Patents

Literature

31results about How to "Excellent salt spray performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano oxide inorganic coated phosphite powder and waterborne coating containing same

ActiveCN106590034ACorrosion resistanceHigh temperature resistantAnti-corrosive paintsPigment physical treatmentWeather resistanceEmulsion

The invention provides nano oxide inorganic coated phosphite powder. The nano oxide inorganic coated phosphite powder is characterized in that phosphite is used as the core, nano oxide is used as the shell to wrap the phosphite, and the mass of the nano oxide is 0.1-10% of the mass of the phosphite. The invention further discloses waterborne coating containing the nano oxide inorganic coated phosphite powder. The waterborne coating is prepared by emulsion base materials, water, the nano oxide inorganic coated phosphite powder, auxiliary pigment, filler, pH regulator and auxiliaries. The nano oxide inorganic coated phosphite powder has the advantages that the phosphite is modified through inorganic coating to increase the dispersing performance and application performance of the phosphite so as to allow the phosphite to be applicable to materials such as ink, plastics, rubber, papermaking and coating, the corrosion resistance, thermal stability, aging resistance, weather resistance and the like of the corresponding materials are increased, and the service life of the corresponding materials is prolonged.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

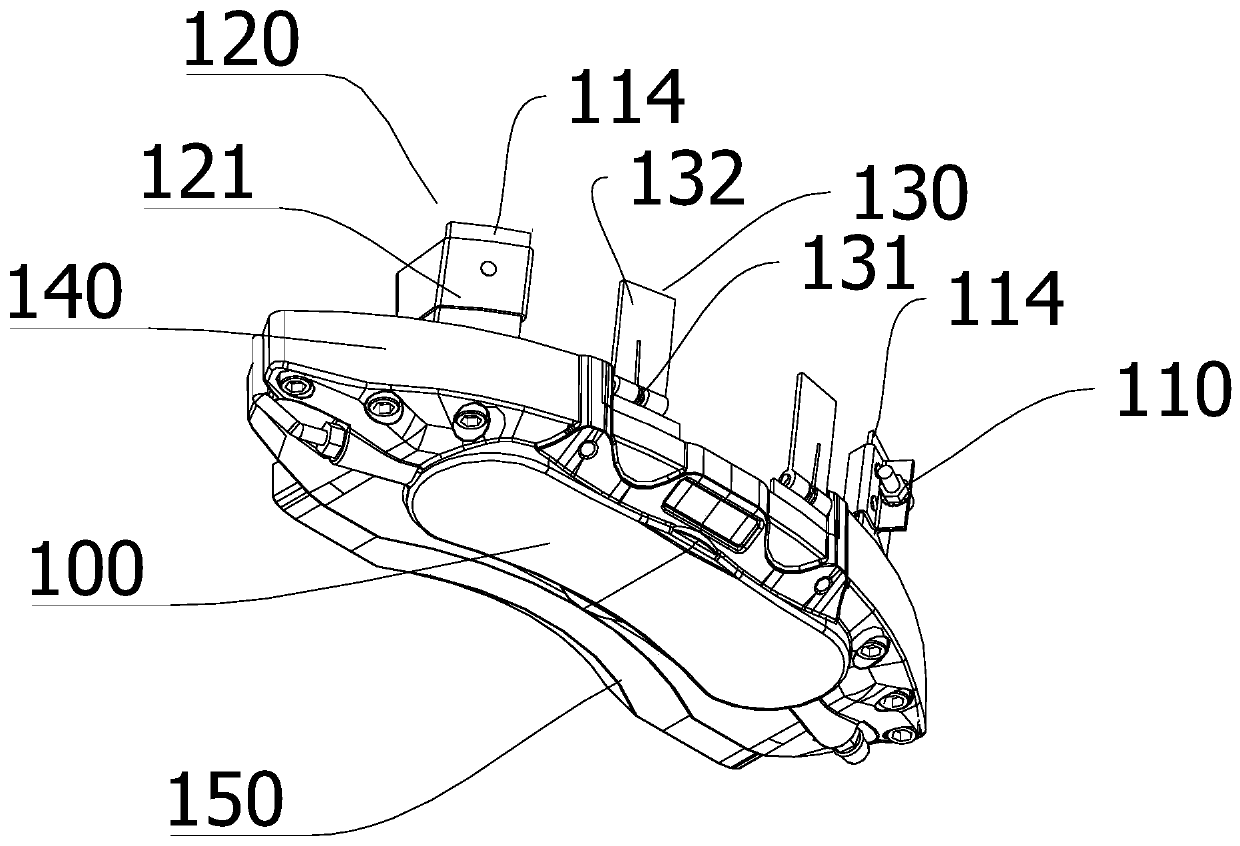

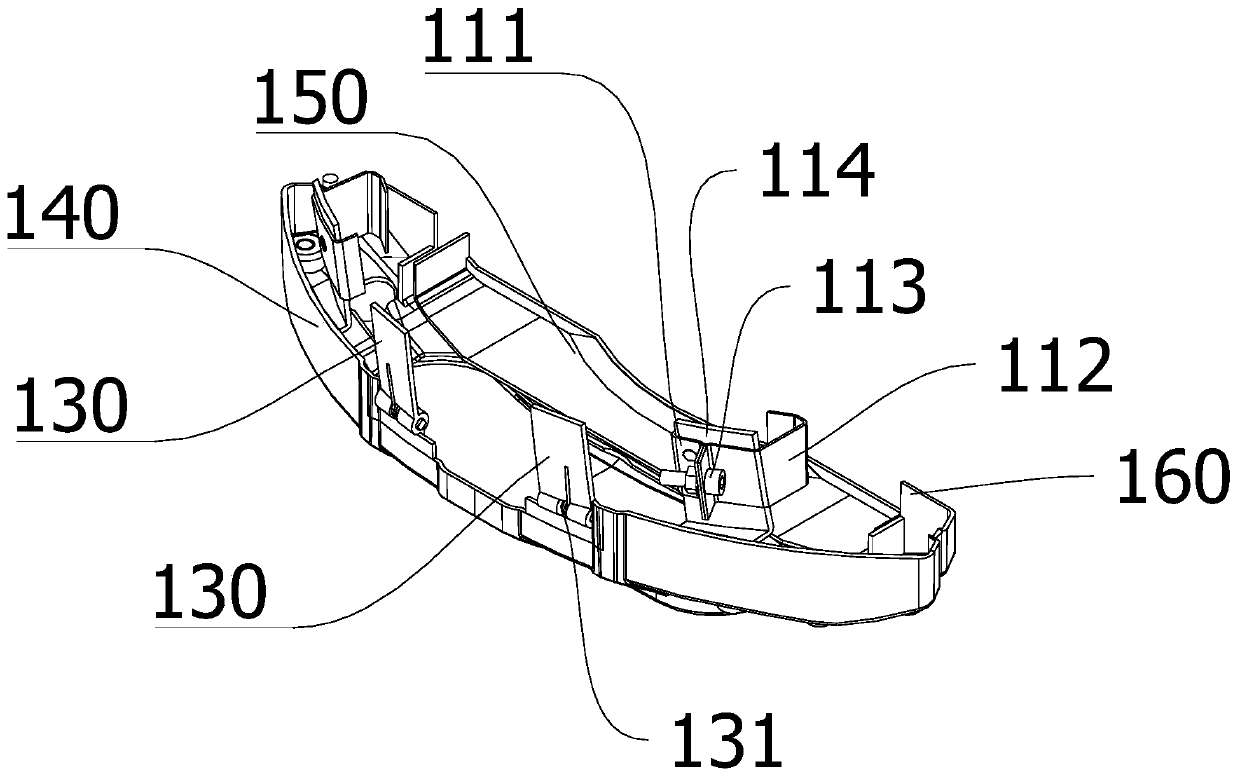

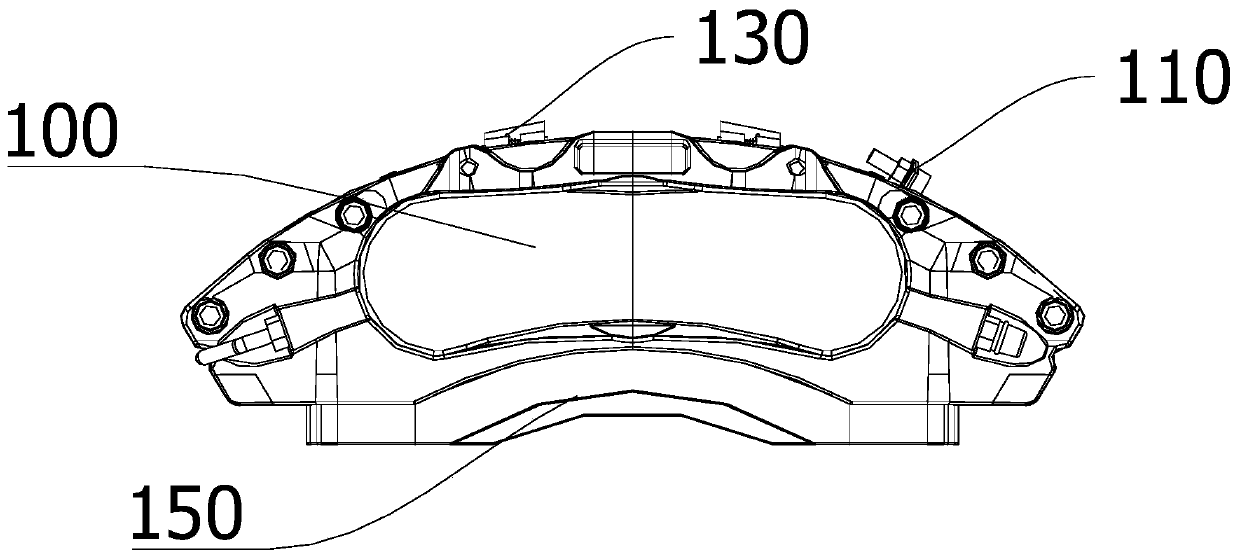

Heat dissipation type car caliper cover

PendingCN110388396ADissipate quicklyEasy to fixInternal combustion piston enginesAxially engaging brakesEngineeringCalipers

The embodiment of the invention provides a heat dissipation type car caliper cover. The car caliper cover comprises a cover body and a fixing part for fixing the cover body to car calipers. A first arc-shaped side plate is arranged on the outer side of the cover body, and a second arc-shaped side plate is arranged on the inner side of the cover body. The fixing part is arranged on the first arc-shaped side plate. A heat transfer assembly is arranged on the first arc-shaped side plate. The heat transfer assembly comprises an elastic pressing sheet and a silica gel sheet arranged on the elasticpressing sheet. When the cover plate is fixed to the car calipers, the silica gel sheet and the outer side wall of a pump body of the car calipers can be in contact through the elastic pressing sheet,and heat can be conducted to the cover body for heat dissipation. According to the heat dissipation type car caliper cover, by arranging the heat transfer assembly on the first arc-shaped side plate,heat transfer is carried out through the elastic pressing sheet and the silica gel sheet, and heat generated by the caliper piston pump body can be fast dissipated.

Owner:张建平

Matt coating paint

InactiveCN104387822AImprove water resistanceImprove insulation performanceCoatingsPolyvinyl butyralMethacrylate

The invention relates to a paint and particularly relates to a matt coating paint. The matt coating paint is prepared from the following components in percentage by weight: 35-45% of modified alkyd resin, 20-30% of tung oil, 10-16% of an epoxy resin composition, 2-5% of terephthalic acid, 12-16% of palm kernelate, 5-8% of ethyl methacrylate, 1-3% of matt acrylic paint, 5-10% of polyvinyl butyral, 3-5% of a defoaming agent, 2-4% of an emulsifying agent and the balance of a paint thinner. A high net structure formed by drying a painted film is less in possibility of ageing, soft and firm, friction-resistant, good in water resistance, alkali-resistant, dampness-heat-resisting, mildew-resisting, excellent in salt spray resistance, mineral-oil-resisting and good in alcohol solvent resistance.

