Aquosity metal finishing composition

A metal surface treatment and composition technology, which is applied in the field of water-based metal surface treatment compositions, achieves the effects of excellent storage stability, excellent corrosion resistance, and favorable conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

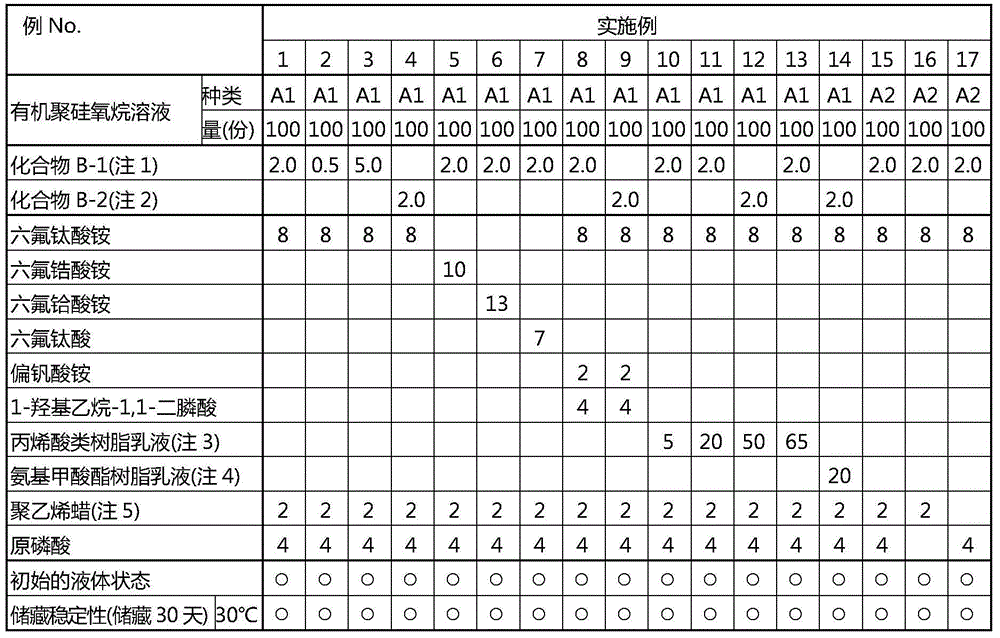

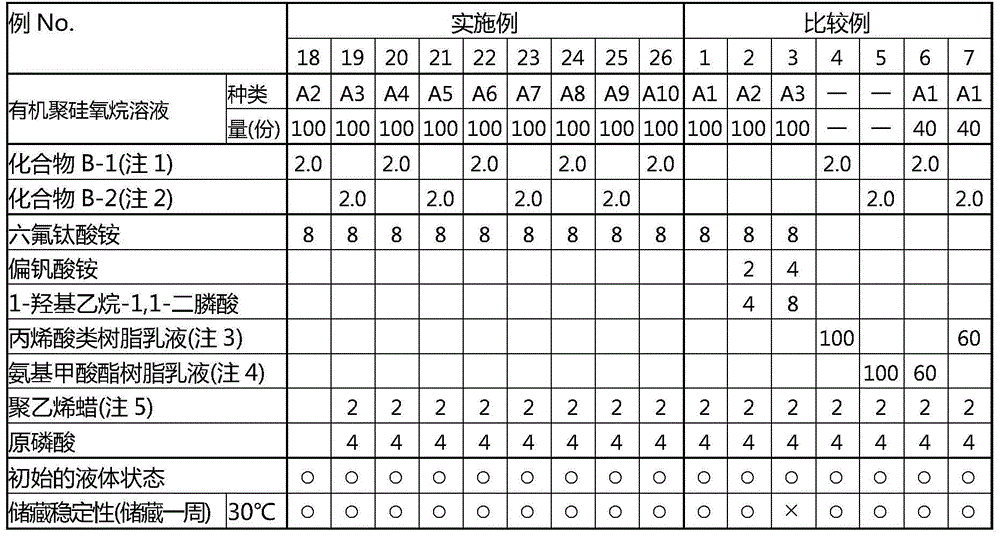

Examples

Embodiment

[0100] Hereinafter, the present invention will be specifically described with reference to Examples and Comparative Examples of the present invention. The present invention is not limited to these Examples and the like. In addition, hereinafter, "parts" and "%" mean "parts by mass" and "% by mass" unless otherwise specified.

