Patents

Literature

46results about How to "Excellent hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature chemical Ni-Cu-P plating solution and chemical Ni-Cu-P plating method applying the solution

InactiveCN102168261AReduce pollutionProtection securityLiquid/solution decomposition chemical coatingEnvironmental resistanceSodium acetate

The invention relates to chemical plating on the surface of a metal material, in particular to a low-temperature ultrasonic wave assisted chemical Ni-Cu-P plating solution used for the surface of a low-carbon steel base material as well as a chemical Ni-Cu-P plating method. The characteristics include adopting nickel sulfate and copper sulfate as the main salt of the plating solution, sodium hypophosphite as a reducing agent, sodium acetate as a buffer, trisodium citrate and lactic acid as complexing agents, succinic acid and glycine as well as ammonium hydrogen fluoride as combined accelerators, potassium iodide and thiourea as stabilizers to prepare the chemical Ni-Cu-P plating solution, and applying the chemical Ni-Cu-P plating solution on the surface of a low-carbon steel substrate by low-temperature ultrasonic wave chemical plating. In the invention, the formula of the plating solution is environment-friendly, meets the environment-friendly requirement of clean production and reduces pollution to environment. The method for chemically plating Ni-Cu-P on the surface of the low-carbon steel substrate obviously lowers the plating application temperature, enables the deposition speed to be fast and effectively improves the performance of the low-carbon steel substrate.

Owner:SHANDONG JIANZHU UNIV

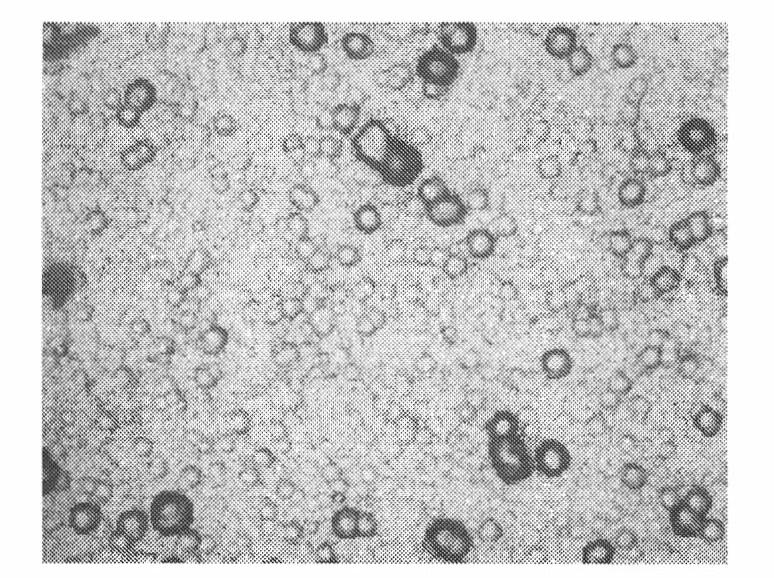

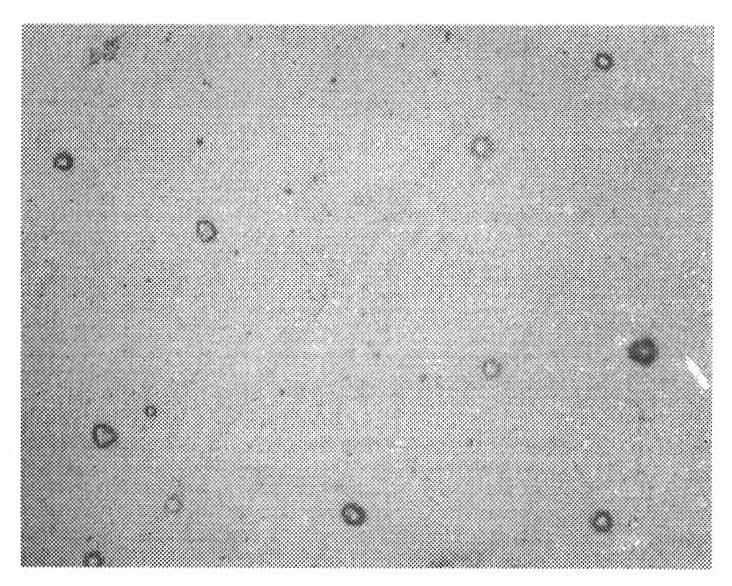

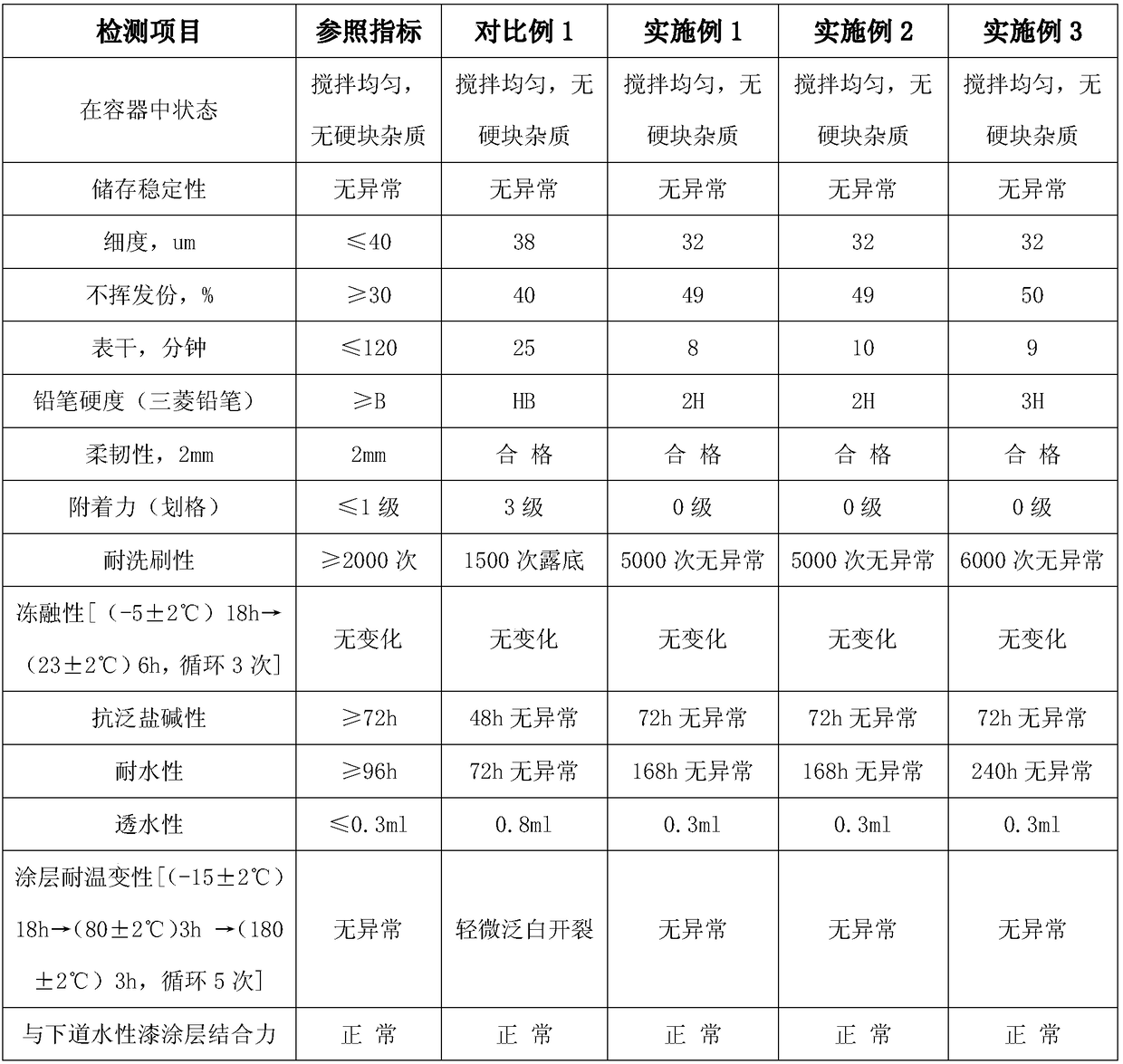

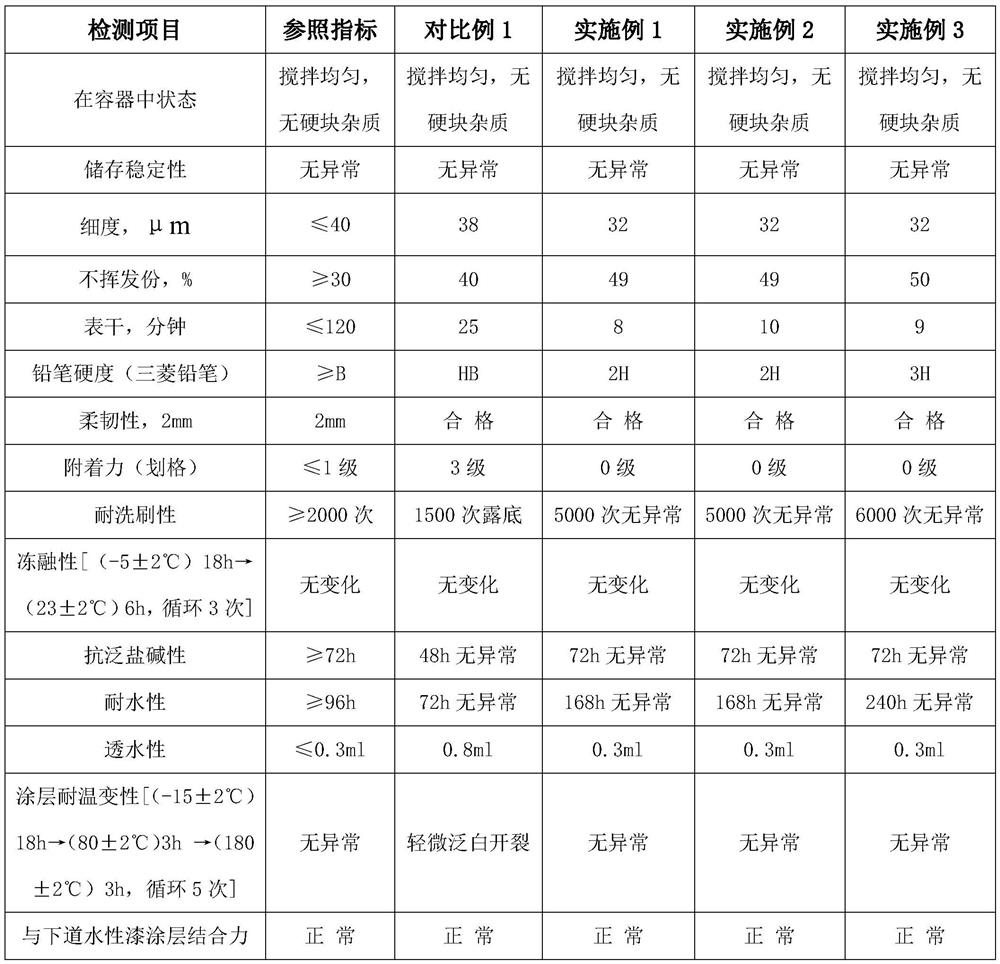

High-adhesion water-based waterproof primer as well as preparation method thereof and application thereof

ActiveCN108456475AGood film formingImprove coating penetration and adhesionPriming paintsMagnesiumHardness

The invention discloses high-adhesion water-based waterproof primer as well as a preparation method thereof and application thereof. The high-adhesion water-based waterproof primer is prepared from the following components in parts by weight: 25-32 parts of composite emulsified polymer emulsion, 2.8-3.3 parts of coupling film-forming agent, 0.6-1 part of hydroxyethyl cellulose, 15-18 parts of titanium dioxide, 4-6 parts of barium sulfate, 4-6 parts of calcium carbonate, 4-6 parts of talcum powder, 1-2 parts of dispersing agent, 0.5-1 part of wetting leveling agent, 0.2-0.4 part of de-foaming agent, 0.2-0.3 part of preservative, 1.8-2.2 parts of anti-freezing agent, 0.1-0.3 part of rheological agent, 0.1-0.3 part of pH regulator, 0.4-0.8 part of thickening agent and 24-31 parts of water. The high-adhesion water-based primer has excellent film-forming property, hardness, flexibility, water resistance, chemical resistance, sealing property, seepage force and adhesion, can be effectively dissolved and permeated into an organic silicon mould release agent on novel material plates such as an art ware, a cement product, a glass magnesium board and a special cast sectional material, is inseamless engagement with the board, and achieves the practical effect of improving coating quality and field construction environment. Moreover, the preparation method is easy, is low in cost, is simple in construction way, and reduces production and construction cost.

Owner:ZHANG ZHOU SAN PAINTS

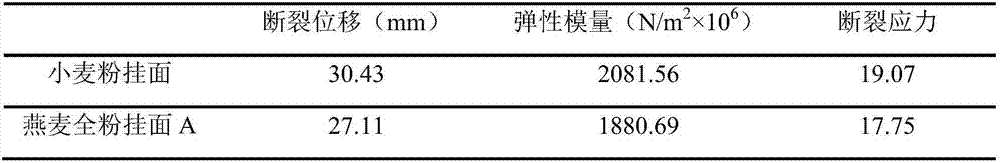

Whole-oat hypolipidemic functional fine dried noodle and production method thereof

InactiveCN106858316AIncrease the amount addedImprove digestion and absorption rateFood preservationInorganic compound food ingredientsSecondary hyperlipidemiaGluten

The invention provides a whole-oat hypolipidemic functional fine dried noodle and a production method thereof. According to the invention, the preprocessed whole oat flour is acquired according to the steps of preparing flour, stabilizing, pre-curing and finely smashing, and then the technologies, such as, formulation optimization, vacuum dough kneading and special rolling, are adopted for increasing the oat additive amount while guaranteeing the organoleptic quality of the fine dried noodle. The oat functional fine dried noodle is prepared from the following raw materials in parts by weight: 10-100 parts of preprocessed whole oat flour, 0-90 parts of wheat flour, 0-10 parts of high-activity gluten powder, 1-3 parts of salt, 0-3 parts of edible glue, 0-3 parts of soda and 0-3 parts of additional starch. According to the invention, under the condition of adding no any additives, 100% oat functional fine dried noodle product is produced, the quality is natural, the functional fine dried noodle belongs to dietary nutrition healthy food and has more obvious effects of reducing blood fat and restraining fat and an excellent staple food choice is supplied for the hyperlipidemia and obese patients.

