Degradable antibacterial composite preservative film as well as preparation method and application thereof

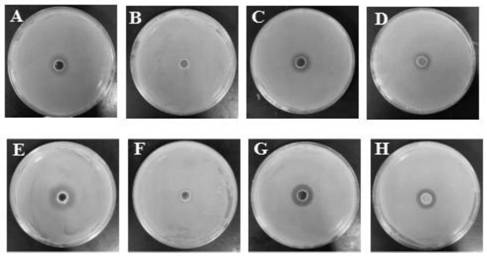

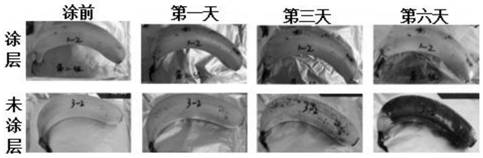

A composite fresh-keeping and composite film technology, applied in the field of food packaging materials, can solve the problems of poor anti-oxidation and antibacterial effects of a single chitosan film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

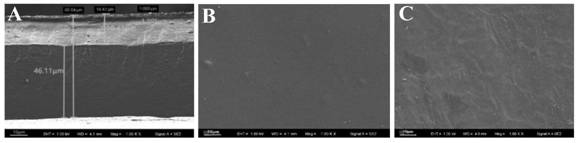

[0031] The invention provides a preparation method of a degradable antibacterial composite plastic wrap, comprising the following steps:

[0032] After mixing the chitosan acetic acid solution and the first glycerin, casting on the carrier to form a chitosan film;

[0033] Casting the tannic acid solution on the chitosan film to obtain a chitosan-tannic acid composite film;

[0034] After mixing the cornstarch solution and the second glycerin, it is cast on the chitosan-tannic acid composite film to obtain a degradable antibacterial composite fresh-keeping film.

[0035] Unless otherwise specified, the present invention has no special requirements on the sources of the raw materials used for the preparation, and commercially available products well known to those skilled in the art can be used.

[0036] In the invention, after mixing the chitosan acetic acid solution and the first glycerin, the chitosan film is cast on the carrier to form the chitosan film.

[0037] In the p...

Embodiment 1

[0066] Weigh 10 g of corn starch and add it to a beaker filled with 200 mL of distilled water, heat in a boiling water bath until the starch is completely gelatinized, cool to 50°C and set aside to obtain a corn starch solution with a mass concentration of 50 g / L;

[0067] Weigh 2.5g of chitosan and add it into 200mL of 2% acetic acid, stir magnetically at 30rpm for 12h to obtain a chitosan solution with a mass concentration of 12.5g / L;

[0068] Weigh 1g of tannic acid and dissolve it in 100mL of distilled water to obtain a tannic acid solution with a mass concentration of 10g / L;

[0069] After mixing 20mL of 12.5g / L chitosan solution and 0.175g of glycerin, cast it on a glass plate and dry it at 45°C for 2h to form a chitosan film; then, cast 20mL of 10g / L tannic acid solution on it , dried at 45°C for 2h to obtain a chitosan-tannic acid composite film; finally, after mixing 20mL of 50g / L cornstarch solution and 0.7g glycerin, cast the chitosan-tannic acid composite film and ...

Embodiment 2

[0071] The difference with embodiment 1 is that the mass concentration of chitosan acetic acid solution is 15g / L, and all the other contents are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com