Owner:青岛市市南区隆德中医药研究所

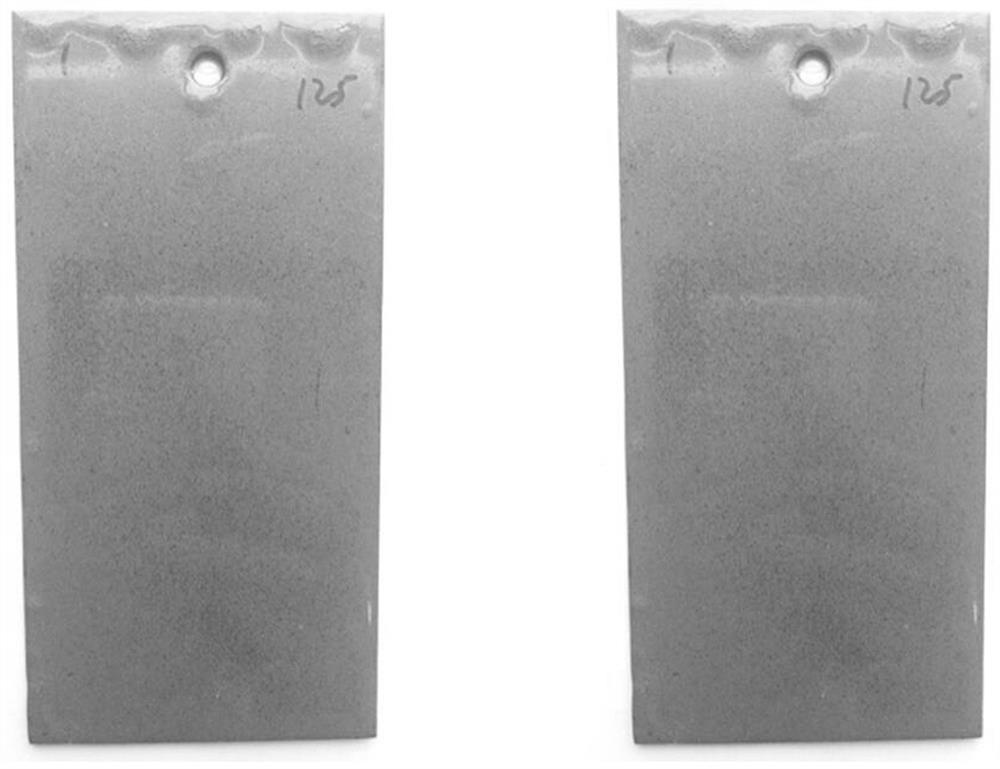

Preparation method of low-temperature curing environment-friendly water-based chromium-zinc-aluminum-free coating

ActiveCN114410221ALow curing temperatureStrong adhesionAnti-corrosive paintsMeth-Low temperature curing

The invention relates to a preparation method of a coating, in particular to a preparation method of a low-temperature curing environment-friendly water-based chromium-zinc-aluminum-free coating, and the prepared low-temperature curing environment-friendly water-based chromium-zinc-aluminum-free coating is free of hexavalent chromium, lead, mercury and cadmium heavy metal ionic compounds and free of volatile toxic solvents such as benzene and xylene. The low-temperature curing environment-friendly water-based chromium-zinc-aluminum-free coating is prepared from the following components in parts by weight: 4 to 20 parts of flaky aluminum powder, 15 to 40 parts of flaky zinc powder, 0.5 to 4 parts of an emulsifying agent, 5 to 25 parts of a dispersing agent, 5 to 20 parts of a cosolvent, 5 to 20 parts of methyltrimethoxysilane (MTMS), 3 to 10 parts of polydopamine, 0.1 to 3 parts of a corrosion inhibitor, 0.01 to 1 part of a thickening agent, 10 to 50 parts of deionized water and 0.01 to 1 part of a de-foaming agent. Under the condition that the stability of the coating and the salt spray performance of the coating are not influenced, the coating also has the characteristics of low-temperature curing, energy conservation, environmental protection, relatively strong adhesive force and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Water soluble low-temperature-solidification appliance insulating varnish and preparation method thereof

The invention discloses a water soluble low-temperature solidification appliance insulating varnish and a preparation method thereof. The water soluble low-temperature solidification appliance insulating varnish comprises a low-temperature latent initiator, wherein the low-temperature latent initiator accounts for 0.10 to 1.5 percent of the total weight of the water soluble low-temperature solidification appliance insulating varnish; and the low-temperature latent initiator is benzoyl peroxide. The preparation method comprises the following steps of: firstly, uniformly mixing acrylic ester, organic silicon resin, polyalcohol, the low-temperature latent initiator and 50 percent de-ionized water with slowly stirring at room temperature; secondly, adding a flatting agent, a curing agent, a defoamer and the other 50 percent de-ionized water in sequence and still stirring slowly; and finally, adding solution of alkylol amine dropwise, and adjusting pH to 8.0 to 9.0 to obtain the required product. When the preparation method is implemented, the baking, solidification and film molding temperature of the varnish is as low as only 80 to 90 DEG C; and a varnish film has high adhesion, high humidity, heat and slat-fog resistance and high water solubility and produces no harmful gas in use.

Owner:深圳市东方亮化学材料有限公司

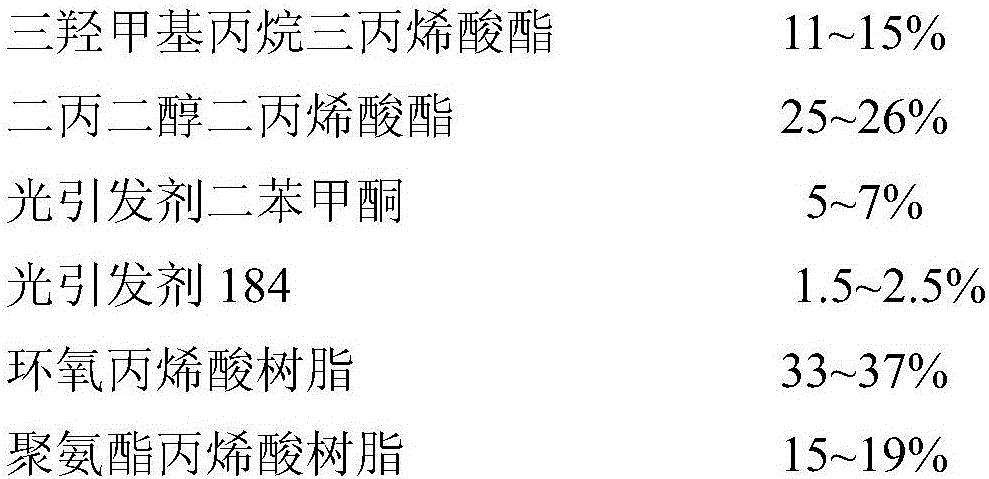

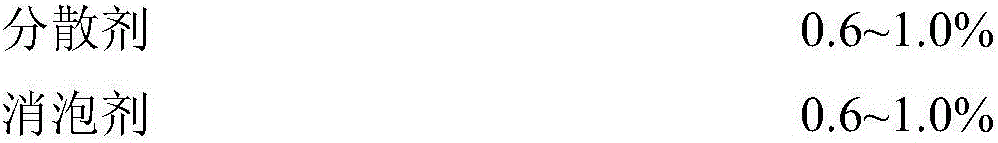

Surface treatment method of plastic parts

ActiveCN105820361ASimple processReduce energy consumptionVacuum evaporation coatingSputtering coatingWastewaterWork in process

The invention relates to a surface treatment method of plastic parts. The surface treatment method comprises the following steps: 1) cleaning the surface of a workpiece; 2) spraying a first organic coating; 3) putting the workpiece into an infrared furnace to carry out leveling drying; 4) putting the workpiece into an ultraviolet curing oven to carry out curing by ultraviolet radiation; 5) hanging the workpiece to a PVD (Plating Vacuum Deposition) furnace, carrying out vacuum evaporation and plating aluminum films to obtain a semi-finished product of which the surface is silver and bright; 6) spraying a second organic coating to the semi-finished product; 7) putting the workpiece into the infrared furnace to carry out pre-drying leveling; 8) putting the workpiece into the ultraviolet curing oven to obtain a finished product. According to the invention, the technological process is simple, the energy consumption is low, zero discharge of wastewater is realized in the whole process, and the pollution to the surrounding environment is avoided; furthermore, the raw materials are low in price and easy to purchase, and no obvious differences occur between the appearance and performances of the coating and the appearance and performances of an electroplating chromium product, and the coating has good corrosion resistance, excellent salt fog performances and higher level in comparison with the traditional plating SC4, so as to be especially suitable for harsh environments of bathrooms and the like.