Owner:KEMEN NOODLE MFG CO LTD

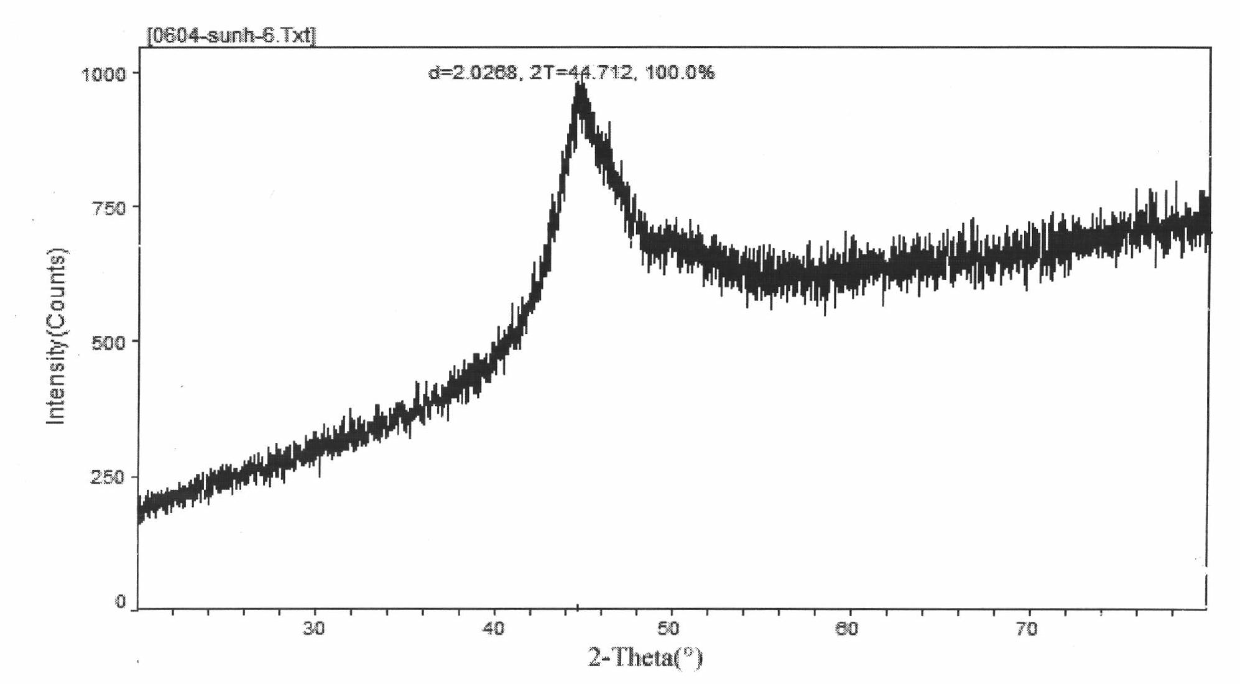

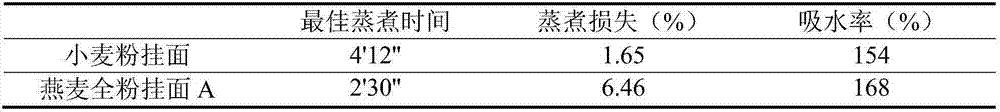

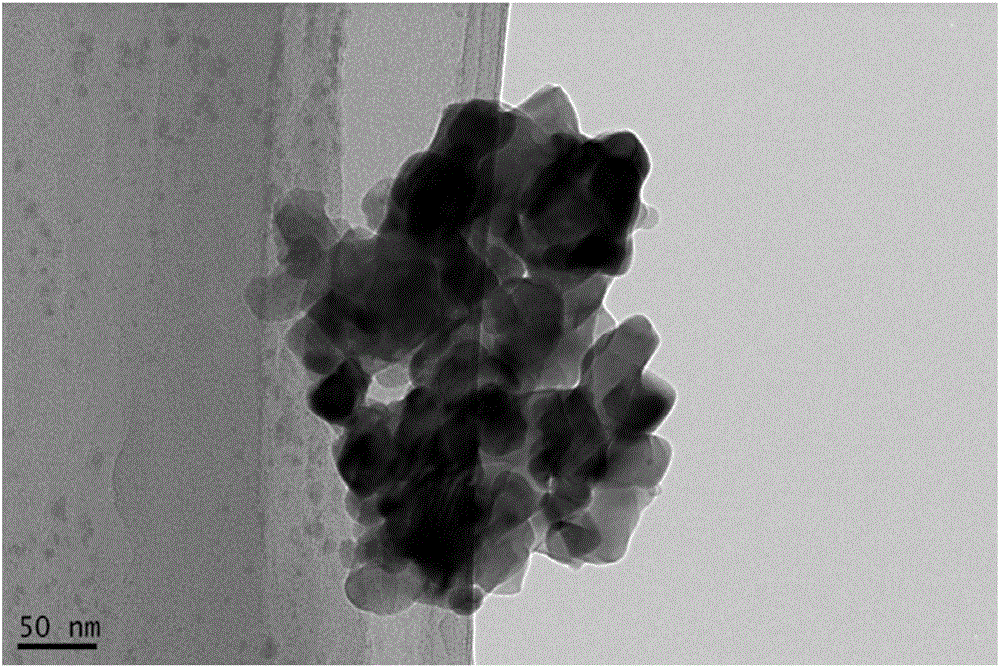

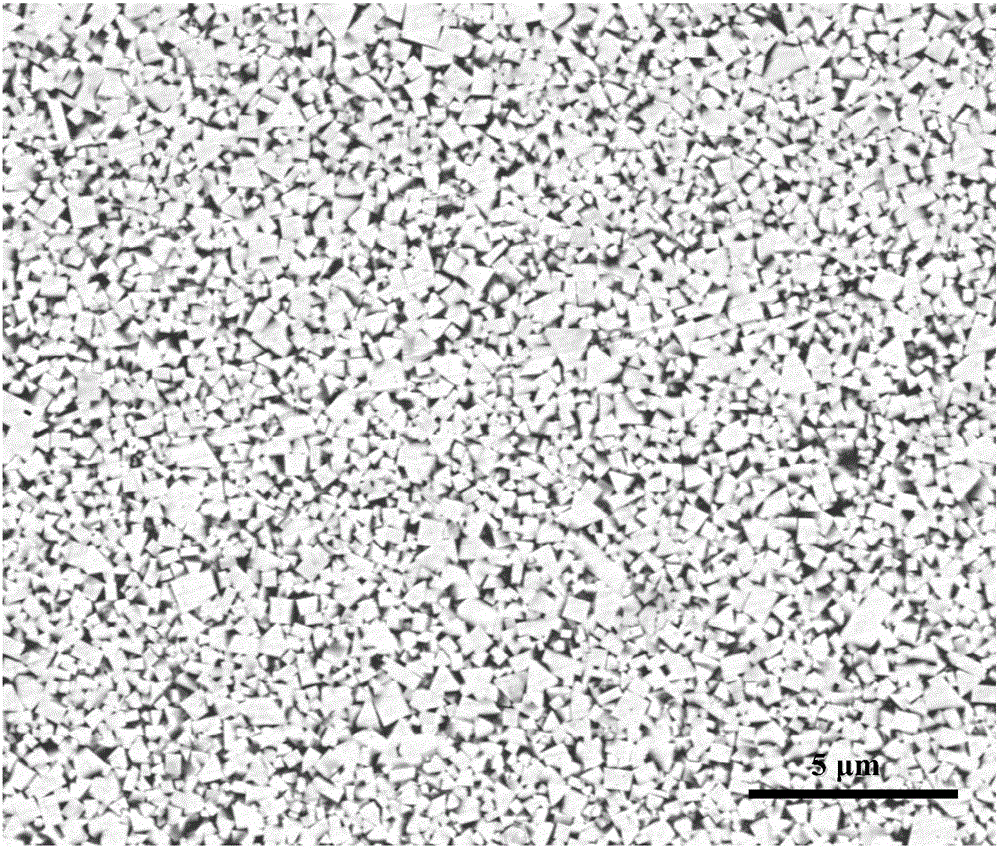

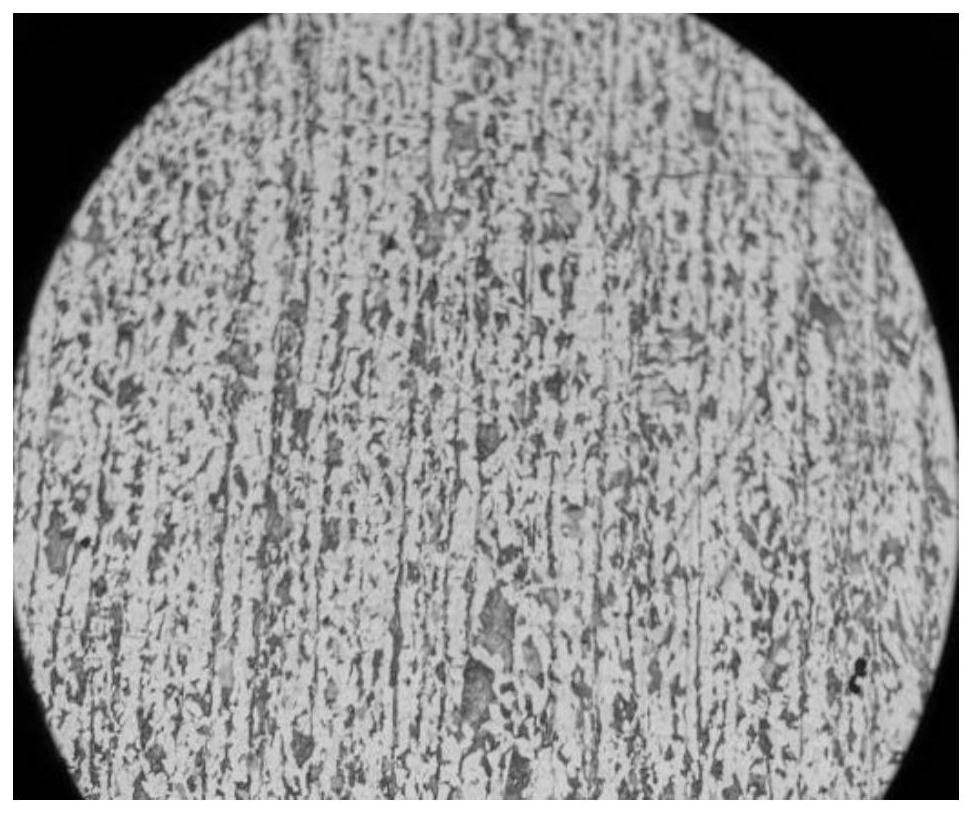

Method for inhibiting cemented carbide grain growth and ultra-fine grain cemented carbide preparation process

ActiveCN106636834AEvenly distributedReduce solubilityTransportation and packagingMetal-working apparatusMicro nanoCarbonization

The invention provides a method for inhibiting cemented carbide grain growth and an ultra-fine grain cemented carbide preparation process. According to the method for inhibiting the cemented carbide grain growth, in the mixing step of the ultra-fine grain cemented carbide preparation procedure, Co-VC micro-nano composite powder is added into WC powder, and the mixture is mixed evenly and is subjected to blank pressing and sintering; and the Co-VC micro-nano composite powder is prepared from V2O5-Co3O4 composite nanopowder through a carbonization and reduction reaction, and the V2O5-Co3O4 composite nanopowder is prepared through a liquid phase chemical precipitation method. The ultra-fine grain cemented carbide preparation process comprises the steps of weighing the Co-VC micro-nano composite powder, mixing the Co-VC micro-nano composite powder with the WC powder, conducting mold pressing to manufacture blanks, and conducting pressure sintering. The method is simple and convenient. Uniform distribution of VC in binding phases in cemented carbide can be guaranteed. Abnormal growth of WC grains is effectively inhibited in the sintering procedure. The hardness, bending strength and other properties of ultra-fine grain cemented carbide prepared through the method are all superior to those of existing cemented carbide prepared in the mode that VC and other inhibitors are added through a mixing method. The ultra-fine grain cemented carbide has prospects of industrial mass production.

Owner:HUNAN UNIV

Alkyd resin for amino baking paint and preparation method thereof

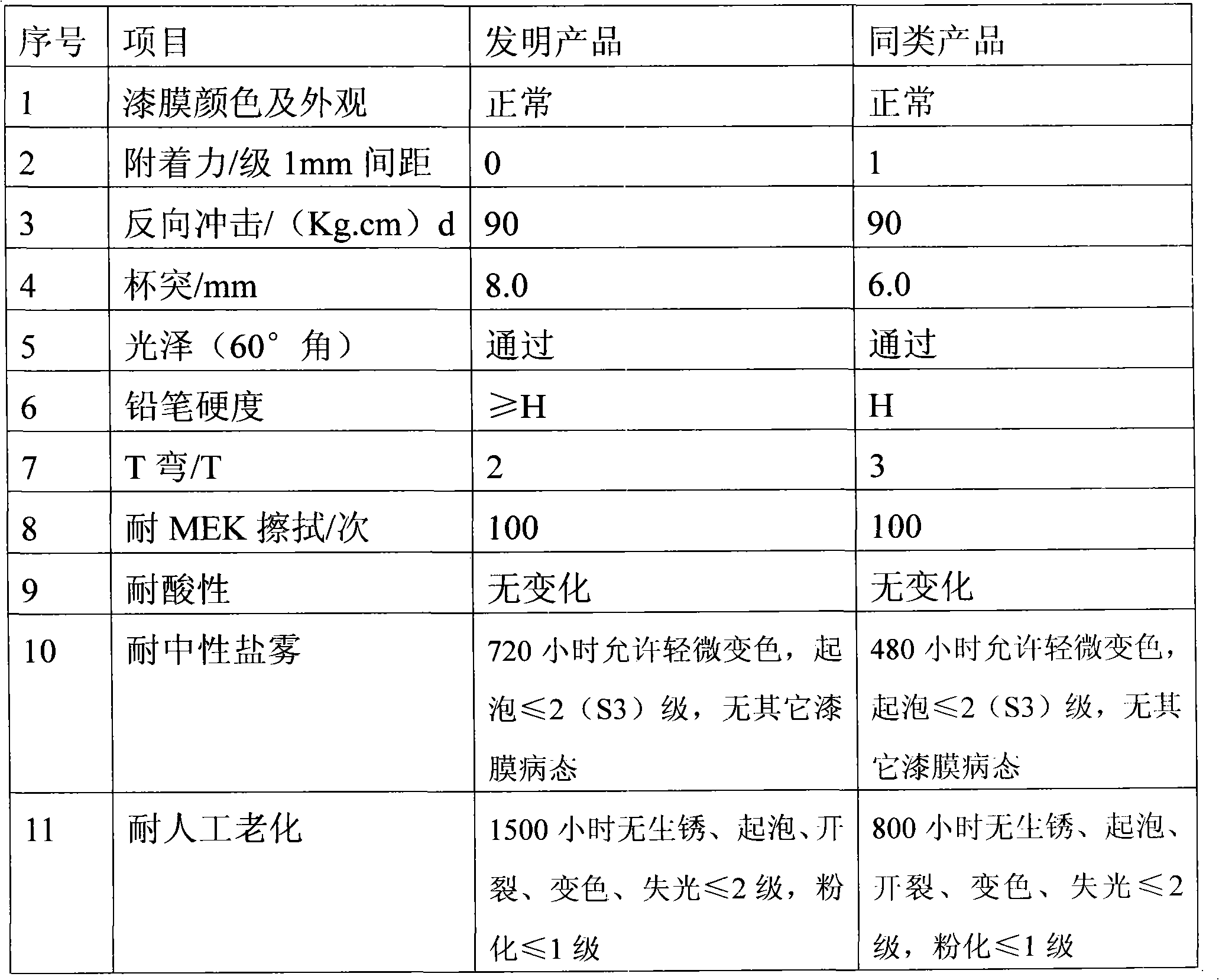

The invention discloses alkyd resin for amino baking paint and a preparation method thereof. The alkyd resin for amino baking paint is prepared from the following components: 10 to 15 parts of dry or half-dry vegetable oil acid, 10 to 15 parts of triatomic alcohol with side chains, 5 to 10 parts of dihydric alcohol with side chains, 20 to 30 parts of phthalic anhydride, 1 to 3 parts of adipic acid, 0.05 to 0.2 part of esterification catalyst, 1 to 5 parts of dimethylbenzene, and 30 to 40 parts of organic solvent. The compositions and the proportions of the raw materials are screened through a lot of experiments, the component proportion is scientific and reasonable, and the alkyd resin for the amino baking paint has good flexibility, shock resistance, rigidity and weather resistance, and is wide in application range. The preparation method of the alkyd resin for amino baking paint is low in production cost, high in preparation efficiency, reasonable in whole process design, strong in operability and easy to implement.

