Environmentally-friendly and antibacterial mildew-proof nanometer coating

A nano-coating and antibacterial technology, which is applied in the field of anti-mildew nano-coatings, can solve the problems of poor antibacterial effect improvement, unreachable, unrealizable, etc., and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

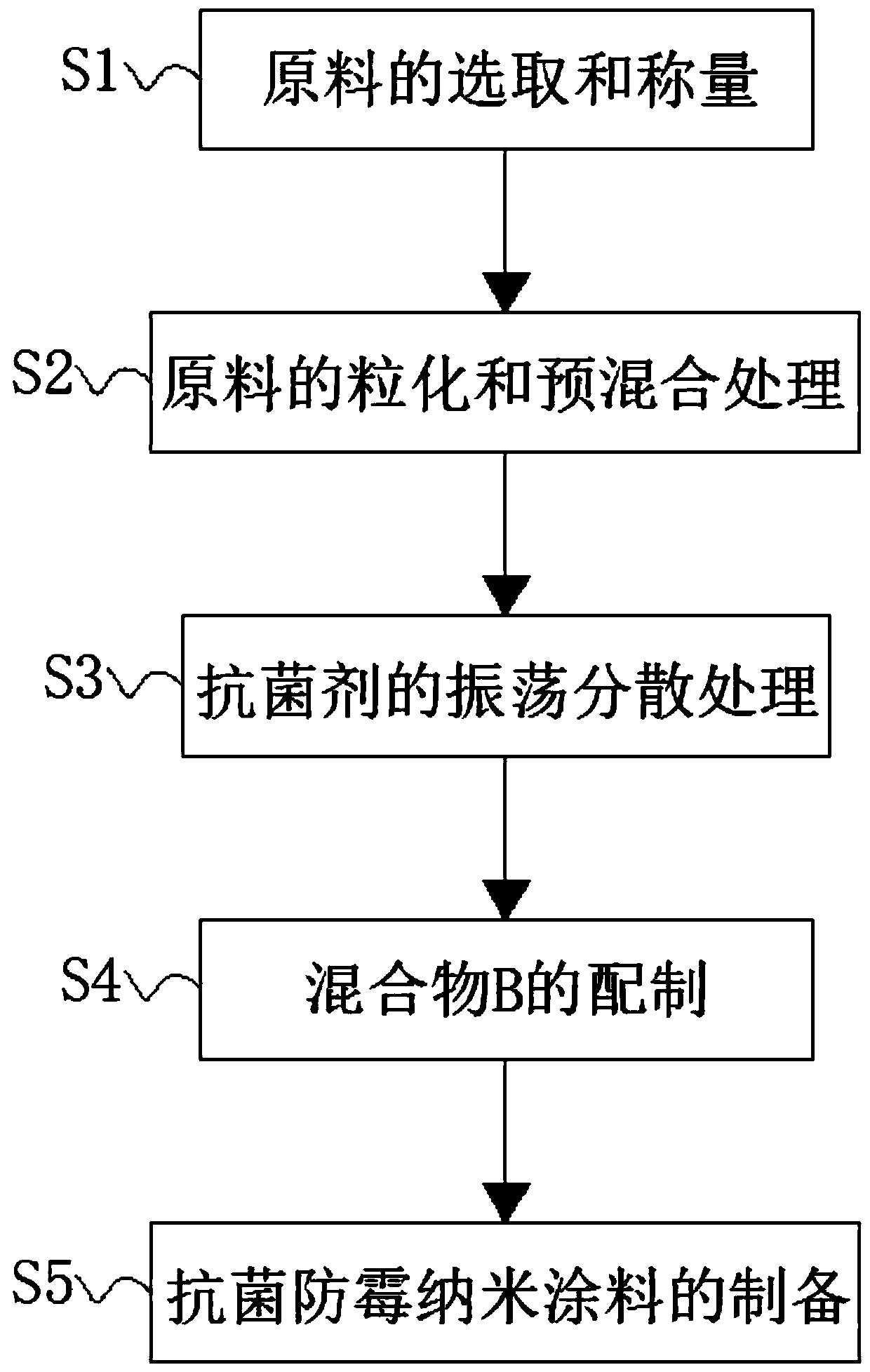

Method used

Image

Examples

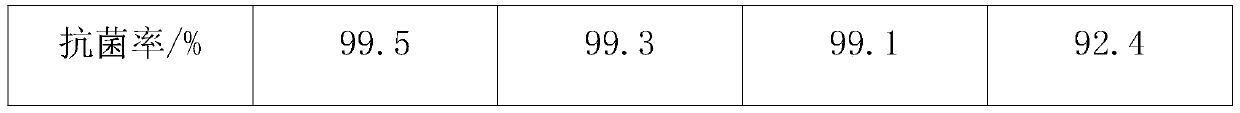

Embodiment 1

[0030] S1. Selection and weighing of raw materials: First, measure 45 parts of organic film-forming base material, 7 parts of composite filler, 2 parts of color masterbatch, 7 parts of composite modified antibacterial agent, 2 parts of defoamer, 2 parts of film forming agent, 2 parts of leveling agent, 4 parts of organic solvent, 2 parts of PH regulator and the balance of deionized water, and then store the weighed components through the batching tank for future use , the organic antibacterial agent is composed of 1H-benzimidazole, picoline, N-iodopropargyloxycarbonyl amino acid and stannous octoate, and the inorganic antibacterial agent is composed of silver zeolite, silver-loaded zirconium phosphate, cuprous oxide and nano oxide Composed of zinc, the organic film-forming base material is a combination of carboxymethyl cellulose, wood rosin, hydroxyethyl cellulose, amber and amaranth resin, hydroxypropyl methyl cellulose and shellac, and the composite filler is calcium carbona...

Embodiment 2

[0036] S1. Selection and weighing of raw materials: First, measure 40 parts of organic film-forming base material, 5 parts of composite filler, 1 part of color masterbatch, 5 parts of composite modified antibacterial agent, 1 part of defoamer, 1 part of film forming agent, 1 part of leveling agent, 3 parts of organic solvent, 1 part of PH regulator and the balance of deionized water, and then store the weighed components through the batching tank for future use , the organic antibacterial agent is composed of 1H-benzimidazole, picoline, N-iodopropargyloxycarbonyl amino acid and stannous octoate, and the inorganic antibacterial agent is composed of silver zeolite, silver-loaded zirconium phosphate, cuprous oxide and nano oxide Composed of zinc, the organic film-forming base material is carboxymethyl cellulose, the composite filler is calcium carbonate, the film-forming agent is acrylate butadiene resin as the base material, and then adding nano-titanium dioxide particles as a mo...

Embodiment 3

[0042] S1. Selection and weighing of raw materials: Firstly, 50 parts of organic film-forming base material, 10 parts of composite filler, 3 parts of color masterbatch, 10 parts of composite modified antibacterial agent, 3 parts of defoamer, 3 parts of film forming agent, 3 parts of leveling agent, 5 parts of organic solvent, 3 parts of PH regulator and the balance of deionized water, and then store the weighed components through the batching tank for future use , the organic antibacterial agent is composed of 1H-benzimidazole, picoline, N-iodopropargyloxycarbonyl amino acid and stannous octoate, and the inorganic antibacterial agent is composed of silver zeolite, silver-loaded zirconium phosphate, cuprous oxide and nano oxide Composed of zinc, the organic film-forming base material is shellac, the composite filler is bentonite, the film-forming agent is acrylate butadiene resin as the base material, and nano-titanium dioxide particles are added as modification additives, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com