Preparation method for superhydrophobic coating with condensation microdroplet self-bouncing properties

A super-hydrophobic coating and characteristic technology, applied in coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., to achieve wide application prospects, good application prospects, and reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

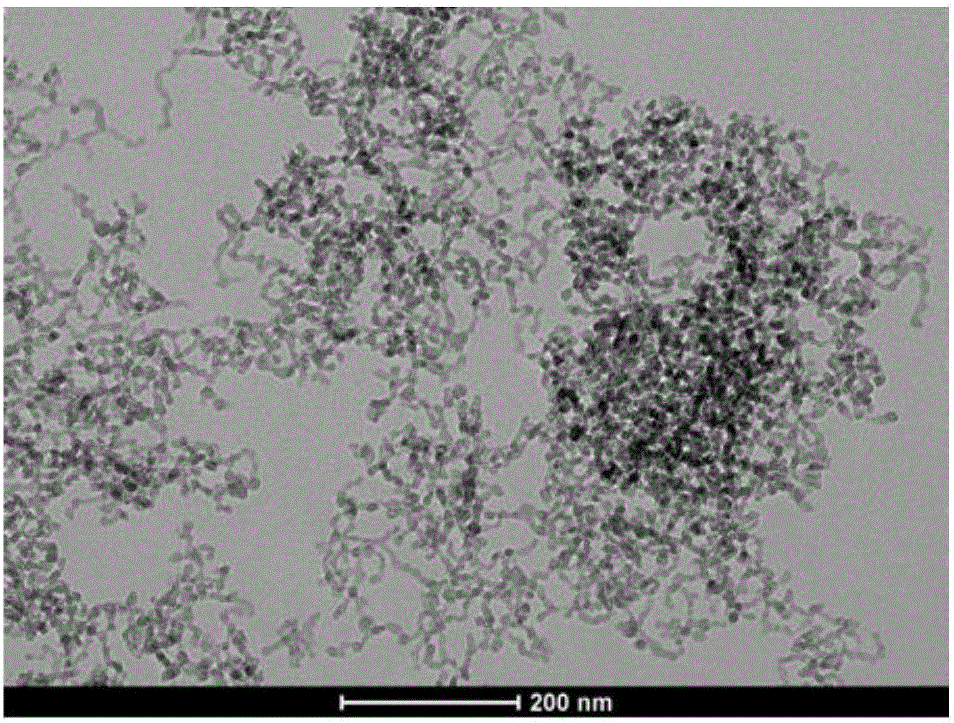

[0033] After 10mL of ammonia solution and 20mL of deionized water were ultrasonically dispersed and mixed for 5 minutes, 2g of acidic chain-type aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, The silicon weight concentration is 10-20%), and a clear mixed solution is obtained after ultrasonic dispersion for 5 minutes. Add the above mixed solution dropwise to 200mL of absolute ethanol solution, ultrasonicate for 5min, then mechanically stir for 5min, then add 1mL tetraethyl orthosilicate solution dropwise, continue mechanically stirring for 60min, then add 0.5mL dropwise The perfluorosilane, and the superhydrophobic coating was obtained after continuous mechanical stirring for 12 hours, and the chain nano-silica after hydrophobic modification still maintained the chain structure, figure 1 Transmission electron micrograph of the coating.

Embodiment 2

[0035]Add 2g of acidic chain-type aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, silica weight concentration 10-20%) to 200mL of absolute ethanol solution, ultrasonic After 10 minutes of mechanical stirring for 10 minutes, the color of the mixed solution began to darken. Add 1 mL of tetraethyl orthosilicate solution dropwise, continue mechanical stirring for 60 minutes, then add 0.5 mL of perfluorosilane dropwise, and finally continue mechanical stirring for 12 hours. Or the reunion is obvious. Add 1 g of alkaline chain-type aqueous silica sol (pH=9-11, diameter 9-15 nm, chain length 40-100 nm, silica weight concentration 30-40%) to 200 mL of absolute ethanol solution After ultrasonication for 10 min, mechanical stirring for 10 min, 1 mL of tetraethyl orthosilicate solution was added dropwise, and after mechanical stirring was continued for 60 min, 0.5 mL of perfluorosilane was added dropwise, and finally mechanical stirring was continued for 12 h to obta...

Embodiment 3

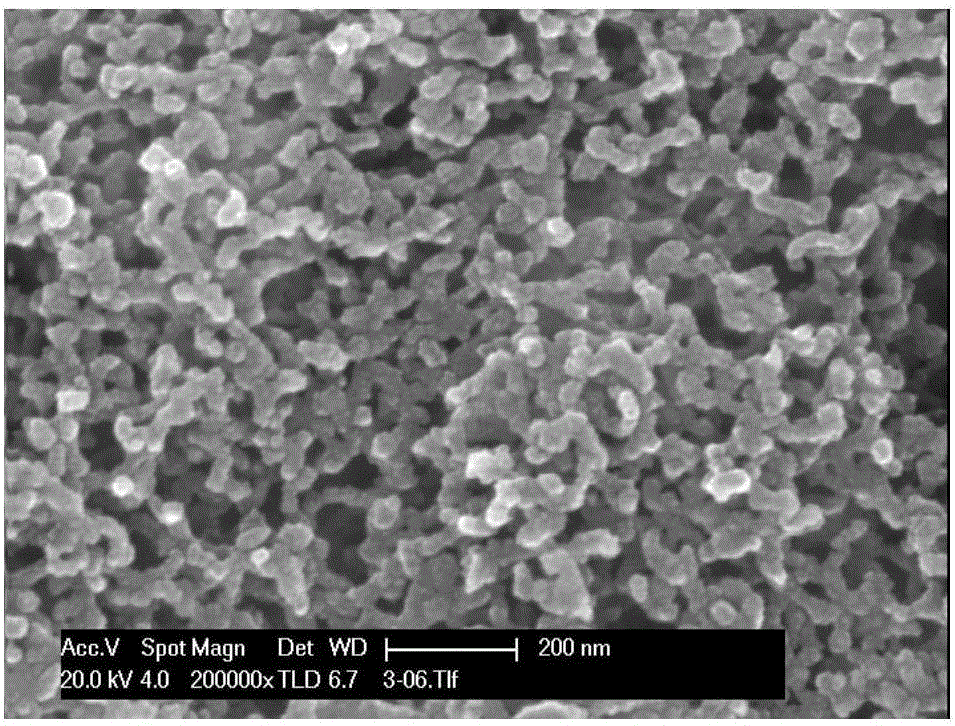

[0037] After 12mL of ammonia solution and 24mL of deionized water were ultrasonically dispersed and mixed for 5 minutes, 3g of chain-type aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, silica weight concentration 10-20%), obtain a clear mixed solution after ultrasonic dispersion for 10 minutes. Add the above mixed solution dropwise to 220mL of isopropanol solution, ultrasonicate for 10min, then mechanically stir for 10min, then add 2mL tetraethyl orthosilicate solution dropwise, continue mechanically stirring for 15min, then add 2mL of Perfluorosilane, after continuous mechanical stirring for 48 hours, a super-hydrophobic coating was obtained, and the coating was dipped and coated on the surface of a clean glass substrate to obtain a nanoporous super-hydrophobic coating. figure 2 Scanning electron micrograph of the coating. Among them, the dip coating process is as follows: soaking time 60s, dipping and pulling speed 100μm / s, residence time 180s, dipping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com