Owner:NINGBO RUNNER INDAL CORP

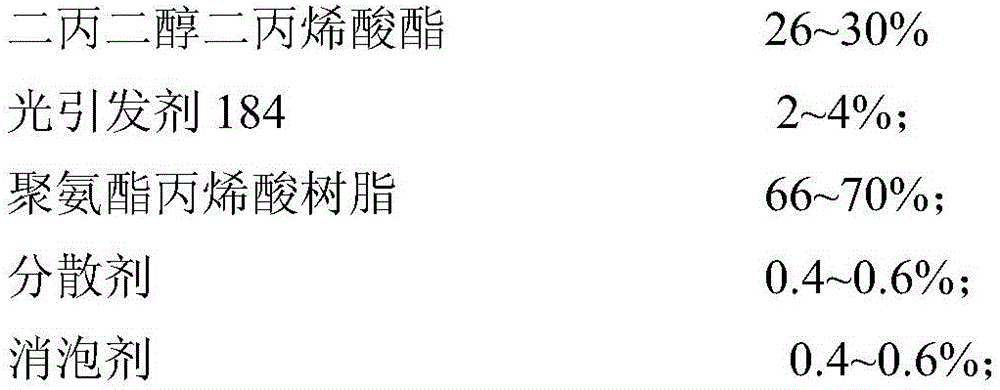

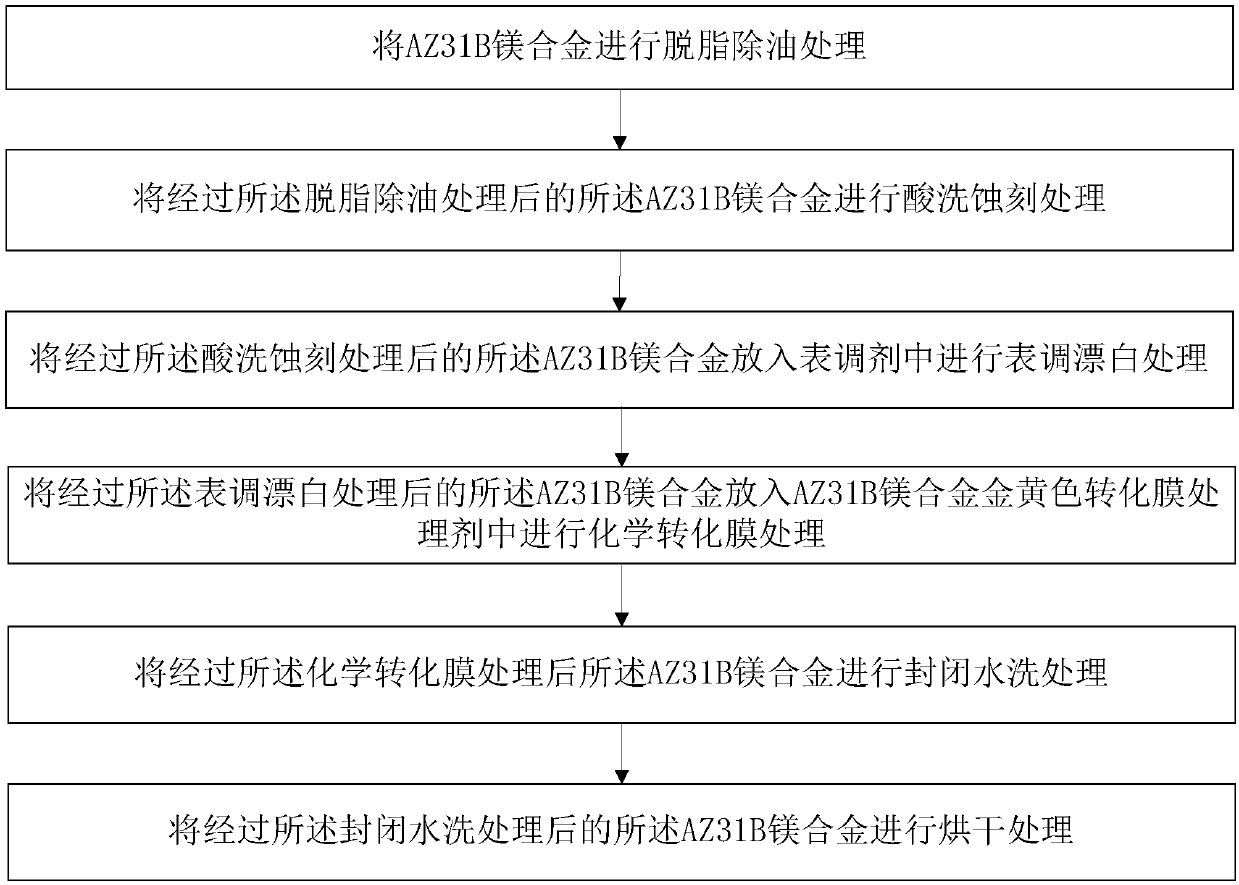

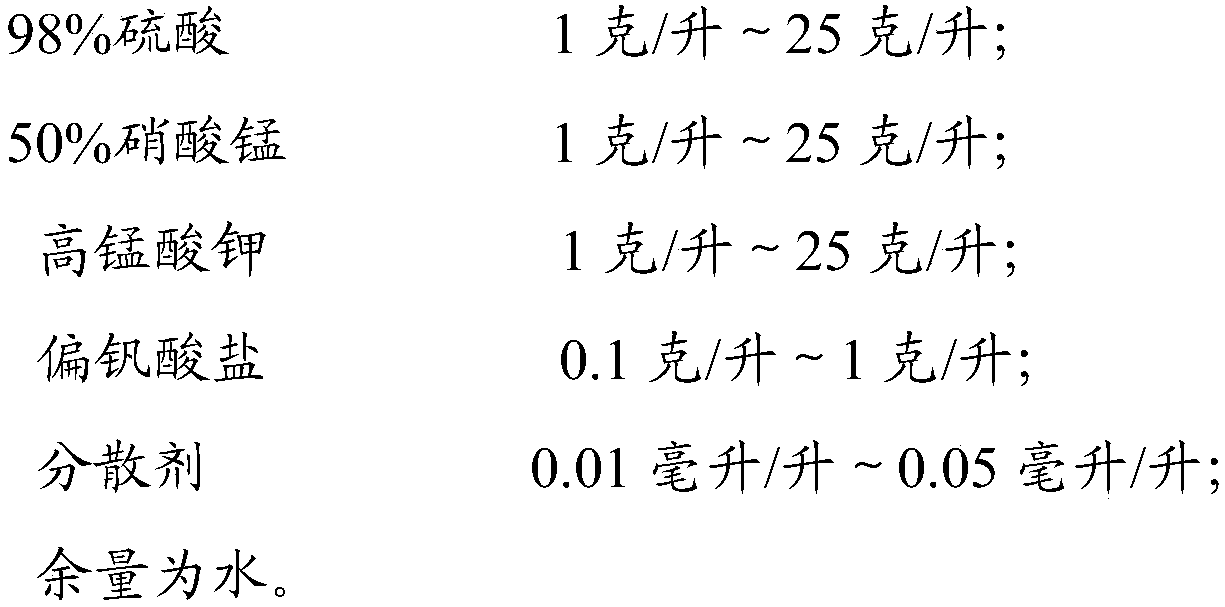

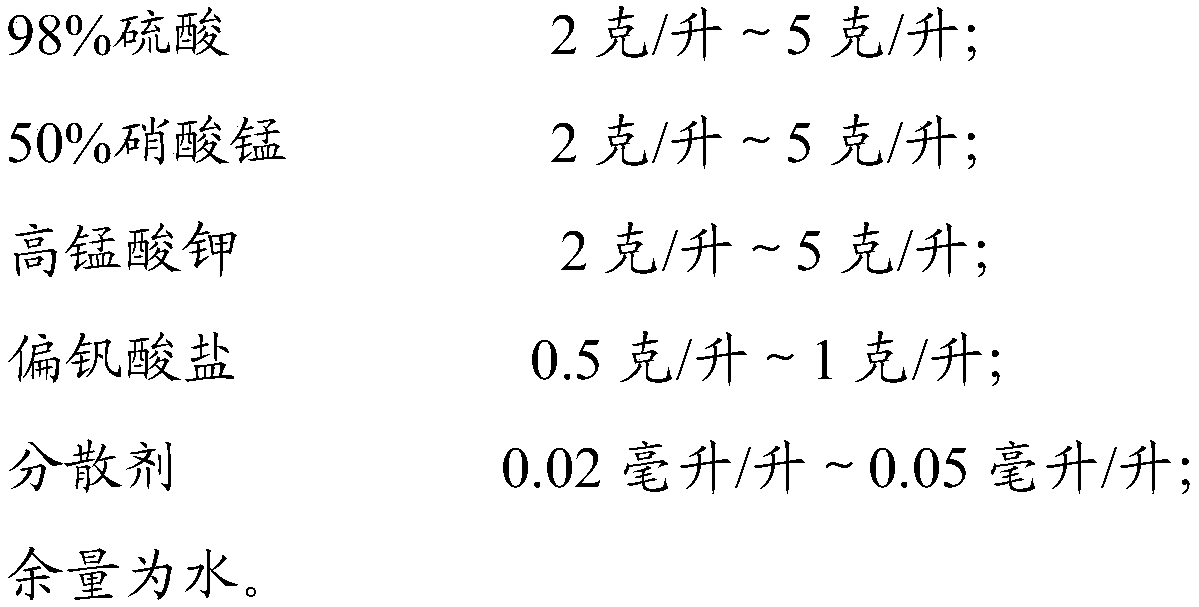

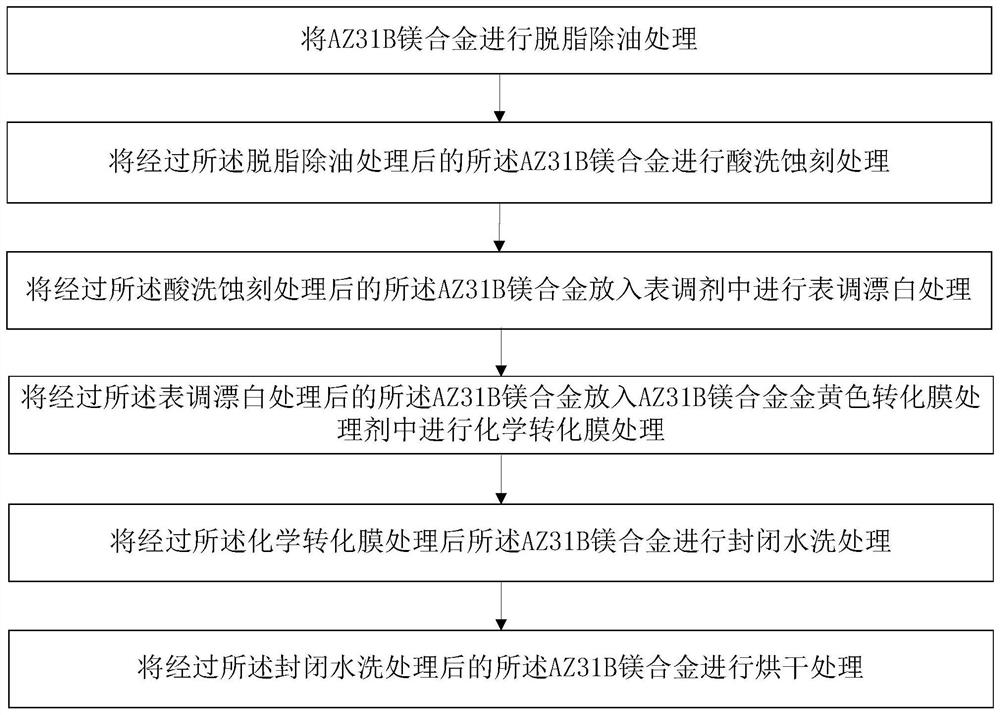

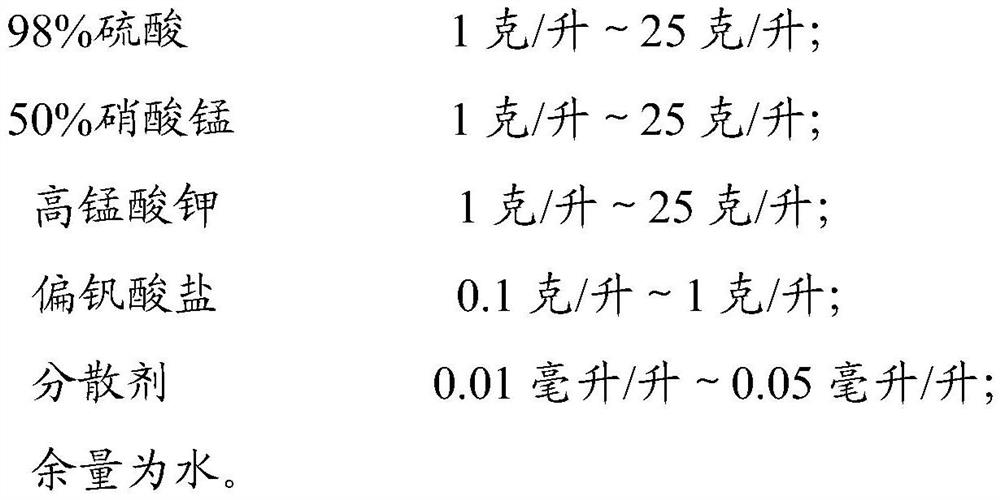

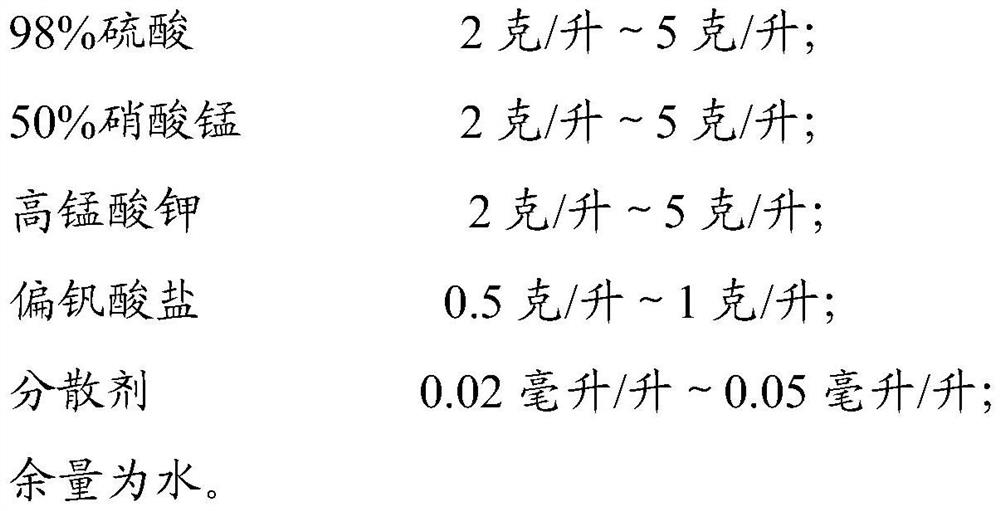

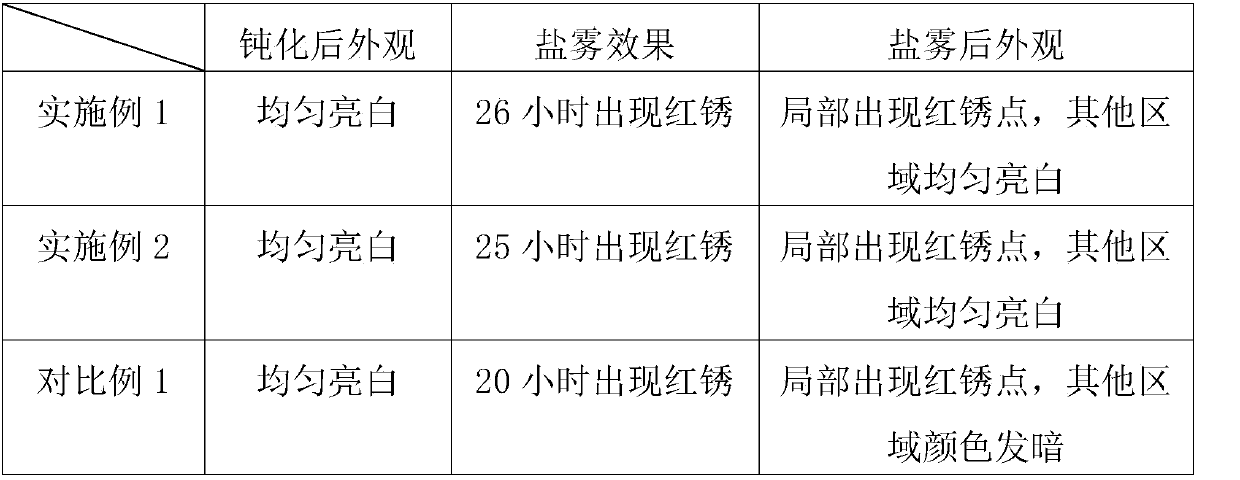

AZ31B magnesium alloy golden conversion film treatment agent and AZ31B magnesium alloy surface treatment method

ActiveCN109536941AImprove corrosion resistanceImprove adhesionMetallic material coating processesNitrateManganese

The invention discloses an AZ31B magnesium alloy golden conversion film treatment agent and an AZ31B magnesium alloy surface treatment method. The AZ31B magnesium alloy golden conversion film treatment agent comprises components with the following concentrations: 1-25 g / l of 98% of sulfuric acid, 1-25 g / l of 50% of manganese nitrate, 1-25 g / l of potassium permanganate, 0.1-1 g / l of metavanadate, 0.01-0.05 ml / l of dispersing agent, and the balance of water. After the AZ31B magnesium alloy golden conversion film treatment agent is applied to the surface treatment of AZ31B magnesium alloys, golden conversion films can be formed on the surfaces of the AZ31B magnesium alloys, so that the corrosion resistance of the AZ31B magnesium alloys can be improved. The formed golden conversion films havethe advantages of good adhesion, good salt mist performance and good film forming uniformity. In addition, the AZ31B magnesium alloy golden conversion film treatment agent contains no phosphorus and chromium, so that the problem of environmental pollution caused by common use of phosphorus and chromium in traditional alloy treatment agents is prevented, no environmental pollution is generated, andthe environmental protection is better.

Owner:广东东明新材科技有限公司

Calcium phosphate-based cement potting material and preparation method thereof

The invention provides a calcium phosphate-based cement potting material. Nano polyimide fibers are uniformly distributed in calcium phosphate-based cement, wherein the mass fraction of the nano polyimide fibers is 1%-10%. Calcium phosphate-based cement is used as a basic packaging material, so that the cost is reduced. The cost of the cement is lower than that of any existing system; the potting material system is resistent to high temperature and can resist a high temperature of 350 DEG C; the nano polyimide fibers are added, so that the hydration process of the cement is improved, and the porosity is reduced; after the cement is finally set, the water mist and salt mist resistance of the cement is improved while the possibility of crack formation is reduced.

Owner:GUANGHUA LINGANG ENG APPL & TECH R&D (SHANGHAI) CO LTD

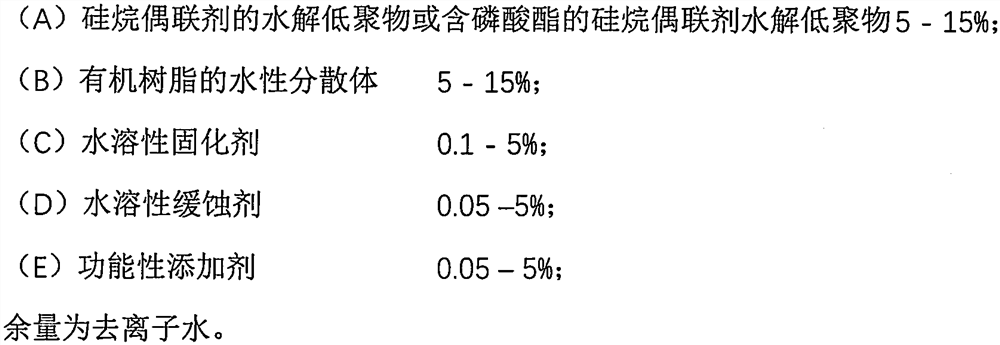

Chromium-free passivation composite used for galvanized steel and capable of being dried at medium and low temperatures and preparing and using methods thereof

InactiveCN112301341AGood resistance to salt sprayFast Film Formation and CuringMetallic material coating processesChromium freeProduction line

Owner:SHANGHAI XINGYU ECOSIL SURFACE MATERIAL

Az31b magnesium alloy golden yellow conversion coating treatment agent and az31b magnesium alloy surface treatment method

ActiveCN109536941BImprove corrosion resistanceImprove adhesionMetallic material coating processesAlloyPolluted environment

The invention discloses an AZ31B magnesium alloy golden conversion film treatment agent and an AZ31B magnesium alloy surface treatment method. The AZ31B magnesium alloy golden conversion film treatment agent comprises components with the following concentrations: 1-25 g / l of 98% of sulfuric acid, 1-25 g / l of 50% of manganese nitrate, 1-25 g / l of potassium permanganate, 0.1-1 g / l of metavanadate, 0.01-0.05 ml / l of dispersing agent, and the balance of water. After the AZ31B magnesium alloy golden conversion film treatment agent is applied to the surface treatment of AZ31B magnesium alloys, golden conversion films can be formed on the surfaces of the AZ31B magnesium alloys, so that the corrosion resistance of the AZ31B magnesium alloys can be improved. The formed golden conversion films havethe advantages of good adhesion, good salt mist performance and good film forming uniformity. In addition, the AZ31B magnesium alloy golden conversion film treatment agent contains no phosphorus and chromium, so that the problem of environmental pollution caused by common use of phosphorus and chromium in traditional alloy treatment agents is prevented, no environmental pollution is generated, andthe environmental protection is better.

