Nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film

A screen protective film, anti-fingerprint technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of reduced image brightness, reduced viewing angle, unsatisfactory, etc., and achieve good stiffness , maintain quality, strong texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

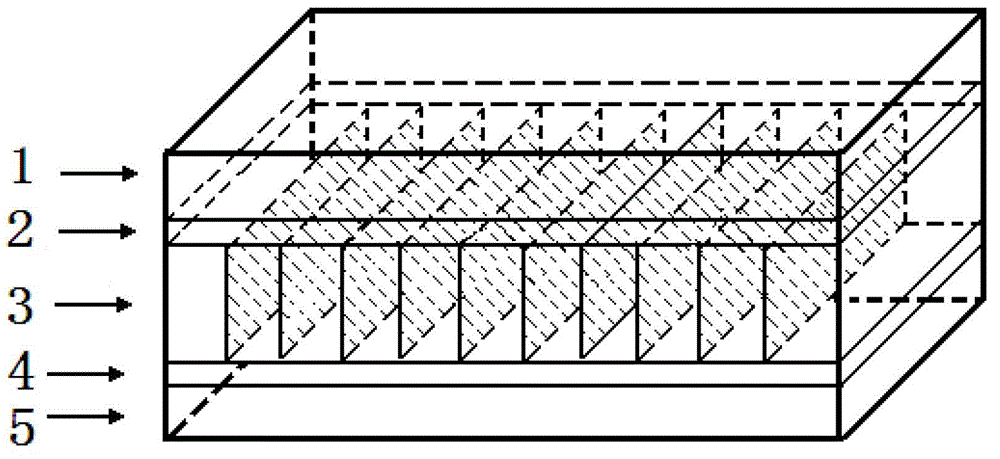

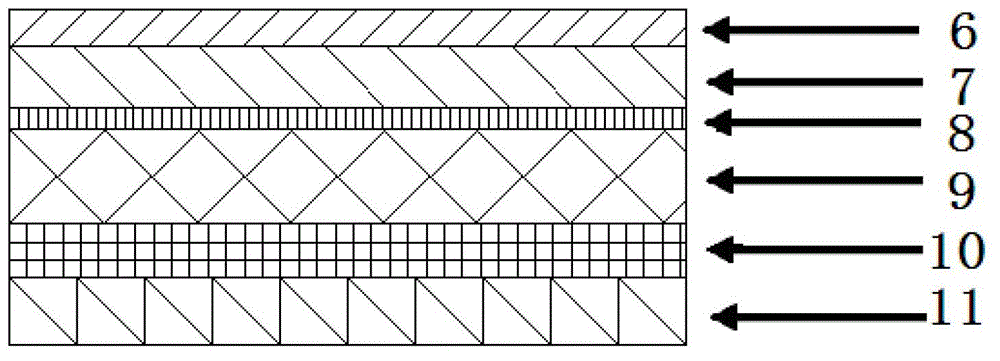

[0037] The structure diagram of the nanometer anti-glare anti-fingerprint anti-peeping screen protective film of the present embodiment is as follows figure 2 As shown, the nano anti-glare anti-fingerprint anti-peeping screen protective film is attached on the glass screen 11, which includes an organic silica gel layer 10, a polarization anti-peeping film layer 9, an adhesive layer 8, and a PET film layer from the inside to the outside. 7 and anti-glare anti-fingerprint nano-coating6. Its preparation is as follows:

[0038] Step 1, preparing a polarization anti-peeping film layer 9 on the organic silica gel layer 10;