Owner:江苏三木化工股份有限公司

PEPSET resin moulding and sand cyclic utilization clean casting technology

ActiveCN103934411AFast and uniform curingLower regenerationFoundry mouldsMould handling/dressing devicesProcess engineeringRaw material

The invention relates to a PEPSET resin moulding and sand cyclic utilization clean casting technology. The technology comprises the following steps: using raw materials to carry out PEPSET resin sand moulding: putting a sand core into a mould cavity, closing the mould cavity by using an automatic mould closer, then casting with molten iron; shaking out the sands after the moulding of product; transferring the old sands into a waste sand regeneration processing system; wherein the regenerated sands can be applied to a cold box core blower to manufacture sand cores, thus the addition amount of new sands is reduced, and the cyclic utilization of old sands is achieved.

Owner:LAIZHOU XINZHONGYAO MACHINERY

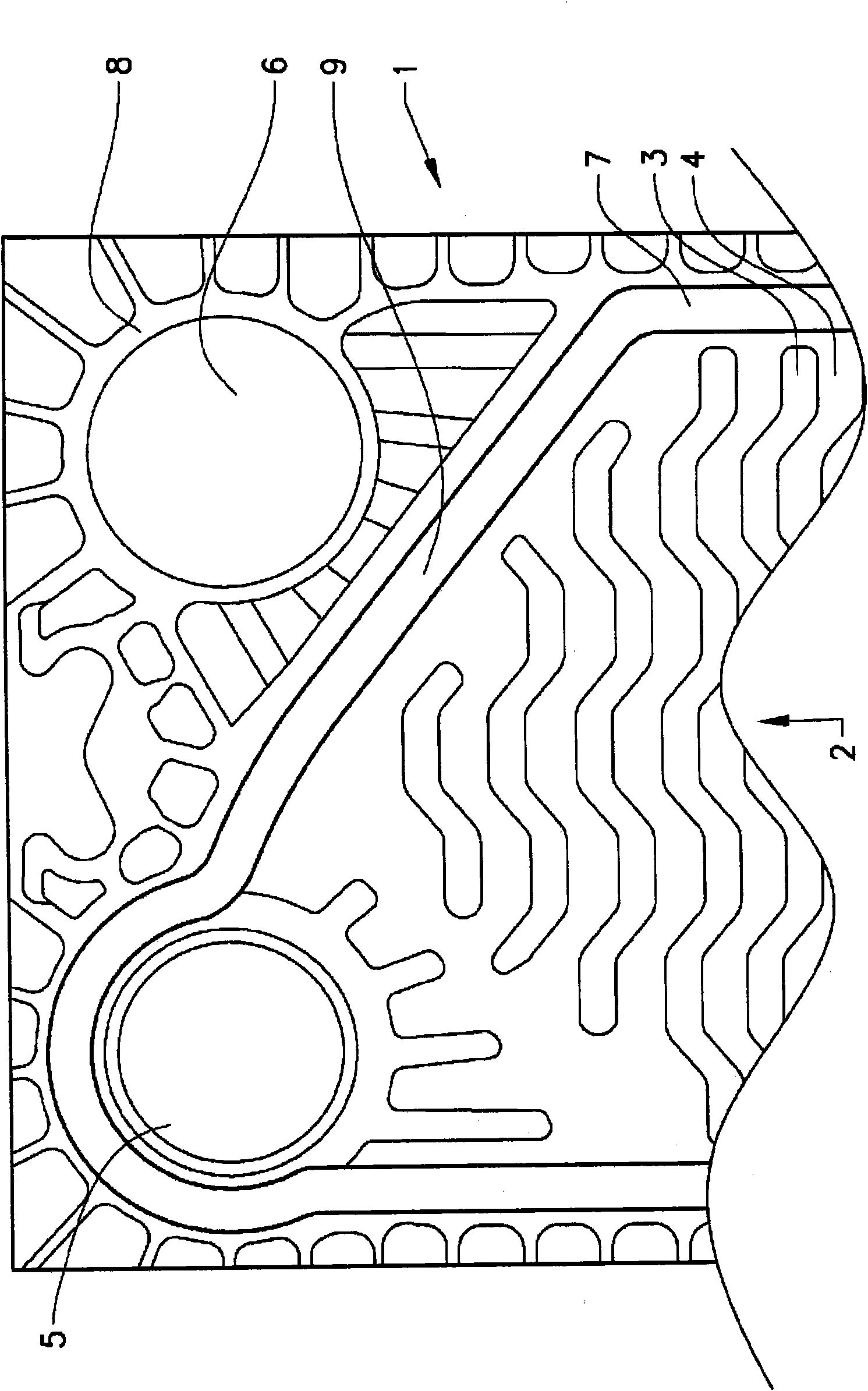

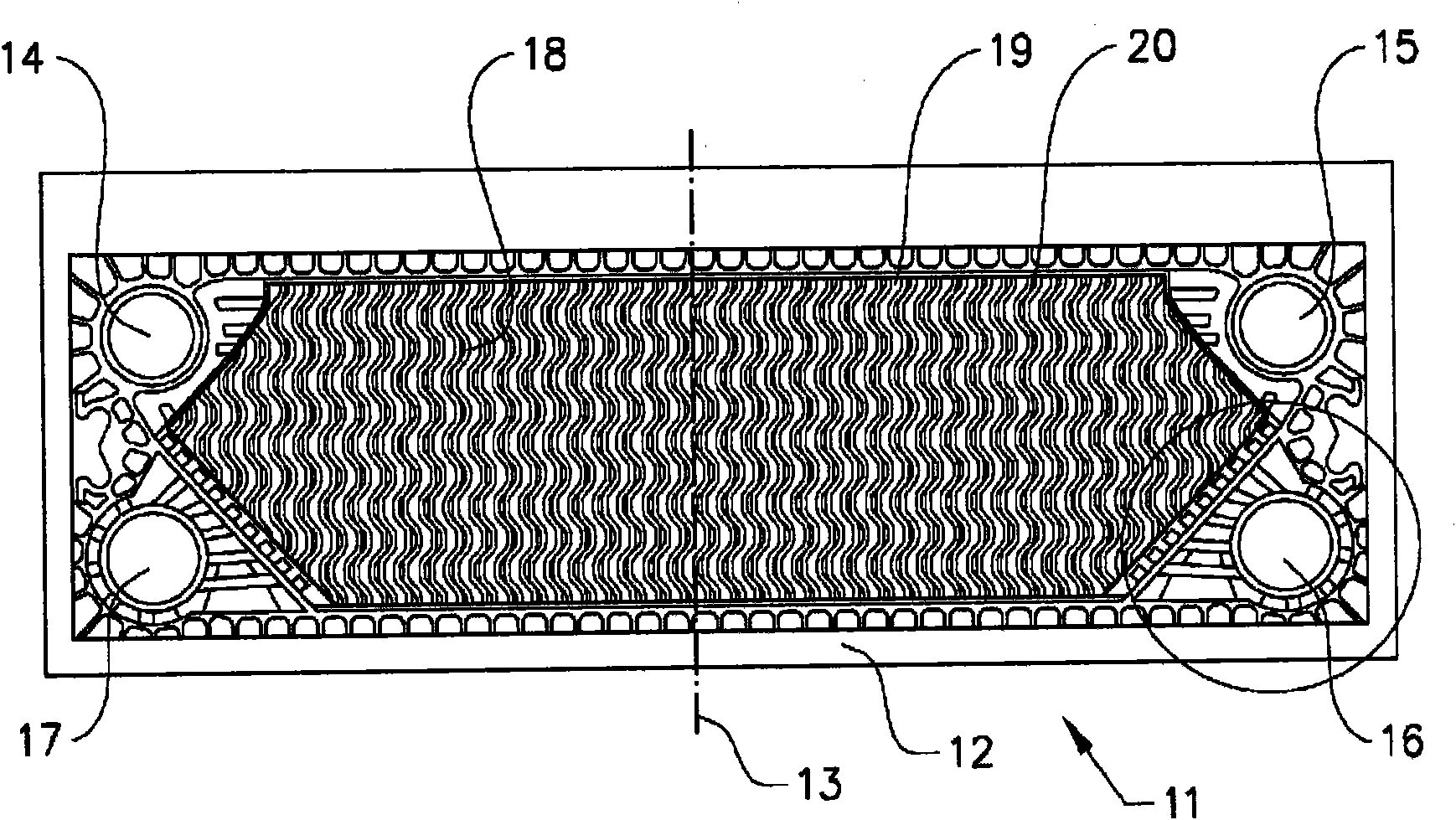

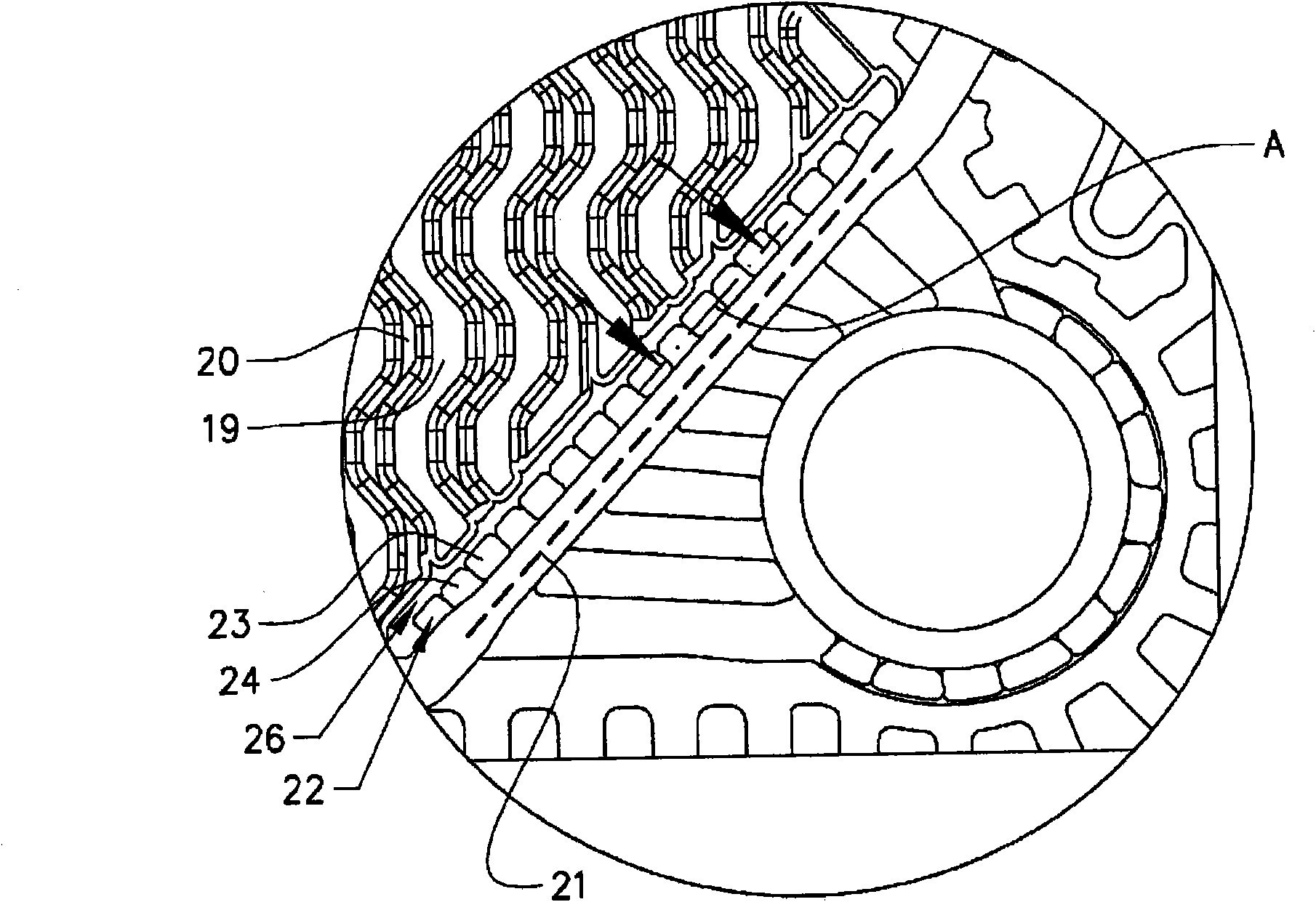

Heat exchanger

ActiveCN101918784AImprove sealingStable supportLaminated elementsStationary plate conduit assembliesContact freeEngineering

A diagonal gasket support (22) in a heat exchanger cassette adapted for a heat exchanger having a contact-free flow channel (28), where the cassette (11, 29) comprises two plates (12) of the same type, where each plate is provided with a corrugated pattern having a plurality of ridges (19) and valleys (20), characterized in that the diagonal gasket support (22) comprises a plurality of indentations (23) and protrusions (24) positioned adjacent each other along a diagonal gasket groove (21). The advantage of such a diagonal gasket support is that a contact-free support at the diagonal gasket is obtained.

Owner:ALFA LAVAL CORP AB

UV (ultraviolet) anti-scratch matte finishing paint

ActiveCN103589324ATo achieve the surface effectExcellent hardnessPolyurea/polyurethane coatingsPhotoinitiatorPolymer chemistry

The invention relates to a coating in the chemical engineering field, in particular to UV (ultraviolet) anti-scratch matte finishing paint. The UV matte finishing paint comprises components in percentage by weight as follows: 5%-13% of polyurethane acrylate, 15%-30% of a monomer, 15%-25% of nitrocotton, 15%-25% of cellulose acetate butyrate, 1%-10% of fumed silica, 3%-7% of a photoinitiator, 0.1%-0.5% of an auxiliary and 5%-10% of a solvent, wherein polyurethane acrylate is a mixture of modified aliphatic polyurethane acrylate and modified aromatic polyurethane acrylate. The UV matte finishing paint can be automatically sprayed on a substrate by equipment, and the production efficiency can be improved greatly; and the excellent levelling property can be obtained after curing of the paint, the UV matte finishing paint has the surface effect of PU (polyurethane) paint, and the hardness and the anti-scratch property of the UV matte finishing paint are superior to those of PU paint.

Owner:HUIZHOU CHANGRUNFA PAINT

General purpose plastic priming paint for automobile and preparation method thereof

The invention relates to a general plastic auto primer and the preparation method thereof, pertaining to the coating technical field. The invention solves the universality of plastic auto primer and is characterized in that the primer comprises the components with certain weight portions, modified thermoplastic acrylic resin of 55-65wt portions, paint of 20-25wt portion, dispersion agent of 0.3-1.0wt portions, flow agent of 0.1-0.3wt portions and solvent of 15-30wt portions. The components are mixed and grinded for preparing the primer. The product of the invention is mainly characterized in that the product is applicable for primer coating of various auto plastic components and for plastic components of different materials, thereby, the product can reduce waste and trouble which are caused by frequent exchange of paint and dramatically improve work efficiency. In addition, the product of the invention has excellent boiling resistance and hot-cold alternation resistance. The product is proved to have better index of pencil hardness, adhesive, impact strength and water resistance, etc. over than the prior product and is expected to replace the prior plastic auto primer product.