Owner:广东东明新材科技有限公司

Passivant for nickel plating and nickel plating passivation method

InactiveCN109652831AExcellent salt spray performanceMetallic material coating processesAlcoholOleic Acid Triglyceride

The invention provides a passivant for nickel plating and with the good salt fog effect and a nickel plating passivation method. The passivant for nickel plating comprises, by weight part, 0.1 to 5 parts of oleic acid, 0.1 to 5 parts of absolute ethyl alcohol and 0.1 to 5 parts of triethanolamine. The oleic acid is vegetable oleic acid. The passivant for nickel plating and the nickel plating passivation method have the good salt fog effect.

Owner:广州传福化学技术有限公司

Metal piece surface imitative copper plating technique

ActiveCN105038507ASimple processReduce energy consumptionAnti-corrosive paintsEpoxy resin coatingsCopper platingTactile sensation

The invention relates to a metal piece surface imitative copper plating technique which is characterized by comprising the following steps: 1) carrying out shot blasting treatment on the metal piece surface to remove surface burr and oil stains; 2) spraying a purpose-made primer on the treated substrate surface; 3) baking the primer-coated workpiece at 150-160 DEG C for 15-25 minutes to obtain a workpiece of which the primer dry film thickness is 20-30 mu m; 4) spraying a purpose-made imitative electroplating real copper finish paint on the primer dry film surface; and 5) baking the workpiece coated with the finish paint at 150-160 DEG C for 15-25 minutes to obtain the finish paint dry film of which the thickness is 10-15 mu m. The metal piece surface treatment method provided by the invention has the advantages of simple technical process, low energy consumption and no wastewater discharge in the overall process, and avoids polluting the surrounding environment. The raw materials are low in price and easy to purchase. The appearance and properties of the coating has the tactile sensation of the copper plating product. The coating has favorable corrosion resistance and excellent salt mist resistance.

Owner:NINGBO RUNNER INDAL CORP

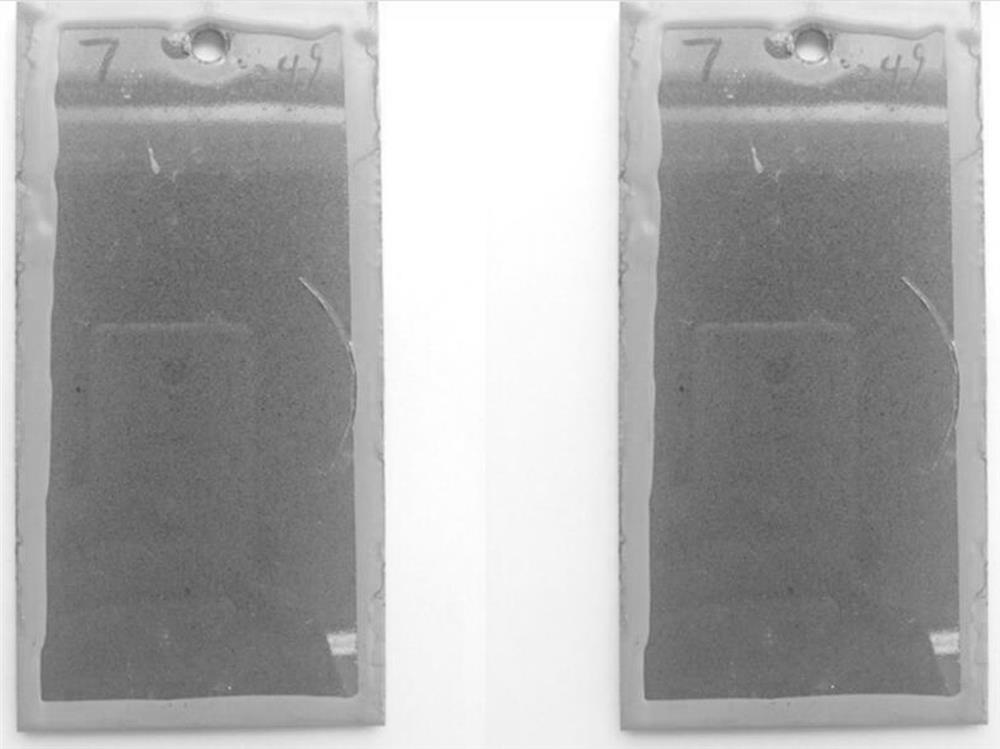

Water-based amino baking varnish for galvanized sheets and preparation method thereof

InactiveCN111205751AImprove performanceGood flexibilityAnti-corrosive paintsPolyester coatingsEpoxyFumed silica

The invention provides water-based amino baking varnish for galvanized sheets and a preparation method thereof. The water-based amino baking varnish is prepared from the following raw materials in parts by weight: 20-35 parts of an aqueous polyester resin, 4 to 8 parts of a water-based amino resin; 5-10 parts of titanium dioxide, 1-3 parts of carbon black, 10-15 parts of barium sulfate, 3 to 5 parts of epoxy modified wollastonite; 0.1 to 0.3 part of bentonite, 0.5 to 1 part of fumed silica, 8 to 15 parts of an alcohol ether auxiliary agent, 1 to 2 parts of a dispersant, 0.5 to 0.8 part of an antifoaming agent, 0.3 to 0.5 part of a wetting agent, 0.3 to 0.5 part of a leveling agent, 1 to 1.5 parts of an amine neutralizer, 0.3 to 0.8 part of an anti-sagging auxiliary agent, 0.5 to 1 part ofan adhesion promoter and 30 to 50 parts of deionized water. The baking varnish has the advantage of high adhesive force on galvanized plates, and can effectively improve the corrosion resistance of the galvanized plates.

Owner:山东七维新材料有限公司

Oil paint having red fluorescent material

InactiveCN105505150AImprove water resistanceNot easy to ageAntifouling/underwater paintsLuminescent paintsMethacrylateEpoxy

The invention relates to a coating, and particularly relates to oil paint having a red fluorescent material. The oil paint comprises the following components by weight percent: 5 to 5.5 percent of barium sulfate, 3 to 4 percent of magnesium sulfate, 1.5 to 2.2 percent of lithium phosphate, 2 to 3 percent of copper nitrate, 35 to 45 percent of modified alkyd resin, 20 to 30 percent of tung oil, 10 to 16 percent of epoxy resin composition, 2 to 5 percent of terephthalic acid, 12 to 16 percent of palm kernel ester, 5 to 8 percent of ethyl methacrylate, 1 to 3 percent of matte acrylic paint, 5 to 10 percent of polyvinyl butyral, 3 to 5 percent of defoaming agent, 2 to 4 percent of emulsifier and the balance of paint thinner. The oil paint can absorb light and can emit red light in a dark environment, a paint film forms a highly netted structure after being dried and is unlikely to age, and the paint film is flexible and firm, resistant to abrasion, good in water resistance, excellent in alkali resistance, dampness and heat resistance, mildew resistance and salty fog resistance, good in mineral oil resistance and alcohol solvent resistance and applicable to objects such as billboards, street advertisements, night roads and barrier markers and the like.

Owner:QINGDAO BEIDOUXINGYUN COMM TECH CO LTD

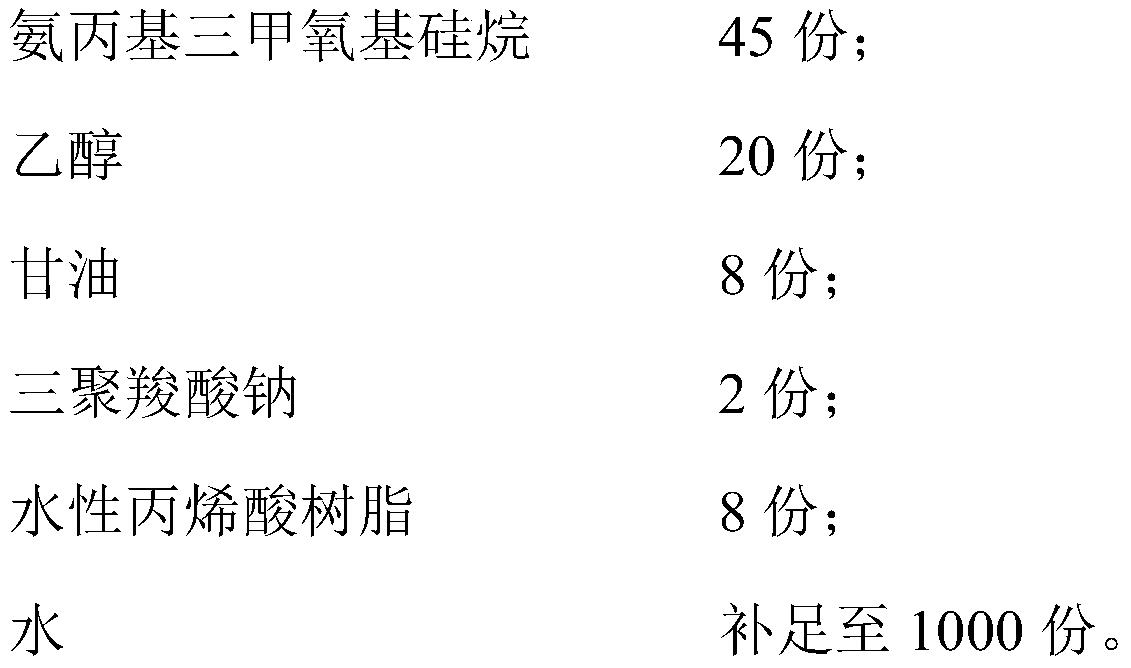

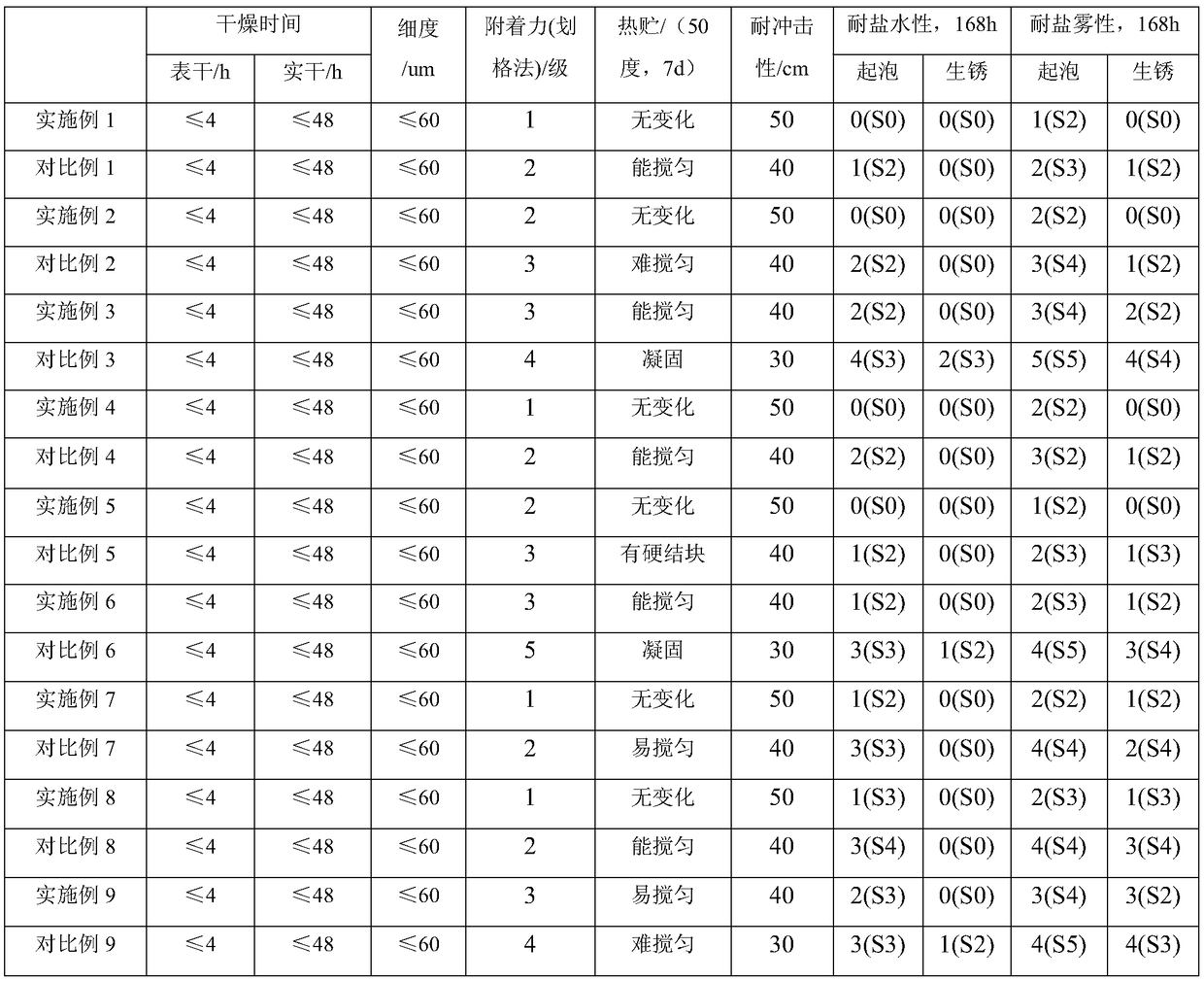

Neutral silane treating agent and preparation method and application thereof

ActiveCN112553613AImprove corrosion resistanceExcellent salt spray performanceMetallic material coating processesSilanesAccelerant

The invention discloses a neutral silane treating agent and a preparation method and application thereof, and relates to the technical field of metal corrosion prevention. Every 1000 parts of raw materials comprise the following components in parts by weight: 0.1-100 parts of a silane coupling agent, 0.1-30 parts of an oxidizing agent, 0.1-20 parts of a sealing agent, 0.1-20 parts of an adhesion promoter and the balance water. The neutral silane treating agent is excellent in corrosion resistance and good in salt spray performance. After the neutral silane treating agent is sprayed, the impact, grid drawing and bending properties of a workpiece are good. The neutral silane treating agent does not contain any heavy metals or harmful substances, does not contain acid-base components, and isenvironmentally friendly. A use method of the neutral silane treating agent is simple, heating is not needed during use, energy loss can be effectively reduced, operation is easy and convenient, and the treatment time can be shortened.

