A kind of solvent-diluted antirust oil for bearings and preparation method thereof

A dilution type anti-rust oil and solvent oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high viscosity, difficult to meet requirements, etc., and achieve the effects of low viscosity, low cost, and good anti-overlap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

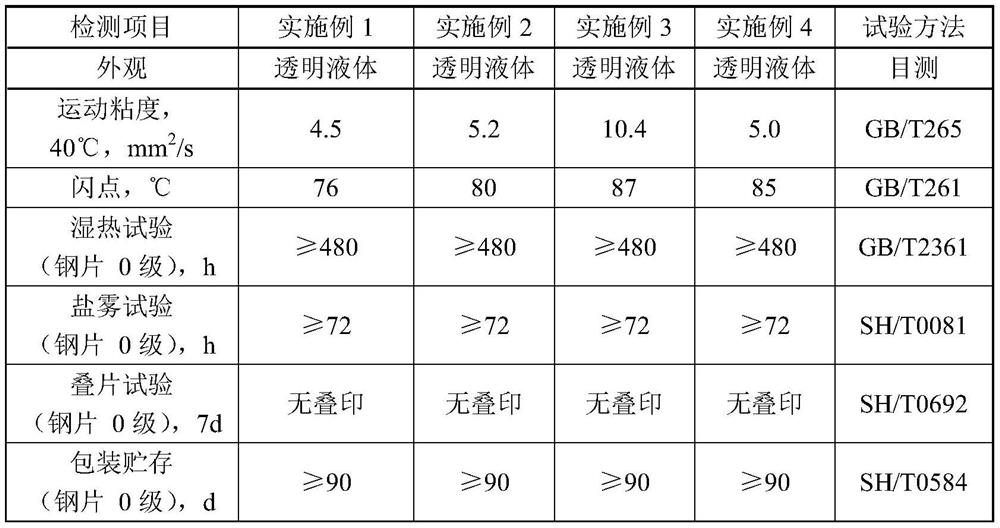

Examples

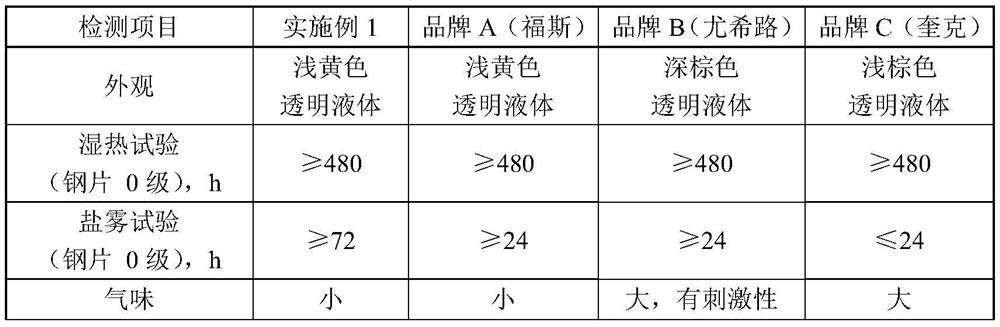

Embodiment 1

[0027] The solvent-diluted antirust oil for bearings of the present embodiment consists of the following components by weight: 250kg No. 25 transformer oil, 90kg dinonylnaphthalene barium sulfonate, 40kg neutral barium sulfonate, 20kg polyisobutylene, 20kg Span -80, 20kg of polymerized linseed oil, 560kg of D70 mineral spirits.

[0028] The preparation method of solvent-diluted antirust oil for bearings of the present embodiment may further comprise the steps:

[0029] Add 250kg of No. 25 transformer oil into the blending kettle, heat it to 110°C, then add 90kg of dinonylnaphthalene barium sulfonate and 40kg of neutral barium sulfonate under constant stirring, control the temperature at 110°C and stir for 1 hour to Dissolve completely; then when the temperature of the dissolved mixture drops to 90°C, add 20kg of polyisobutylene, 20kg of Span-80, and 20kg of polymerized linseed oil, then stir for 2 hours, and add 560kg of D70 solvent when the mixed system is cooled to room temp...

Embodiment 2

[0031] The solvent-diluted antirust oil for bearings of the present embodiment is made up of the components of the following weights: 320kg L-AN10# total loss system oil, 80kg dinonylnaphthalene barium sulfonate, 50kg neutral barium sulfonate, 20kg division Pan-80, 30kg of polymerized linseed oil, 500kg of D70 mineral spirits.

[0032] The preparation method of solvent-diluted antirust oil for bearings of the present embodiment may further comprise the steps:

[0033] Add 320kg L-AN10# total loss system oil into the blending kettle, heat to 100°C, then add 80kg dinonylnaphthalene barium sulfonate and 50kg neutral barium sulfonate under constant stirring, and control the temperature at 100 ℃ for 1 hour until completely dissolved; then when the temperature of the dissolved mixture drops to 90 ℃, add 20kg of Span-80 and 30kg of polymerized linseed oil, then stir for 2 hours, add 500kg of D70 solvent oil when cooling to room temperature, After stirring evenly, use a filter bag wi...

Embodiment 3

[0035] The solvent-diluted antirust oil for bearings of the present embodiment consists of the following components by weight: 350kg L-AN32# total loss system oil, 70kg dinonylnaphthalene barium sulfonate, 50kg neutral barium sulfonate, 10kg oxidation Paraffin, 30kg Span-80, 20kg polymerized linseed oil, 470kg D80 solvent oil.

[0036] The preparation method of solvent-diluted antirust oil for bearings of the present embodiment may further comprise the steps:

[0037] Add 350kg L-AN32# total loss system oil into the blending kettle, heat to 100°C, then add 70kg dinonylnaphthalene barium sulfonate and 50kg neutral barium sulfonate under constant stirring, and control the temperature at 100 Stir for 1 hour until completely dissolved; then when the temperature of the dissolved mixture drops to 90°C, add 10kg of oxidized paraffin, 30kg of Span-80, and 20kg of polymerized linseed oil, then stir for 2 hours, and wait until the mixed system drops to room temperature At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com