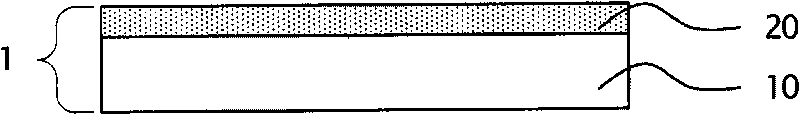

Hard coat film and curable resin composition for hard coat layer

A technology of curable resin and hard coating, applied in the direction of coating, layered products, etc., can solve the problems of impairing operability, difficult to achieve mechanical strength, cracking of hard coating, etc., and achieve the effect of excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0363] Hereinafter, examples are given to further specifically describe the present invention. The present invention is not limited by these descriptions.

[0364] The series of embodiments A are experimental examples related to the first hard coat film and the third hard coat film. The series of embodiments B are experimental examples related to the second hard coating film.

[0365]

Embodiment A1

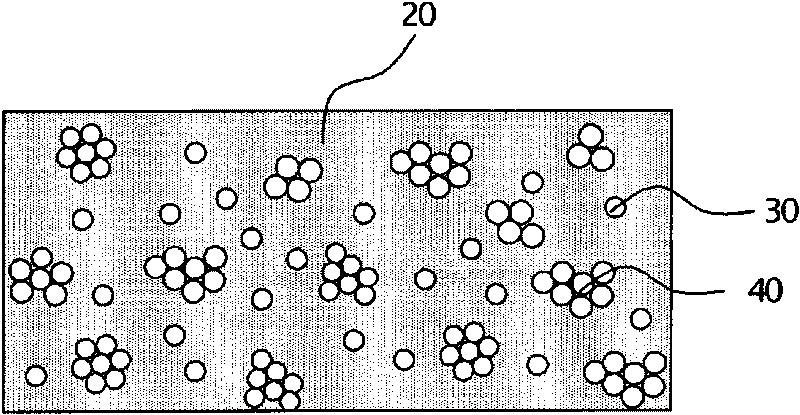

[0367] (1) Preparation of special-shaped silica particles

[0368] In 2000g of silica fine particles (1) (manufactured by Nikki Catalyst Chemicals Co., Ltd., SI-550, average primary particle size 5nm, SiO 2 Concentration: 20% by weight, Na content in silica: 2700ppm), add 6000g of ion exchange water, then add 400g of cation exchange resin (Mitsubishi Chemical Co., Ltd., SK-1BH), stir for 1 hour and carry out dealkalization treatment . Next, after separating the cation-exchange resin, 400 g of anion-exchange resin (manufactured by Mitsubishi Chemical Corporation, SANUPC) was added, stirred for 1 hour, and deanionized. Add 400 g of cation exchange resin (Mitsubishi Chemical Corporation, SK-1BH) again, stir for 1 hour, and perform dealkalization treatment to prepare SiO 2 A dispersion of silica fine particles at a concentration of 5% by weight. At this time, the Na content in the silica particles was 200 ppm.

[0369] Next, the pH of the dispersion liquid was adjusted to 4.0 ...

Embodiment A2

[0381] In the preparation of the special-shaped silica microparticles of the above-mentioned Example A1, except that the average connection number of the silica microparticles was 5, the same operation as the above-mentioned Example A1 was performed to produce the silica microparticles of Example A2. Hard coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com