Owner:佛山市顺德区美硕金属表面技术有限公司

A method for surface treatment of plastic parts

ActiveCN105820361BSimple processReduce energy consumptionVacuum evaporation coatingSputtering coatingVacuum evaporationPollution

The invention relates to a surface treatment method of plastic parts. The surface treatment method comprises the following steps: 1) cleaning the surface of a workpiece; 2) spraying a first organic coating; 3) putting the workpiece into an infrared furnace to carry out leveling drying; 4) putting the workpiece into an ultraviolet curing oven to carry out curing by ultraviolet radiation; 5) hanging the workpiece to a PVD (Plating Vacuum Deposition) furnace, carrying out vacuum evaporation and plating aluminum films to obtain a semi-finished product of which the surface is silver and bright; 6) spraying a second organic coating to the semi-finished product; 7) putting the workpiece into the infrared furnace to carry out pre-drying leveling; 8) putting the workpiece into the ultraviolet curing oven to obtain a finished product. According to the invention, the technological process is simple, the energy consumption is low, zero discharge of wastewater is realized in the whole process, and the pollution to the surrounding environment is avoided; furthermore, the raw materials are low in price and easy to purchase, and no obvious differences occur between the appearance and performances of the coating and the appearance and performances of an electroplating chromium product, and the coating has good corrosion resistance, excellent salt fog performances and higher level in comparison with the traditional plating SC4, so as to be especially suitable for harsh environments of bathrooms and the like.

Owner:NINGBO RUNNER INDAL CORP

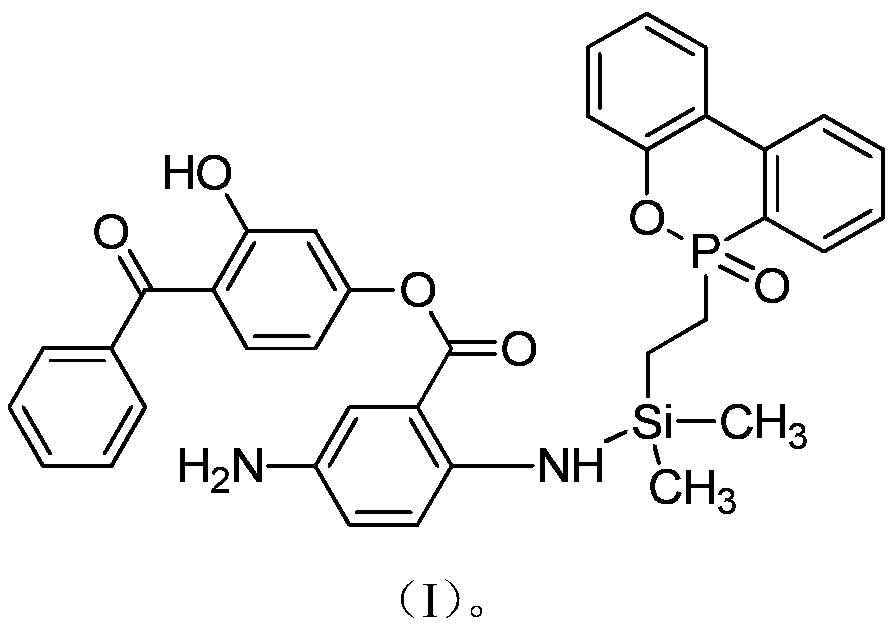

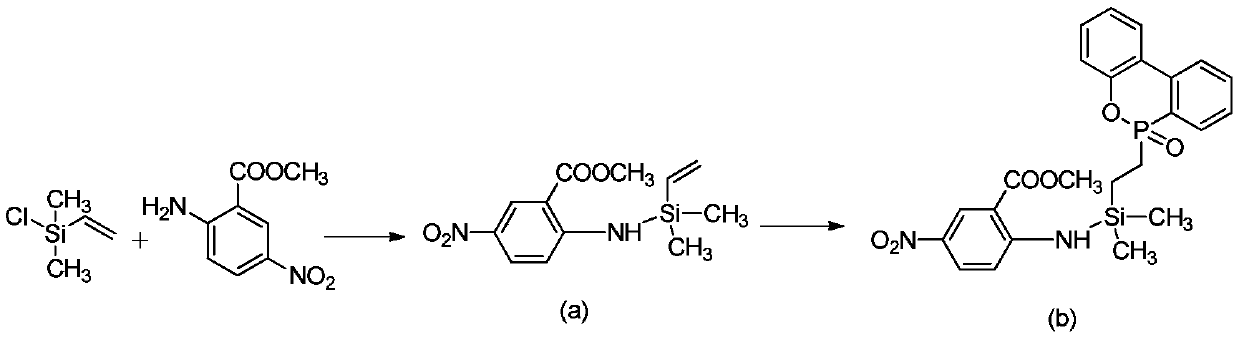

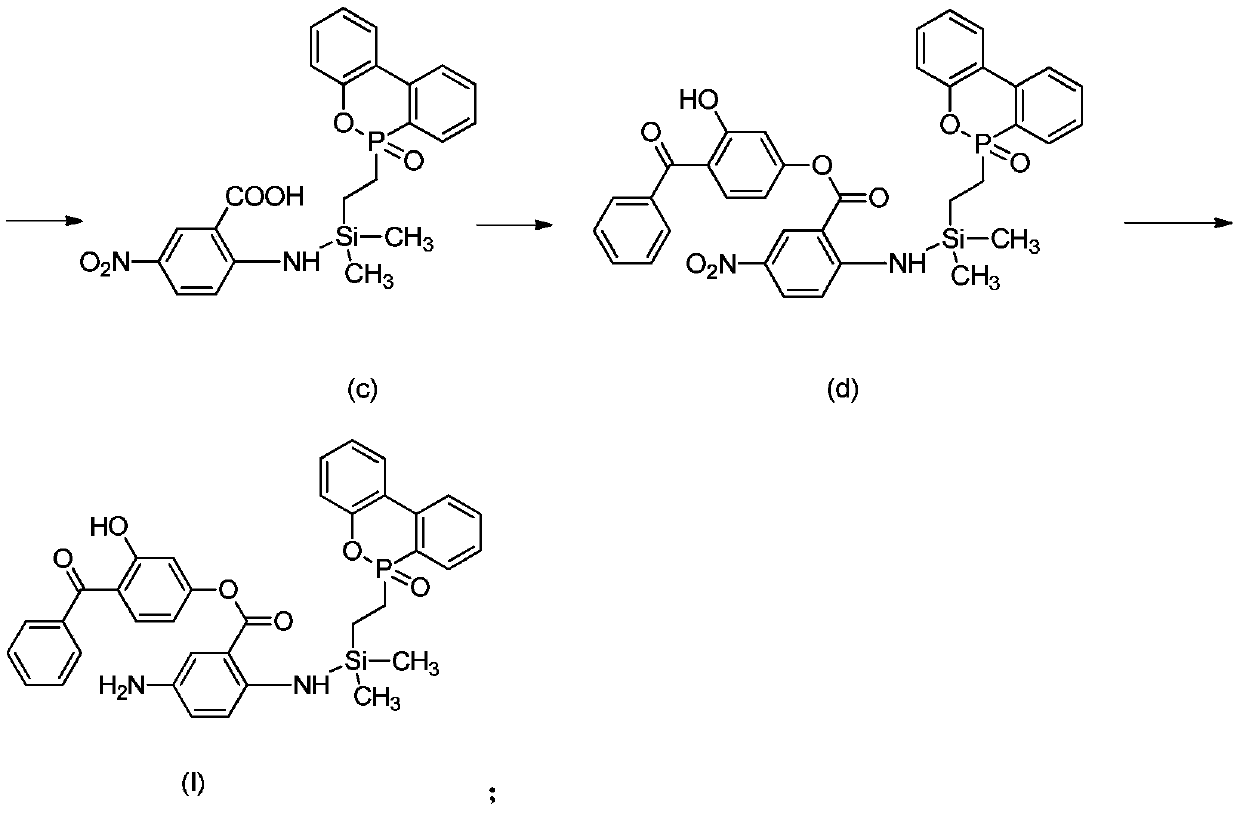

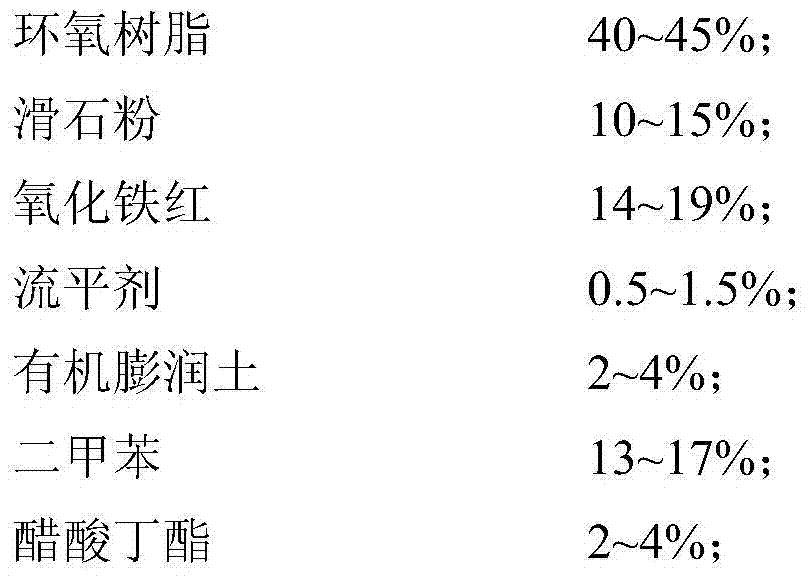

Curing agent for high-solid water-based coating

The invention provides a curing agent for a high-solid water-based coating. The curing agent comprises, by weight, 1 part of a compound represented by formula (I), 2-3 parts of trimethylolpropane triglycidyl ether, 2-3 parts of dimethylethanolamine and 1-2 parts of chitosan. The curing agent allows the water-based epoxy coating with ultralow VOC and high solid content to be obtained, and the coating has the advantages of simple formula and low cost, no addition of a wetting agent or a dispersing agent, direct dilution of an epoxy emulsion with water, excellent salt spray performance, easinessin being thickened, good anti-sagging performance, adjustment of the drying speed according to the construction environment, low VOC, convenience in construction, avoiding of gun blocking and pipelineblocking, and convenience in cleaning.

Owner:上海瀚岱化学有限公司

A process of imitating copper plating on the surface of metal parts

ActiveCN105038507BSimple processReduce energy consumptionAnti-corrosive paintsEpoxy resin coatingsWater dischargeCopper plating

The invention relates to an imitation copper plating process on the surface of metal parts, which is characterized in that it comprises the following steps: 1) carrying out shot blasting treatment on the surface of metal parts to remove burrs and oil stains on the surface; 2) spraying a 3) Bake the primer-coated workpiece at 150-160°C for 15-25 minutes to obtain a workpiece with a primer dry film thickness of 20-30μm; 5) Bake the coated workpiece at 150-160° C. for 15-25 minutes to obtain a dry film thickness of 10-15 μm. The metal parts surface treatment method provided by the present invention has simple technological process, low energy consumption, no waste water discharge in the whole process, and avoids pollution to the surrounding environment; moreover, the price of raw materials is low, easy to purchase, and the appearance and performance of the coating are excellent The texture of electroplated copper products has good corrosion resistance and excellent salt spray performance.

Owner:NINGBO RUNNER INDAL CORP

Composition of high-corrosion-resistance blue zinc-nickel alloy passivator

InactiveCN111485265ALow costExcellent salt spray performanceMetallic material coating processesSodium sulfateSodium nitrite

The invention discloses a composition of a high-corrosion-resistance blue zinc-nickel alloy passivator. The composition comprises an agent A and an agent B. The agent A comprises cobalt salt, sodium salt and deionized water. The cobalt salt is a mixture of one or more kinds in cobalt nitrate, cobaltous sulfate, cobaltous sulfate and cobalt carbonate. The sodium salt in the agent A is a mixture ofone or more kinds in sodium selenite, sodium nitrate, sodium sulfate and sodium chloride. The agent B comprises chromium salt, alkali, acid, sodium salt and deionized water. The chromium salt in the agent B is a mixture of one or more kinds in chromic nitrate, chromic chloride and chromium sulfate. The alkali in the agent B is a mixture of one or more kinds in sodium hydroxide, potassium hydroxideand chromic hydroxide. The acid in the agent B is a mixture of one or more kinds in citric acid, citric acid, malonic acid, oxalic acid and ethane diacid. The sodium salt in the agent B is a mixtureof one or more kinds in sodium oxalate, sodium binoxalate, sodium citrate, sodium lactate and sodium sulfate.

