Patents

Literature

98results about "Shellac coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ph-sensitive sacrificial materials for the microfabrication of structures

ActiveUS20130066045A1High removal rateAltered solubilityShellac coatingsPharmaceutical delivery mechanismSolubilityPorosity

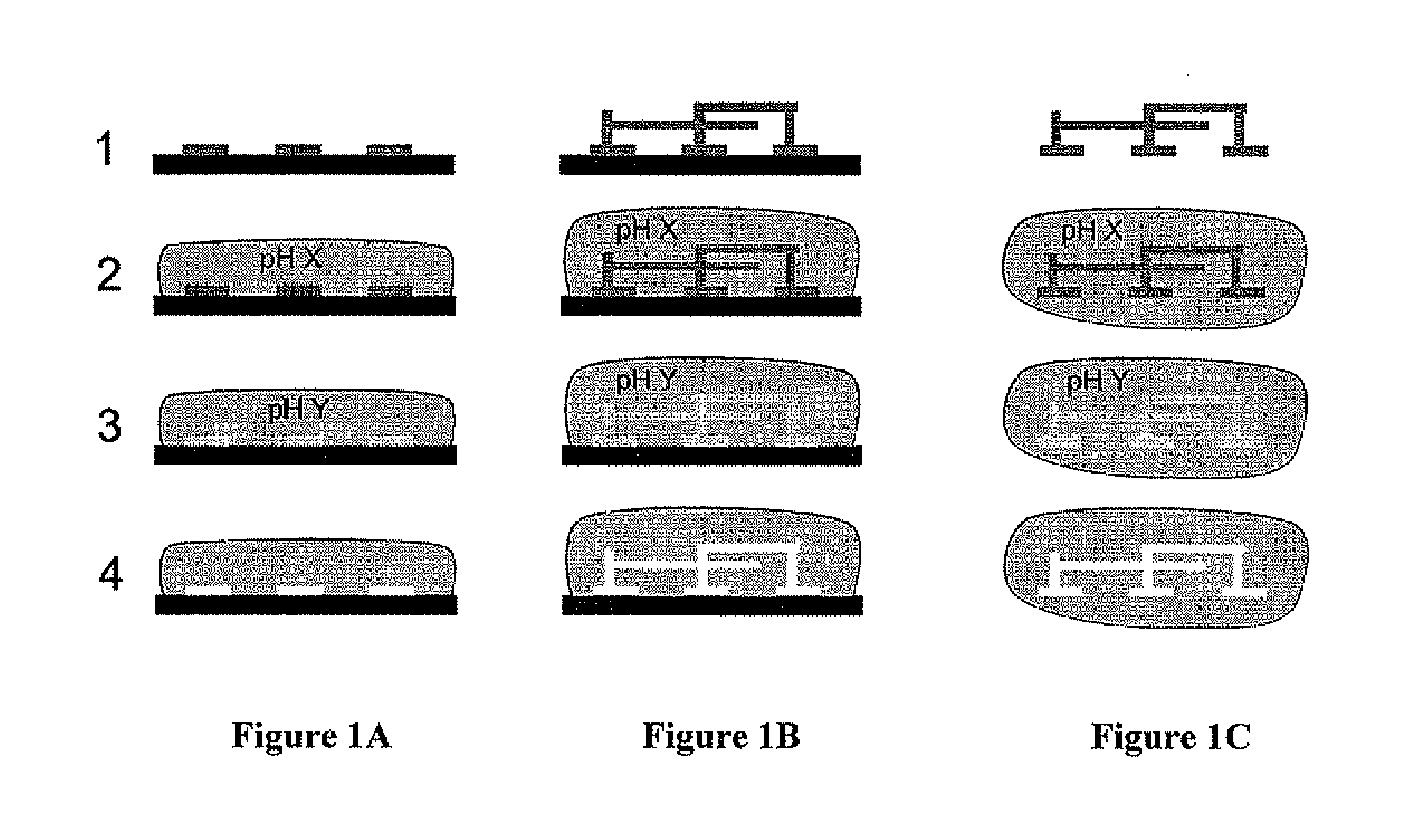

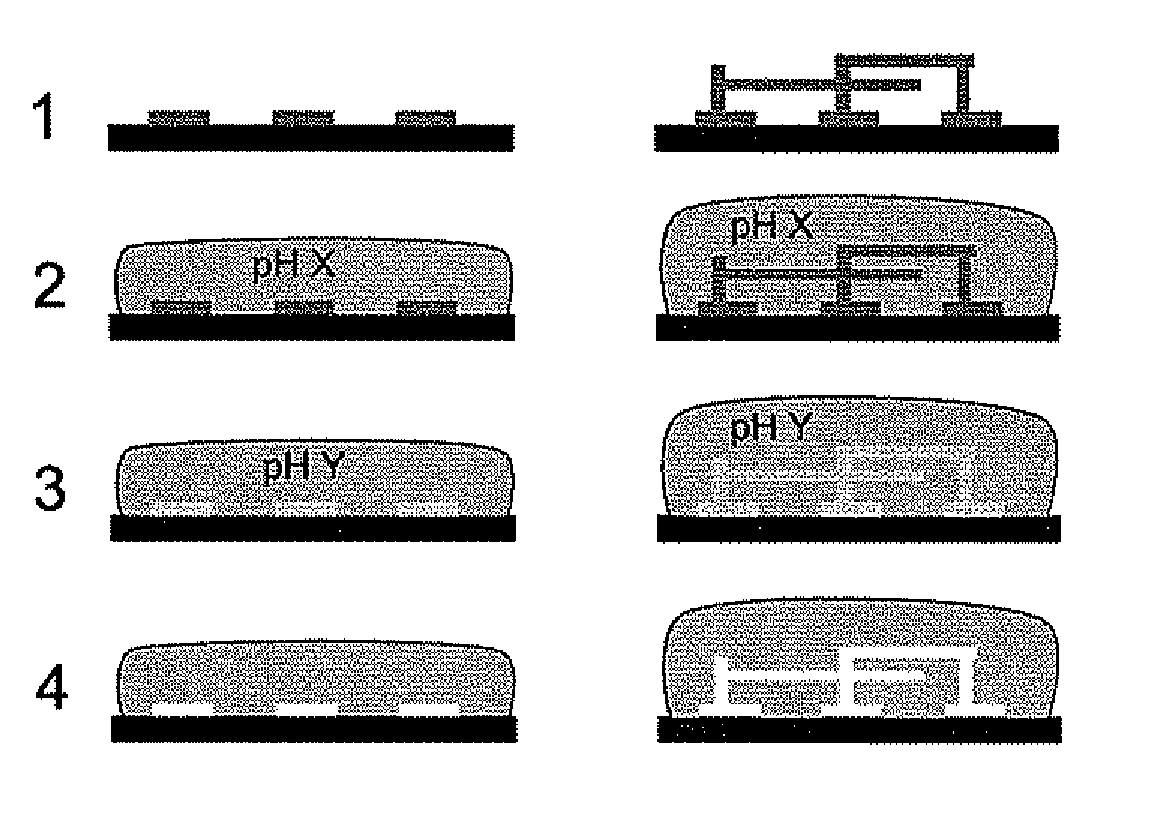

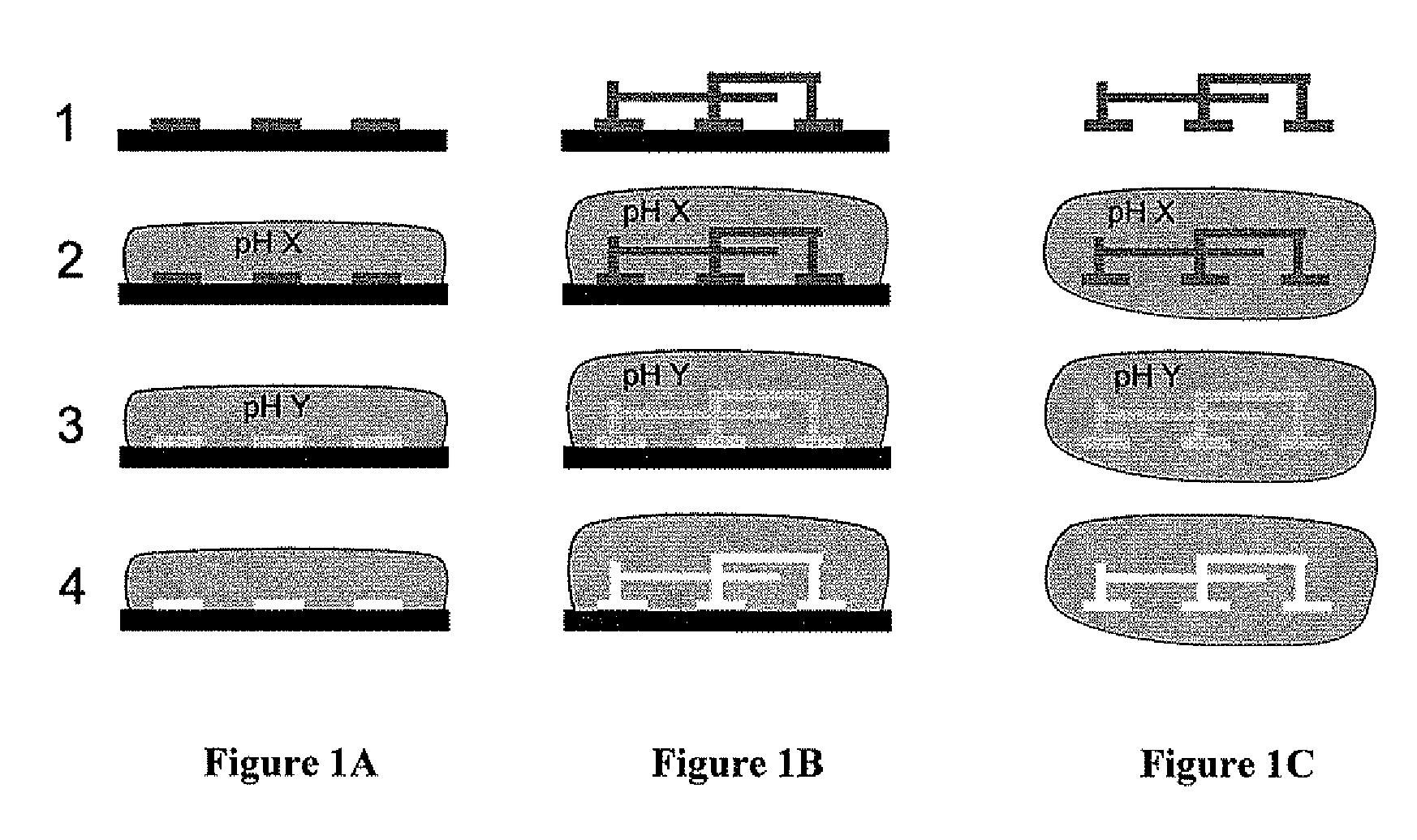

Methods for microfabricating composite materials and composite materials prepared there from are described herein. The sacrificial material can be etched or patterned to create a two-dimensional and / or three-dimensional sacrificial material structure. The resulting sacrificial material structure can be embedded in one or more embedding materials. The sacrificial material(s) are materials whose solubility can be altered by application of a stimulus typically pH, and / or temperature, light, pH, pressure, presence of absence of ions, and combinations thereof. The embedding materials can contain one or more additives that modify one or more properties of the embedding materials, such as degradation properties, porosity, mechanical properties, viscosity, conductive properties, and combinations thereof. The composite materials can be used in tissue engineering, drug screening, toxin detection, drug delivery, filtrations, bioseparations, and as microfluidic devices for fluid mixing and structural repair.

Owner:MASSACHUSETTS INST OF TECH +1

Water dispersible enteric coating formulation of nutraceutical and pharmaceutical dosage forms

InactiveUS20090252767A1Good dispersionHigh hiding powerBiocideShellac coatingsFood gradeWater dispersible

The present invention relates to formulations for use as enteric coatings. More particularly, the present invention relates to a formulation comprising a dry blend of food grade ingredients that can be readily dispersed in water. This dispersion exhibits low viscosity and can easily be coated onto solid dosage forms through spraying and the like to provide an enteric coating on the solid dosage form.

Owner:HERCULES INC

Powder coating, method for production thereof, method for using said powder coating and coated article

InactiveUS20060014031A1BondImprove bindingShellac coatingsLiquid surface applicatorsProduction rateShellac

The present invention provides a powder paint excellent in productivity and cost, because the powder paints that are not adhered to the substrate can recovered and reused. And in case of using the powder paint of the present invention, coating efficiency is high and fine textured coated films excellent in attractiveness of appearance and water resistance can be obtained, because the base paint powder and the pigment particle thereof hardly separate. The powder paints of the present invention are characterized in that the pigment particles are bound to the base paint powders via shellac. The powder paints of the present invention not only allows uniform and firm binding of pigment particles to base paint powders by the action of shellac, but also provides the resulting coated films with excellent attractiveness of appearance.