Owner:唐山威克涂料化工有限公司

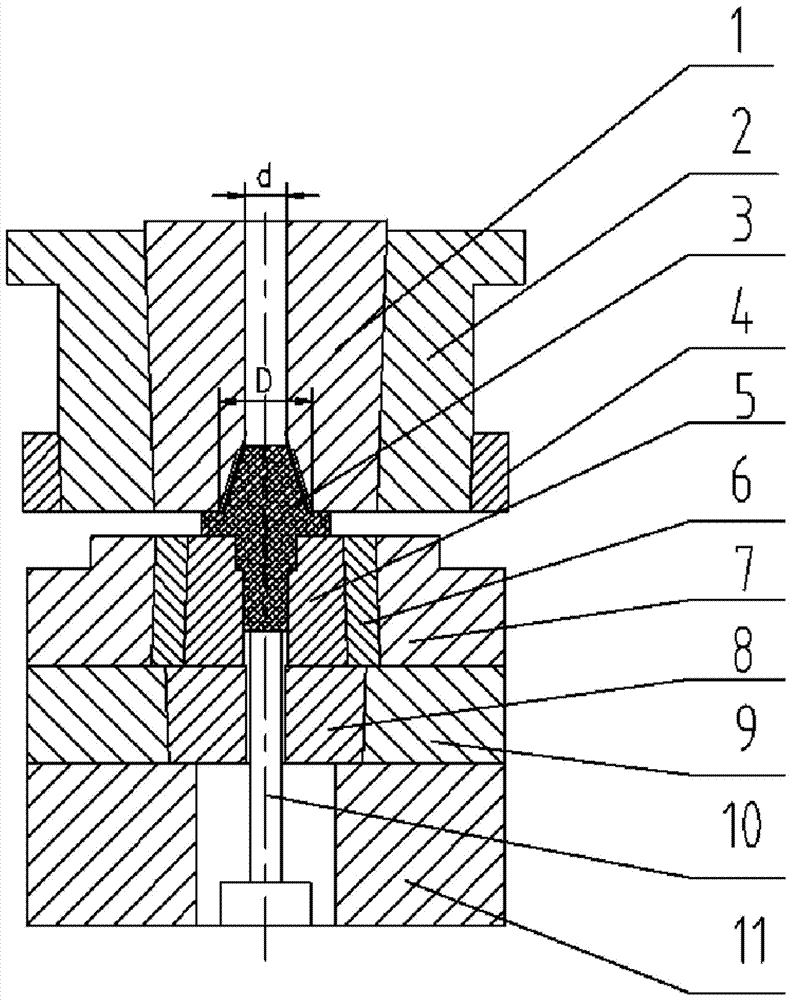

Precise near-net forming technology and device for bevel gear shaft

The invention discloses a precise near-net forming technology and device for a bevel gear shaft. The technology comprises the following steps of (a) precise saw cutting of a bar; (b) annealing treatment; (c) blank lubrication by adopting a high polymer lubricant; (d) conical blank preforming through cold heading: preliminarily preforming the blank according to a bevel angle of the bevel gear shaft and the shape of a shaft step and laying a foundation for next near-net forming of a bevel gear and a step shaft; (e) molybdenum disulfide lubrication: mixing molybdenum disulfide powder and engine oil at a ratio of (30-40wt%):(60-70wt%), coating the surface of the preformed blank with the prepared molybdenum disulfide and directly putting the preformed blank into a near-net forming die for molding; (f) precise near-net forming: forming the bevel gear shaft on a precise near-net forming device; (g) machining according to the requirements; and (h) forming of a product. The forming device comprises four parts, such as a set of combined bevel gear die, a set of combined step shaft die, a reinforcing plate and an ejector stopper.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

UV matte top-coat paint for vacuum spraying

InactiveCN104530923ATo achieve the surface effectExcellent hardnessEpoxy resin coatingsGas phaseSilicon dioxide

The invention discloses a UV matte top-coat paint for vacuum spraying. The UV matte top-coat paint is prepared from the following components in parts by weight: 20-35 parts of epoxy acrylate, 35-60 parts of a monomer, 5-10 parts of a filler, 0.1-0.5 part of gas-phase silica, 3-6 parts of a photoinitiator, 0.4-0.6 part of a flow agent, 0.3-0.5 part of a defoamer and 0.2-0.5 part of a wetting dispersant, wherein the epoxy acrylate is modified epoxy acrylate with a Meiyatu code number of Changrunfa to be YTM2100. The UV matte top-coat paint is automatically sprayed on a substrate by using vacuum spraying equipment, so that the production efficiency can be greatly improved; by virtue or reasonable matching of the raw material, as very good levelling property can be obtained after the UV matte top-coat paint is cured, the surface effect of a PU paint can be achieved, and the rigidity and the scraping resistance are superior to those of the PU paint.

Owner:HUIZHOU CHANGRUNFA PAINT +1

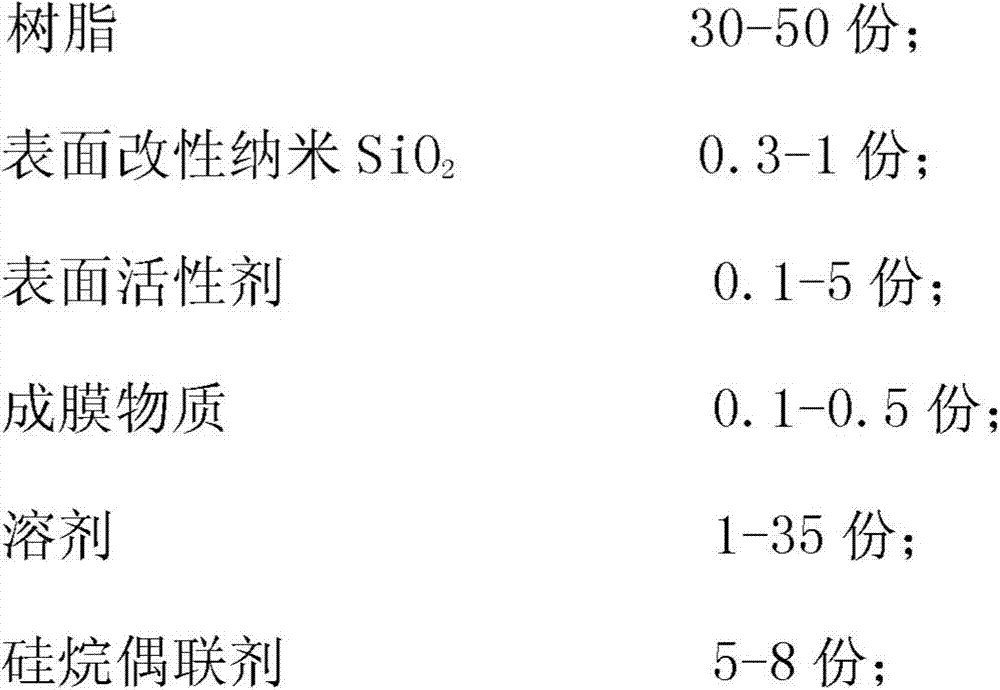

Color change-preventing and wear-resistant protective agent of automotive interior metal zipper

InactiveCN105440847AExcellent hardnessAuxiliaries are environmentally friendly and non-toxicFireproof paintsAnti-corrosive paintsSolventProtective Agents

The invention discloses a color change-preventing and wear-resistant protective agent of an automotive interior metal zipper. The color change-preventing and wear-resistant protective agent is prepared from the following components in parts by weight: 30 to 50 parts of resin, 0.3 to 1 part of surface modified nano SiO2, 0.1 to 5 parts of surfactant, 0.1 to 0.5 part of film forming matter, 1 to 35 parts of solvents, 5 to 8 parts of silane coupling agent and deionized water as the rest. According to the color change-preventing and wear-resistant protective agent, the zipper is soaked in a protective agent solution, or the protective agent is sprayed to the surface of the zipper, so as to form a uniform dense bright protective layer, so that the metal zipper is prevented from discoloring and fading, and the color overlapping of the metal zipper to fabrics is reduced, so as not to influence the product quality. The color change-preventing and wear-resistant protective agent is favorable for environmental protection and has the advantages of simplicity in arrangement, low treatment cost and convenience when the color change-preventing and wear-resistant protective agent is used for protecting the surface of the zipper.

