Fingerprint-resistant transparent coating layer and preparation method thereof

A clear coating, fingerprint-resistant technology, used in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of fingerprint stain residue, loss of effect, weak adhesion on smooth glass surfaces, etc., to achieve excellent fingerprint resistance. The effect of excellent fingerprint resistance and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

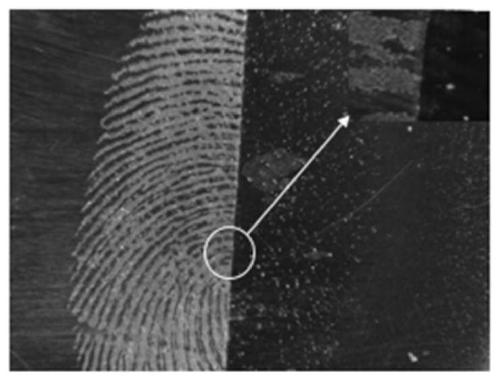

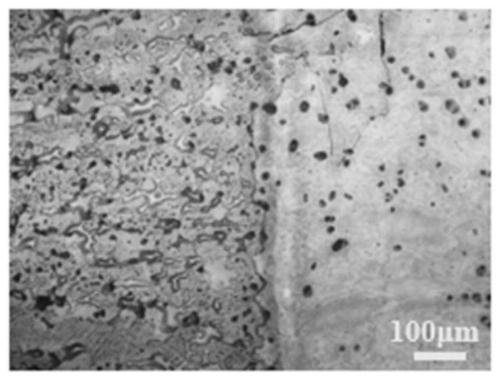

[0019] Take 1 mass part of alkyd varnish, 0.6 mass part of catalyst dibutyl tin dilaurate, 1 mass part of curing agent JIAO-HI100, 0.6 mass part of leveling agent BYK333, and 0.6 mass part of adhesion promoter BYK-4500 0.8 parts by mass, 5 parts by mass of diluent butyl acetate, and 1 part by mass of perfluoropolyether DAIKIN L-200 were mixed and mechanically stirred for 5 hours to obtain a fingerprint-resistant transparent coating, which was coated on the cleaned transparent glass by dip coating sheet surface. The dipping process is as follows: the dipping speed is 500 μm / s, the dipping time is 60s, and the number of dipping times is 2 times. After dipping, put it in an oven at 80°C for 2 hours to cure, and perform fingerprint resistance performance characterization on glass slides with fingerprint-resistant transparent coatings. as attached figure 1 As shown, the left side of the picture is the coating part. It can be seen that after pressing the fingerprint, the residue i...

Embodiment 2

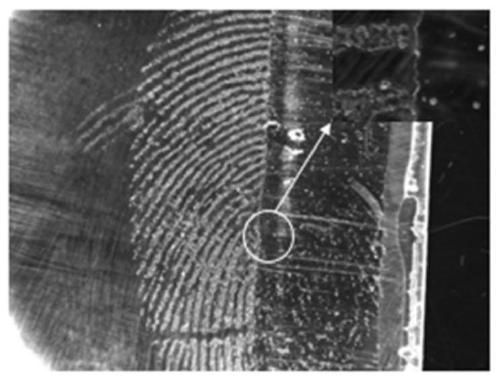

[0021] Take 3 parts by mass of ester glue varnish, 1.5 parts by mass of catalyst dibutyltin dilaurate, 2 parts by mass of curing agent JIAO-HI100, 8 parts by mass of leveling agent TEGO4501, and 2.4 parts by mass of adhesion promoter LTH parts, 18 parts by mass of diluent butyl acetate, 3 parts by mass of perfluoropolyether DAIKIN L-200, mixed mechanically for 5 hours to obtain a fingerprint-resistant transparent coating, which was coated on the surface of a cleaned transparent glass slide by wiping . The rubbing process is: drop 0.5mL of paint on the base of 20cm 2 On the base (every 20cm 2 The substrate needs about 0.5mL paint), wipe it back and forth with a dust-free cloth until it is evenly coated on the surface of the substrate, then put the sample in an oven to cure, and perform fingerprint resistance performance on the glass slide with fingerprint-resistant transparent coating. By comparing the residual rate of fingerprints with and without coating, the anti-fingerpri...

Embodiment 3

[0023] Take 2 parts by mass of shellac varnish, 1 part by mass of catalyst dibutyltin dilaurate, 1 part by mass of curing agent JIAO-HI100, 5 parts by mass of leveling agent BYK3451, and 5 parts by mass of adhesion promoter BYK-4510 1 part by mass, 14 parts by mass of diluent butyl acetate, and 3 parts by mass of perfluoropolyether DuPont GPL105 to obtain a fingerprint-resistant transparent coating, which is coated on the surface of a cleaned transparent glass slide by dip coating. The dipping process is as follows: the dipping speed is 500 μm / s, the dipping time is 80s, and the number of dipping times is 2 times. After dip-coating, place it in an oven at 80°C for 2 hours to cure. The fingerprint-resistant performance of the glass slide with the anti-fingerprint transparent coating is characterized. By comparing the residual rate of fingerprints with and without coating, the anti-fingerprint rate of the coating is 65%. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com