Graphene modified nitrile rubber and preparation method thereof

A technology of graphene modification and nitrile rubber, which is applied in the field of graphene rubber composite materials, can solve the problems of poor high and low temperature resistance of nitrile rubber, and achieve the effects of good heat resistance, slow vulcanization speed and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

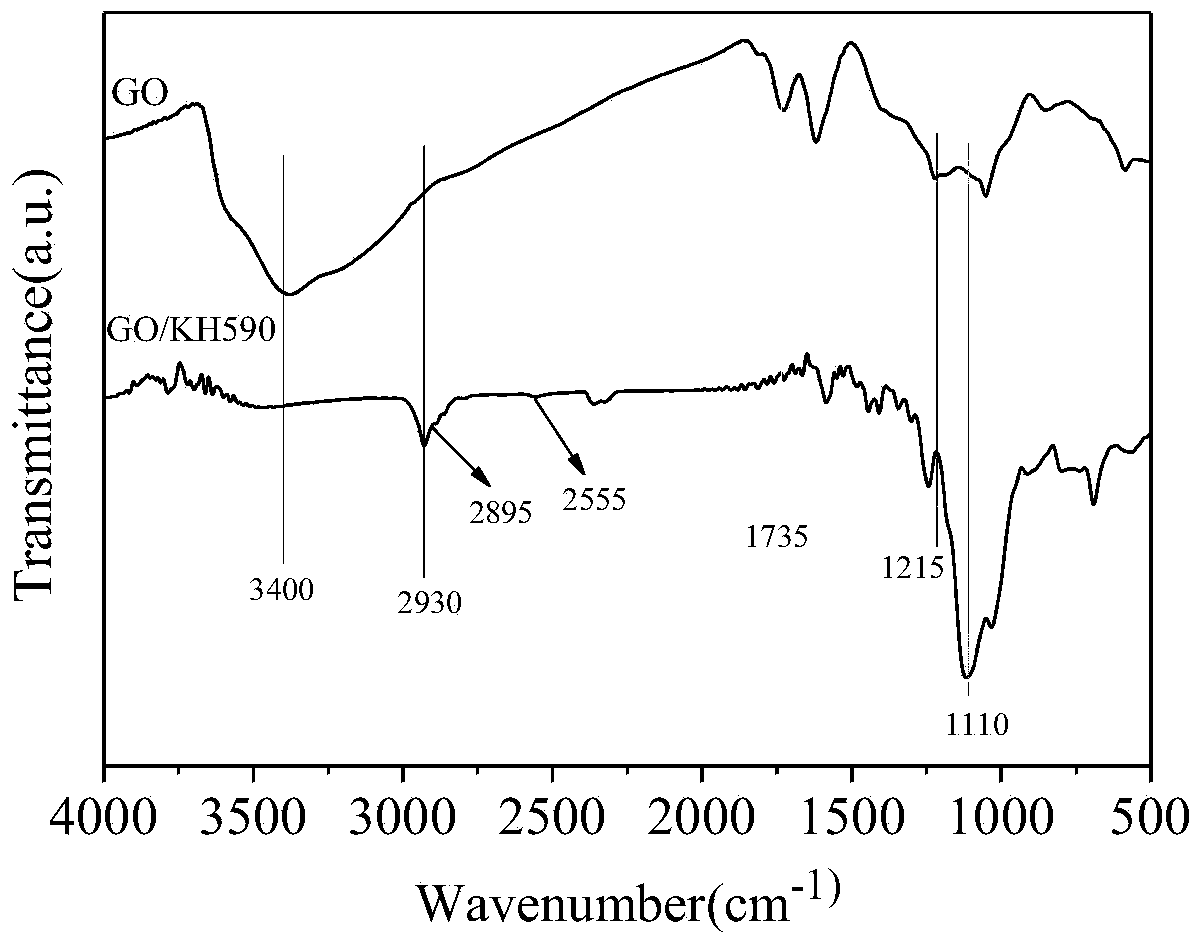

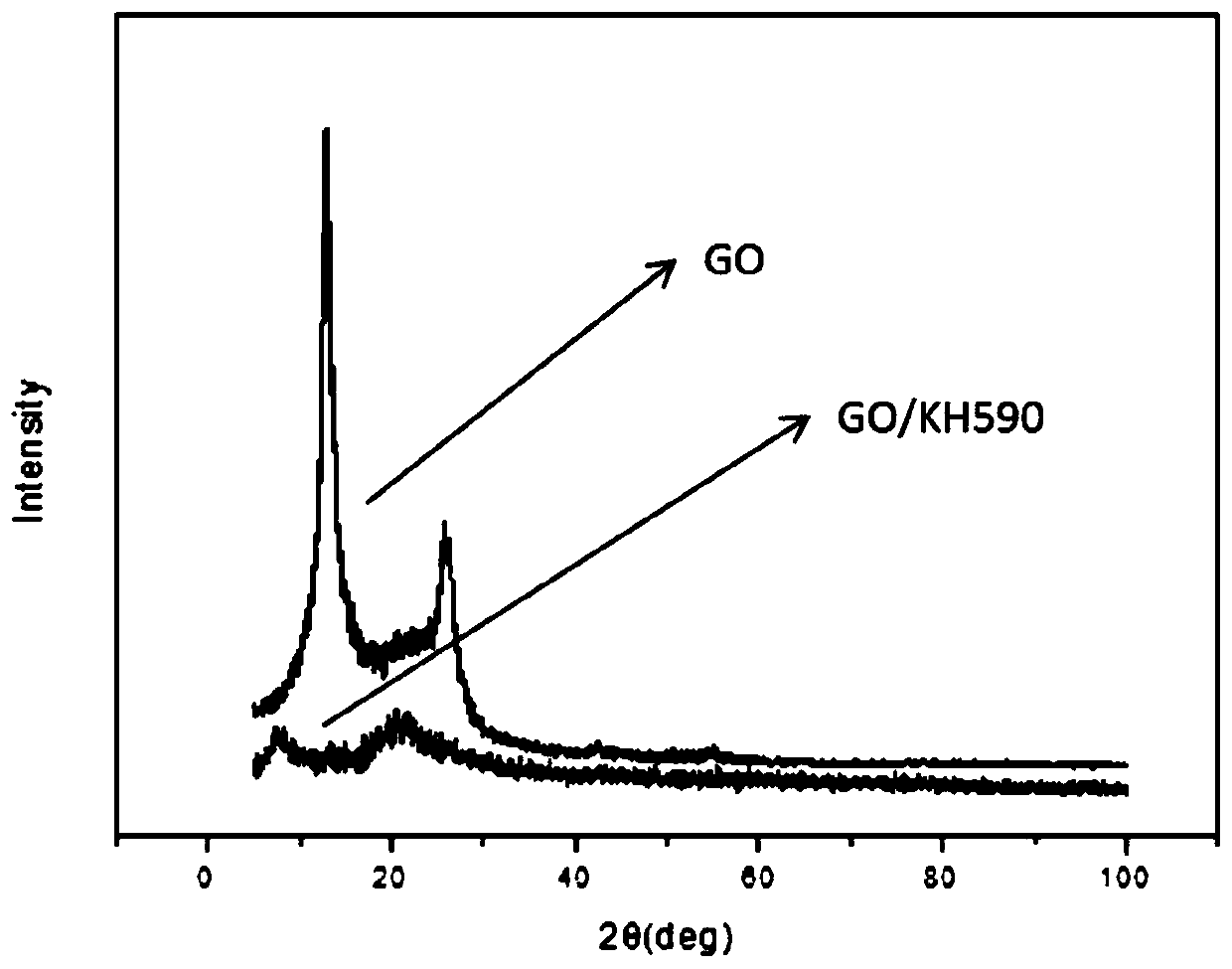

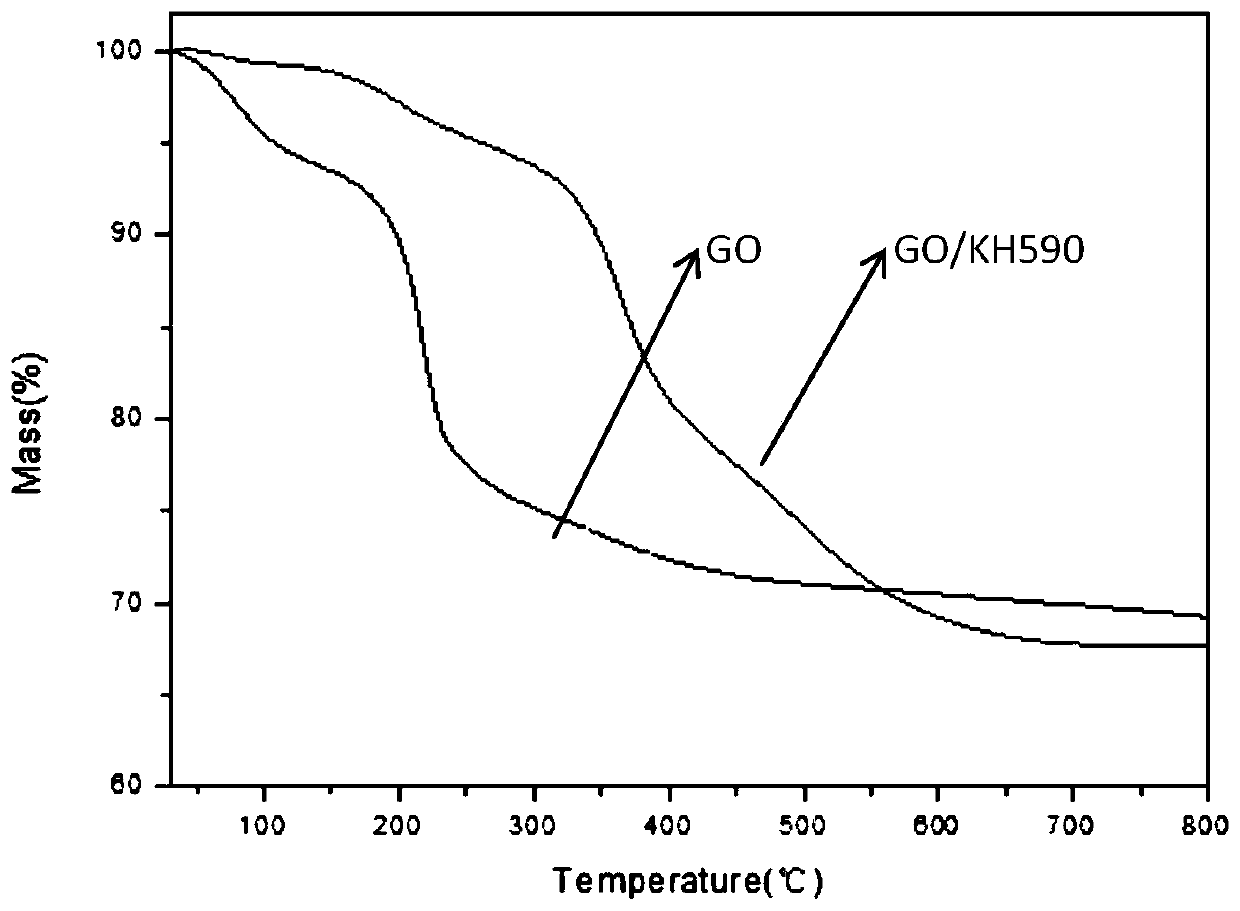

Method used

Image

Examples

Embodiment 1

[0050] A kind of graphene modified nitrile rubber, comprises the component of following parts by weight:

[0051] 80 parts of nitrile rubber, 20 parts of modified graphene oxide-carboxylated nitrile rubber masterbatch, 1.5 parts of vulcanizing agent, 1.5 parts of vulcanization accelerator, 3 parts of vulcanization activator, 2 parts of plasticizer, 1 part of anti-aging agent, filler 27 copies,

[0052] Among them, the nitrile rubber is carboxylated butyl rubber, the combined acrylonitrile content in the carboxylated nitrile rubber is 33-40%, and the carboxyl content is 3-5%; the modified graphene oxide-carboxylated nitrile