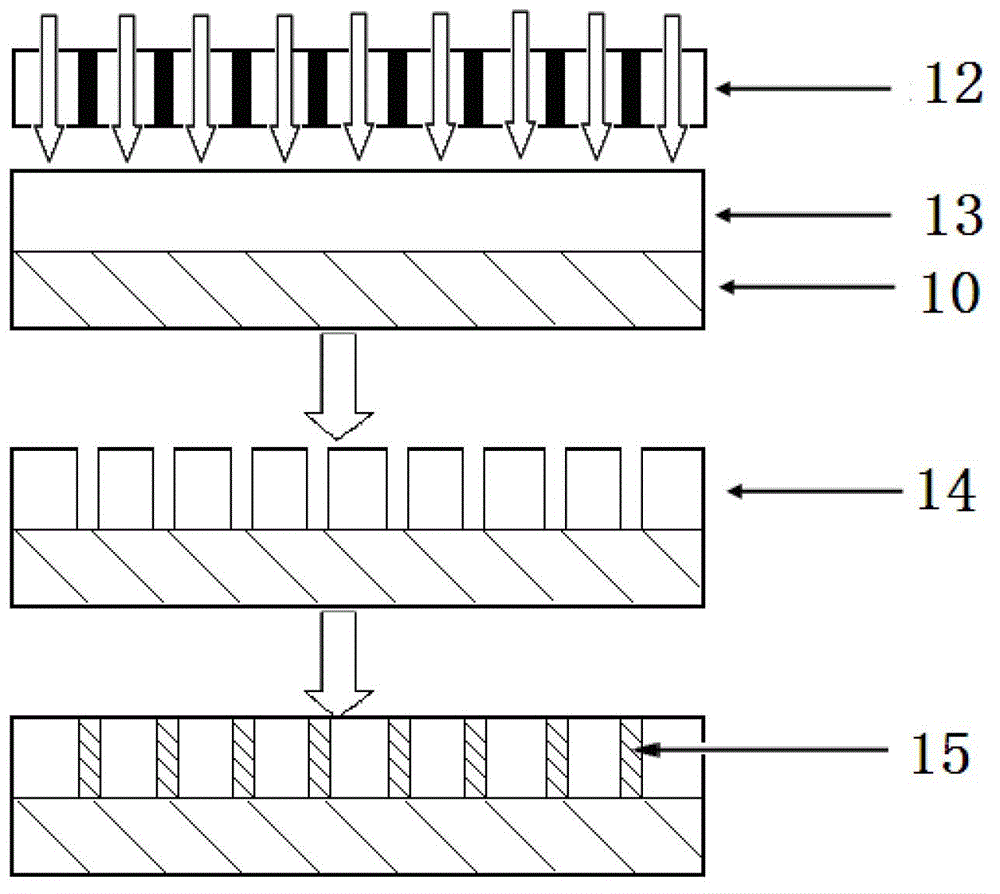

[0039] The structure and preparation method of the polarization anti-peeping film layer are as follows: image 3 As shown, the details are as follows:

[0040] 1) On the organic silica gel layer 10, coat a layer of photoresist 13 (polyvinyl alcohol laurate), control the thickness of the coating to 200-1500 microns; then irradiate the coating with ultraviolet...

Embodiment 2

[0048] The present embodiment is the same as embodiment 1, the difference is:

[0049] In step one 1), the photoresist is epoxy-based ultraviolet negative photoresist; the thickness of the photoresist coating is 200 microns; the distance between gratings 12 is 100 microns; in step one 2), ethyl acetate is used to dissolve the Cross-linked photoresist; in step 1 3), fill the cavity with opaque titanium dioxide; pre-disperse ultrafine titanium dioxide in room temperature curable low-viscosity resin (glycidyl ester type epoxy resin and aliphatic amine co- mixture);

[0050] Step 3, the fluorosilicon polymer is polydimethylsiloxane-b-polyheptafluorobutyl methacrylate; the addition of 2.5% by weight of the fluorosilicon polymer with a particle size of 700 nanometers Silicon; the prepared anti-glare and anti-fingerprint nano-coating has a thickness of 0.2 microns.

Embodiment 3

[0052] The present embodiment is the same as embodiment 1, the difference is:

[0053] In step 1), the photoresist is cyclized polyisoprene-bisazide UV photoresist; the thickness of the photoresist coating is 500 microns; the distance between the gratings 12 is 250 microns; in step 1 3) , Fill the cavity with opaque pigment particles; pre-disperse the opaque pigment particles in a low-viscosity resin that can be cured at room temperature (a linear high Molecular compounds);

[0054] Step 3, the fluorosilicon polymer is a blend of polytrifluoropropylmethylcyclotrisiloxane and polytrifluoropropylmethyldichlorosilane; adding 5% by weight to the total weight of the fluorosilicon polymer %, a particle size of 1000 nanometers of silicon dioxide; the prepared anti-glare and anti-fingerprint nano coating thickness is 3.0 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com