Scratch-resistant super-hydrophobic material based on fiber array and preparation method thereof

A super-hydrophobic and scratch-resistant technology, which is applied in the direction of surface coating liquid devices, pre-treated surfaces, coatings, etc., can solve the problem that super-hydrophobic materials stay in the laboratory stage, and the hydrophobic performance and scratch resistance performance need to be further improved. Improvement and other issues, to achieve the effect of excellent superhydrophobic properties, excellent scratch resistance properties, low outgassing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

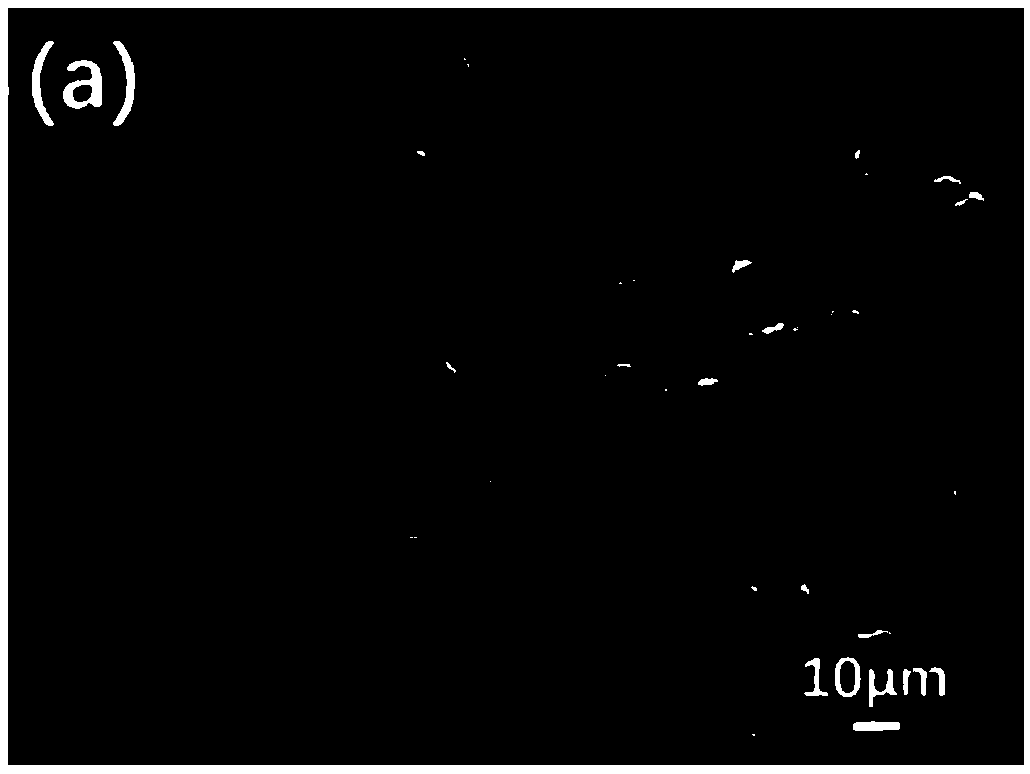

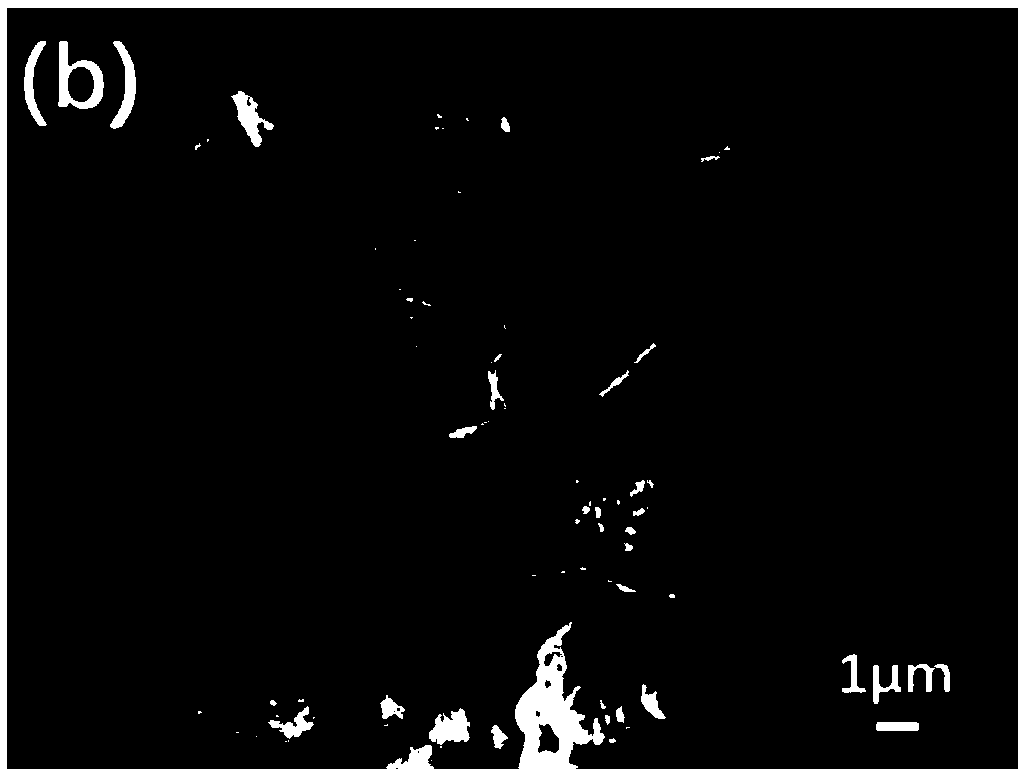

Image

Examples

Embodiment 1

[0054] In this embodiment, the preparation method of scratch-resistant superhydrophobic material based on fiber array is as follows:

[0055] (1) Use a fiber chopping machine to make nylon fluff with a length of 300 μm;

[0056] (2) Sieve the obtained nylon fluff through a mechanical vibrating sieve for 2 hours, so that the chopped fibers pass through screens of different meshes respectively, and fibers with similar lengths stay in the screens of the same mesh. Chopped fibers have better dispersibility. The mesh numbers of the sieves are respectively: 50 mesh, 100 mesh, 200 mesh, 300 mesh and 400 mesh;

[0057] (3) 5 g of chopped fibers after sieving are placed on the bottom electrode plate;

[0058] (4) Use a 250 μm scraper to scrape polyacrylate adhesive on the surface of the aluminum foil substrate and paste it on the top electrode plate, keeping the distance between the top electrode plate and the bottom electrode plate at 10 cm;

[0059] (5) Pass 20kV high-voltage dire...

Embodiment 2

[0069] In this embodiment, the preparation method of scratch-resistant superhydrophobic material based on fiber array is as follows:

[0070] (1) Use a fiber chopping machine to make polypropylene staple fibers with a length of 600 μm;

[0071] (2) sieve the obtained polypropylene staple fibers through meshes of 50 mesh, 100 mesh, 200 mesh, 300 mesh and 400 mesh, and sieve for 2 hours;

[0072] (3) Use a scraper to evenly scrape the adhesive glue on the surface of the substrate to form an adhesive layer with a thickness of 100 μm;

[0073] (4) Take out some short fibers and place them on the bottom electrode plate; paste the polymethyl methacrylate plate coated with 100 μm thick adhesive on the top electrode plate, and adjust the voltage between the bottom electrode plate and the top electrode plate as 30kV and keep the voltage for 10s; the short fibers fly vertically to the surface of the substrate under the action of a high-voltage electric field to form a fiber array;

[...

Embodiment 3

[0079] In this embodiment, the preparation method of the scratch-resistant superhydrophobic material based on the fiber array is as follows: (1) use a fiber chopping machine to produce nylon staple fibers with a length of 500 μm;

[0080] (2) sieve the nylon staple fibers obtained through the meshes successively: 50 mesh, 100 mesh, 200 mesh, 300 mesh and 400 mesh, and sieve for 2 hours;

[0081] (3) Use a scraper to scrape the adhesive glue on the surface of the substrate evenly to form an adhesive layer with a thickness of 150 μm;

[0082] (4) Take out some short fibers and place them on the bottom electrode plate; paste the aluminum foil coated with 150 μm thick adhesive on the top electrode plate, adjust the voltage between the bottom electrode plate and the top electrode plate to be 30kV and maintain the voltage for 15s; The short fibers fly vertically to the surface of the substrate under the action of a high-voltage electric field to form a fiber array;

[0083](5) Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com