Owner:KUBOKO PAINT CO LTD +1

Glass oil paint

ActiveCN103897564AEconomical to makeStrong adhesionShellac coatingsPolyester coatingsLacquerOil paint

The invention relates to an glass oil paint which comprises the following components in parts by weight: 20-27 parts of modified dry oil, 12-17 parts of hydroxyethyl cellulose, 3-6 parts of butyl stearate, 12-15 parts of water-soluble resin, 5-8 parts of lac resin, 3-6 parts of lacquer resin, 12-15 parts of zinc phosphate, 4-6 parts of zinc molybdate, 11-16 parts of mica powder, 1-4 parts of citric acid, 2-4 parts of antiseptic antirust emulsion and 5-8 parts of thinners. According to the glass oil paint, raw materials are common in the market, so that the production cost is low, and the glass oil paint has strong adhesive force, acid and alkali resistance and water resistance, can effectively remove and prevent iron rust due to addition of the antiseptic antirust emulsion, and can be smeared on glass, so as to meet the demands of people.

Owner:SHANGHAI DABAO CHEM PROD

Small-area damage repairing liquid and repairing process for oil paint surface of wood facing

ActiveCN103484021AMeet the requirements of high-quality restorationImprove repair effectShellac coatingsPretreated surfacesEngineeringSand-paper

The invention discloses a small-area damage repairing liquid and repairing process for oil paint surface of wood facing. The repairing process comprises the following steps: dripping 502 glue at a damage part of the wood paint surface and the peripheral area that is 5-10 times of the damage area, scattering wood powders on the 502 glue after the glue penetrates, leveling the convex part by a knife, repeating the steps for 4-5 times until the original damage part and the peripheral area thereof are level; coating the 502 glue again, polishing by 180# sand paper until no pore is existent, and then leveling by 320# sand paper; dipping the repairing liquid by white cloth, coating the repairing liquid on the whole area to be repaired, and then toning to be the color which is the same as the ground color of the original wood paint surface by pigments and the repairing liquid, dipping by the while cloth, lightly coating on the area to be repaired, then toning to be the color which is the same as the grain decoration of the original wood paint surface by pigments and the repairing liquid, and repairing the area grains of the ground color; and selecting a finish paint spray with the corresponding luminosity according to the luminosity of the original wood paint surface and then spraying the finish paint spray at the repairing area. The paint surface repaired by the repairing process with the repairing liquid is even and flat, and is harmonious in color.

