Underwater high-adhesion organosilicone marine antifouling paint and cured coating and preparation method thereof

A marine anti-fouling and high-adhesive technology, applied in the field of marine anti-fouling coatings and underwater coatings, can solve the problems of restricting wide-ranging applications, easy to fall off, low surface energy, etc., to ensure hydrophobicity and low surface energy characteristics , The production process is simple, and the effect of prolonging the service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

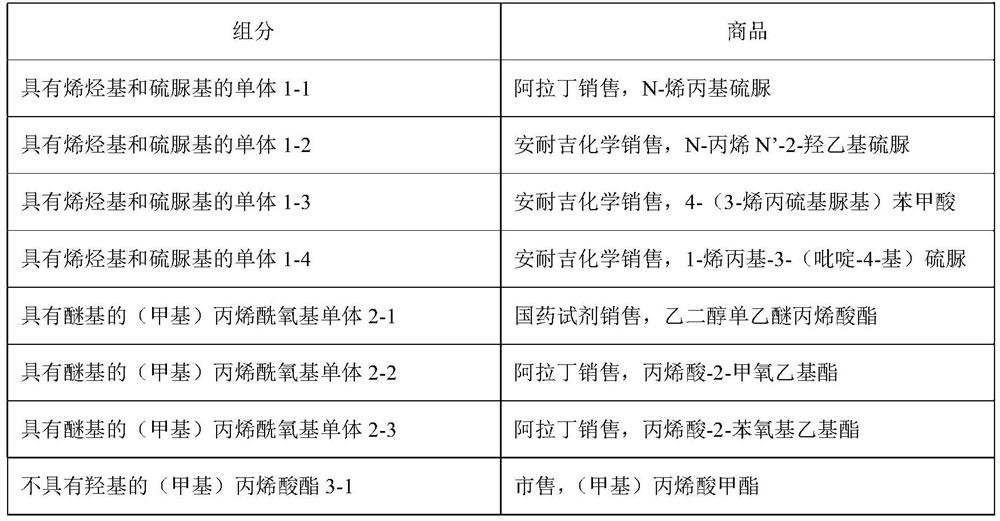

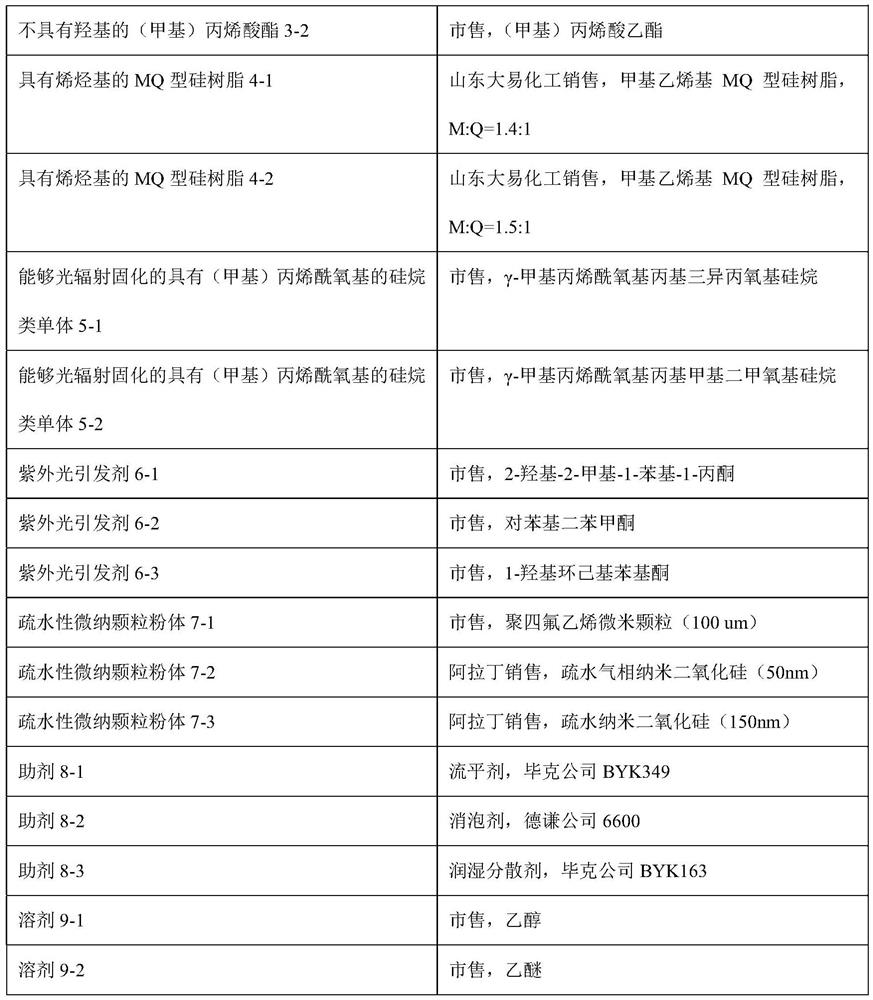

[0053] Configure silicone antifouling paint 1 according to the composition and configuration method in Table 2.

[0054] Table 2

[0055]

[0056]

[0057] The preparation method of organosilicon marine antifouling coating composition and its cured coating is as follows:

[0058] In a light-proof environment (30°C), the above-mentioned components (100g in total) were sequentially added into a brown sealed glass bottle with a capacity of 200g, and the LC-DMS-S digital display magnetic stirrer produced by Lichen Technology Co., Ltd. was used. Under 220rpm, magnetic stirring for 30 minutes;

[0059] In a light-proof environment, paint the uniformly stirred coating composition on a steel plate, and after standing for 40 minutes, perform radiation curing by an ultraviolet radiation source.

Embodiment 2

[0061] Configure silicone antifouling paint 2 according to the composition and configuration method in Table 3.