rubber masterbatch is modified oxidation Graphene-carboxylated nitrile rubber masterbatch Ⅰ; the vulcanizing agent is dicumyl peroxide; the vulcanization accelerator is 1 part of N-cyclohexane-2-benzothiazyl sulfenamide and dimethyl distearate 0.5 parts of zinc thiocarbamate; the vulcanization activator is zinc oxide; the plasticizer is dioctyl adipate; the...

Embodiment 2

[0061] A kind of graphene modified nitrile rubber, comprises the component of following parts by weight:

[0062] 85 parts of nitrile rubber, 15 parts of modified graphene oxide-carboxylated nitrile rubber masterbatch, 1.7 parts of vulcanizing agent, 2 parts of vulcanization accelerator, 3 parts of vulcanization activator, 3 parts of plasticizer, 1.5 parts of anti-aging agent, filler 30 servings,

[0063] Among them, the nitrile rubber is carboxylated butyl rubber, the combined acrylonitrile content in the carboxylated nitrile rubber is 33-40%, and the carboxyl content is 3-5%; the modified graphene oxide-carboxylated nitrile rubber masterbatch is modified oxidation Graphene-carboxylated nitrile rubber masterbatch II; the vulcanizing agent is benzoyl peroxide; the vulcanization accelerator is 1.2 parts of N-oxydiethylene-2-benzothiazole sulfenamide and diethyl dithio Zinc carbamate 0.8 part; vulcanization activator is zinc oxide; plasticizer is dioctyl azelate; anti-aging age...

Embodiment 3

[0072] A kind of graphene modified nitrile rubber, comprises the component of following parts by weight:

[0073] 85 parts of nitrile rubber, 15 parts of modified graphene oxide-carboxylated nitrile rubber masterbatch, 1.7 parts of vulcanizing agent, 2 parts of vulcanization accelerator, 3 parts of vulcanization activator, 3 parts of plasticizer, 1.5 parts of anti-aging agent, filler 30 servings,

[0074] Among them, the nitrile rubber is carboxylated butyl rubber, the combined acrylonitrile content in the carboxylated nitrile rubber is 33-40%, and the carboxyl content is 3-5%; the modified graphene oxide-carboxylated nitrile rubber masterbatch is modified oxidation Graphene-carboxylated nitrile rubber masterbatch Ⅰ; the vulcanizing agent is dicumyl peroxide; the vulcanization accelerator is 1.2 parts of N-oxydiethylene-2-benzothiazole sulfenamide and diethyl disulfide 0.8 parts of zinc carbamate; the vulcanization activator is zinc oxide; the plasticizer is dioctyl adipate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com