Heatable part of a pump housing

a pump housing and heat sink technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problem of unproblematic movement, and achieve the effect of extending the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

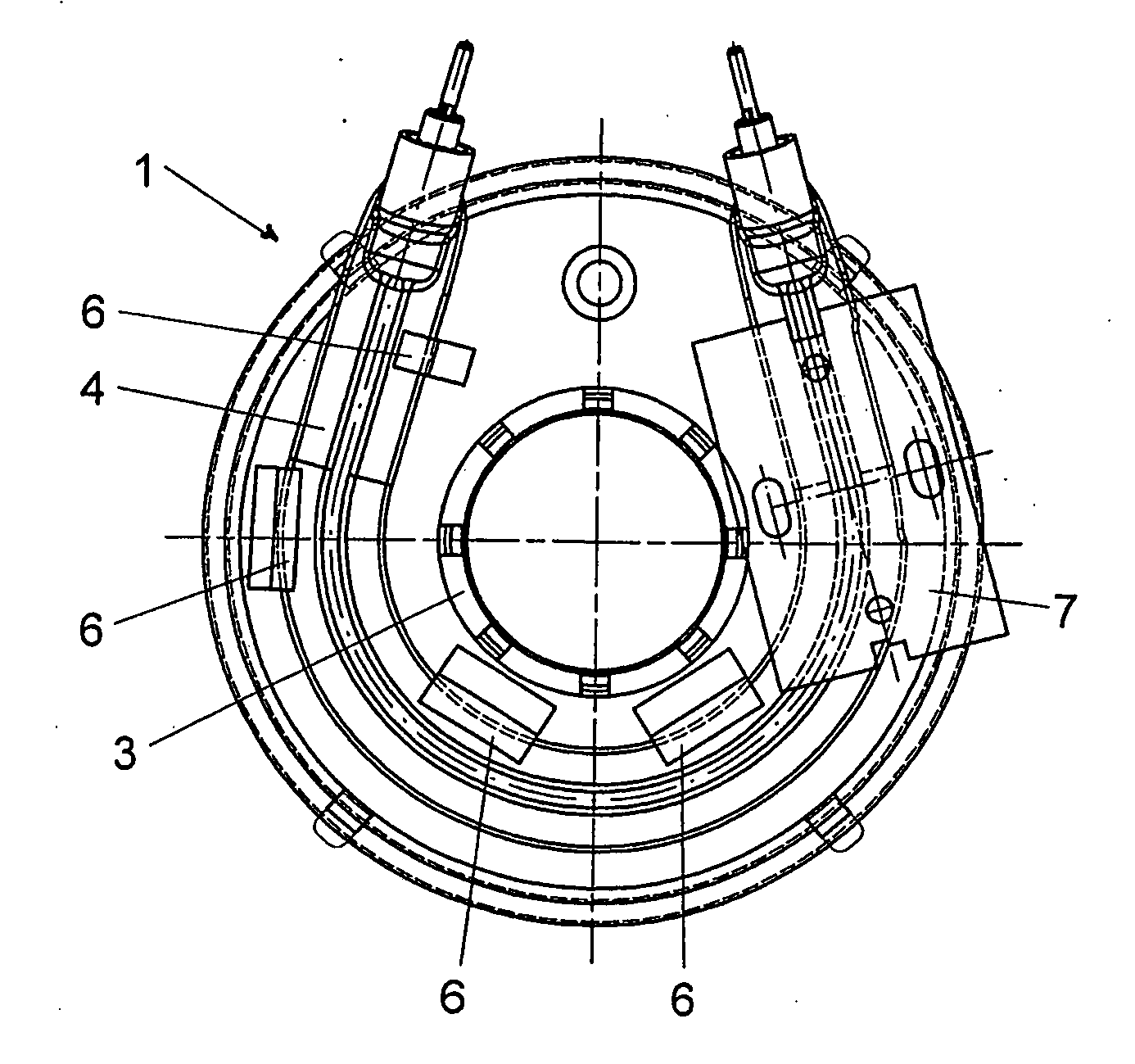

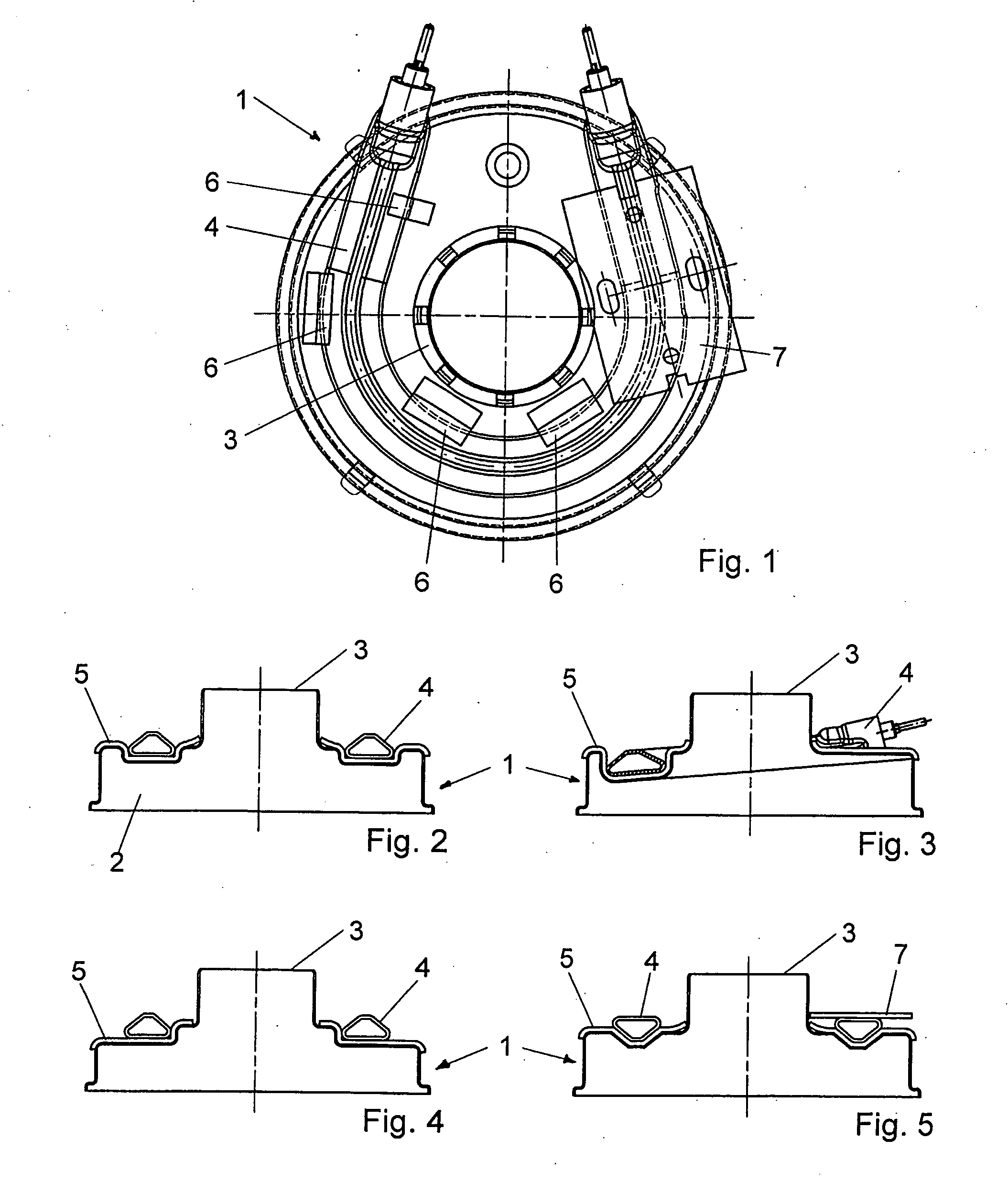

[0019]The pump housing part 1 shown in FIGS. 1 and 2 is a cap. The housing part 1 has a base body made of stainless steel 2 forming a connecting tube 3. The pump housing part 1 can be heated with a U- or C-shaped tubular heating element 4, which is soldered onto a heat distribution sheet 5 that spreads over a cover surface of the housing part and is soldered with it.

[0020]As shown in the sectional view of FIG. 2, the heat distribution sheet 5 covers a U- or C-shaped groove in the housing part. The groove can have an angular cross-section, particularly rectangular or trapezoidal, or a U-shaped cross-section. The tubular heating element 4 is arranged in this groove, such that it touches both the side walls of the groove. On both the sides, the heat distribution sheet 5 projects by more than 0.5 cm beyond the side walls of the groove. An advantage of this is that a larger area of contact is created between the tubular heating element 4 and the heat distribution sheet 5. It is preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com