Owner:IANGSU COLLEGE OF ENG & TECH

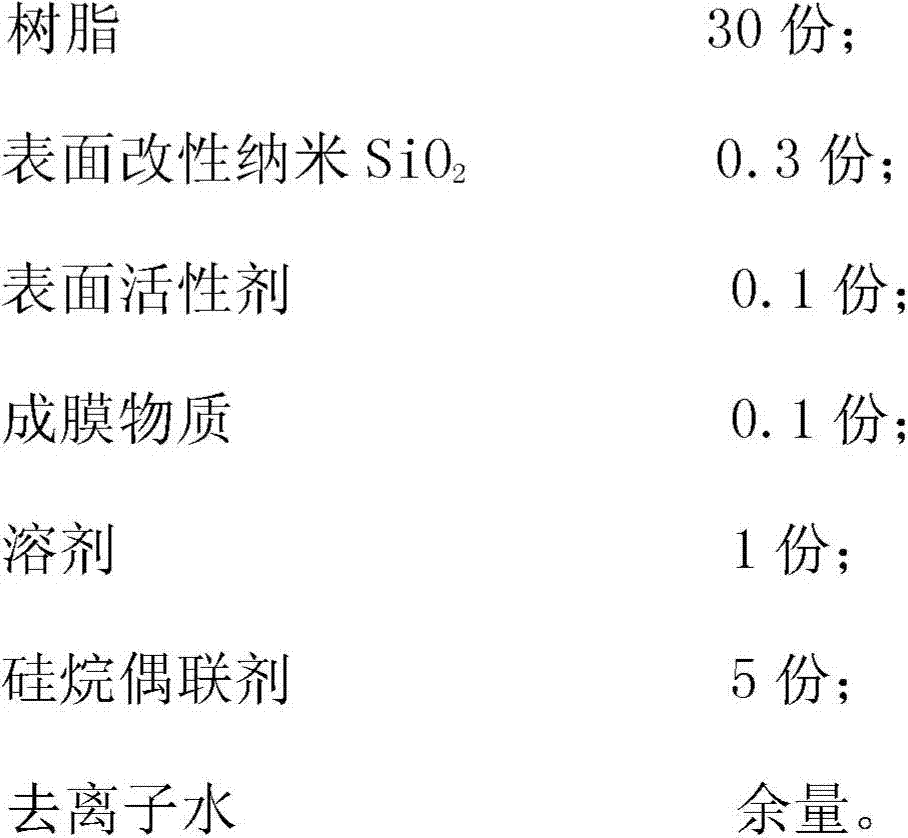

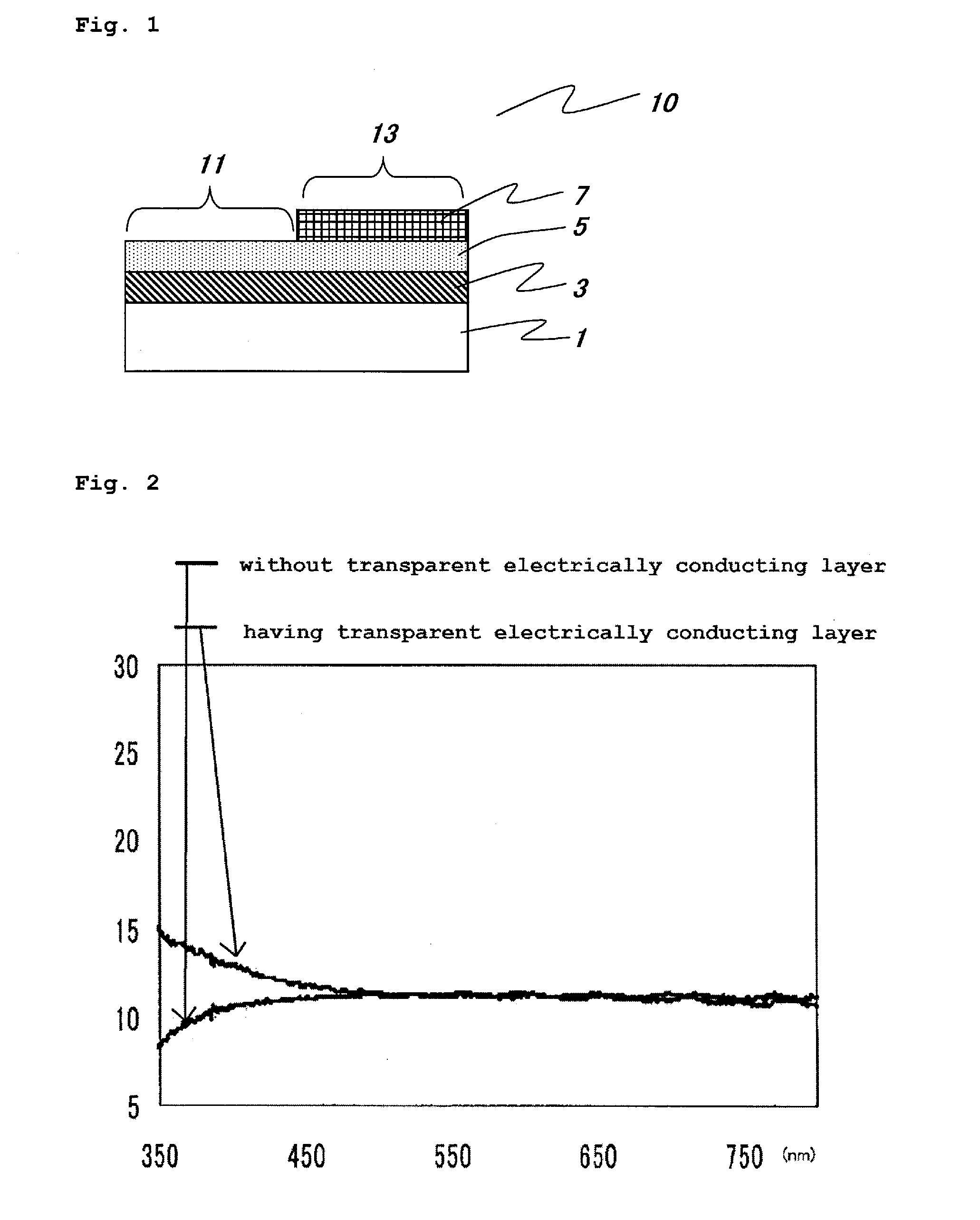

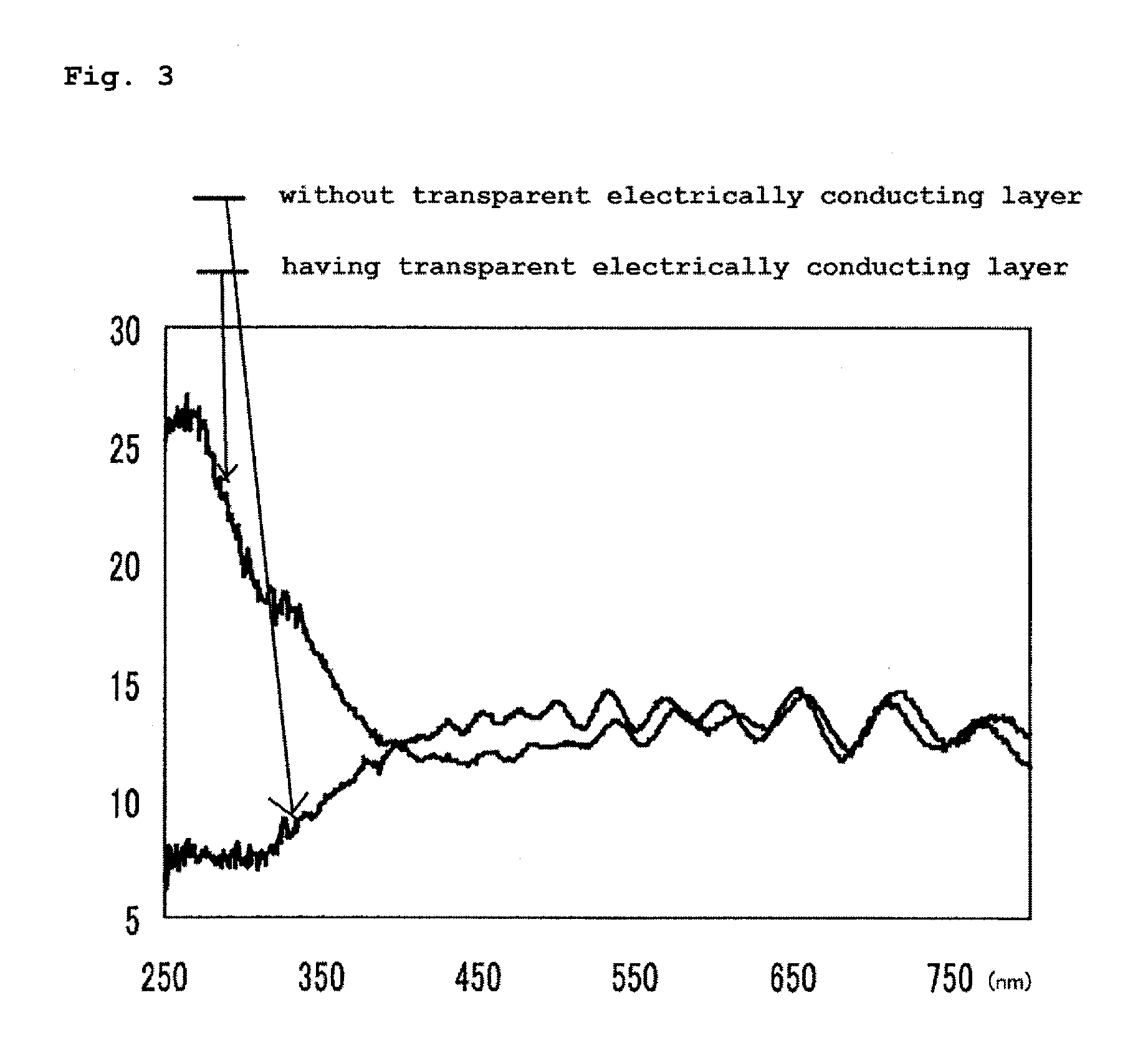

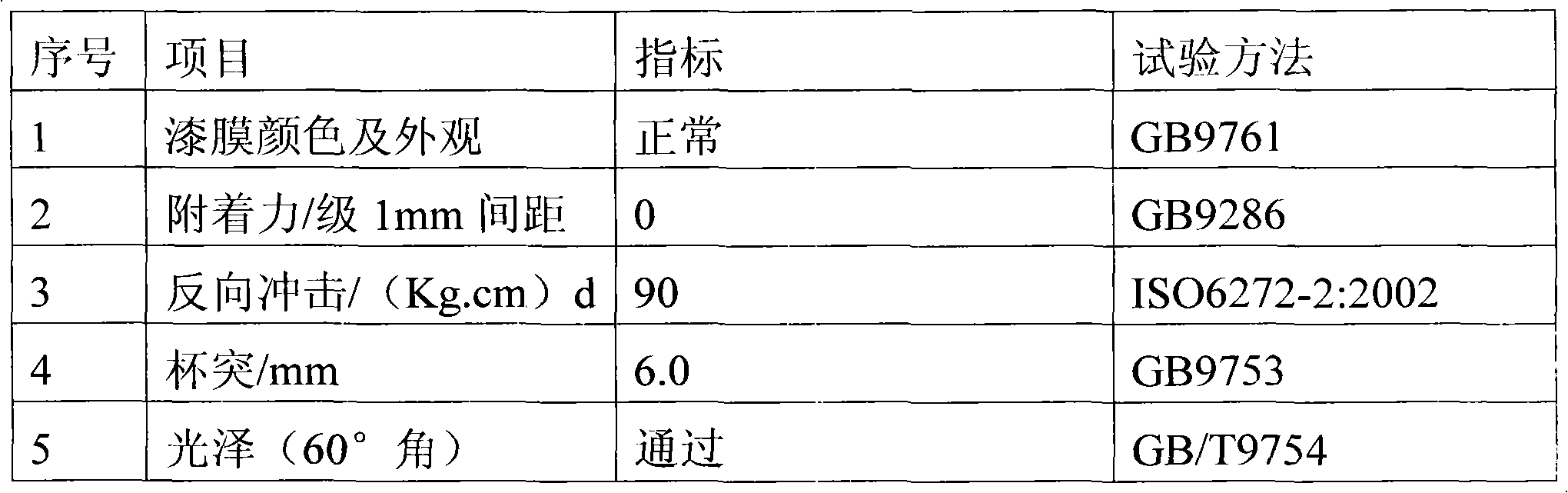

Electroconductive laminate and touch panel using thereof

ActiveUS20160216804A1Excellent hardnessHigh visibilitySynthetic resin layered productsVacuum evaporation coatingPolycarbonateChemistry

The electroconductive laminate according to the present invention is obtained by laminating a hard coat layer and an electrically conducting layer on at least one surface of a polycarbonate base. This electroconductive laminate is characterized in that the hard coat layer is formed from a hard coating composition which contains (A) a phenolic novolac acrylate having two or more acrylate groups, (B) an orthophenyl phenol acrylate containing 1-2 mol of an ethylene oxide structure in each molecule and (C) a bisphenol skeleton-containing diacrylate containing 2-4 mol of an alkylene oxide structure having two or three carbon atoms in each molecule.

Owner:TEIJIN LTD +1

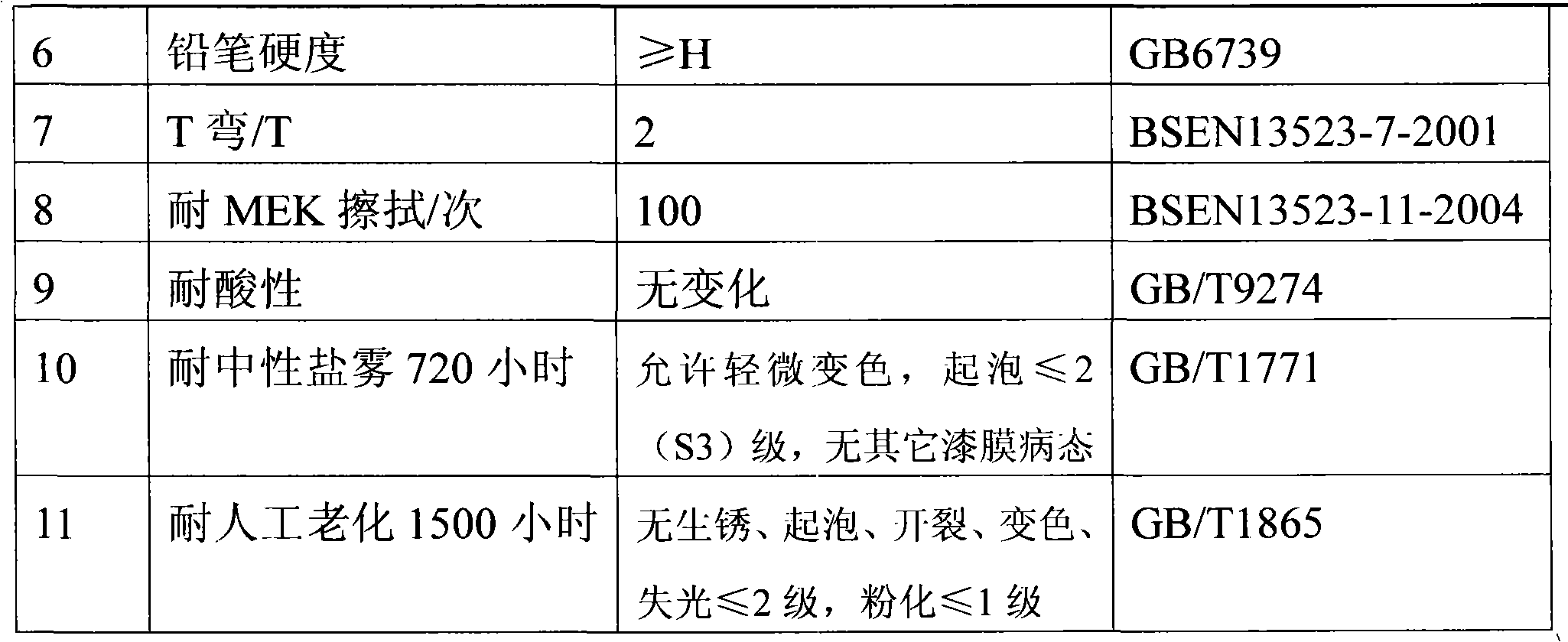

Grainy topcoat used in color plate surface coating, and preparation method thereof

InactiveCN102925034AImprove visual effectsEmission reductionPolyester coatingsPolyester resinSolvent

The invention provides a grainy topcoat used in color plate surface coating, and a preparation method thereof. The invention belongs to the technical field of paints. The topcoat assists in ameliorating a problem of steel surface decoration effect. The grainy topcoat is characterized in comprising the substances of, by weight: 45-55 parts of SK-ES410 saturated polyester resin, 8-11 parts of CYTEC303 amino resin, 30-35 parts of a pigment, 0.3-1.0 parts of a BYK110 dispersing agent, 0.5-1.2 parts of a BYK354 leveling agent, 5-10 parts of a solvent, and 0.3-1 parts of a KING N-5225 catalyst. The substances are blended and grinded, such that the topcoat is obtained. According to the topcoat provided by the invention, a formula is optimized, paint film surface state is changed, product application time is prolonged, and color plate surface coating quality is improved. As a result of tests, various indexes of the product are better than existing products, product service life is greatly improved, and product colors are enriched.

Owner:唐山威克涂料化工有限公司

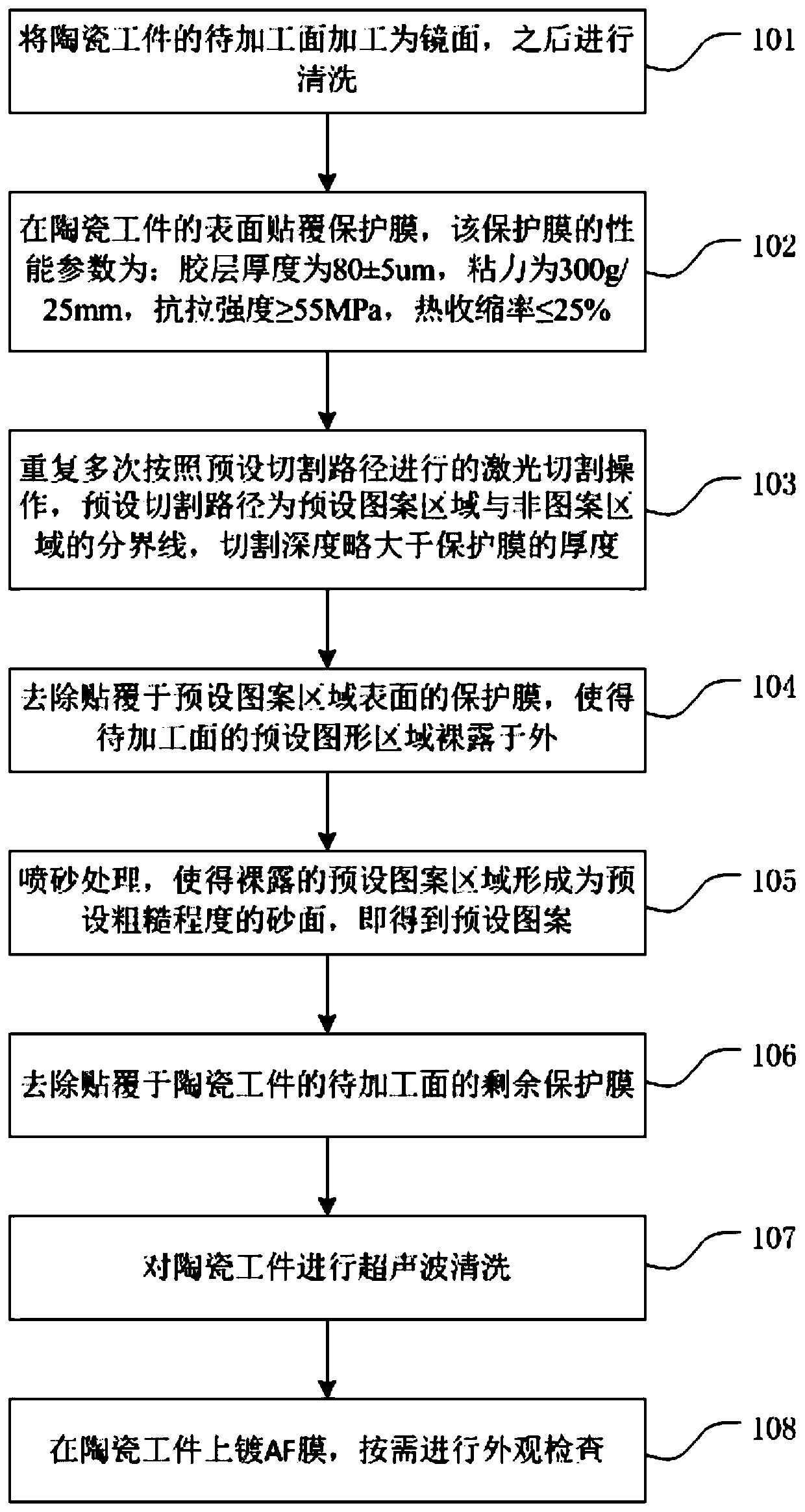

Ceramic surface pattern machining method, ceramic and electronic equipment shell

ActiveCN110919203AExcellent hardnessExcellent wear resistanceDecorative surface effectsLaser beam welding apparatusSurface patternSand blasting

The invention relates to the field of ceramic and discloses a ceramic surface pattern machining method, ceramic and an electronic equipment shell. The method comprises the steps that a protecting filmis attached to the surface of a ceramic workpiece, and performance parameters of the protecting film include the thickness being 80+ / -5 micrometers, viscous force being 300 g / 25 mm, the tensile strength being larger than or equal to 55 MPa, and the hot-shrinkage rate being smaller than or equal to 25%; on the to-be-machined face, laser cutting operation is carried out according to a preset cutting path, the preset cutting path is a boundary of a pattern area and a non-pattern area, and the cutting depth is no smaller than the thickness of the protecting film; the protecting film covering thepreset pattern area is removed; the to-be-machined face is subjected to sand blasting treatment until the preset pattern area is formed into a sand face with the preset roughness; and the remaining protecting film is removed. According to the method, the protecting film applied to the ceramic workpiece is designed and manufactured according to the special performance parameters, meanwhile, the laser cutting and sand blasting technology is utilized, pattern manufacturing of high-hardness ceramic surfaces is achieved, and higher machining precision and machining quality are achieved.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