Owner:常州新纪元材料科技有限公司

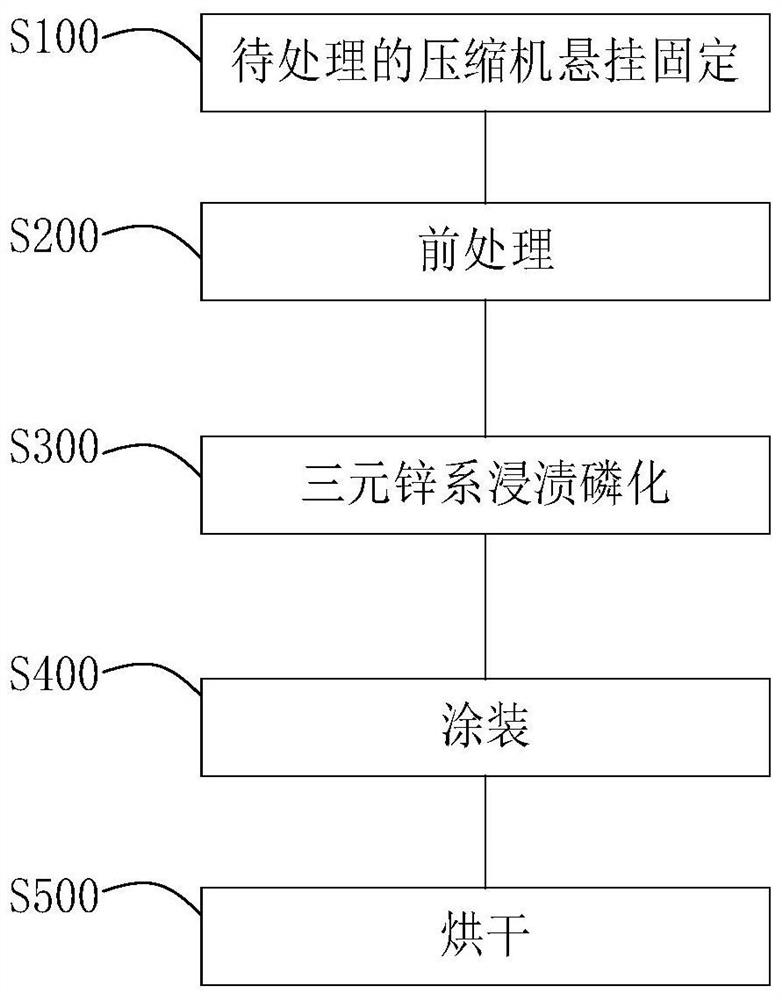

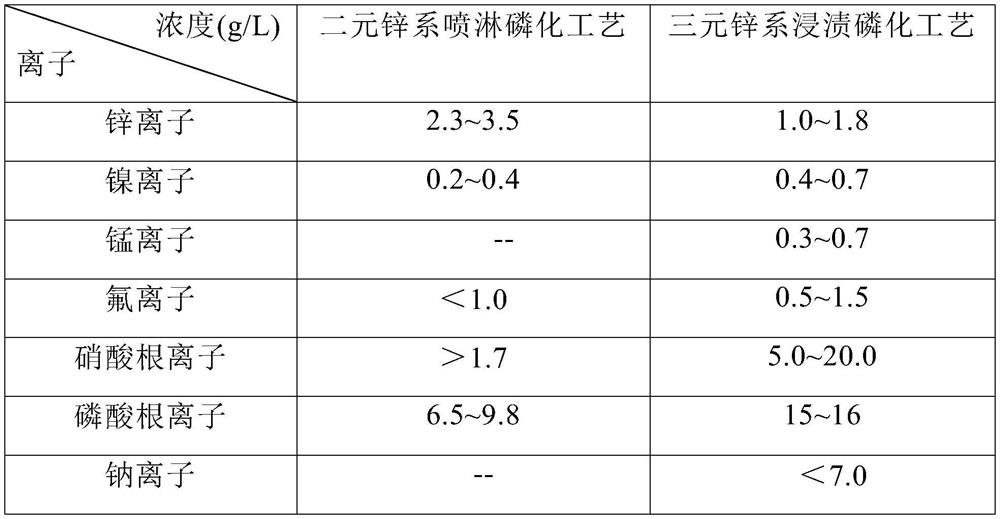

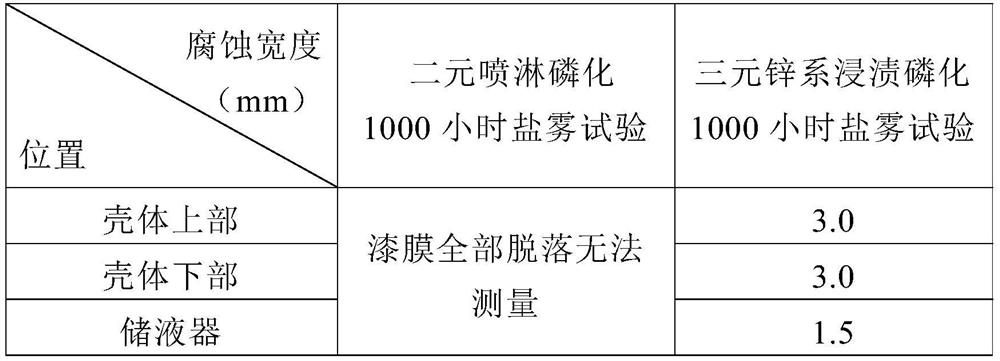

Compressor surface treatment method

PendingCN113088953AFind out whyExcellent salt spray performanceElectrophoretic coatingsMetallic material coating processesChemistryProcess engineering

The invention provides a compressor surface treatment method. The method comprises the steps that a compressor to be treated is suspended and fixed; a pretreatment procedure is executed, wherein the pretreatment procedure comprises a degreasing treatment procedure for removing oil stains on the surface of a shell of the compressor by using degreasing fluid and a surface conditioning treatment procedure; a dipping phosphating procedure is executed; an electrophoretic coating procedure is executed; and a drying procedure is executed. According to the compressor surface treatment method, an original spraying phosphating process of the compressor is replaced with the dipping phosphating process, the problem that a compact oxide layer formed on the surface of the shell due to a hot jacket process is difficult to remove is effectively solved, a phosphating film formed through dipping is more compact, and by combining the electrophoretic coating process, a formed compressor surface paint film has better salt spray resistance.

Owner:绵阳海立电器有限公司 +1

Structural component of electronic product and preparation method thereof and electronic product

InactiveCN110551931AExcellent salt spray performanceMetallic material coating processesTelephone set constructionsThiazoleSalt spray test

The invention discloses a structural component of an electronic product and a preparation method thereof and the electronic product. The preparation method for the structural component of the electronic product comprises the steps that (1) a copper alloy raw material composite is die-cast and molded, and a preliminary product of the structural component of the electronic product is acquired; and with the total weight of the copper alloy raw material composite as the benchmark, the copper alloy raw material composite comprises, by weight, 30-50% of copper, 25-40% of manganese, 4-6% of aluminum,10-17% of nickel, 0.01-10% of silicon and 0.001-0.03% of beryllium; (2) the preliminary product of the structural component of the electronic product is soaked in a protective agent solution, whereinthe protective agent comprises benzotriazole and 2-mercaptobenzothiazole; and (3) the structural component of the electronic product is acquired through surface treatment. The structural component ofthe electronic product can pass a salt spray test and is suitable for manufacturing electronic products with high surface accuracy requirements.

Owner:BYD CO LTD

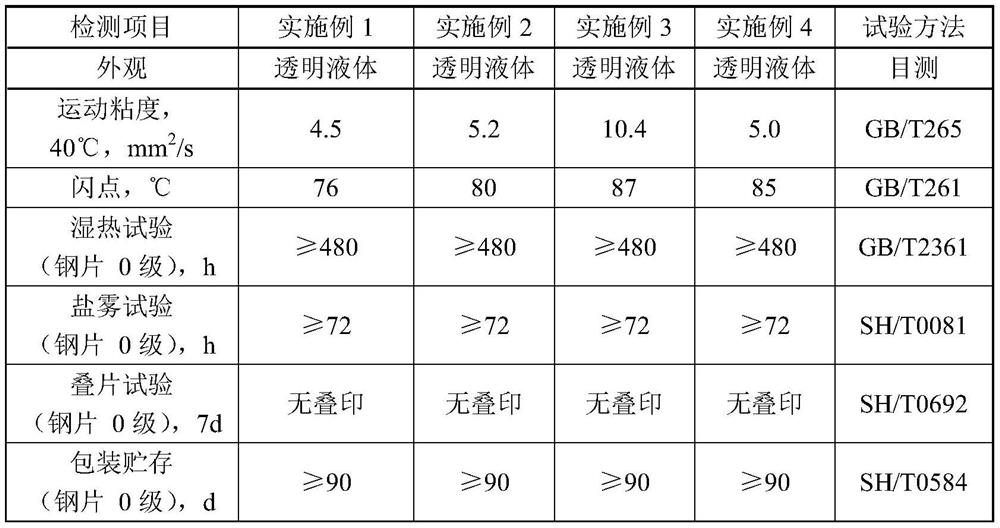

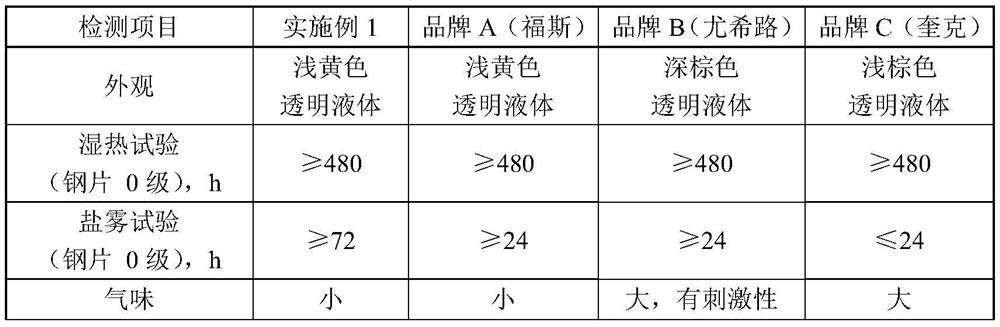

A kind of solvent-diluted antirust oil for bearings and preparation method thereof

ActiveCN109988663BImprove permeabilityHigh strengthLubricant compositionSaline mistPhysical chemistry

The invention relates to a solvent-diluted antirust oil for bearings and a preparation method thereof, belonging to the technical field of antirust oil. The solvent-diluted antirust oil for bearings of the present invention is composed of the following components in weight percent: 25% to 35% of base oil, 9% to 14% of antirust agent, 1% to 3% of spar, and 2% to 5% of film forming agent. %, the balance is solvent oil; the base oil is any one of transformer oil and L-AN total loss system oil. The solvent-diluted antirust oil for bearings of the present invention has low viscosity and strong permeability, and can meet the requirements of spray oiling and rapid dip coating for bearings and parts; it has good film-forming effect, high oil film strength, and good moisture and salt spray resistance. , which can meet the anti-rust requirements of bearing manufacturers in coastal areas; has good anti-overlapping properties, and is suitable for the packaging process of stacking bearings and parts; the appearance, smell, and anti-rust performance are better than imported products, and the price is far lower than imported products. It has broad market application prospects.

Owner:LUOYANG BEARING RES INST CO LTD

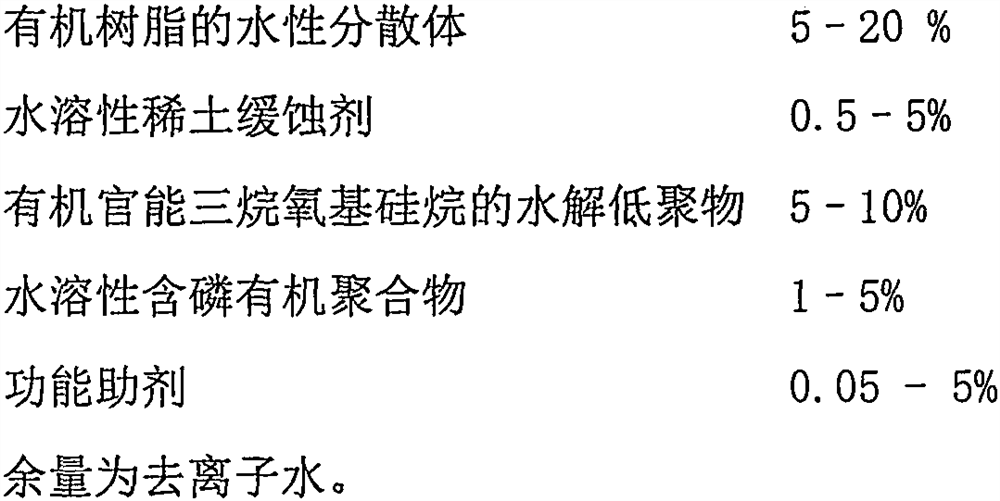

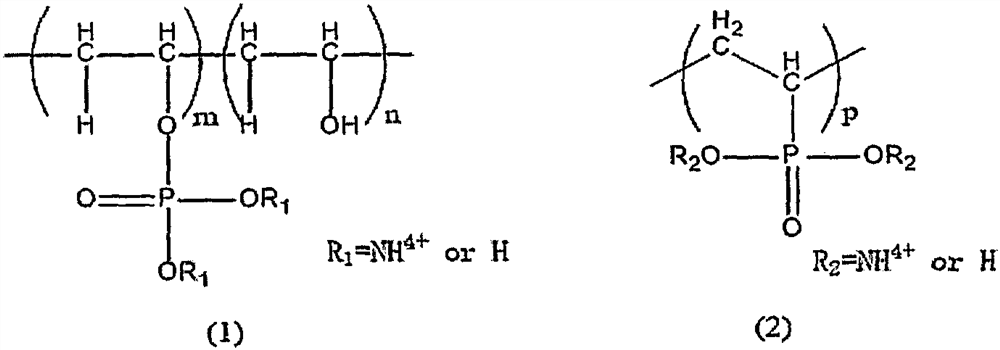

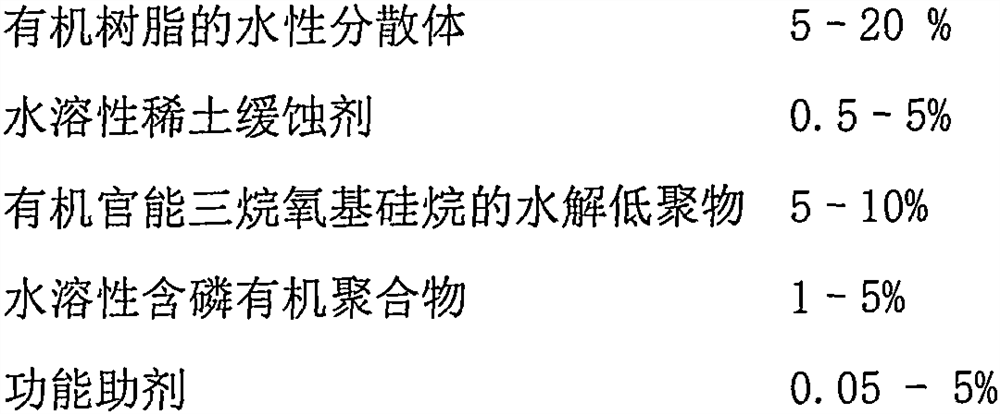

Chromium-free passivation composition for galvanized sheet and method for making and using the same

ActiveCN112301342BGood alkali resistanceExcellent salt spray performanceMetallic material coating processesChromium freeOligomer

The invention provides a chromium-free passivation composition for galvanized sheet and its production and use method, the composition includes water and the following components: aqueous dispersion of organic resin, water-soluble rare earth corrosion inhibitor, organic functional Hydrolyzed oligomers of trialkoxysilanes and water-soluble phosphorus-containing polymers. The chromium-free passivation composition of the present invention not only has excellent corrosion resistance and damp heat resistance, but also has excellent alkali resistance. The purpose of using the aluminum-zinc plate in a highly alkaline environment can be achieved. The invention also discloses the preparation and application method of the chrome-free surface treatment composition.

