Preparation method for curing fingerprint-resistant urethane acrylate with electron beam

A urethane acrylate and electron beam curing technology is applied in the preparation of fingerprint-resistant urethane acrylate, and the preparation field of electron beam curing fingerprint-resistant urethane acrylate can solve cracks, poor adhesion of inorganic silicon films, large expansion coefficient, etc. problem, to achieve the effect of excellent fingerprint resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

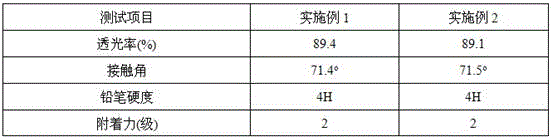

Embodiment 1

[0017] First, under the protection of nitrogen, add 1.0 molar parts of 1-methyl-1H-imidazole-5-carboxylic acid and 1.0 molar parts of 2,2,3,3,4,4,5, 5,6,6,7,7,7-pentadecafluoro-1-nonanol and 0.12 molar parts of carbodiimide and 0.20 molar parts of 4-dimethylaminopyridine and 150 ml of dichloromethane, mechanically stirred at 25°C For 1 hour, the raw materials were fully mixed, and the temperature was kept at 25°C for 48 hours with mechanical stirring, the reaction was stopped, 450 ml of distilled water was added to the reaction kettle, the mechanical stirring was stopped for 1 hour, the mechanical stirring was stopped, and the liquid was separated for 2 hours. Chloromethane phase, dichloromethane was distilled off under reduced pressure to obtain 1-methyl-1H-5-acid-2,2,3,3,4,4,5,5,6,6,7,7,7- Pentafluoro-1-nonyl ester.

[0018] Then, in another dry reactor, add 1.0 mole parts of 1-methyl-1H-5-acid-2,2,3,3,4,4,5,5,6,6,7,7, 7-Pentadecafluoro-1-nonyl ester and 1.1 molar parts of...

Embodiment 2

[0022] First, under the protection of nitrogen, add 1.0 molar parts of 1-methyl-1H-imidazole-5-carboxylic acid and 1.0 molar parts of 2,2,3,3,4,4,5, 5,6,6,7,7,7-pentadecafluoro-1-nonanol and 0.12 molar parts of carbodiimide and 0.20 molar parts of 4-dimethylaminopyridine and 150 ml of dichloromethane, mechanically stirred at 25°C For 1 hour, the raw materials were fully mixed, and the temperature was kept at 25°C for 48 hours with mechanical stirring, the reaction was stopped, 450 ml of distilled water was added to the reaction kettle, the mechanical stirring was stopped for 1 hour, the mechanical stirring was stopped, and the liquid was separated for 2 hours. Chloromethane phase, dichloromethane was distilled off under reduced pressure to obtain 1-methyl-1H-5-acid-2,2,3,3,4,4,5,5,6,6,7,7,7- Pentafluoro-1-nonyl ester.

[0023] Then, in another dry reactor, add 1.0 mole parts of 1-methyl-1H-5-acid-2,2,3,3,4,4,5,5,6,6,7,7, 7-pentadecafluoro-1-nonyl ester and 1.1 molar parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com