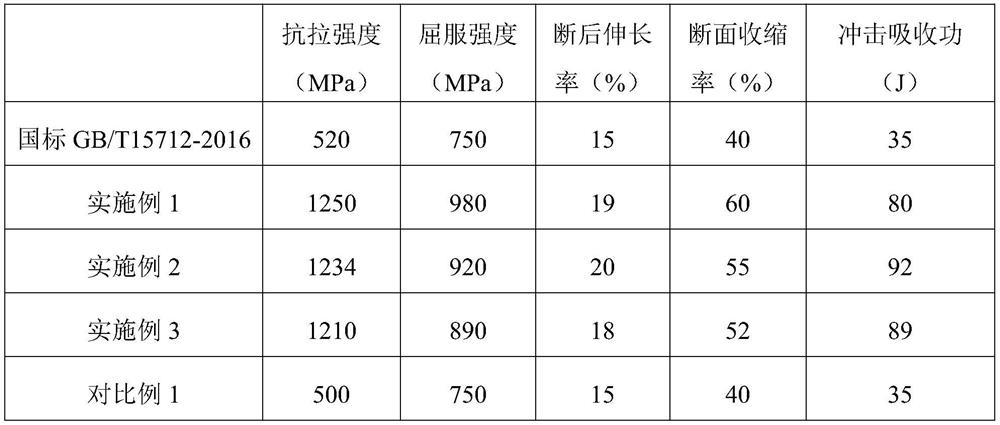

Rolling production method for improving toughness of steel on line

ActiveCN113245365AReduce heating energy consumptionReduce manufacturing costWork heating devicesMetal rolling arrangementsTemperingContinuous rolling

The invention discloses a rolling production method for improving the toughness of steel on line. A continuous casting billet is taken as a raw material. The rolling production method sequentially comprises the following working procedures of billet heating, descaling, rough rolling, continuous rolling, through-water cooling, finish rolling through a bar reducing and sizing mill and cooling through a cooling bed, and finally a finished product bar is obtained; wherein a rolled material subjected to continuous rolling is subjected to through-water cooling to 650-850 DEG C, after through-water cooling, the rolled material is subjected to self-tempering to obtain the finish rolling temperature of the bar reducing and sizing mill, the finish rolling temperature is 500-700 DEG C, and the temperature of the bar on the cooling bed is 480-650 DEG C. According to the method, KOCKS rolling is adopted for finish rolling of the bar reducing and sizing mill, proeutectoid ferrite in a non-required form is eliminated by controlling the finish rolling temperature and the cooling temperature after rolling, the toughness of the steel is improved, and the grain size, hardness and mechanical performance of the non-quenched and tempered steel can be controlled by adopting the rapid cooling technology after rolling.

Owner:DAYE SPECIAL STEEL CO LTD

Ice skate blade provided with alloy coating and used for skating shoes

The invention provides an ice skate blade provided with an alloy coating and used for skating shoes. A matrix blade of the ice skate blade is subjected to heat treatment, different hardness degrees required by different parts of the ice skate blade are obtained, so that after being coated with the coating, the ice skate blade body has rigidity and toughness of resisting and transmitting ice push-off power, and a cutting edge can be wear-resistant enough and has surface roughness as small as possible. Besides, alloy coated powder of the skate blade alloy coating adopts a specific alloy element composition proportion, so that the hardness of the alloy coating is remarkably improved, and the ice skate blade has quite high wear resistance, good hardness and oxidation resistance.

Owner:HUAINAN BAIBANG PNEUMATIC TECH CO LTD

Aqueous dispersion, method for manufacturing the same, and image forming method

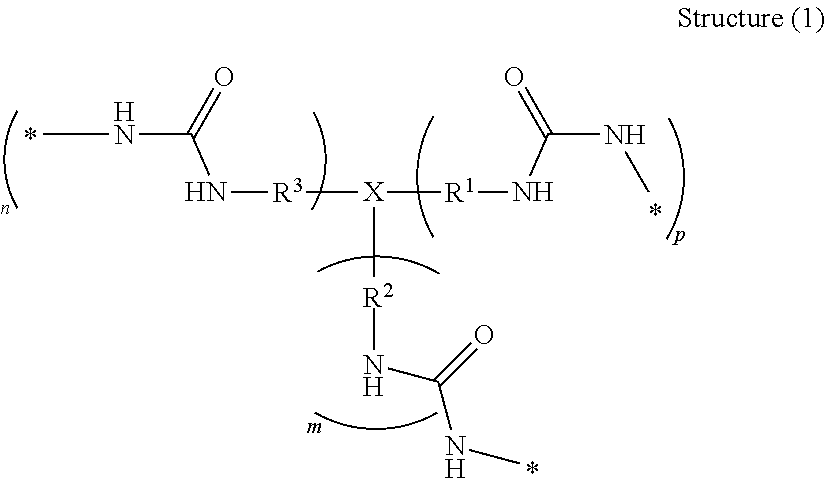

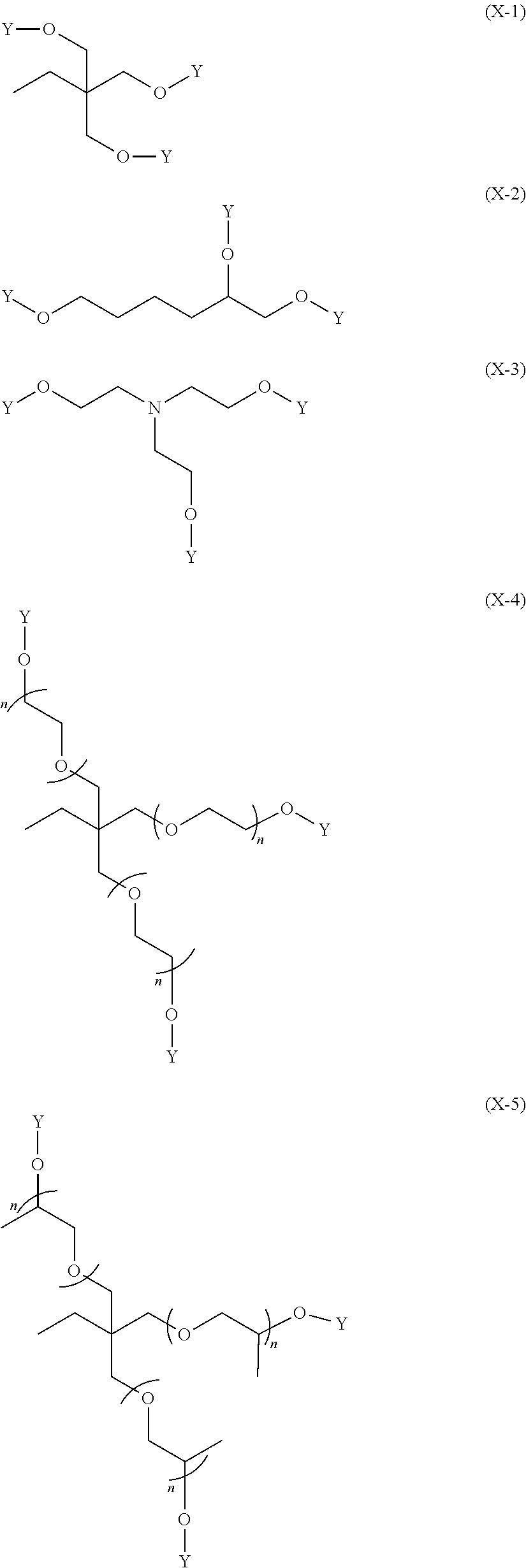

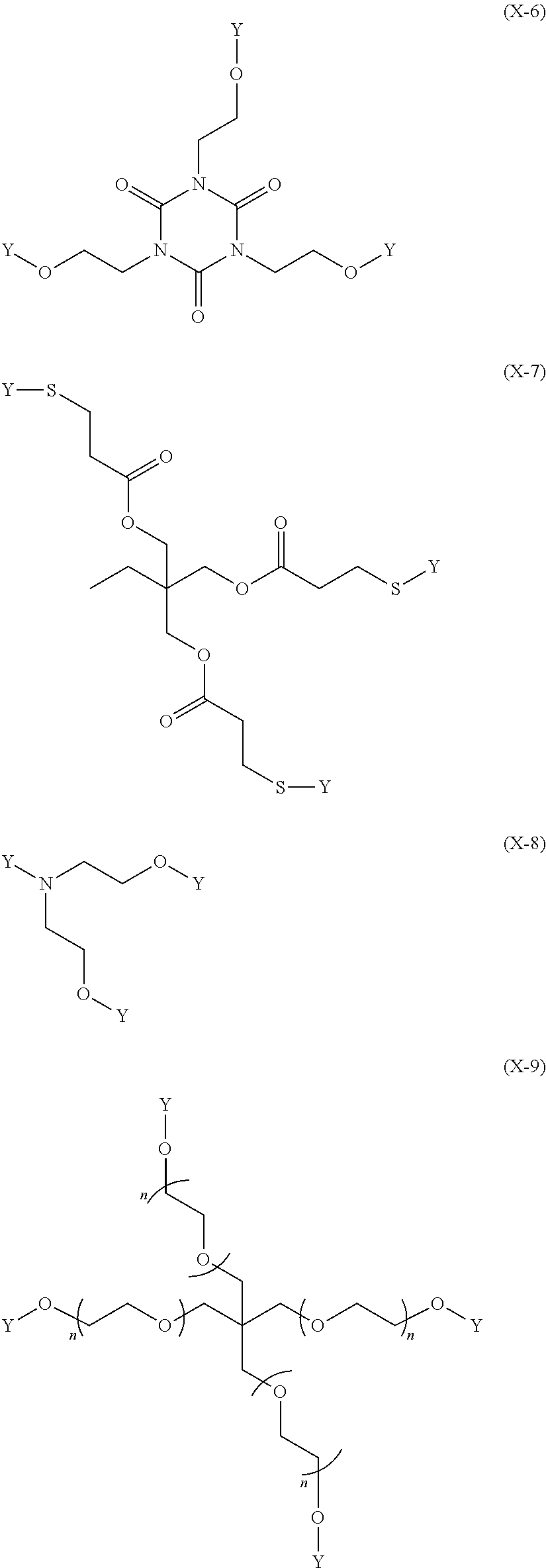

ActiveUS20180127612A1Excellent hardnessExcellent surface conditionInksPolyurea/polyurethane coatingsUreaChemistry

Provided is an inkjet ink including: a resin having a polymerizable resin; a gel particle which includes a polymerizable group, includes a three-dimensional cross-linked structure containing at least one selected from the group consisting of a urethane bond and a urea bond, and includes a photopolymerization initiator in the interior of the gel particle; and water, in which a total amount of a solid content of the gel particle with respect to a total amount of the resin having a polymerizable group is 0.1% by mass to 100% by mass. Also provided are a method for manufacturing the inkjet ink and an inkjet recording method using the inkjet ink.

Owner:FUJIFILM CORP

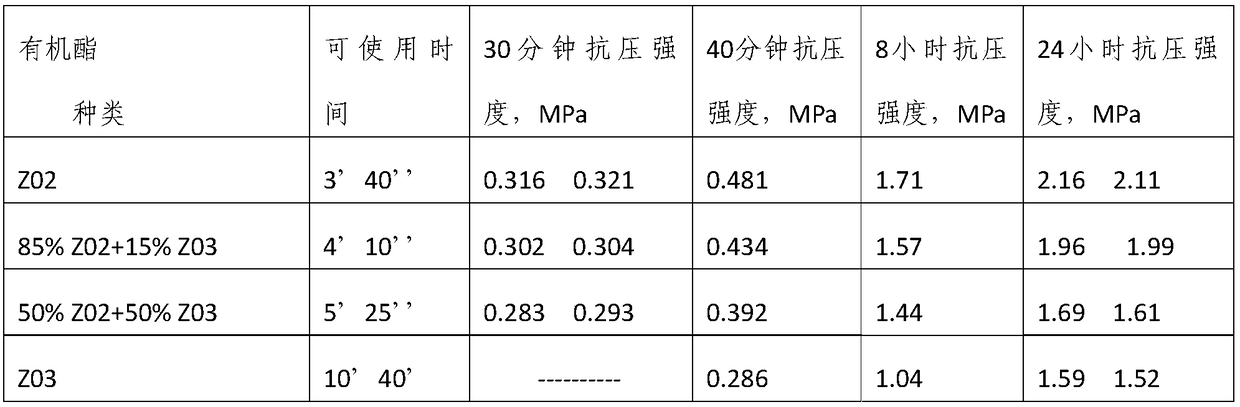

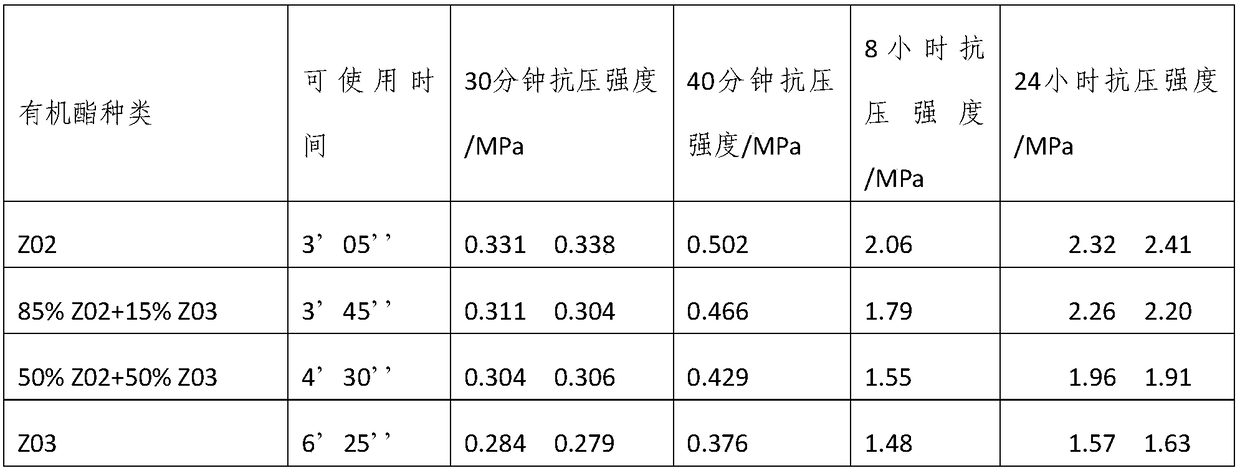

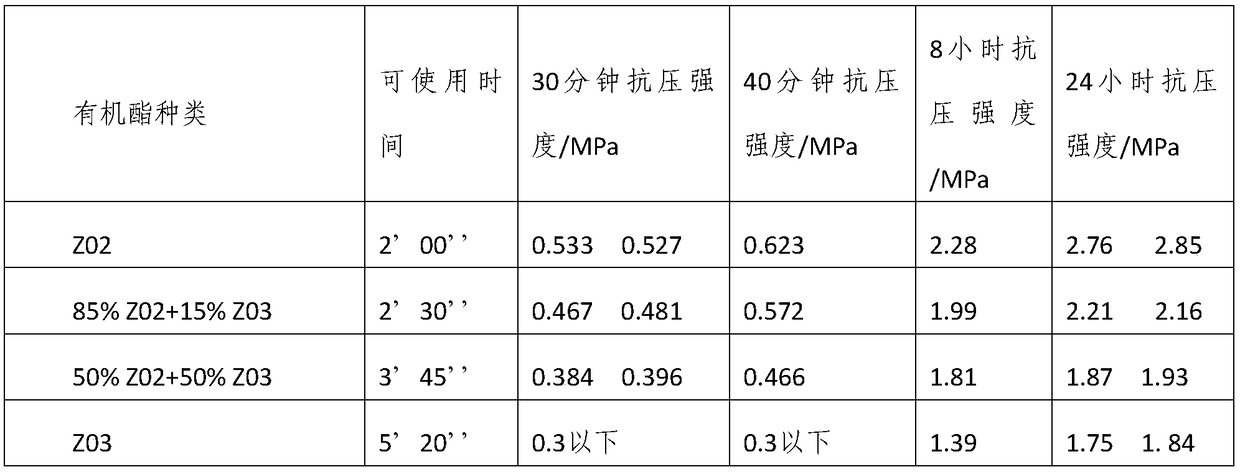

Modified organic ester for environment-friendly casting and preparation method

InactiveCN109108212ANon-toxicNo pollution in the processFoundry mouldsFoundry coresOrganic EsterCITRATE ESTER

The invention discloses modified organic ester for Environment-friendly casting. The modified organic ester comprises one of or a mixture of more of acetin, propylene carbonate and citrate. When the modified organic ester is used in water glass self-hardening sand, the organic ester and a binder account for 0.35 to 0.6 percent and 2.0 to 3.2 percent of the mass of the original sand. Compared withthe ordinary organic ester, the environment-friendly modified organic ester has the advantages of high environmental adaptability, good mold sand mobility, good sand hard permeability and high strength of the sand mold after being hardened, the basic raw material is environment-friendly and can reach the food grade, the price of the finished product organic ester is only half of the ordinary organic ester, and the environment-friendly modified organic ester is suitable for producing large, medium and small-sized casting, and can satisfy the molding production of one box with multiple components and one box with multiple varieties. The invention belongs to the field of a novel product of organic ester and application thereof in casting molding sand.