Owner:SHANGHAI JIEYANG IND

Antifouling of shellfish and aquaculture apparatus

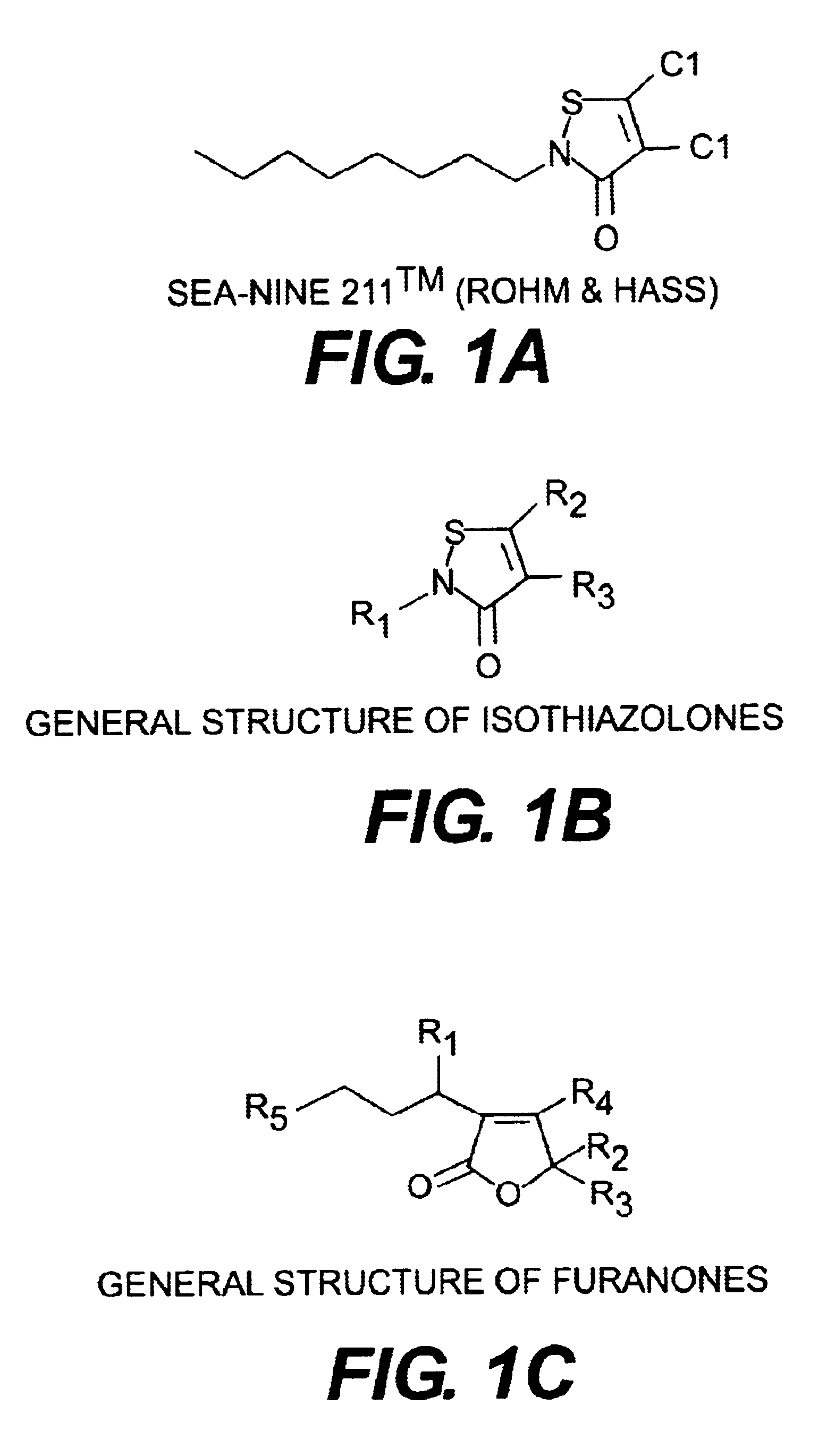

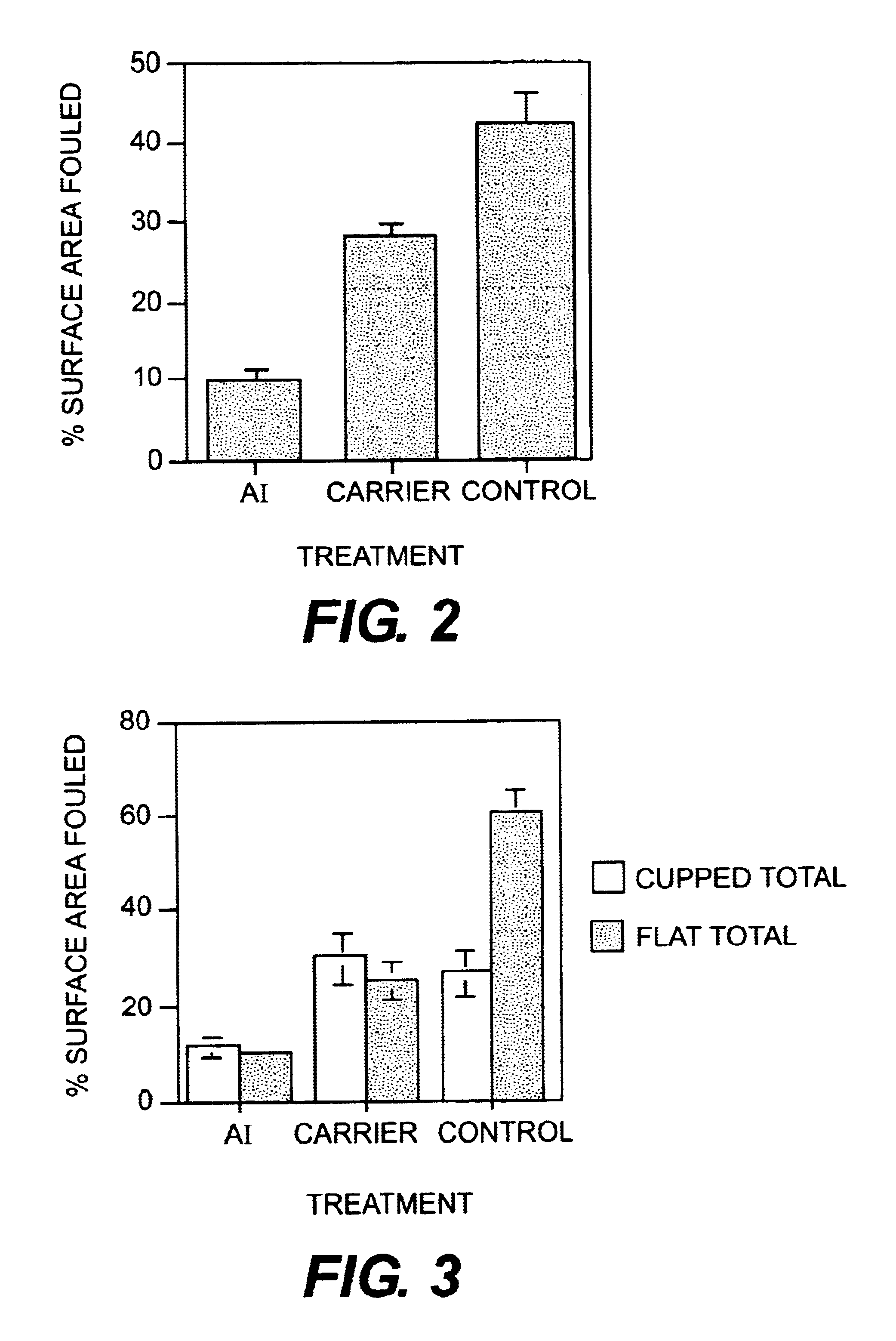

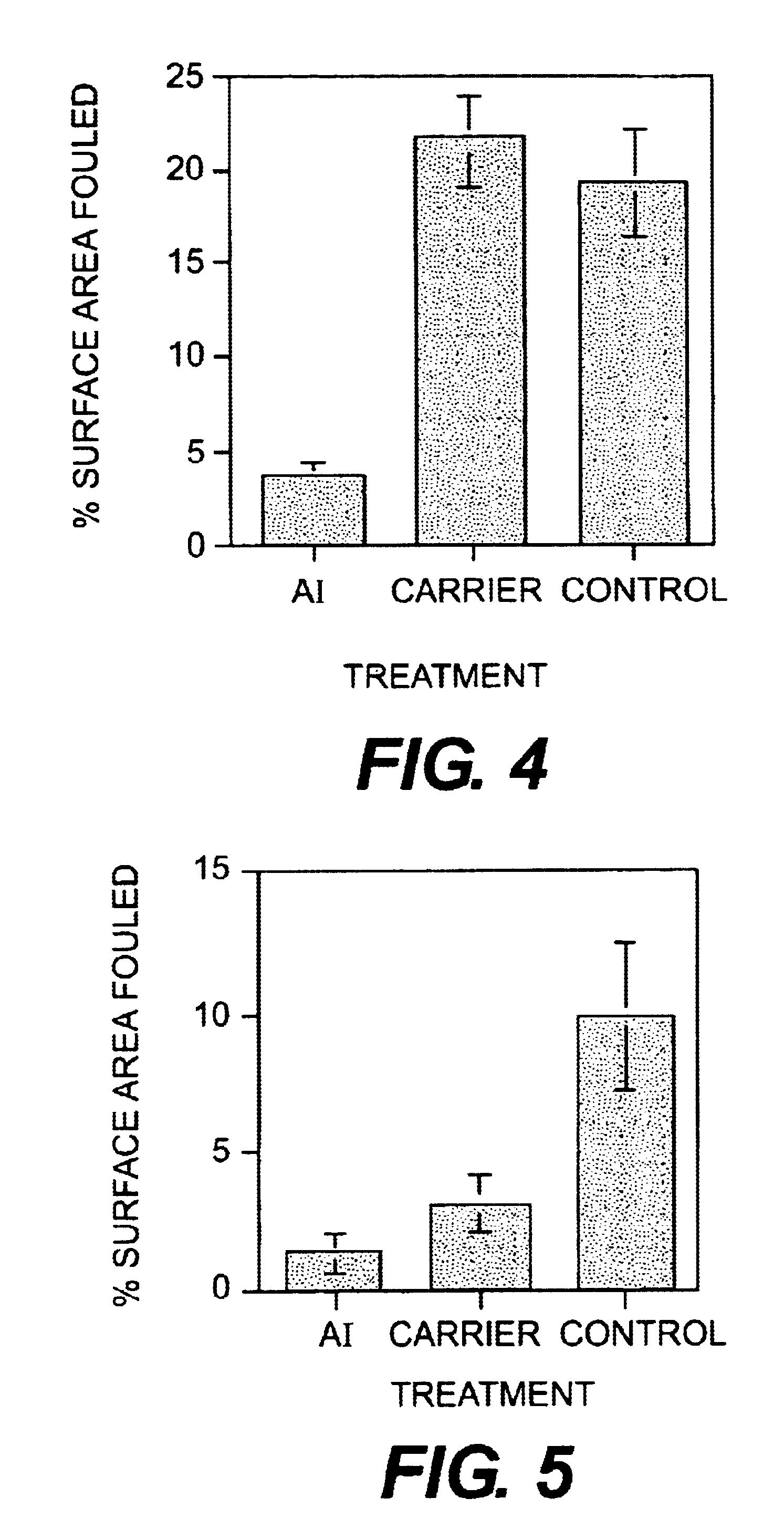

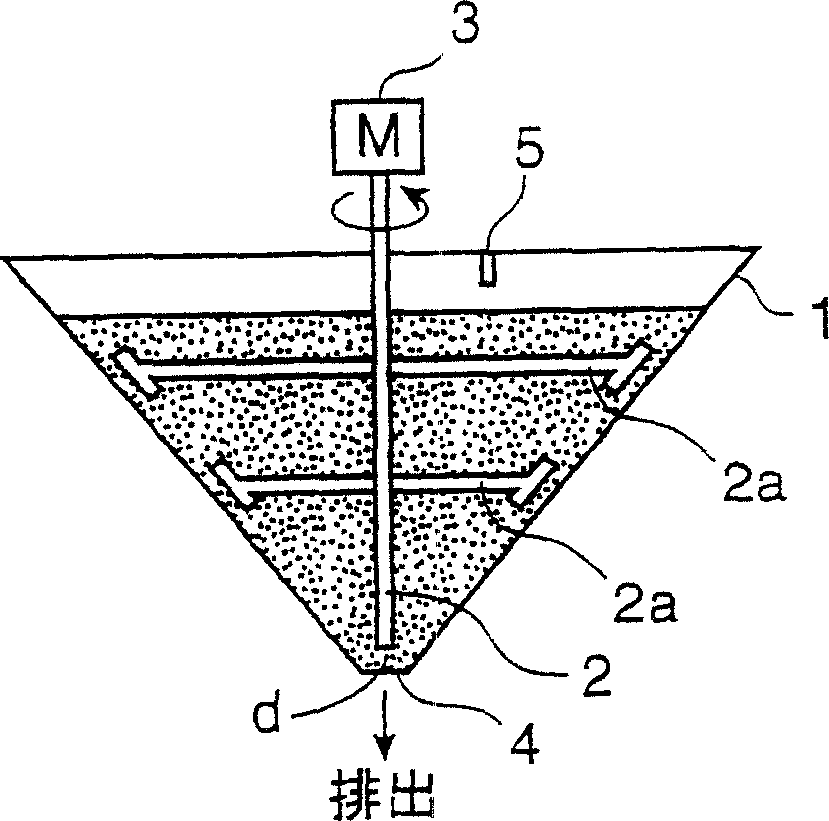

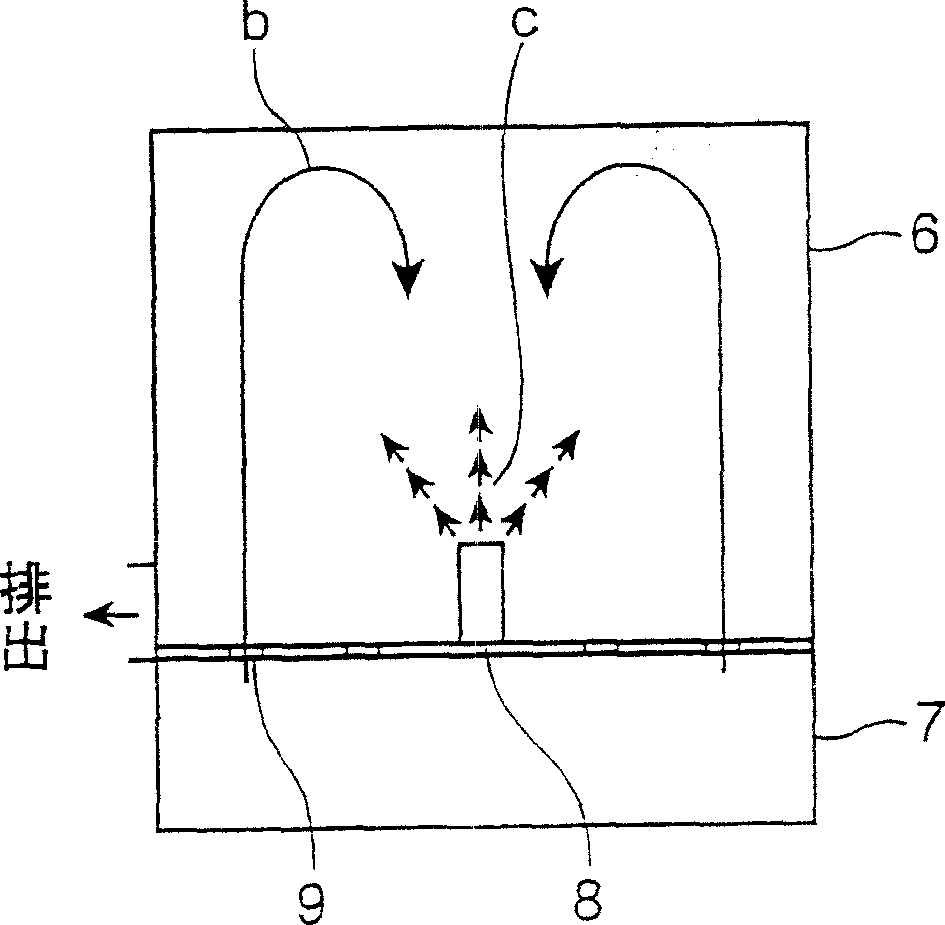

InactiveUS6692557B1Reduces and prevents foulingNon-toxicShellac coatingsBiocideAquatic animalAquatic product

An antifouling coating composition comprising a carrier and an antifouling agent belonging to the families of isothiazolones or furanones, wherein the composition is substantially non-toxic to a cultured marine or aquatic animal when applied to the animal; and uses of the antifouling composition to reduce or inhibit fouling of marine or aquatic animals and aquaculture apparatus.

Owner:UNISEARCH LTD

Composite varnish and preparation method thereof

InactiveCN102408772AImprove surface antimicrobial propertiesGood dispersionShellac coatingsAntifouling/underwater paintsPolymer scienceSilver particles

The invention relates to a composite varnish and a preparation method thereof. The composite varnish comprises raw material varnishes, uniformly-dispersed nano silver particles, nano titanium dioxide particles and quantum dots, wherein the mass percentage of the nano silver particles in the composite varnish is 0.01%-0.05%, the mass percentage of the nano titanium dioxide particles in the composite varnish is 0.05%-0.5%, and the content of the quantum dots in the composite varnish is 0.01-0.1 micro mol / L. The preparation method comprises the following step of: a. in-situ reduction of nano silver in the raw material varnishes: adding a silver salt solution in the raw material varnishes according to a volume ratio (the silver salt solution to the raw material varnishes) of 1: 5 to 1: 20, and stirring till the mixture is even. The composite varnish is used for carrying out a film-coating treatment on the surface of a medical appliance, improving the bacteria resistance of the surface of the medical appliance, further, endowing the surface of the medical appliance with pollution detectability, and thus, a novel idea and a novel direction are provided for the development and the application of antimicrobial medical appliances.

Owner:SOUTHEAST UNIV

Powder coating, method for production thereof, method for using said powder coating and coated article

InactiveCN1711328AImprove water resistanceEasy to separateShellac coatingsLiquid surface applicatorsProduction rateShellac

A paint powder is characterized in that pigment particles are bound to the base paint powder by shellac. The powder coating exhibits strong and uniform binding of pigment particles to its base coating powder, and can also provide a coating film that exhibits excellent designability due to the action and effect of shellac. The powder coating does not separate the pigment particles from the base coating powder, which are components of the powder coating, shows good coating workability, and can provide a coating film with a smooth surface , has excellent designability and exhibits high water resistance, and has excellent productivity and economy because powder coatings that are not adhered to articles to be coated can be recycled and reused.

