Food-contactable super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating and food technology, applied in coatings, shellac coatings, devices for coating liquids on surfaces, etc., can solve problems such as complex and time-consuming processes, environmental pollution, and unsuitable for food contact, and achieve technological progress Simple, small sliding angle, and the effect of preventing liquid food from sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

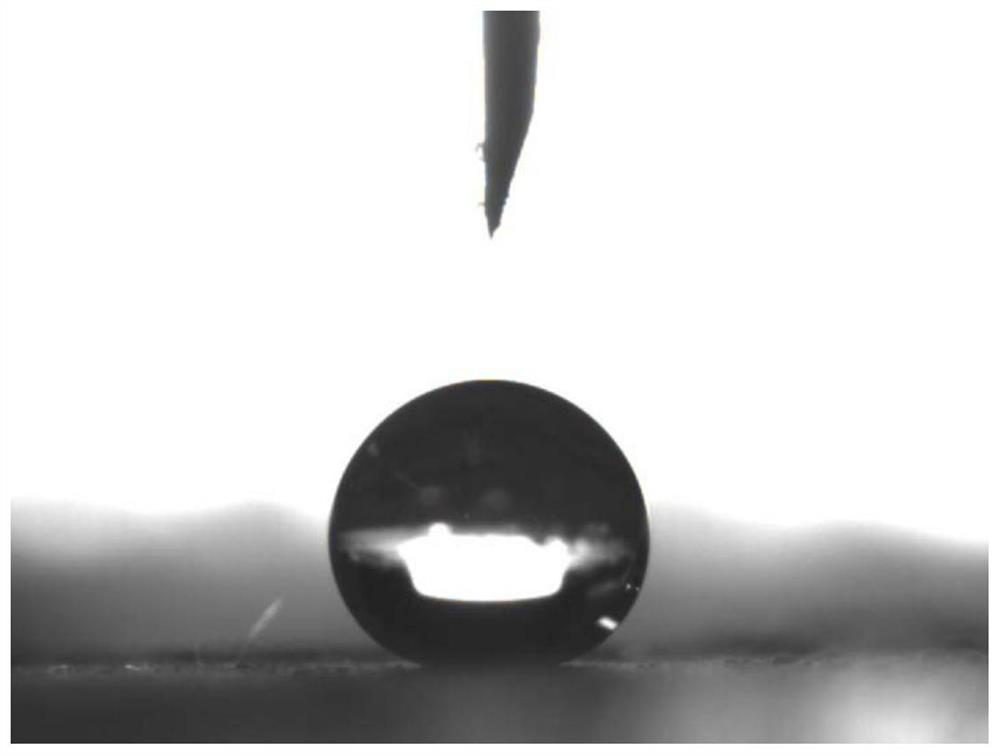

[0036] Take 4.5g of shellac, add it to 91g of absolute ethanol, carry out magnetic stirring at room temperature for 15 minutes, filter out ethanol insoluble matter, add 1.5g of ethyl cellulose, continue magnetic stirring for 5 minutes, raise the temperature to 70°C, and then add 3g of stearic acid was stirred magnetically for 5 minutes to obtain a coating mixture (wherein the mass concentration of stearic acid was 3 wt%, that of shellac was 4.5 wt%, and that of ethyl cellulose was 1.5 wt%). At 6mL / 100cm 2 The amount of impregnation coated glass plate, placed in 60 ℃ and dried for 10min to obtain food contact super-hydrophobic coating.

[0037] The resulting coating had a contact angle of 151.9° and a sliding angle of 7°. The adhesion level of the fork method is 4A.

Embodiment 2

[0039] Take 4g of shellac, add 92g of absolute ethanol, stir magnetically at room temperature for 15min, filter out ethanol insolubles, add 1g of ethyl cellulose, continue magnetically stirring for 5min, raise the temperature to 70°C, then add 3g of hard shellac Fatty acid, magnetically stirred for 5 minutes to obtain a coating mixture (wherein, the mass concentration of stearic acid is 3wt%, the mass concentration of shellac is 4wt%, and the mass concentration of ethyl cellulose is 1wt%). At 6mL / 100cm 2 The amount of impregnation coated glass plate, placed at 50 ℃ and dried for 20min to obtain a food contact super-hydrophobic coating.

[0040] The resulting coating had a contact angle of 153.1° and a sliding angle of 6°. The adhesion level of the fork method is 4A.

Embodiment 3

[0042] Choose one of water-based polyurethane, EVA emulsion, and gum arabic as the bonding matrix.

[0043] Take 4g of bonding matrix, add 92g of absolute ethanol, stir magnetically at room temperature for 15min, filter out ethanol insoluble matter, add 1g of ethyl cellulose, continue magnetically stirring for 5min, raise the temperature to 70°C, and then add 3g of stearic acid, and magnetically stirred for 5 minutes to obtain a coating mixture. At 6mL / 100cm 2 The amount of impregnation coated glass plate, placed at 50 ℃ and dried for 20min to obtain a food contact super-hydrophobic coating.

[0044] The properties of the prepared food-contact superhydrophobic coating are shown in Table 1.

[0045] Table 1 Performance comparison table of different bonding matrices

[0046] bonding matrix Waterborne Polyurethane EVA emulsion gum arabic Contact angle / ° 110 104 91 Sliding angle / ° 63 67 79 Adhesion grade / A 1A 3A 2A

PUM

| Property | Measurement | Unit |

|---|---|---|

| Antenna | aaaaa | aaaaa |

| Sliding angle | aaaaa | aaaaa |

| Antenna | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com