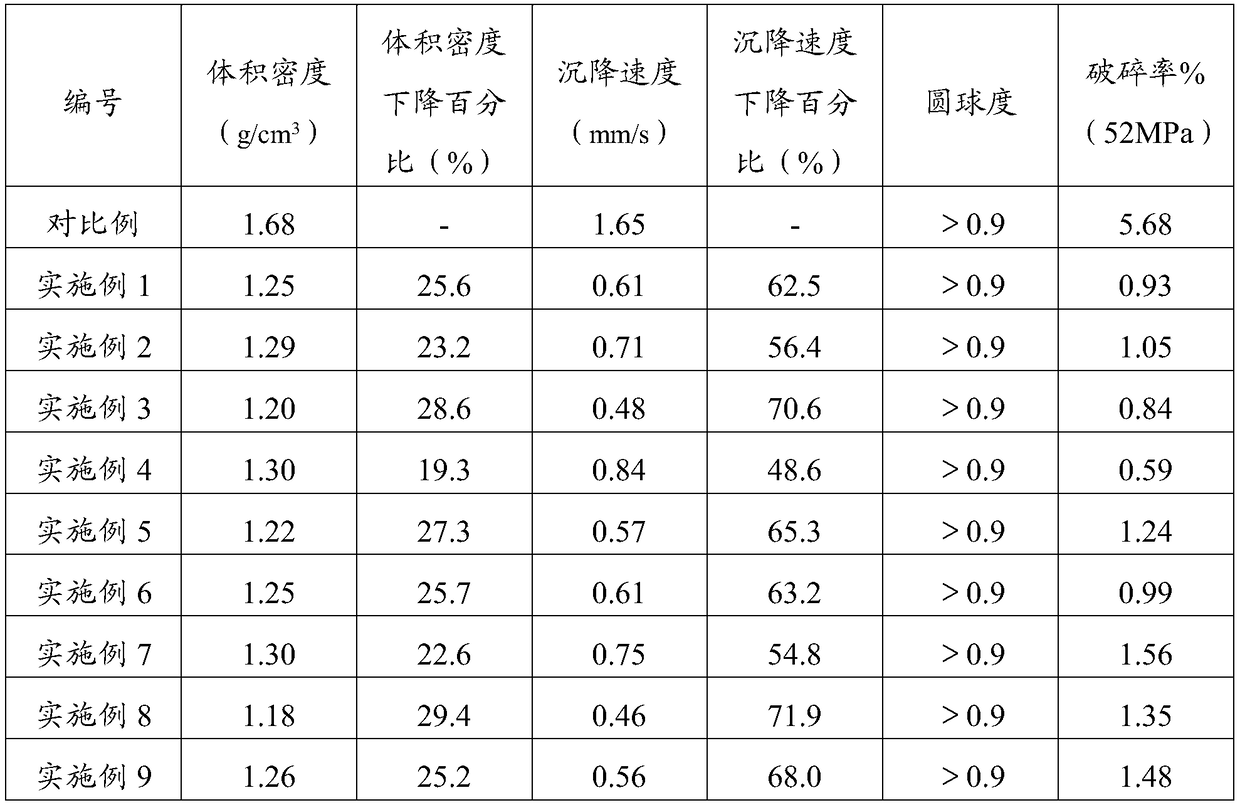

Embodiment 1

[0044] In parts by weight, the preparation raw materials include: 100 parts of ceramsite; 4 parts of resin; 10 parts of activated carbon; 0.6 part of coupling agent; 0.2 part of curing agent; 1 part of lubricant.

[0045] Preparation method: Add 5000g of commercial ceramsite proppant with a particle size of 20-40 mesh into 10L of sulfuric acid solution with a mass concentration of 1%, soak for 2 hours, wash until neutral and set aside. Take 500g of activated carbon powder (200-400 mesh), 200g of phenolic resin, stir evenly in the sand mixer, add the treated ceramsite and 30g of coupling agent KH550, stir into balls, and then add 10g of curing agent ammonium chloride, Continue to stir, add 50g of lubricant calcium stearate before the coated ceramsite is agglomerated, and continue to stir until the membrane material is completely solidified to obtain a low-density coated ceramsite-coated proppant.

Embodiment 2

[0047] In parts by weight, the preparation raw materials include: 100 parts of ceramsite; 2 parts of resin; 10 parts of activated carbon; 1 part of coupling agent; 0.2 part of curing agent; 1 part of lubricant.

[0048] Preparation method: Add 5000g of commercial ceramsite proppant with a particle size of 20-40 mesh into 10L of sulfuric acid solution with a mass concentration of 5%, soak for 8 hours, wash until neutral and set aside. Take 500g of activated carbon powder (200-400 mesh) and 100g of phenolic resin, stir evenly in the sand mixer, add the treated ceramsite and 50g of coupling agent KH550, stir, and after the coating is uniform, add curing agent six Methylenetetramine 10g, continue to stir, add 50g of lubricant calcium stearate before the coated ceramsite is agglomerated, continue to stir until the membrane material is completely solidified, and obtain a low-density coated ceramsite-coated proppant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com