Owner:KANSAI PAINT CO LTD +1

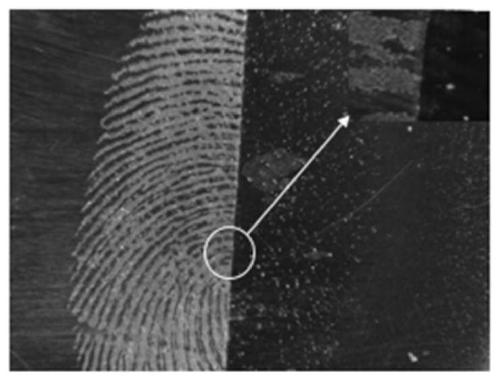

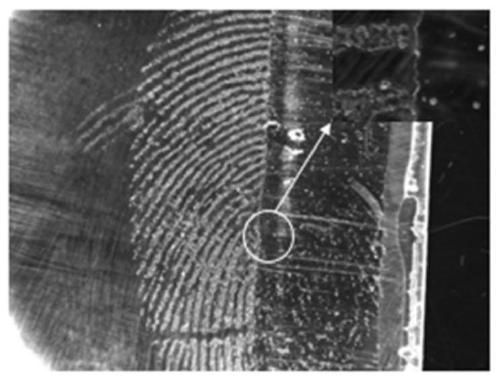

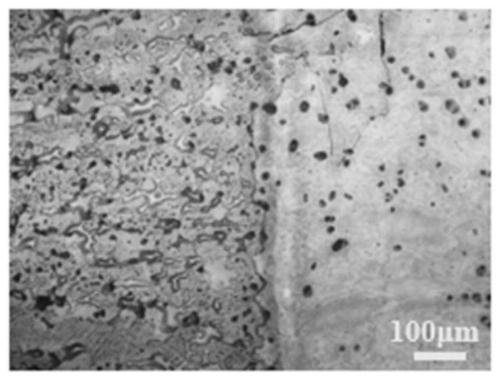

Fingerprint-resistant transparent coating layer and preparation method thereof

InactiveCN111303737AStrong visual transparencyExcellent fingerprint resistanceShellac coatingsLiquid surface applicatorsWoven fabricPerfluoropolyether

The invention provides a fingerprint-resistant transparent coating layer and a preparation method thereof. The preparation method comprises the following steps: under the condition of a room temperature, sequentially adding acrylic resin, a catalyst, a leveling agent, an adhesion promoter, a curing agent, a diluent and perfluoropolyether into a material mixing pot, and carrying out stirring so asto obtain a fingerprint-resistant transparent resin coating material; wiping a to-be-coated substrate with alcohol and acetone through a non-woven fabric so as to remove oil stains in sequence, and spraying or wiping the fingerprint-resistant transparent resin coating material onto the substrate, or dip-coating the substrate in the fingerprint-resistant transparent resin coating material to form afilm, wherein the substrate is glass, polished stainless steel or bright plastic; and putting a coated substrate into a drying oven at 80-120 DEG C, and carrying out curing for 1-2 hours so as to obtain the fingerprint-resistant transparent resin coating layer on the substrate. The hydrophobic and oleophylic fingerprint-resistant transparent coating layer prepared by using the preparation methodprovided by the invention has a deionized water contact angle of 95-100 degrees and a tetradecane contact angle of 10-15 degrees, and belongs to a hydrophobic and oleophylic fingerprint-resistant coating layer.

Owner:SOUTHEAST UNIV

Shellac for increasing heat resistance of varnish, and modification method thereof

ActiveCN103849312AImprove toughnessImprove heat resistanceShellac coatingsFrench polishPolymer scienceVegetable oil

Embodiments of the invention disclose a shellac for increasing heat resistance of a varnish. The main components of the shellac comprise, by weight, 40-50% of shellac, 3-7% of dry vegetable oil, 5-9% of glycerol, 10-20% of a rosin resin, 5-10% of pentaerythritol, and 10-15% of a modification promoter. Embodiments of the present invention further disclose a shellac modification method for increasing heat resistance of a varnish. The modification method comprises: stirring shellac and a rosin resin, dissolving into a diluent, taking a modification promoter and adding to the obtained solution, and heating until completely dissolving, wherein the heating temperature is 50-80 DEG C; adding dry vegetable oil, pentaerythritol and glycerol to the obtained mixed solution, stirring while heating to a temperature of 40-82 DEG C, and carrying out a reaction for 1-4 h to obtain a modified shellac solution; and preparing the modified shellac solution into the shellac varnish finished product. According to the present invention, the dry heat resistance and the wet-heat resistance of the shellac paint film can further be substantially increased, and no harm on the environment and the human body during the construction and use process is generated.