Owner:内蒙古第一机械集团股份有限公司

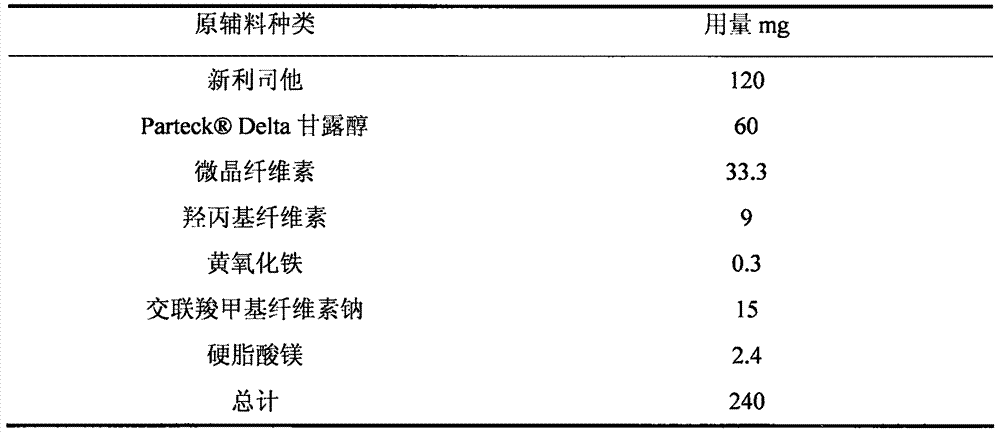

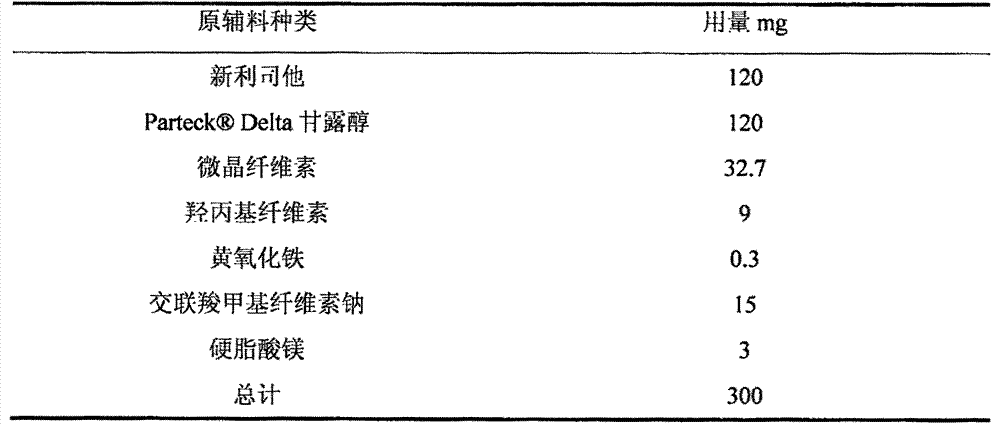

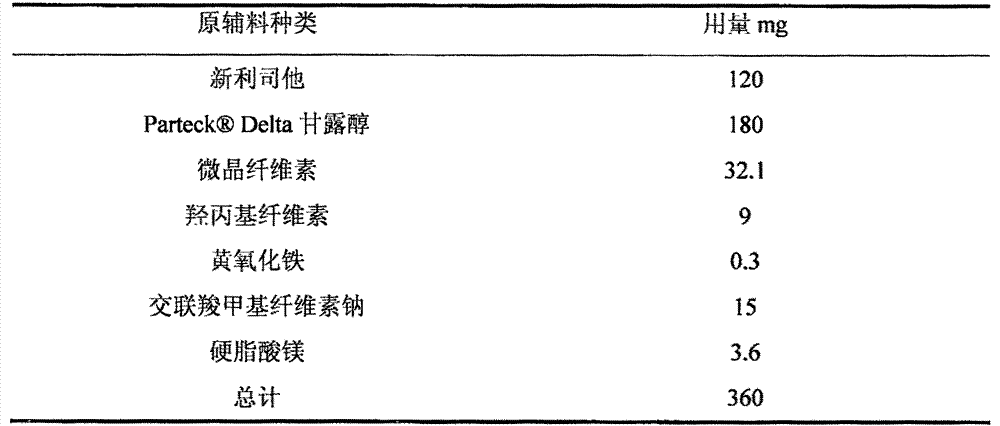

Medicinal preparation containing cetilistat and preparation method thereof

InactiveCN107397728AExcellent hardnessExcellent disintegration speedOrganic active ingredientsMetabolism disorderPharmaceutical formulationCetilistat

The present invention relates to a kind of pharmaceutical preparation containing Neolistat, and this preparation is mainly made up of Neolistat, mannitol, binding agent, disintegrant and lubricant; The present invention also relates to the preparation method of this pharmaceutical preparation, adopts The new lisstat tablet prepared by the invention has the advantages of good disintegration performance, good drug stability, simple process operation and the like, and is particularly suitable for industrial production and clinical use.

Owner:BEIJING JIMEITANG MEDICINE RES CO LTD

Universal plastic primer for automobile and preparation method

The invention discloses a universal plastic primer for an automobile and a preparation method. The preparation method is characterized by comprising the following steps of weighing each raw material according to a proportion, adding modified thermoplastic acrylic resin into a dispersing agent, uniformly stirring, adding a pigment and a solvent while stirring, dispersing and grinding the mixture until the fineness is less than 20 microns, discharging the mixture, adding a leveling agent while stirring after cooling, and performing uniform stirring.

Owner:王志龙

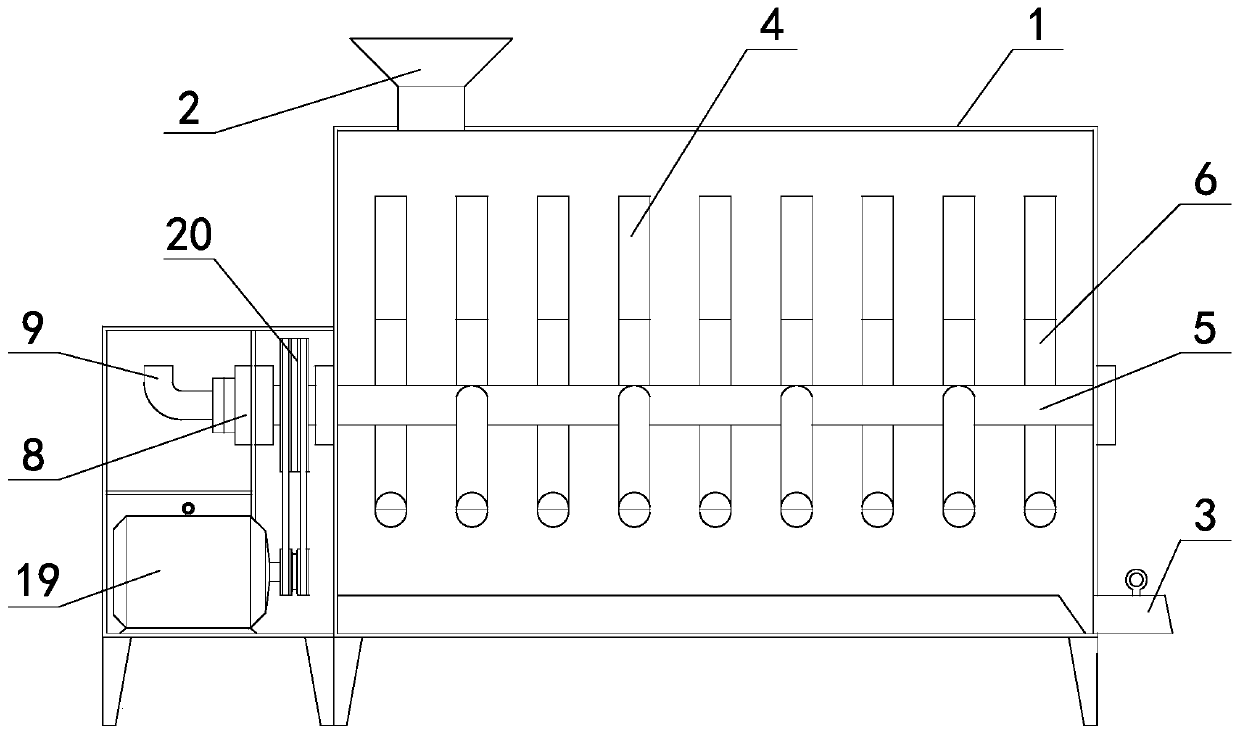

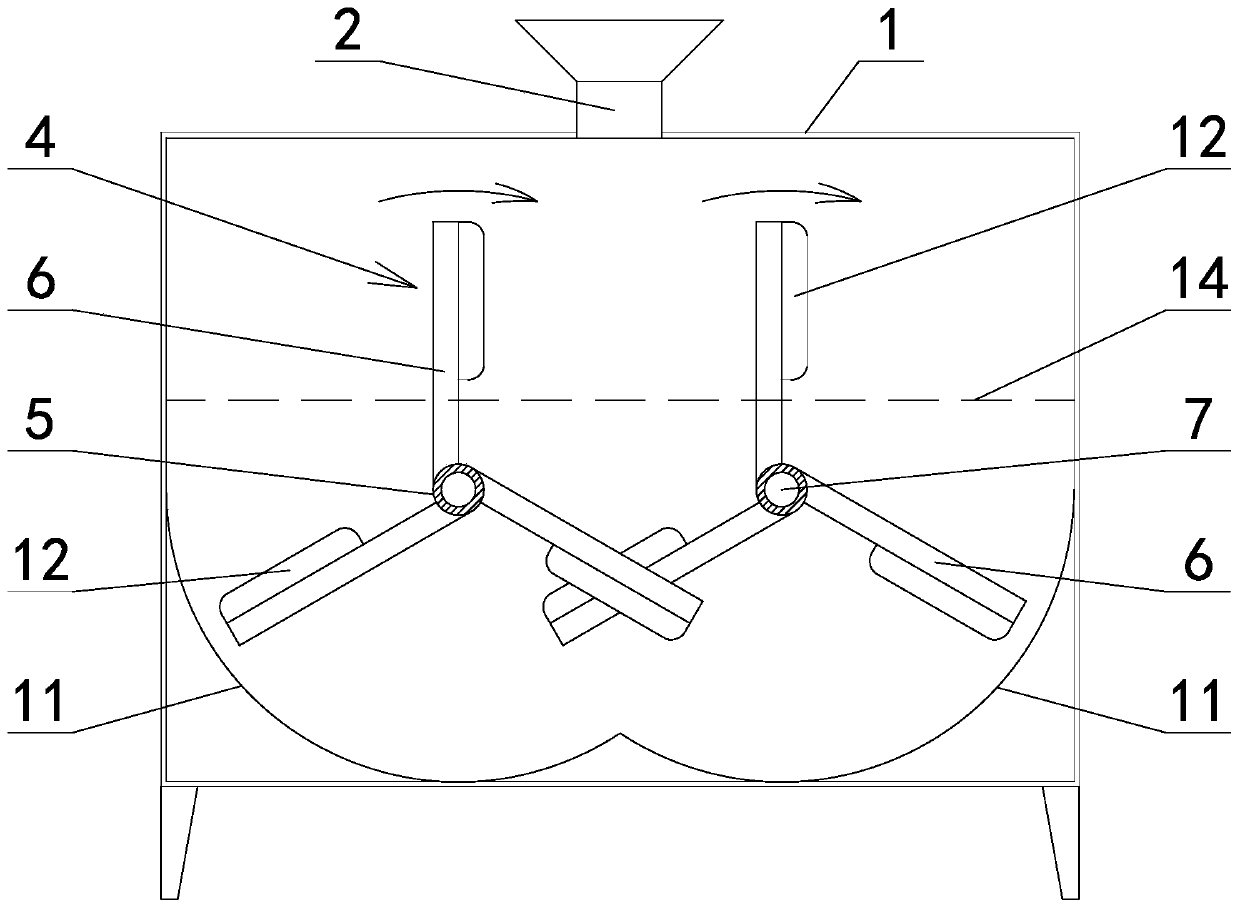

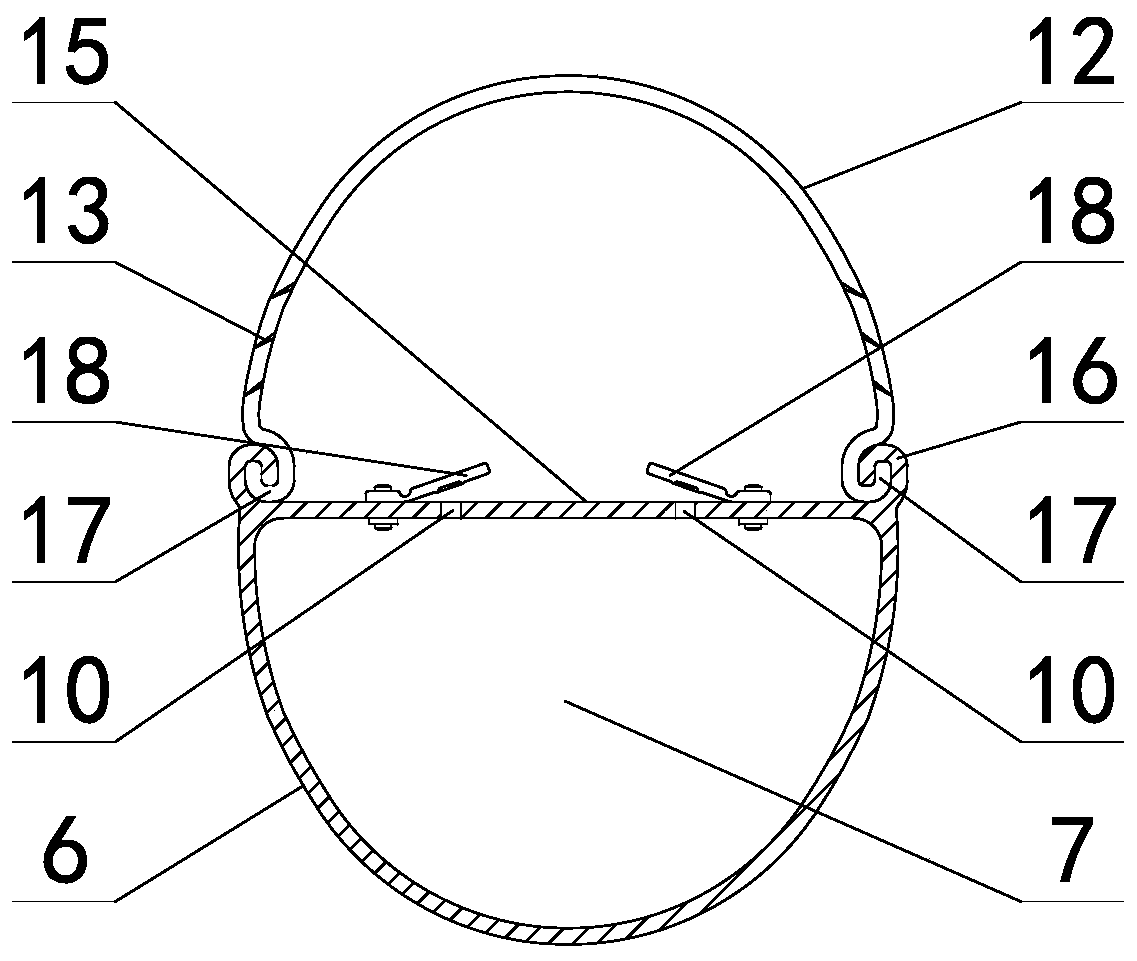

Formula of egg stinky tofu, processing method and device thereof

ActiveCN110720519AHigh in nutrientsFull of nutritionCheese manufactureFood scienceBiotechnologyAnimal science

