Plastic package motor with sealing property

A plastic-encapsulated motor and sealing performance technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems that affect the service life of the motor and the motor is stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

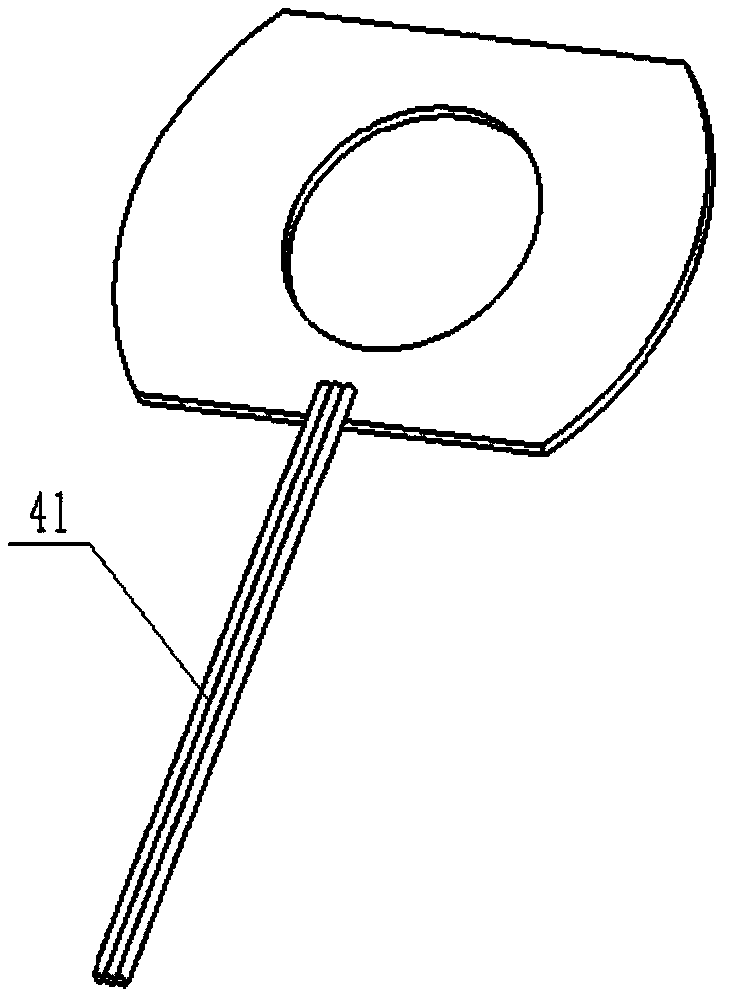

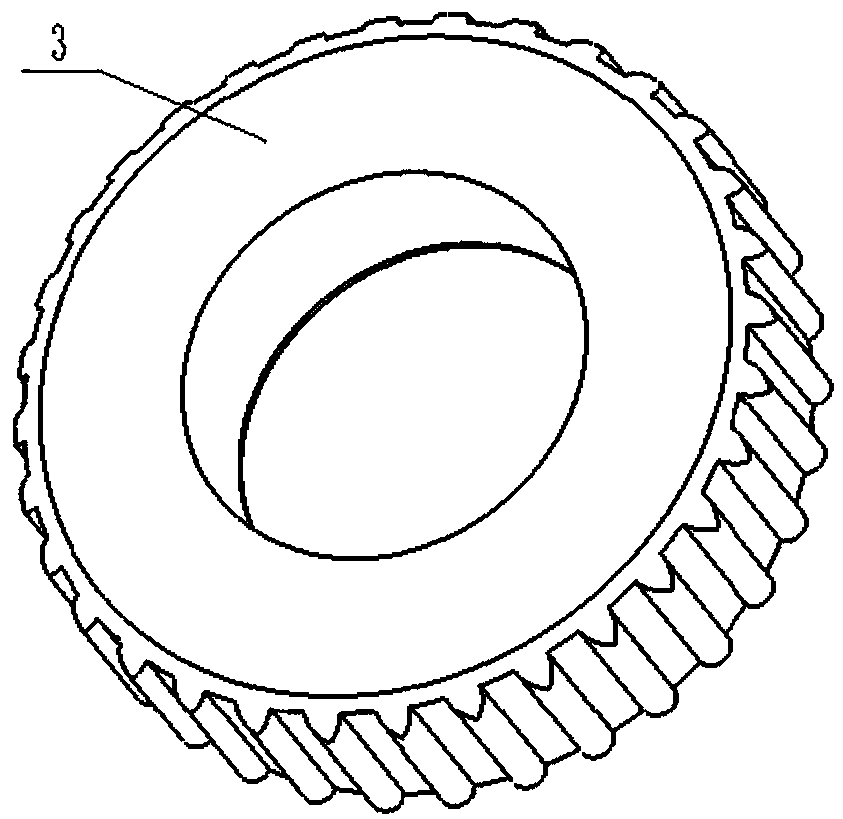

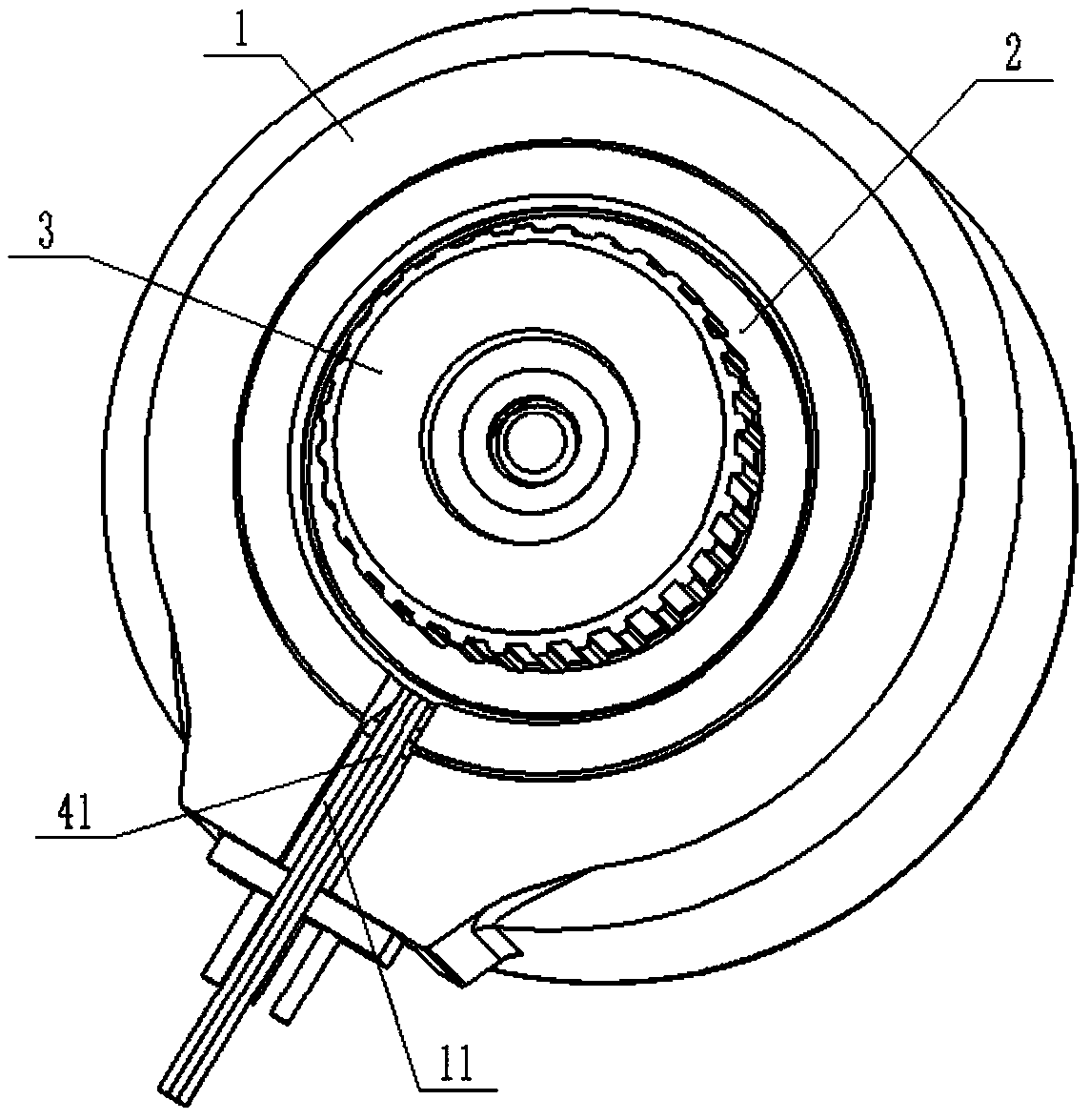

Embodiment 1

[0022] Such as Figure 1~4 As shown, a plastic-sealed motor with sealing performance includes a plastic-sealed motor body and shockproof rubber rings 3 installed at both ends of the plastic-sealed motor body. The plastic-sealed motor body includes a stator assembly and a plastic casing 1 around the stator assembly. The end surface of the plastic casing 1 A wire groove 11 is provided, and the power cord 41 of the PG component 4 is drawn out from the wire outlet on the plastic casing 1 and nested in the wire groove 11. A sealing ring 42 is set on the power wire 41, and the sealing ring 42 is set in the wire groove 11. The bottom of the shockproof rubber ring 3 is provided with a bump 32 that compresses the seal ring 42 in the wire groove 11, and the bump 32 at the bottom of the shockproof rubber ring 3 is pressed against the seal ring 42 located in the wire groove 11, so that the wire groove 11, The sealing ring 42 sleeved on the power cord 41 and the protrusion 32 are squeezed ...

Embodiment 2

[0028] refer to Figure 1~3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that one side of the sealing ring 42 is provided with an opening, and the sealing ring 42 with one side opening can be locked at any time. Putting it on the power cord 41 is sufficient to reduce the time for the sealing ring 42 to be placed on the power cord 41 when the power cord 31 is too long, thereby optimizing the installation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com