Owner:云南楚山源生物科技有限公司

Method for adding layer of preservative film on packaging material and article

InactiveCN109880527ANo lossThe process is simple and scientificShellac coatingsRosin coatingsOrganic solventAlcohol

The invention discloses a method for adding a layer of preservative film on a packaging material and an article. Cyclopropene is used as an active ingredient, and the preparation method comprises thefollowing steps: adding encapsulated or adsorbed cyclopropene into a high polymer material which can be dissolved in absolute ethyl alcohol or an organic solvent according to a ratio of 1-10% by usingan encapsulating agent or an adsorbent, conducting uniform stirring to prepare a liquid, and directly spraying or brushing the liquid on a packaging material and an article to form a layer of preservative film, so as to enable the packaging material and the article have a fresh-keeping function. The method is simple and scientific in process, and 1-MCP gas is almost not lost. The fresh-keeping material is relatively stable under a drying condition and can be stored for a long time. When wet air is encountered, 1-MCP can be slowly released to keep fruits, vegetables and flowers fresh, the effect is reliable, and application is convenient.

Owner:陕西沃农农业科技有限公司

Ph-sensitive sacrificial materials for the microfabrication of structures

ActiveUS9458357B2High removal rateAltered solubilityShellac coatingsPharmaceutical delivery mechanismSolubilityPorosity

Methods for microfabricating composite materials and composite materials prepared there from are described herein. The sacrificial material can be etched or patterned to create a two-dimensional and / or three-dimensional sacrificial material structure. The resulting sacrificial material structure can be embedded in one or more embedding materials. The sacrificial material(s) are materials whose solubility can be altered by application of a stimulus typically pH, and / or temperature, light, pH, pressure, presence of absence of ions, and combinations thereof. The embedding materials can contain one or more additives that modify one or more properties of the embedding materials, such as degradation properties, porosity, mechanical properties, viscosity, conductive properties, and combinations thereof. The composite materials can be used in tissue engineering, drug screening, toxin detection, drug delivery, filtrations, bioseparations, and as microfluidic devices for fluid mixing and structural repair.

Owner:MASSACHUSETTS INST OF TECH +1

Natural emulsion, aqueous woodenware paint containing same, preparation methods of natural emulsion and paint

InactiveCN103725018ADon't worry about sourceSave resourcesShellac coatingsRosin coatingsNatural resinFoaming agent

The invention relates to a natural emulsion. The natural emulsion comprises the compositions in percent by weight: 1-2% of an emulsifier, 40-70% of plant oil, 5-30% of natural resin, 5-30% of an active monomer polymer and 8-15% of water. The invention also relates to aqueous woodenware paint prepared from the natural emulsion, and the aqueous woodenware paint is characterized by comprising the compositions in percent by weight: 1-3% of water, 81-88% of the natural emulsion, 3-10% of a cosolvent and 0-10% of a pigment or filling material, and preferably also comprising 0.7-1.2% of an anti-foaming agent, 0.3-0.6% of a wetting agent, 0.2-0.5% of a slip agent, 0.5-1% of a levelling agent and 2-4% of a hardening agent. Compared with conventional aqueous paint, the natural aqueous woodenware paint provided by the invention employs the renewable natural emulsion as the emulsion, so that petroleum resource is saved; and also, plant oil and natural resin in the natural emulsion in the paint are biodegradable under the effect of lipase, so that the waste paint can be biodegraded by employing lipase, and thus the paint has no pollution to environment and is green and environment-friendly.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Process for preparing environment protection coating material by lacca modifying

InactiveCN1752166AImprove mechanical propertiesImprove adhesionShellac coatingsNatural resin chemical modificationInorganic saltsAlloy

A process for preparing the environment protection type paint by lac modifying includes such steps as copolymerizing between natural lac and organic amine containing more than two aminos to obtain modified lac polymer, and mixing it with other polymer, slow-releasing agent and inorganic salt to obtain the paint with different components for wood, copper and its alloy, Al-Mg alloy, etc. Its advantages are high protecting and anticorrosion effect, high storage stability and no need of benzene solvent.

Owner:UNIV OF SCI & TECH BEIJING

Medical quick-drying water-based antirust paint and preparation method thereof

InactiveCN104877486AHas a deoxidizing effectPaint levelingShellac coatingsAnti-corrosive paintsShellacPhenol

The invention discloses a medical quick-drying water-based antirust paint and a preparation method thereof. The paint is prepared from an acrylic acid emulsion, a shellac copolymer emulsion, zinc oxide, ethanol, phenol, sodium metaborate, light calcium carbonate, barium sulfate, iron oxide red and talcum powder. When being used for resisting rust and corrosion for medical devices, the paint has the deoxidization effect. The coated film appears iron red and is smooth, the viscosity is 60-80s, and the hardness is 3-5. The adhesive force is first-grade; the paint has high water resistance, and does not have abnormity after being immersed in water; the impact strength is 500-700 N / cm; the paint has high salt tolerance, and can not discolor or blister after being immersed in a 3% sodium chloride water solution at 25 DEG C for 10-30 days; the surface drying time is 10-30 minutes; and the solid drying time is 2-6 hours. The paint has the advantages of simple preparation method and simple and accessible raw materials, and can be widely produced and continuously substituted for the existing materials.

Owner:SUZHOU BEC BIOLOGICAL TECH

Formaldehyde-absorption flame-retardant automobile interior trim paint

InactiveCN104497876AProtect colorProtection lifeFireproof paintsShellac coatingsPolyethylene vinyl acetateShellac

The invention discloses a formaldehyde-absorption flame-retardant automobile interior trim paint. The formaldehyde-adsorption flame-retardant automobile interior trim paint comprises 10 to 15 parts of microcrystalline wax, 4 to 8 parts of silicone oil, 4 to 10 parts of shellac, 8 to 15 parts of fatty alcohol polyoxyethylene ether, 1 to 3 parts of acrylonitrile, 4 to 8 parts of an emulsifier, 0.5 to 0.15 part of a mildew inhibitor, 25 to 45 parts of ethanol, 15 to 20 parts of water, 1 to 3 parts of 2-hydroxy-4-n-octyloxybenzophenone, 5 to 8 parts of silicone-containing polyethylene vinyl acetate, 1 to 3 parts of talcum powder, and 1 to 5 parts of a fire retardant. The formaldehyde-absorption flame-retardant automobile interior trim paint is capable of absorbing ultraviolet light and formaldehyde gas, protecting automobile interior trim colour, prolonging automobile interior trim service life, and realizing flame prevention.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