[0062] table 3

[0063]

[0064] The preparation method of organosilicon marine antifouling coating composition and its cured coating is as follows:

[0065] In a light-proof environment (25°C), the above-mentioned components (100g in total) were sequentially added into a brown sealed glass bottle with a capacity of 200g, and the LC-DMS-S digital display magnetic stirrer produced by Lichen Technology Co., Ltd. was used. Under 100rpm, magnetic stirring for 60 minutes;

[0066] In a light-proof environment, paint the uniformly stirred coating composition on a steel plate, and after standing for 40 minutes, perform radiation curing by an ultraviolet radiation source.

Embodiment 3

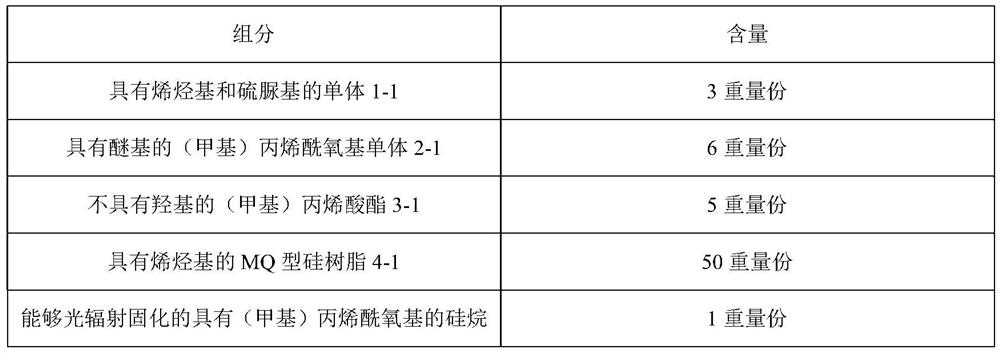

[0068] Configure silicone antifouling paint 3 according to the composition and configuration method in Table 4.

[0069] Table 4

[0070]

[0071] The preparation method of organosilicon marine antifouling coating composition and its cured coating is as follows:

[0072] In a light-proof environment (45°C), the above-mentioned components (100g in total) were sequentially added into a brown sealed glass bottle with a capacity of 200g, and the LC-DMS-S digital display magnetic stirrer produced by Lichen Technology Co., Ltd. was used. Under 100rpm, magnetic stirring for 30 minutes;

[0073] In a light-proof environment, paint the uniformly stirred coating composition on a steel plate, and after standing for 30 minutes, perform radiation curing by an ultraviolet radiation light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com