Thermal dissipation apparatus used for high-calorific-value electronic parts and components and preparation method for thermal dissipation apparatus

A technology of electronic components and heat dissipation devices, which is applied in the field of heat dissipation of high-calorie electronic components in laser display, can solve problems such as difficult to meet heat dissipation requirements and decline in heat dissipation effects, and achieve improved accumulation, lower surface energy levels, and thermal conductivity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

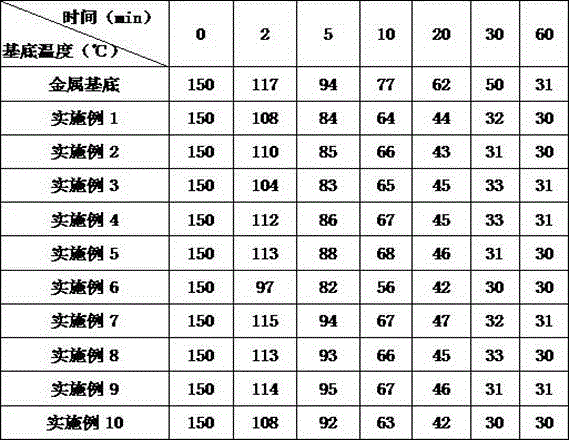

Examples

Embodiment 1

[0024] A method for preparing a heat dissipation device for high-calorie electronic components, first using detergent, acetone solution, deionized water and isopropanol solution to thoroughly clean the copper base, and drying after cleaning; on the surface of the copper base, use The heat dissipation coating was prepared by spin coating, and the film thickness was 5 μm. The heat dissipation coating was composed of the following raw materials in weight percentage: 5% graphene oxide, 10% glycerol, 0.7% fluorine-containing additive, and 7% hydroquinone , tetrahydrofuran 21%, shellac 56.3%; heat-curing treatment was carried out on the prepared heat-dissipating coating, and the treatment time was 30s;

Embodiment 2

[0026] A method for preparing a heat sink for electronic components with high calorific value. First, the aluminum substrate is thoroughly cleaned with detergent, acetone solution, deionized water and isopropanol solution, and then dried after cleaning; the surface of the substrate is sprayed The heat-dissipating coating was prepared by the method, and the film thickness was 20 μm. The heat-dissipating coating was composed of the following raw materials in weight percentage: 7% graphene oxide, 5% glycerol, 1.5% fluorine-containing additive, 5% hydroquinone, tetrahydrofuran 22.5%, shellac 59%; heat-cure the prepared heat-dissipating coating, and the processing time is 30s;

Embodiment 3

[0028] A method for preparing a heat sink for high-calorific electronic components. Firstly, the copper-aluminum alloy substrate is thoroughly cleaned with detergent, acetone solution, deionized water and isopropanol solution, and dried after cleaning; A heat-dissipating coating was prepared by a roller coating method with a film thickness of 50 μm. The heat-dissipating coating was composed of the following raw materials in weight percent: 15% graphene oxide, 20% glycerol, 0.5% fluorine-containing additive, 6.5% hydroquinone %, tetrahydrofuran 23%, shellac 35%; heat-curing treatment was carried out to the heat-dissipating coating prepared, and the treatment time was 30s;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com