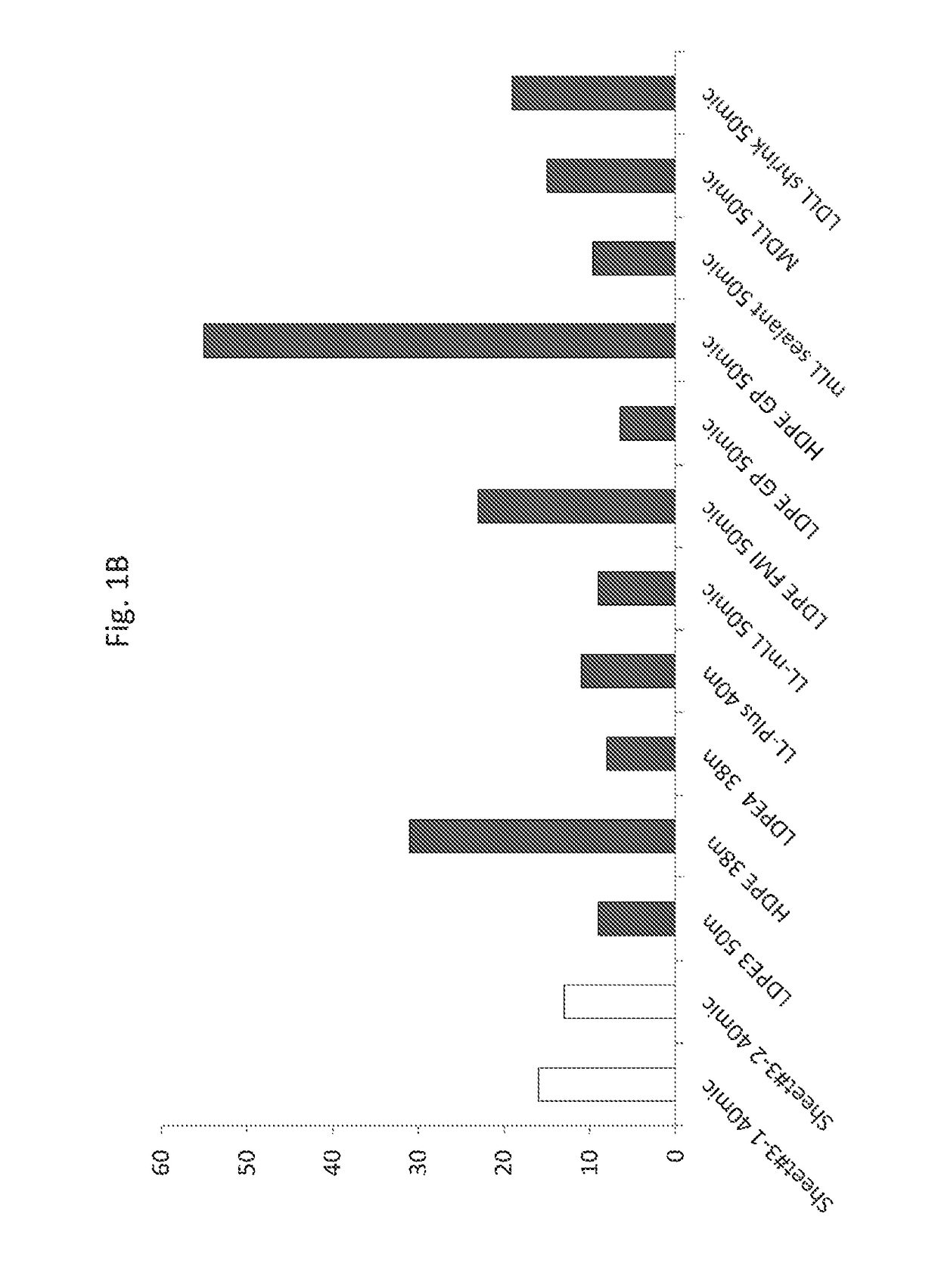

Biodegradable sheets

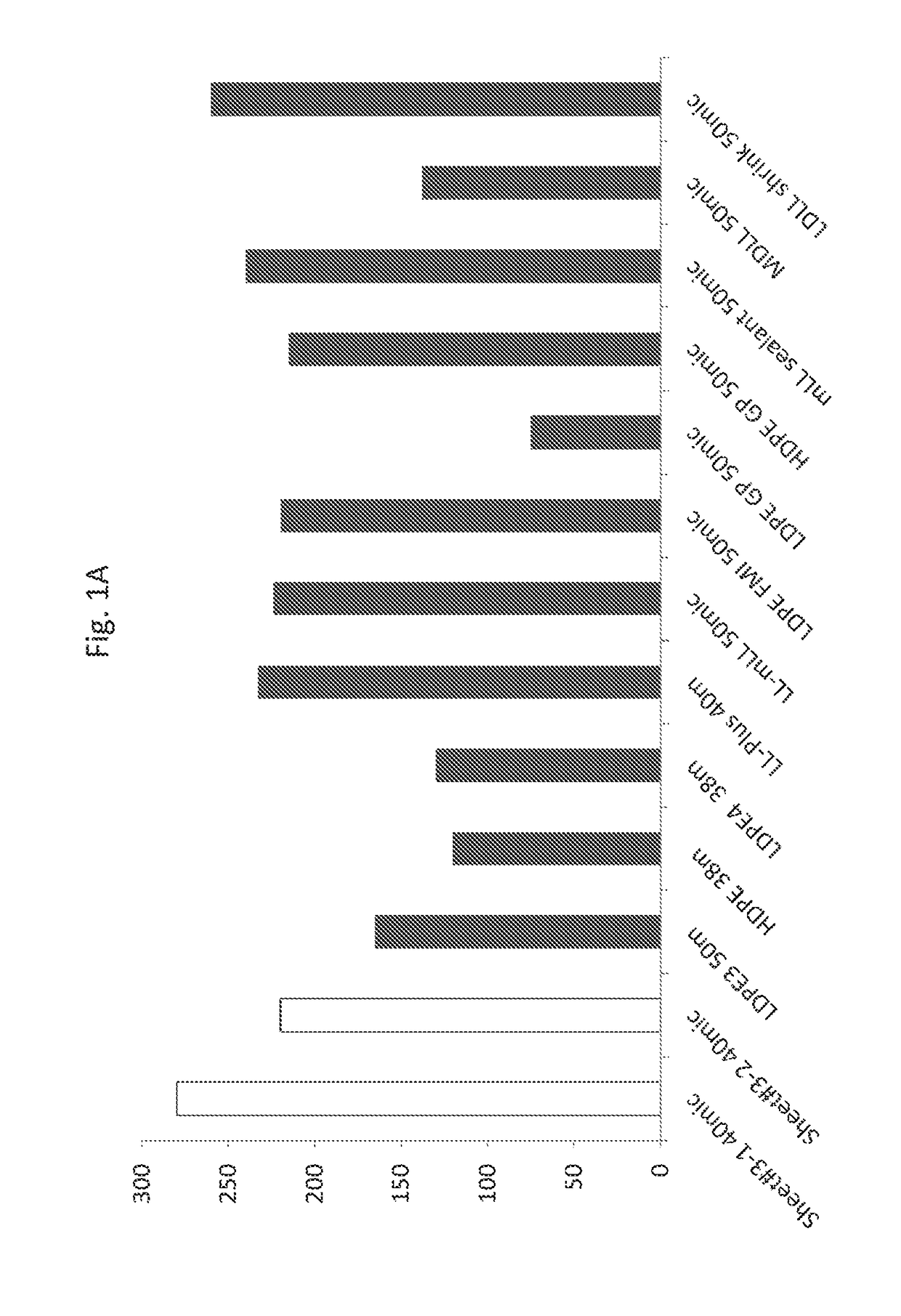

ActiveUS20180281359A1Low oxygen permeabilityReduce water permeabilityShellac coatingsBio-packagingPolymer scienceBiodegradable polymer

The present invention relates to a biodegradable sheet comprising at least two polymer layers, wherein a first polymer layer comprises a mixture of at least two different biodegradable polymers selected from the group consisting of PLA, PCL, PBS and PBSA; and wherein a second polymer layer comprises a biodegradable polymer selected from the group consisting of PBS, PBSA, a mixture of PLA and PBS, and a mixture of PLA and PBSA.

Owner:TIPA CORP

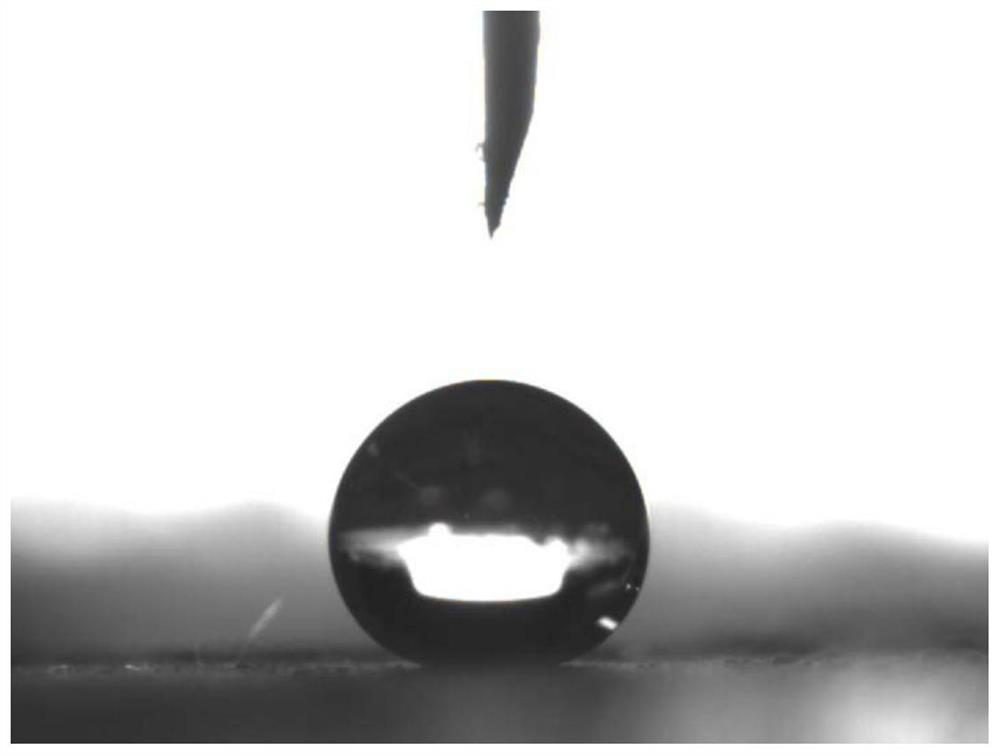

Food-contactable super-hydrophobic coating and preparation method thereof

ActiveCN113444451AInhibition of adhesionSimple processShellac coatingsSpecial surfacesCelluloseShellac

The invention relates to a food-contactable super-hydrophobic coating and a preparation method thereof, and belongs to the technical field of preparation of super-hydrophobic materials, and the super-hydrophobic coating mainly comprises the following raw materials: stearic acid, shellac and ethyl cellulose. The preparation method comprises the following steps: stirring and dissolving the shellac in absolute ethyl alcohol, adding the ethyl cellulose and the stearic acid to prepare a mixed solution, dipping a coating base material in the mixed solution, and forming the coating at a certain temperature. The raw materials used for preparing the super-hydrophobic coating are non-toxic and pollution-free, the super-hydrophobic coating can be used as a material for food contact, the process is simple, the binding property of the coating and a base material is good, the super-hydrophobic coating can be prepared on various base materials to endow the base materials with super-hydrophobicity, and the effect of preventing liquid food adhesion is achieved.

Owner:JIANGNAN UNIV

Durable insulating coating

InactiveCN104327730AAging resistantGood preservativeShellac coatingsAnti-corrosive paintsMetasilicateAntioxidant

The invention discloses a durable insulating coating. The durable insulating coating is prepared from lac resin, an antistatic agent, a dispersing agent, a conductive control agent, a pigment and filler, a preservative and an antioxidant, wherein the antistatic agent is glyceryl stearate; the dispersing agent is fatty acid polyethylene glycol ester; the conductive control agent is hydroxyl silicone oil; the pigment and filler is calcium metasilicate; the preservative is isobutyl 4-hydroxybenzoate; and the antioxidant is p-phenylenediamine. The durable insulating coating disclosed by the invention is prepared from the lac resin, the antistatic agent, the dispersing agent, the conductive control agent, the pigment and filler, the preservative and the antioxidant, so that the prepared product is good in insulating effect, high in safety, good in anti-corrosive properties, high in aging resistance, low in cost, stable in quality and long in service life.

