Metal mesh cage film-plating clamping device

A clamping device and metal mesh technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of workpiece collision damage, damage to workpiece edges and edges, etc., to avoid collision damage , Improve production efficiency, the effect of small free space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A new type of metal mesh cage coating clamping system proposed by the present invention is further described as follows in conjunction with the accompanying drawings and embodiments:

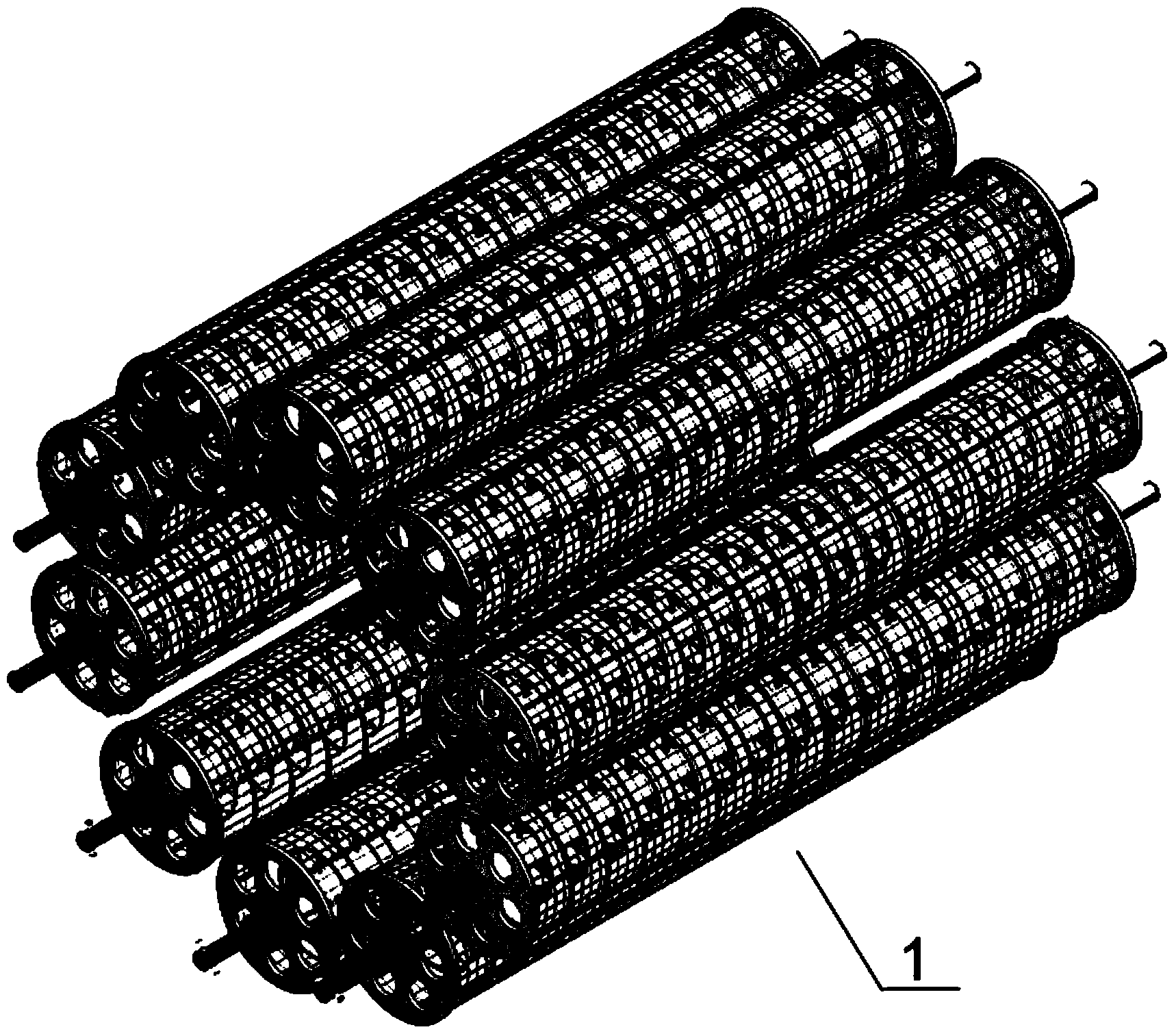

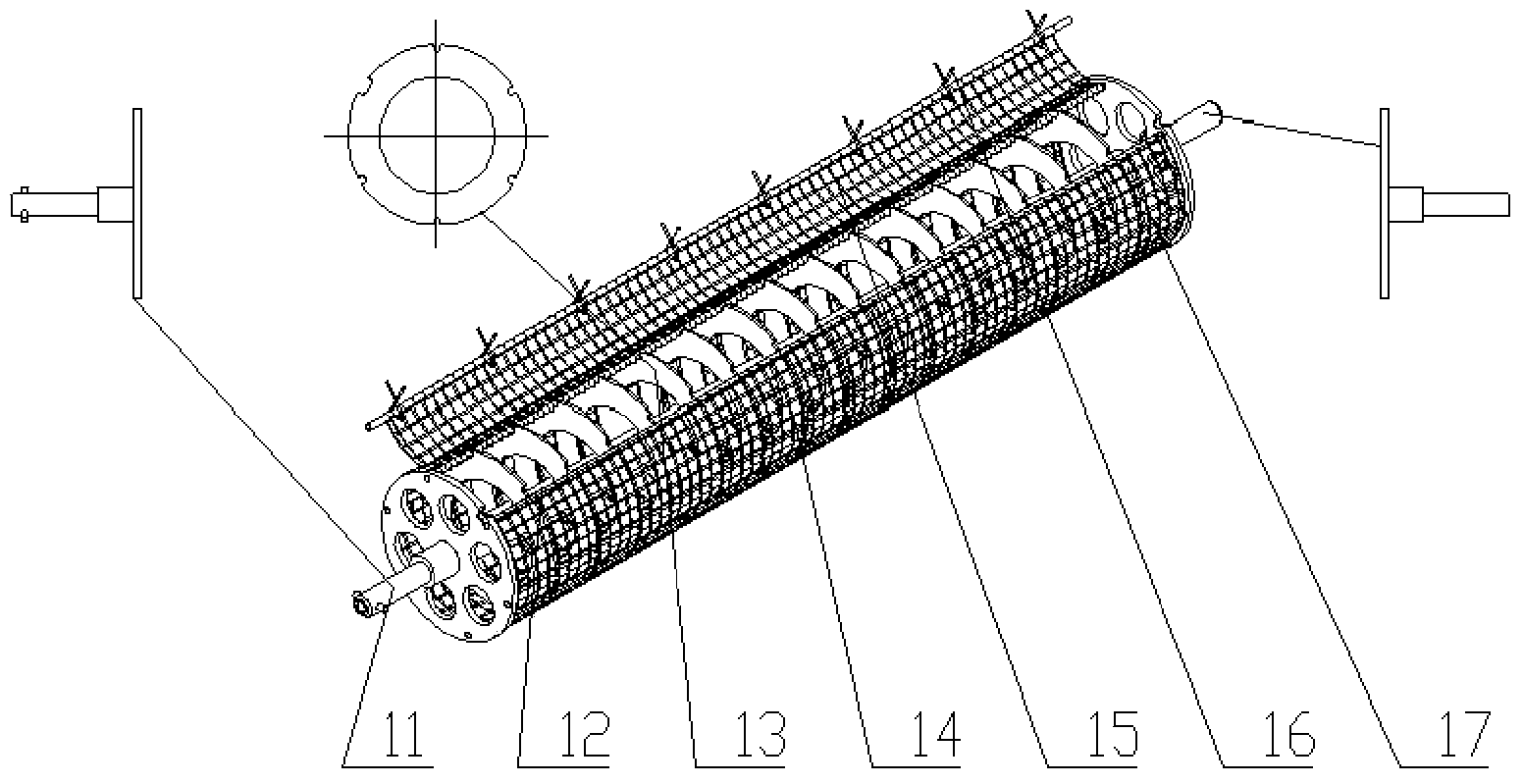

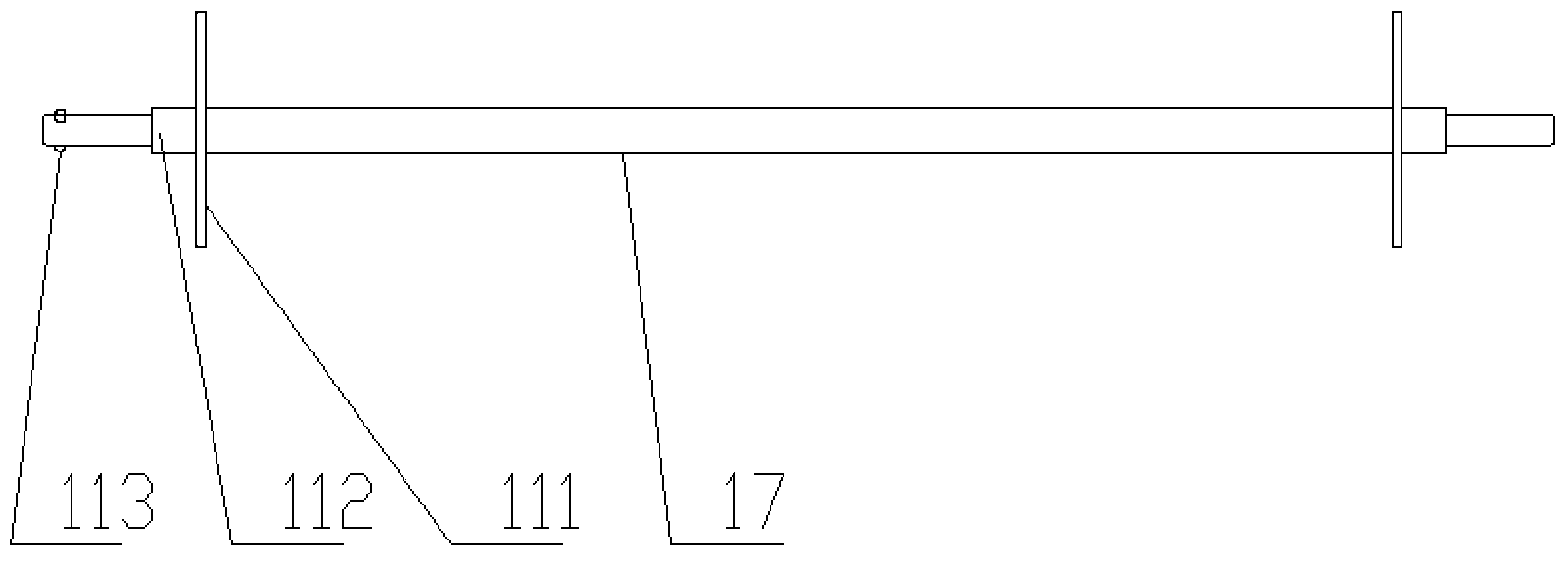

[0018] The embodiment of the first new metal mesh cage coating clamping device for vacuum ion coating machine proposed by the present invention Figure 1-3 As shown, the device of this embodiment consists of 10 mesh cages 1 arranged side by side to form a circumferentially distributed planetary cylindrical fixture. The maximum diameter of the fixture is about 586mm, and the length is about 807mm (equivalent to the size of the coating inner chamber of the coating machine) . Each net cage is the slender cylinder that has support shaft 11 at both ends, and each net cage is shaped as a circular tube; each net cage is installed on a planetary turret mechanism (figure Not shown in, this mechanism does not belong to the composition structure of the present invention); Each cage realizes a horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com