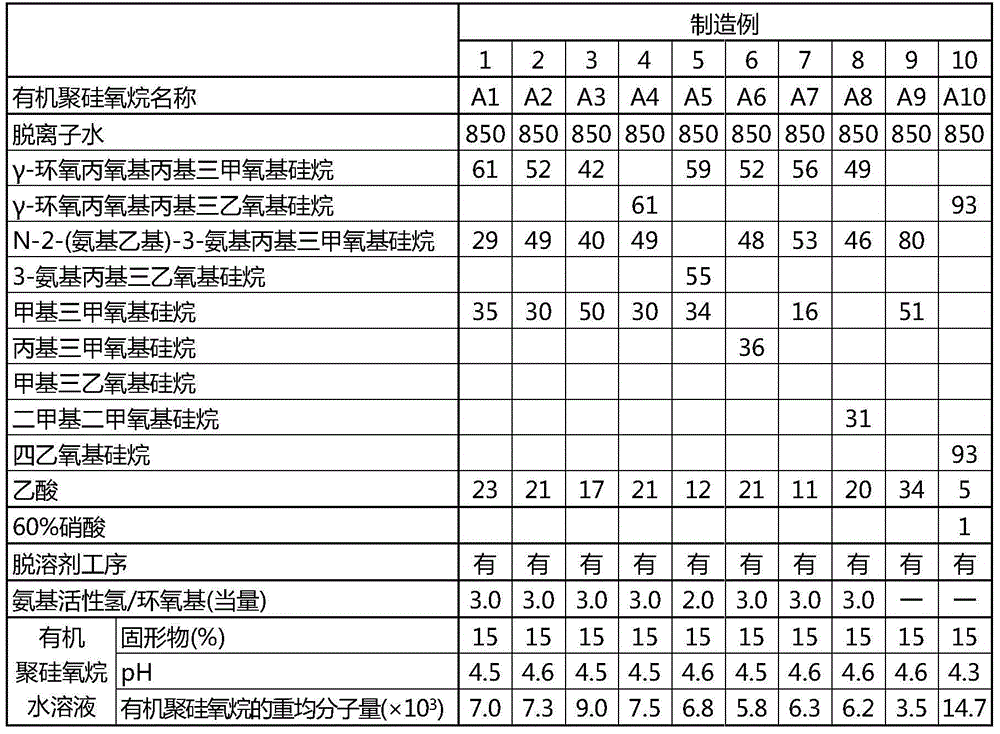

[0101] Production of organopolysiloxane (A)

manufacture example 1

[0103] Into a detachable flask equipped with a reflux condenser, a thermometer, and a stirrer, mix 850 parts of deionized water and 23 parts of acetic acid, and then add γ-glycidoxypropyltrimethoxyl while cooling in an ice bath. A mixture of 61 parts of silane and 35 parts of methyltrimethoxysilane was stirred and dissolved for 30 minutes. Next, 29 parts of N-2-(aminoethyl)-3-aminopropyltrimethoxysilane was slowly injected and dissolved therein, and it was reacted at 80 degreeC for 5 hours, and the aqueous medium of organopolysiloxane was obtained. according to 1 As a result of H-NMR measurement, it was confirmed that no epoxy group remained in the organopolysiloxane. Next, the aqueous medium of the organopolysiloxane was distilled under reduced pressure at 60 to 70° C. and concentrated until the solid content concentration became 15% by mass. In this way, alcohol produced by hydrolysis was distilled off together with water, and then filtered through a 200-mesh filter to obt...

manufacture example 2~9

[0107] In manufacture example 1, except having changed the formulation composition as shown in Table 1, it carried out similarly to manufacture example 1, and prepared organopolysiloxane A2-A9 aqueous solution. The alcohol concentration of any of the aqueous solutions of organopolysiloxanes A2 to A9 measured by a gas chromatograph was less than 1.5%, and no flash point was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com