Owner:江苏博腾新材料股份有限公司

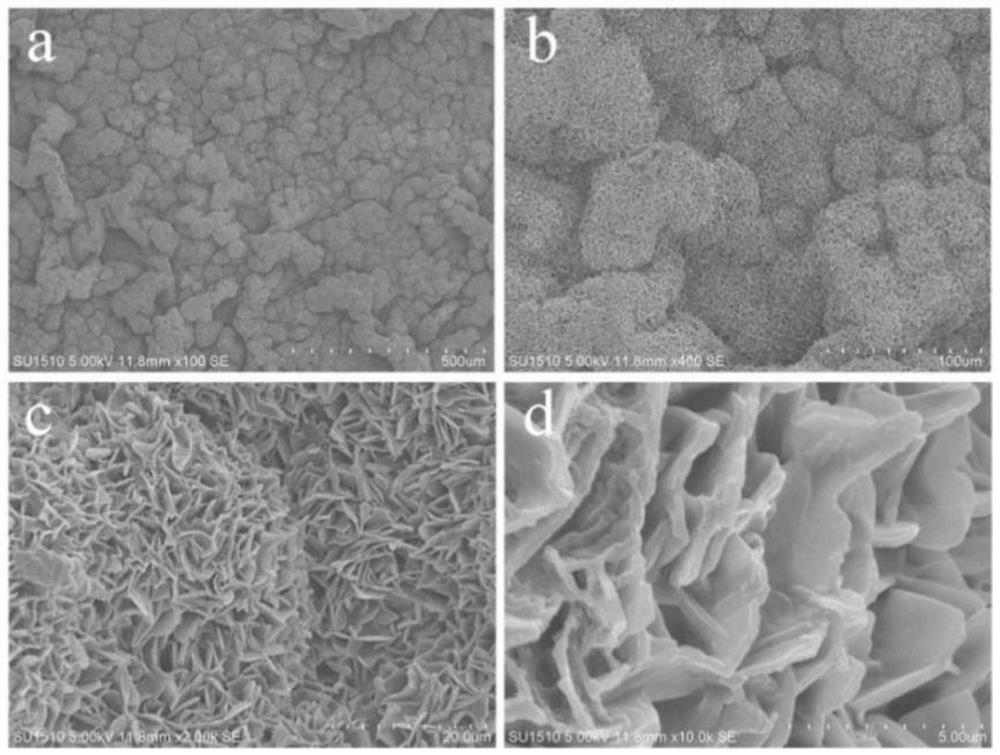

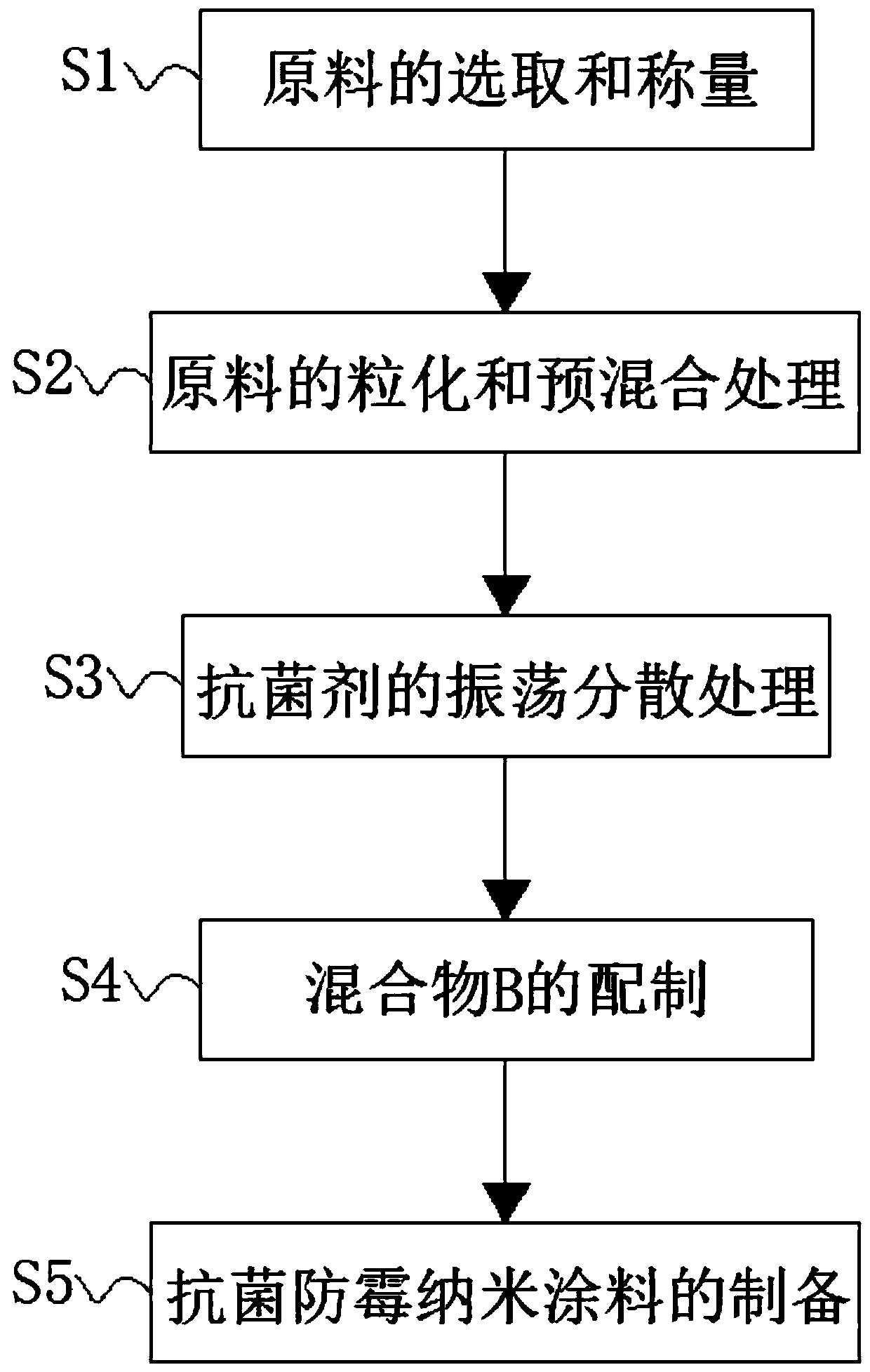

Environmentally-friendly and antibacterial mildew-proof nanometer coating

InactiveCN110903707AImprove antibacterial propertiesStrong heat resistanceShellac coatingsAntifouling/underwater paintsMasterbatchOrganic film

The invention discloses an environmentally-friendly and antibacterial mildew-proof nanometer coating and a preparation method thereof. The environmentally-friendly and antibacterial mildew-proof nanometer coating provided by the invention comprises the following raw materials in parts by weight: 40-50 parts of an organic film-forming base material, 5-10 parts of a composite filling material, 1-3 parts of color masterbatch, 5-10 parts of a composite modified antibacterial agent, 1-3 parts of an antifoaming agent, 3-5 parts of a film-forming agent, 1-3 parts of a leveling agent, 3-5 parts of anorganic solvent and 1-3 parts of a pH regulator, with the balance being deionized water, wherein the composite modified antibacterial agent is composed of 60-70% of an organic antibacterial agent and30-40% of an inorganic antibacterial agent. The invention relates to the technical field of coatings. The environmentally-friendly and antibacterial mildew-proof nanometer coating provided by the invention has the following advantages: by adoption of the composite antibacterial agent, the composite antibacterial agent is dispersed into the coating base material in a nanometer manner, so the antibacterial effect of the coating is significantly improved; and through combined application of the inorganic antibacterial agent and the organic antibacterial agent, the purpose of strong antibacterialproperties, strong heat resistance and strong long-acting properties of the coating are achieved, so the antibacterial effect of the coating is further improved, and the coating is beneficial to use.

Owner:湖南太子化工涂料有限公司

Heat-insulating self-cleaning architectural coating and preparation method thereof

InactiveCN104277670AImprove adhesionImprove wear resistanceShellac coatingsAntifouling/underwater paintsPolymer scienceEthyl acetate

The invention discloses a heat-insulating self-cleaning architectural coating, which is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of a bisphenol epoxy resin, 20-30 parts of a nano silicon resin, 3-4 parts of 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, 0.5-1.0 part of aluminium oxide, 1-2 parts of glyceryl tristearate, 3-5 parts of polytetrafluoroethylene powder, 1-2 parts of shell-lac, 2-3 parts of polyethylene wax, 3-4 parts of fly ash floating beads, 0.3-0.4 part of azodiisobutyronitrile, 0.2-0.4 part of polyether modified siloxane, 1-2 parts of zinc naphthenate, 1-3 parts of polymerized silica, 6-9 parts of self-cleaning slurry, 1-2 parts of aminopropyltriethoxysilane, 10-13 parts of ethyl acetate, and 5-7 parts of ethylene glycol. The coating disclosed by the invention is used for solving the problem that a coat is poor in fouling resistance, easily polluted, and not ideal enough in heat insulation effect. The added fly ash floating beads are good in heat insulation effect and low in cost, and the added self-cleaning slurry has a good self-cleaning effect; the coating disclosed by the invention is high in adhesion and good in abrasion resistance, and has excellent heat insulation and self-cleaning functions; and the coating is low in production cost, simple in operation and wide in application range.