Owner:SHANGHAI XINGYU ECOSIL SURFACE MATERIAL

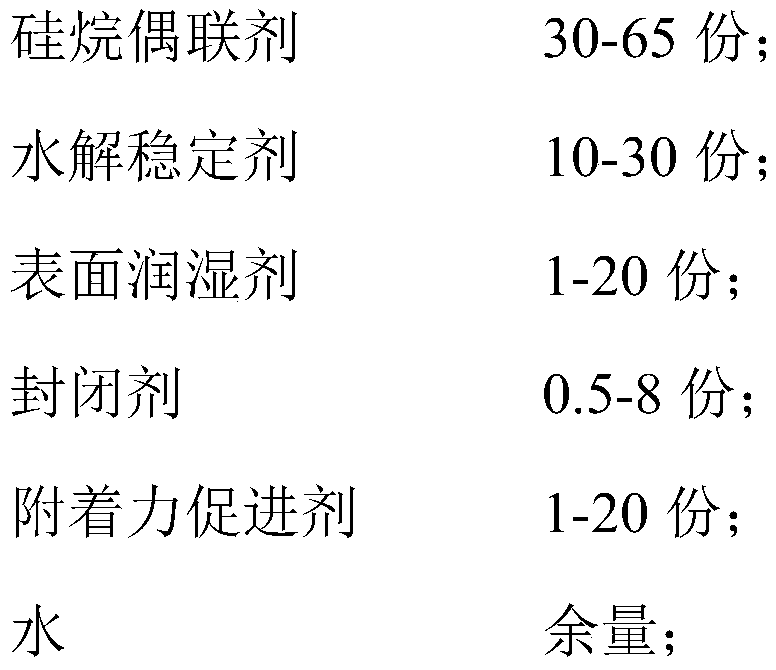

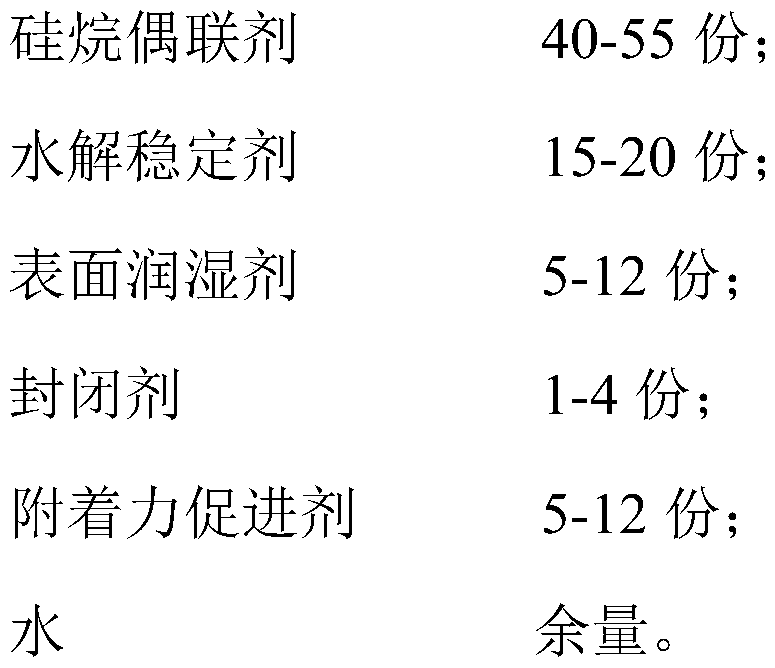

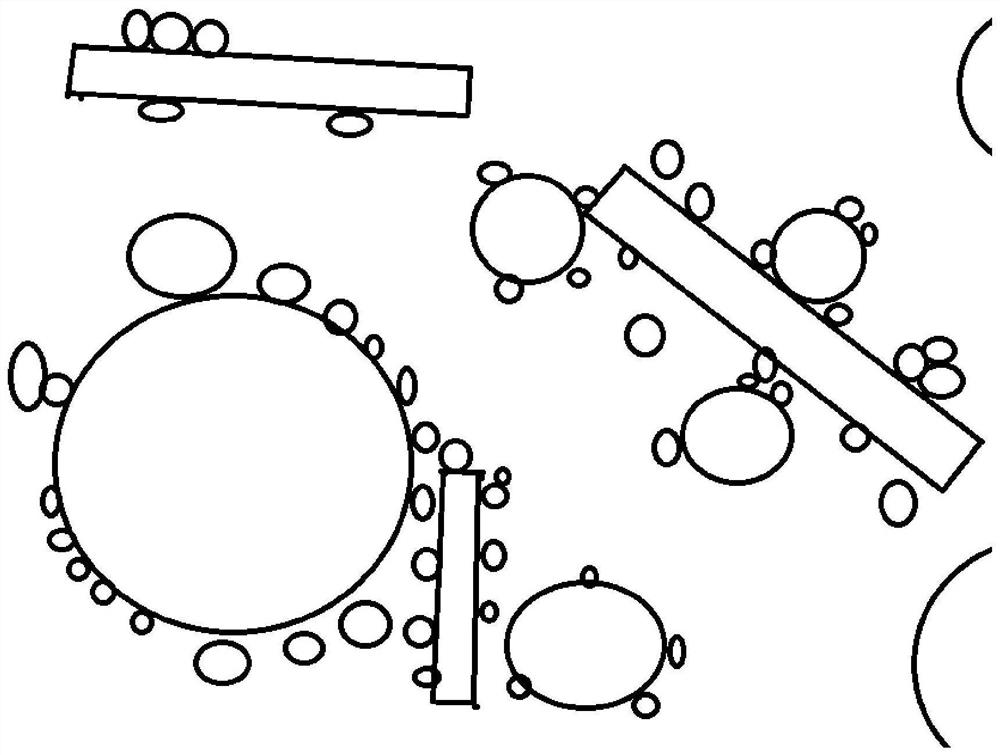

Silane treating agent and method for preparing silane treating agent

ActiveCN107460465BImprove corrosion resistanceExcellent salt spray performanceMetallic material coating processesTriethoxysilanePhosphate

The invention discloses a silicane treating agent and a method for preparing the silicane treating agent. The silicane treating agent comprises the following components of, by weight, 30-65 parts of silicane coupling agents, 10-30 parts of hydrolytic stabilizing agents, 1-20 parts of surface wetting agents, 0.5-8 parts of sealing agents, 1-20 parts of adhesion promoting agents, and the balance water, wherein the total weight parts is 1000, and the silicane coupling agents are amino propyl trimethoxy silicane and / or amino propyl triethoxy silicane. The operation process of the silicane treating agent is simple, a good ceramization effect can be obtained, a metal part processed by the silicane treating agent is excellent in corrosion resistance, and the method can completely replace a traditional phosphate conversion and chromate passivated surface treatment technology.

Owner:佛山市顺德区美硕金属表面技术有限公司

A kind of phosphite powder body coated with nano-oxide inorganic coating and water-based coating containing the powder body

ActiveCN106590034BCorrosion resistanceHigh temperature resistantAnti-corrosive paintsPigment physical treatmentWeather resistanceEmulsion

The invention provides nano oxide inorganic coated phosphite powder. The nano oxide inorganic coated phosphite powder is characterized in that phosphite is used as the core, nano oxide is used as the shell to wrap the phosphite, and the mass of the nano oxide is 0.1-10% of the mass of the phosphite. The invention further discloses waterborne coating containing the nano oxide inorganic coated phosphite powder. The waterborne coating is prepared by emulsion base materials, water, the nano oxide inorganic coated phosphite powder, auxiliary pigment, filler, pH regulator and auxiliaries. The nano oxide inorganic coated phosphite powder has the advantages that the phosphite is modified through inorganic coating to increase the dispersing performance and application performance of the phosphite so as to allow the phosphite to be applicable to materials such as ink, plastics, rubber, papermaking and coating, the corrosion resistance, thermal stability, aging resistance, weather resistance and the like of the corresponding materials are increased, and the service life of the corresponding materials is prolonged.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Calcium phosphate-based cement potting material and manufacturing method thereof

The invention provides a calcium phosphate-based cement potting material, wherein nano-polyimide fibers are evenly distributed in the calcium-phosphate-based cement, wherein the mass fraction of the nano-polyimide fibers is 1%-10%. The use of calcium phosphate-based cement as the basic packaging material reduces costs. The cost of cement is lower than the cost of any existing system; and high temperature resistance, the above potting material system can withstand high temperature of 350 °C; and the process of cement hydration is improved by adding nano polyimide fibers, Reduced porosity. After the final setting of the cement, the possibility of crack formation is reduced, and the ability of the cement to resist water and salt spray is improved.

Owner:GUANGHUA LINGANG ENG APPL & TECH R&D (SHANGHAI) CO LTD

High-weather-resistance finish paint for protecting ship composite material and preparation method thereof

InactiveCN113416487AImprove stabilityImprove reliabilityAnti-corrosive paintsXylyleneWeather resistance

The invention relates to a high weather-resistant finishing paint for protecting a ship composite material, which is prepared from the following components in parts by weight: 80 to 100 parts of modified epoxy organic silicon resin, 20 to 60 parts of mica powder, 1 to 3 parts of BYK110, 15 to 25 parts of xylene, 1 to 2.5 parts of organic bentonite and 15 to 20 parts of amine curing agent. The modified epoxy organic silicon resin and the flaky mica powder are used as main raw materials, and the flaky mica powder forms a complex and diversified multi-layer uniform distribution state in a resin base material by utilizing the compounding synergistic effect of the modified epoxy organic silicon resin and the flaky mica powder, so that the invasion path of moisture and corrosion factors on the surface of the composite material is effectively prolonged; the finished high-weather-resistance finish paint has excellent mechanical properties and high weather resistance, and can better improve the marine environment resistance of a composite material and a ship when being coated on a composite material structure part of the ship for use, thereby effectively improving the stability and reliability of the operation of the ship.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

