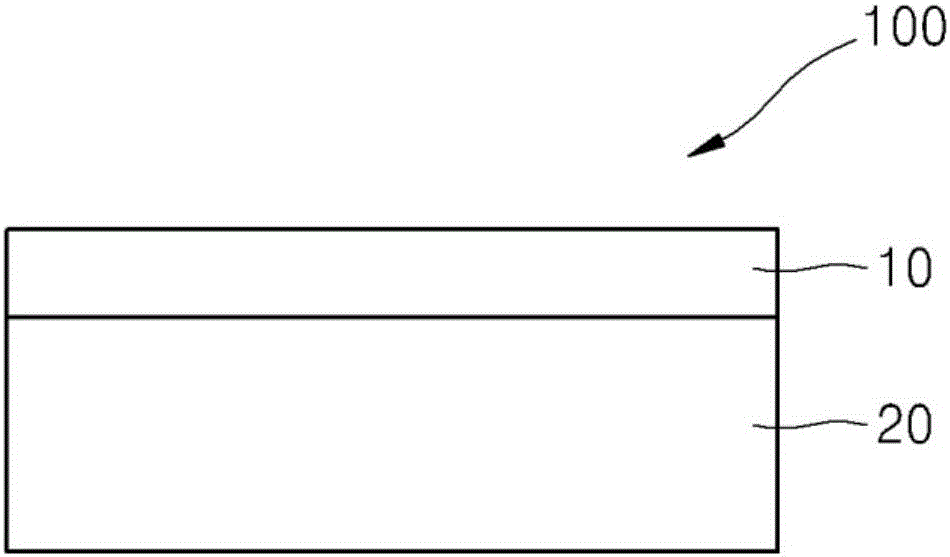

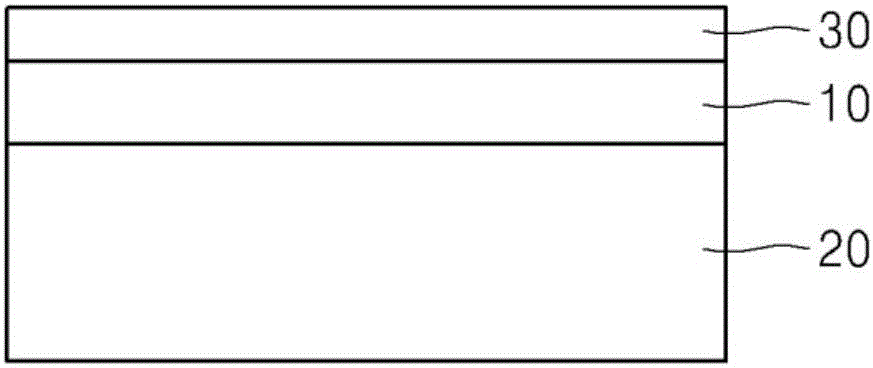

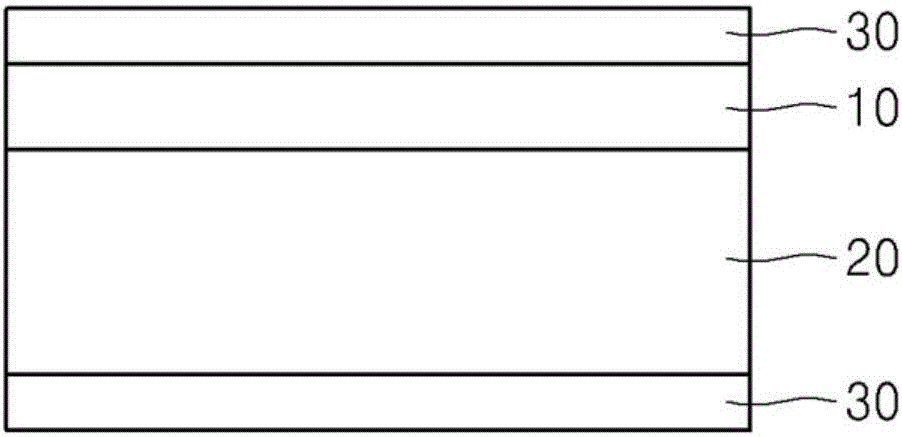

High hardness multi-layer sheet

A multi-layer, high-hardness technology that is applied to layered products, synthetic resin layered products, and electronic equipment. It can solve problems such as weak impact resistance and achieve easy application, excellent dimensional stability, and excellent bending properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0071] Polymethyl methacrylate-1 (acrylic copolymer)

[0072] With 83 parts by weight of methyl methacrylate (MMA), 2 parts by weight of styrene, 15 parts by weight of N-cyclohexylmaleimide, 0.2 parts by weight of n-octyl mercaptan as a chain transfer agent and as 0.1 parts by weight of the azobisisobutyronitrile (AIBN) mixed solution of the polymerization initiator is put into the aqueous dispersant solution (250 parts by weight of ion-exchanged water + 2 parts by weight of the polymerization dispersant), and polymerized at 80°C for 4 hours , and further polymerized at 110° C. for 2 hours to remove residual monomers and then dried to prepare polymethyl methacrylate-1 (acrylic copolymer) in the form of beads. The polymethyl methacrylate-1 had a molecular weight of 130,000 and a Tg of 132°C.

[0073] Polymethylmethacrylate-2 (acrylic copolymer)

[0074] In addition to changing the N-cyclohexylmaleimide in the preparation method of the above-mentioned polymethyl methacryla...

experiment example

[0086] Experimental example: Physical property evaluation of multilayer structure

[0087] 1) Pencil hardness: The hardness of the said Example and the comparative example was measured using ASTM D3363-05 (Mitsubishi pencil, 1 kg load).

[0088] 2-1) Initial curvature: After making the high-hardness multilayer sheets of the above-mentioned examples and comparative examples into test pieces with a width of 60 mm and a height of 100 mm, measure the height of the corners and the bottom surface, and use a gap gauge (Gapgauge) to measure The degree of upward bending was analyzed.

[0089] 2-2) Post-curvature: Under the conditions of temperature 85°C and humidity 85%, after placing the test piece of the above-mentioned high-hardness multilayer sheet for 72 hours, measure the height from the corner and the bottom surface, and use the gap to measure Instrument (Gapgauge) to analyze the degree of upward bending.

[0090] Table 2

[0091]

[0092] Referring to Table 2 above, it ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com