Owner:ANHUI LENCAQI BUILDING MATERIAL

Laser quenching light-absorbing coating and preparation method thereof

PendingCN112111227AImprove absorption rateSimple preparation processShellac coatingsRadiation-absorbing paintsLaser quenchingMetallic materials

The invention relates to the technical field of laser surface modification, in particular to a laser quenching light-absorbing coating and a preparation method thereof, and the laser quenching light-absorbing coating is prepared by mixing a solvent and aggregate; the solvent comprises the following components in parts by mass: 5-12 parts of a binder; 0.2-0.8 part of an anti-settling agent; 0.02-0.60 part of a thickening agent; 0.10-1.60 part of a wetting agent; 0.1-3.0 part of a leveling aid; 4.0-16.0 parts of a diluent; 0.02-0.60 part of a dispersing agent; 10-60 parts of anhydrous alcohol; 40-100 parts of distilled water. The coating can improve the laser absorptivity of a metal material, avoids local burn of a workpiece, guarantees the machining quality of the workpiece, and improves the hardness of the workpiece.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Aqueous shellac coating agent and production process therefor, and coated food and production process therefor, coated drug and production process therefor, glazing composition for oil-based confectionary, glazing process, and glazed oil-based confectionary using same

InactiveUS20060075927A1Maintain good propertiesQuality improvementShellac coatingsConfectioneryShellacPhosphate

There are provided an aqueous-shellac coating agent comprising shellac, a basic amino acid and / or a basic phosphate, as well as a production process therefor; a coated food and a coated drug that have been coated with such a coating agent; a glazing. composition for oil-based confectionary which is in a liquid form and comprises an aqueous shellac solution (A) containing shellac, a basic amino acid and / or a basic phosphate dissolved in water, a thickener (B), and / or a sugar (C); a process for glazing oil-based confectionary in which this glazing composition is applied to oil-based confectionary to be glazed, thereby generating a glaze; and glazed oil-based confectionary produced using this process for glazing oil based confectionary;

Owner:FREUNT IND

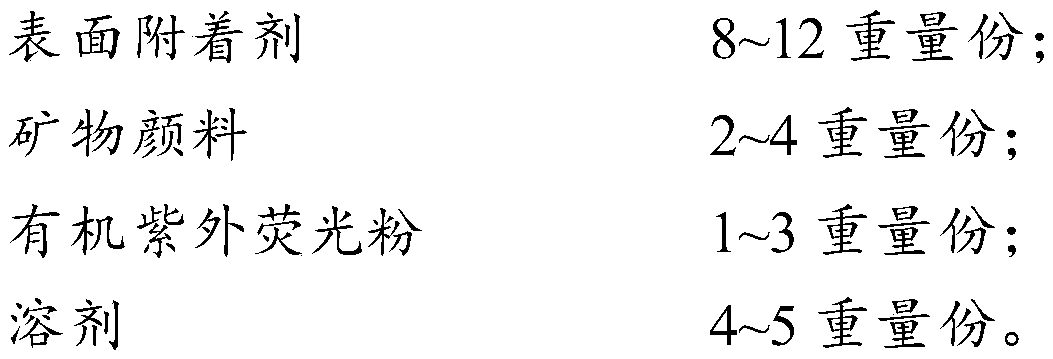

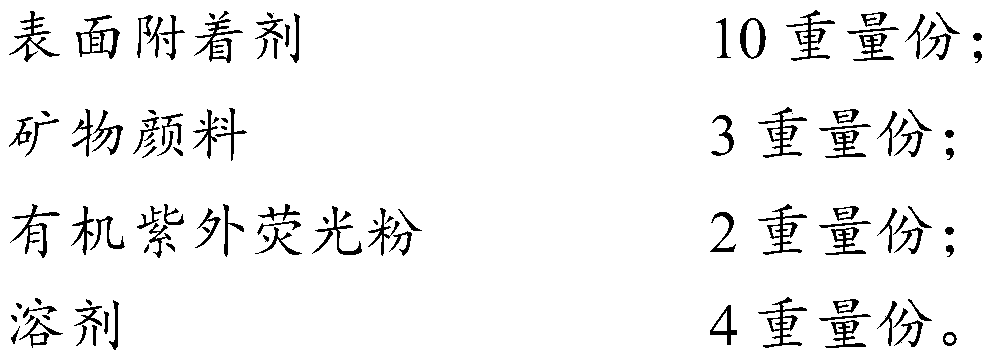

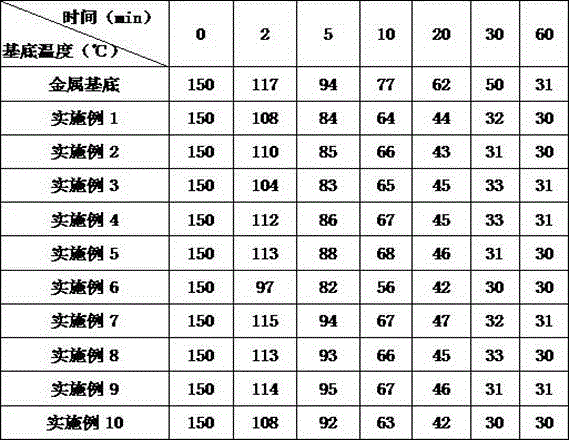

Recognizable fluorescent pigment for repairing bronze cultural relic and preparation method thereof, and method for repairing bronze cultural relic

ActiveCN105505380ALong lasting colorNot easy to decolorizeShellac coatingsAnti-corrosive paintsFluorescenceUltraviolet lights

The invention provides a recognizable fluorescent pigment for repairing a bronze cultural relic, which comprises the following components in parts by weight: 8-12 parts of surface adhesive agent, 2-4 parts of mineral pigment, 1-3 parts of organic ultraviolet fluorescent powder and 4-5 parts of solvent. When the fluorescent pigment provided by the invention is used for repairing the bronze cultural relic, the repaired part can not be easily detected under sunlight and can be easily detected under ultraviolet light, thereby solving the industrial problems of recognizability and beautiful appearance in cultural relic repair. The fluorescent pigment has the advantages of durable material color and low tendency to decolorization, and can not damage the cultural relic.

Owner:UNIV OF SCI & TECH OF CHINA

Lacquering method for wooden pencil

InactiveCN107964358AFlat surfaceNo crackShellac coatingsImpregnation spraying apparatusEnvironmental resistanceShellac

The invention discloses a lacquering method for a wooden pencil. The method includes the following operation steps: (1) using 800# abrasive paper to perform polishing treatment on the surface of a moulded wooden pencil, and then spraying a modification solution on the surface; (2) brushing shellac varnish on the surface of the wooden pencil subjected to treatment by step (1); and (3) 2-3h later after brushing of the shellac varnish, brushing colored finish paint on the surface of the wooden pencil evenly, and conducting drying to obtain a finished product. The lacquering method for the woodenpencil provided by the invention has the advantages of simple operation, low cost, green and environmental protection, the prepared pencil has the characteristics of smooth surface, no crack, uniformcolor and difficult decolorization, and the quality of the pencil is greatly enhanced.

Owner:界首市元宝山木制品有限公司

Metal cans coated with shellac-containing coatings

Owner:PPG IND OHIO INC

Light absorption coating for laser quenching, and preparation method thereof

InactiveCN107629530AUniform performanceImprove performanceShellac coatingsRosin coatingsLaser quenchingHardness

The invention discloses a light absorption coating for laser quenching, and a preparation method thereof, and belongs to the technical field of laser quenching. The light absorption coating for laserquenching comprises 80-100 parts of silica, 150-200 parts of industrial alcohol, 10-20 parts of a binder, 15-25 parts of metal oxide, 12-18 parts of a thickener and 3-8 parts of rosin. The preparationmethod of the light absorption coating for laser quenching comprises the following steps: S1, pouring 80-100 parts of silica, 10-20 parts of the binder, 15-25 parts of metal oxide, 12-18 parts of thethickener and 3-8 parts of rosin into a ball mill, and carrying out ball milling; and S2, pouring the ball-milled raw materials obtained in step S1 into 150-200 parts of industrial alcohol, and uniformly stirring the ball-milled raw materials and the industrial alcohol to obtain the light absorption coating. The light absorption coating greatly improves the hardness of workpieces to avoid local burns of the workpieces, and ball milling of the light absorption coating by using the ball mill greatly improves the performances of the light absorption coating and makes the particle size of the light absorption coating uniform and fine. The light absorption coating and the preparation method have the advantages of low cost and no pollution to the environment.

Owner:XUZHOU WANDA SLEWING BEARING

Thermal dissipation apparatus used for high-calorific-value electronic parts and components and preparation method for thermal dissipation apparatus

ActiveCN105611805AReduce weightImprove thermal conductivityShellac coatingsModifications by conduction heat transferOxygenElectron

The invention discloses a thermal dissipation apparatus used for high-calorific-value electronic parts and components and a preparation method for the thermal dissipation apparatus. The thermal dissipation apparatus comprises a thermal dissipation coating layer (1) and a metal substrate (2), wherein the thermal dissipation coating layer (1) is compounded by graphene oxide, glycerine, a fluorine-containing additive, hydroquinone, tetrahydrofuran and shell-lac based on a creation proportion. The graphene oxide with high thermal conductivity, high radiation and high specific surface area is taken as the main thermal dissipation medium, and the graphene oxide is uniformly dispersed in solvent to prepare the coating; and the shell-lac and the fluorine-containing additive are introduced, so that the interface matching characteristic between the metal substrate and the thermal dissipation coating layer is effectively improved; erosion on the metal substrate by water and oxygen is isolated; meanwhile, dust accumulation on the surface of the thermal dissipation apparatus is weakened, so that the service life of the thermal dissipation apparatus is prolonged; problems existing in thermal dissipation of the high-calorific-value electronic parts and components can be solved by the thermal dissipation apparatus; and furthermore, the thermal dissipation apparatus has the features of high thermal dissipation efficiency, simple preparation process, long service life and green and environmental protection property.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Composite coating special for lithium battery and preparation method thereof

PendingCN109796877AImprove adhesionControl thermal runawayShellac coatingsStarch coatingsAlkanePolyvinyl alcohol

The invention discloses a composite coating special for a lithium battery and a preparation method thereof. The composite coating special for the lithium battery is prepared from, by weight, 20-30 parts of an adhesive, 1-3 parts of a stabilizer, 5-7 parts of an anticorrosive agent, 1-3 parts of seconary alkane sulphonate sodium, 1-2 parts of polyvinyl alcohol, 1-3 parts of bentonite, 1-3 parts ofglucan, 10-15 parts of silicon dioxide soil, 5-10 parts of solvents and 3-5 parts of activated carbon. The composite coating special for the lithium battery is higher in safety performance, good in thermal stability, high in mechanical strength and good in adhesive force, the implementation mode is simple, and the coating can be used in spray-coating, brush-coating and other modes.

Owner:无锡至极动能科技有限公司

Metal cans coated with shellac-containing coatings

Owner:PPG IND OHIO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com