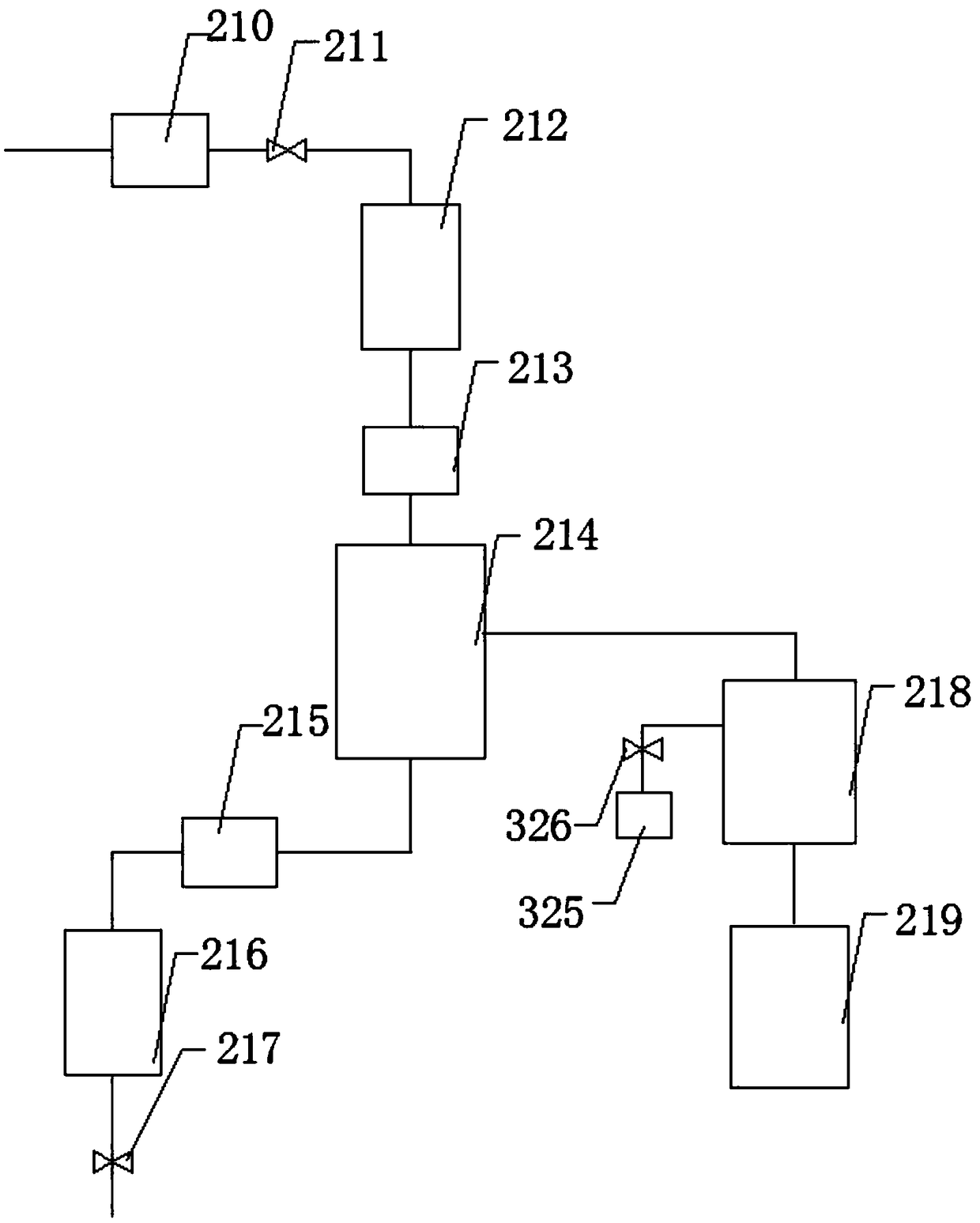

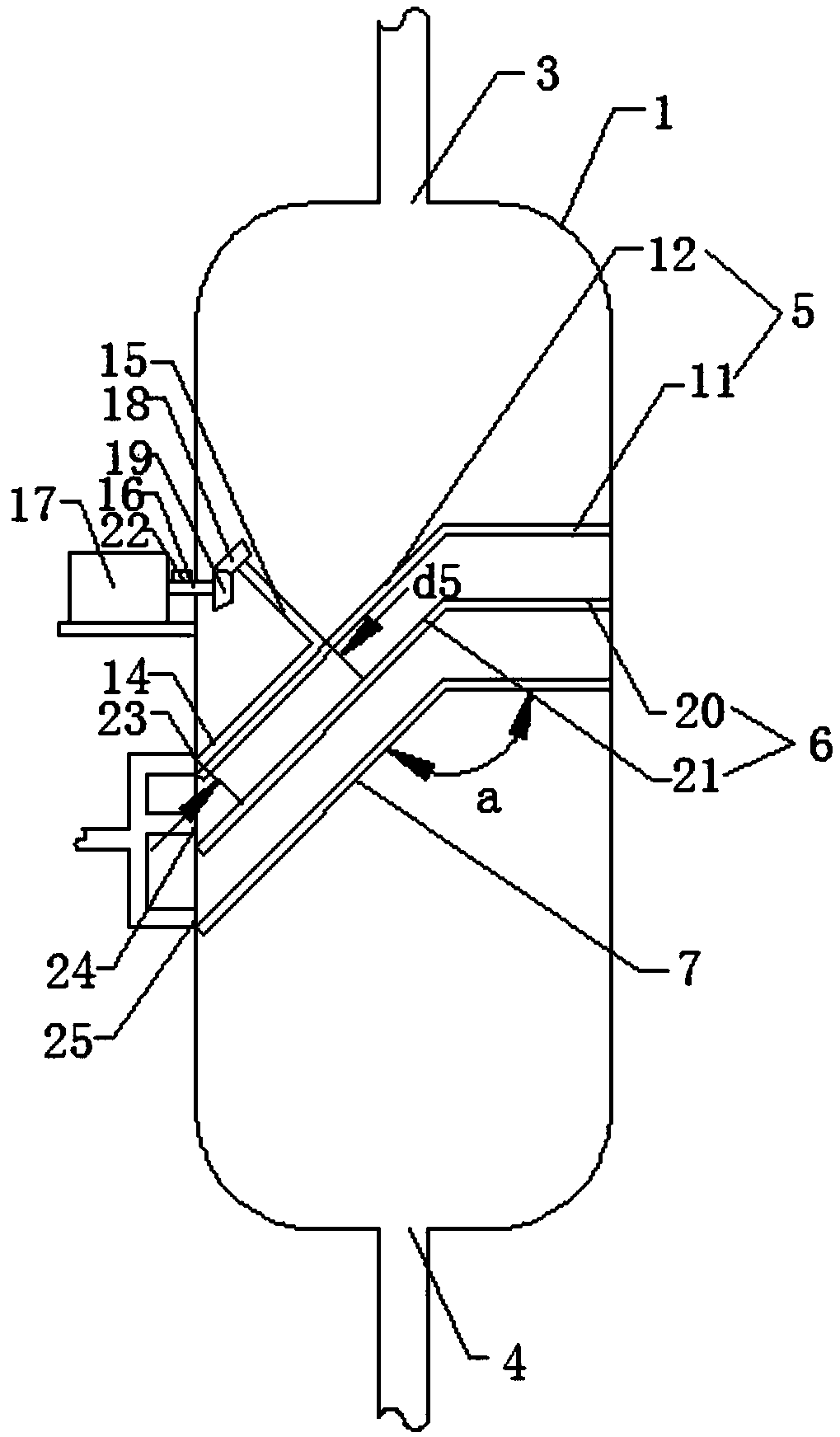

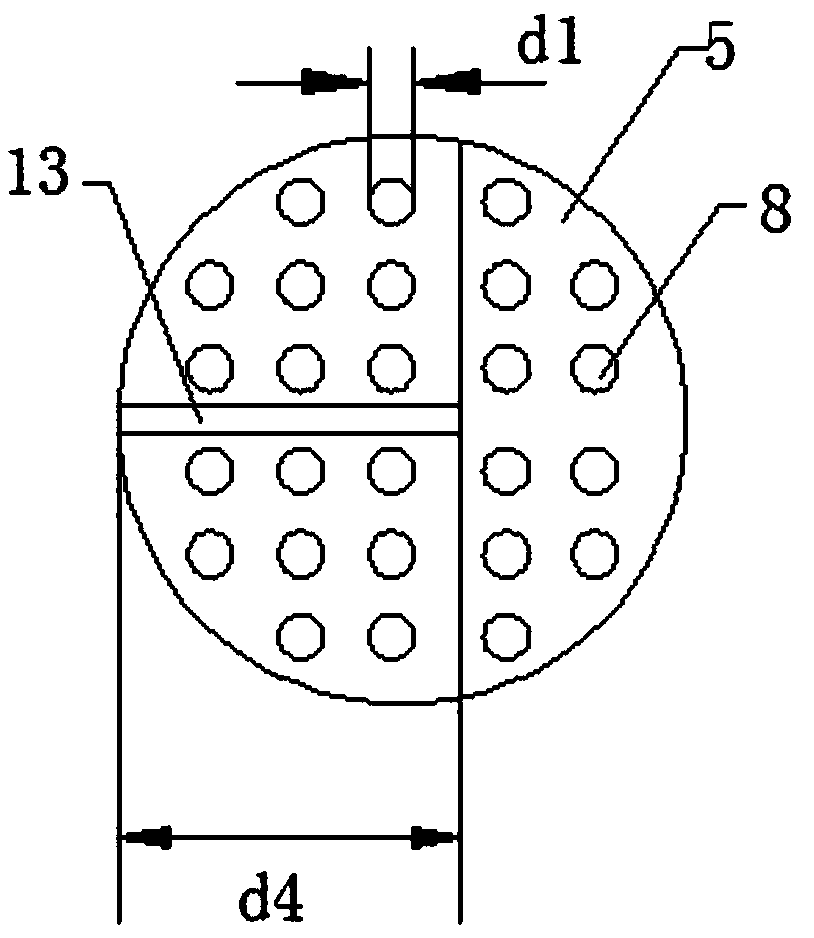

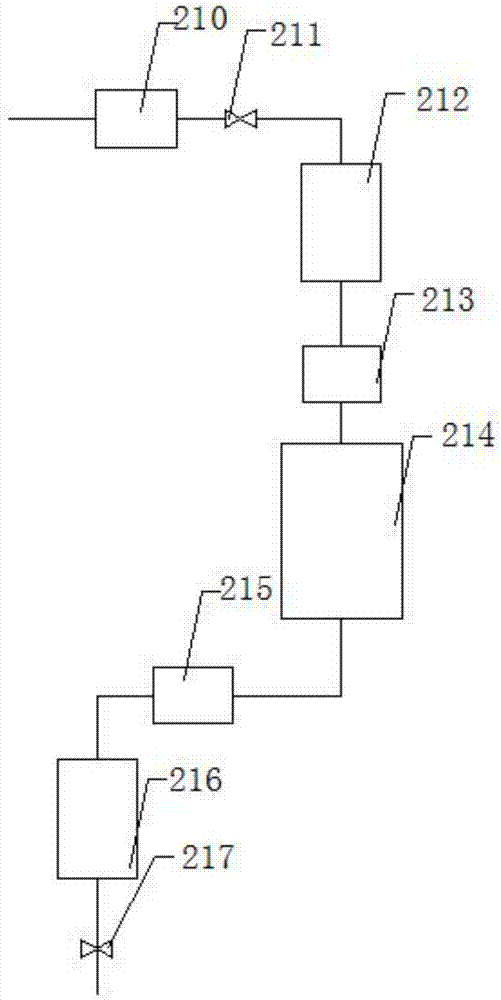

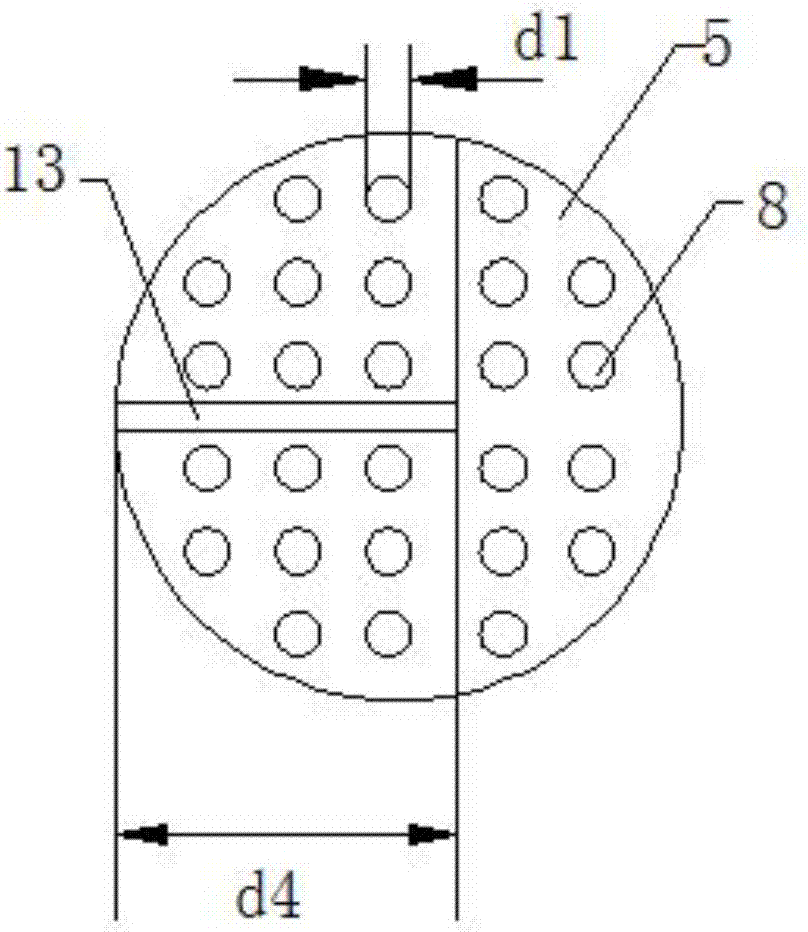

A multifunctional vacuum oil purifier

ActiveCN107321047BSmooth dischargeEffective filteringVapor condensationFiltration circuitsInlet valveCooling effect

The invention provides a multifunctional vacuum oil purifier. The vacuum oil purifier comprises an oil inlet pump, an oil inlet valve, a rough filter, a heater, a vacuum tank, an oil outlet pump, a fine filter, an oil outlet valve, a condenser, a waste liquor tank, a vacuum pump and a check valve, wherein one end of the oil inlet valve is connected with the oil inlet pump through a pipeline, the other end is connected with the rough filter through a pipeline, the rough filter is connected with the heater through a pipeline, the heater is connected with the vacuum tank through a pipeline, the vacuum tank is connected with the oil outlet pump through a pipeline, the oil outlet pump is connected with the fine filter through a pipeline, the oil outlet pump is connected with the oil outlet valve through a pipeline, the vacuum tank is connected with the condenser through a pipeline, the lower end of the condenser is connected with the waste liquor tank through a pipeline, the condenser is connected with the vacuum pump through a pipeline, the check valve is arranged between the condenser and the vacuum pump, an atomizer is arranged in the vacuum tank, a heating device is arranged in the heater, and a fine filter tank is arranged in the fine filter. The vacuum oil purifier is high in working efficiency, the purity of purified lubricating oil is high, and the cooling effect of the condenser is good.

Owner:镇江市长江机电设备厂有限公司

A kind of bright treatment liquid for magnesium alloy die castings

Owner:山西银光华盛镁业股份有限公司

Oil-water separation device for vacuum oil purifier

The invention provides an oil-water separation device for a vacuum oil purifier. The oil-water separation device comprises an oil feed pump, an oil feed valve, a rough filter, a heater, a vacuum tank, an oil discharge pump, a fine filter and an oil discharge valve, wherein one end of the oil feed valve is connected with the oil feed pump through a pipeline, the other end of the oil feed valve is connected with the rough filter through a pipeline, the rough filter is connected with the heater through a pipeline, the heater is connected with the vacuum tank through a pipeline, the vacuum tank is connected with the oil discharge pump through a pipeline, the oil discharge pump is connected with the fine filter through a pipeline and connected with the oil discharge valve through a pipeline, an atomizer is arranged in the vacuum tank, a heating device is arranged in the heater, and a fine filter tank body is arranged in the fine filter. The heater in the oil-water separation device has a good heating effect, and the purity of the purified lubricating oil is high through multistage filtration.

Owner:镇江市长江机电设备厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com