The invention discloses a formula of egg stinky tofu, a processing method and a device thereof, which belong to the technical field of bean product processing. The fresh blank of the egg stinky tofu comprises the following components in parts by weight: 200-240 parts of soybeans, 100-150 parts of eggs, 2-4 parts of lactone, 1-2 parts of TG enzyme, 2-4 parts of gypsum powder, 2-4 parts of monoglyceride and 0.2-0.4 part of edible oil. Wherein the fermentation liquor is prepared from the following components in parts by weight: 100 parts of yellow serofluid, 1.5 to 2.5 parts of table salt, 1.0 to2.0 parts of white granulated sugar and 0.08 to 0.12 part of food-grade sodium carbonate. The egg stinky tofu is nutritional food provided by the invention, which is rich in nutrition, special in taste and rich in fragrance, meets more and higher requirements of people on food flavor, and has great practical significance.

Owner:ZUMING BEAN PROD

Water-soluble colorful putty coating for exterior wall

The invention relates the water-soluble colored putty paint, comprising 20-40wt% calcium powder, 50-80wt% powder enamel, and 0.4-0.8wt% hydroxypropylmethylcellulose or 0.2-0.4wt% cellulose ethyl ether. The invention has the advantages of good water resistance, hardness, long life, nondiscolouring, convenient transport, storing and construction.

Owner:周创浩

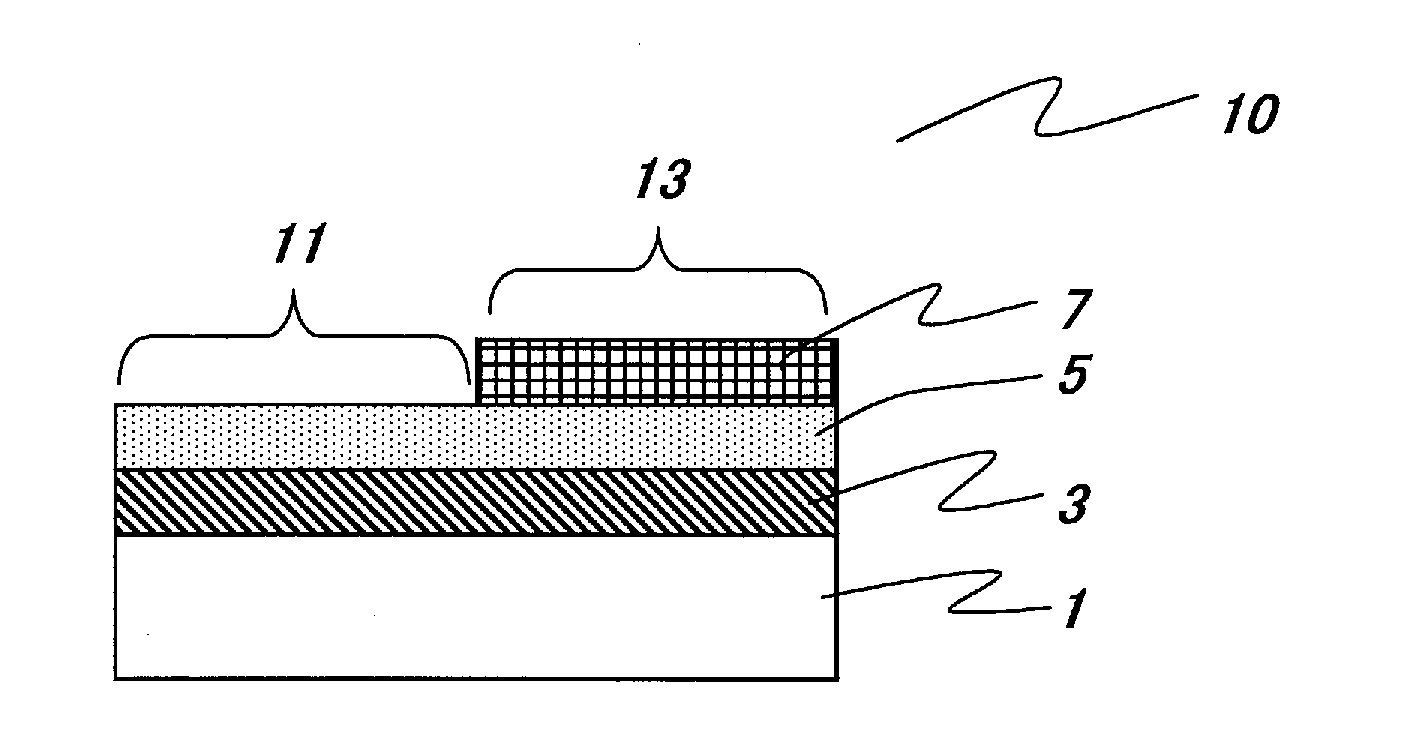

Electromagnetic steel sheet coated with insulating film, process for producing same, and coating material for forming insulating film

InactiveUS20190160786A1Excellent hardnessHigh hardnessLiquid surface applicatorsSynthetic resin layered productsSolventIsocyanate

An electromagnetic steel sheet coated with an insulating film with excellent hardness and suitable for use as a material for iron cores of large-sized electric-power generators; and a process for producing the electromagnetic steel sheet coated with an insulating film. The purpose is achieved with a coating material for forming insulating films, the coating material including a solvent and components (A) to (C) contained therein in the respective amounts on a solid basis. (A) A water-compatible carboxylated resin; 100 parts by mass. (B) An aluminum-containing oxide; more than 40 parts by mass but less than 300 parts by mass per 100 parts by mass of the component (A). (C) At least one crosslinking agent selected from the group containing of melamine, isocyanates, and oxazoline; 100 parts by mass or more but less than 300 parts by mass per 100 parts by mass of the component (A).

Owner:JFE STEEL CORP

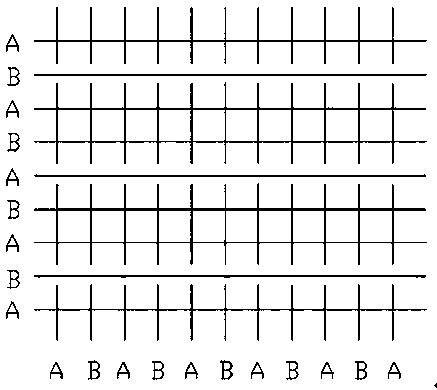

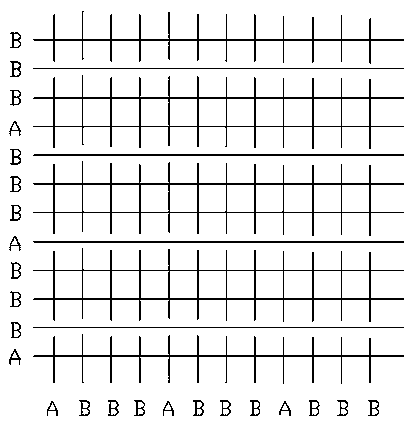

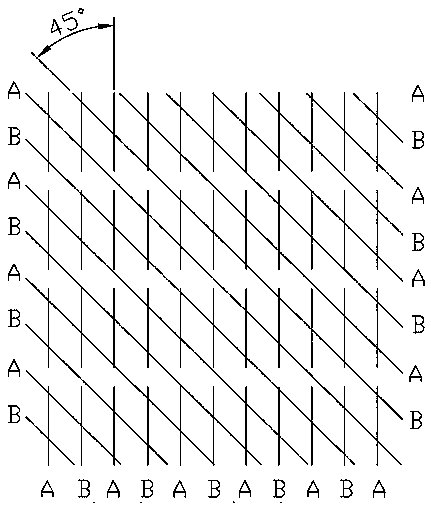

Fiber-like composite phase ceramic and preparation method

ActiveCN110183226AImprove compactnessExcellent densityAdditive manufacturing apparatusCeramic shaping apparatusFiberMechanical impact

The invention discloses a fiber-like composite phase ceramic and a preparation method. The ceramic is of a multi-layer piling structure, wherein each layer of the ceramic consists of 1-50 one-dimensional silk-like first ceramics printed according to a printing path of a 3D printer, and 1-50 one-dimensional silk-like second ceramics printed according to another printing path of the 3D printer, in parallel distribution; and printing paths between two adjacent layers are perpendicular to each other or are in a certain included angle. By adopting the ceramic, the toughness of the ceramic can be greatly improved, the toughness of the ceramic is remarkably prior to that of a laminated composite phase ceramic, and in case of mechanical impact, energy can be greatly absorbed by interferences formed by phase constitution differences of silk-like ceramic units, and cracking development can be prevented.

Owner:NINGBO VULCAN TECH CO LTD

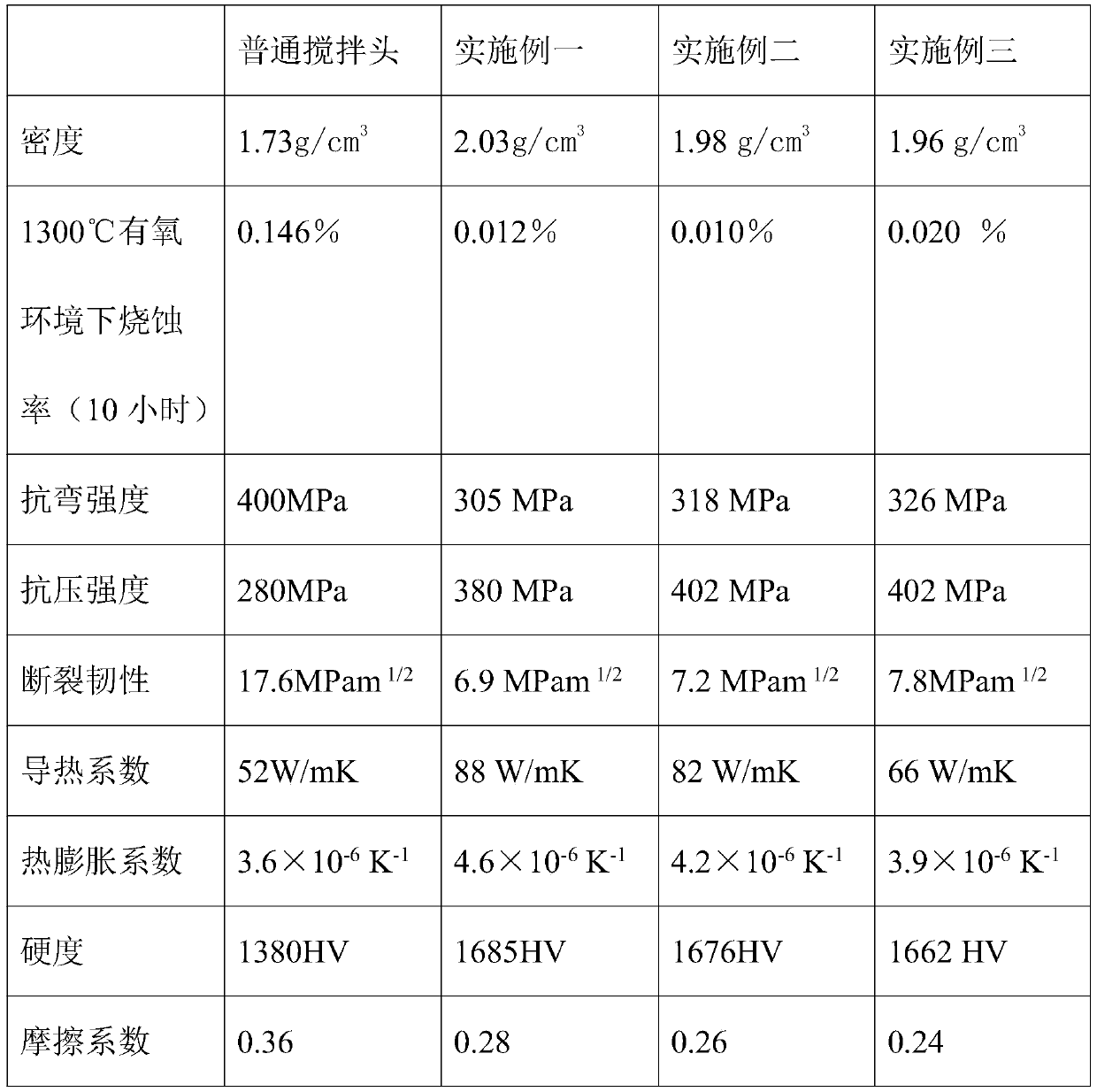

High-performance carbon ceramic friction welding stirring head and preparation method thereof

ActiveCN109824376AExcellent hardnessExcellent mechanicsNon-electric welding apparatusMaterials preparationFriction welding

The invention discloses a high-performance carbon ceramic friction welding stirring head and a preparation method thereof. The preparation method comprises the following steps: manufacturing a friction welding stirring head primary blank; pretreating the Cf / C composite friction welding stirring head primary blank; densifying the Cf / C composite friction welding stirring head primary blank; and preparing a SiC coating of a Cf / C-SiC composite friction welding stirring head pre-finished product.The high-performance carbon ceramic friction welding stirring head and a preparation method thereof belongs to the technical field of ceramic-based composite material preparation, and the high-performance carbon ceramic friction welding stirring head and the preparation method thereof ensure that residual free carbon and free silicon in the material fully react, and simultaneously remove other impurities, so that the hardness and the wear resistance of the Cf / C-SiC composite material friction welding stirring head are greatly improved; a layer of compact SiC coating can be prepared on the surface of the material through further SiC deposition treatment, the oxidation resistance of the stirring head at high temperature is greatly improved; meanwhile, the purity of surface silicon carbide is more than 99%, the surface hardness is further improved, and the service life of the stirring headis greatly prolonged.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

Inorganic ceramic paint

InactiveCN107201062AImprove the decorative effectMeet individual requirementsCoatingsStainCerium oxide

The invention relates to a building coating, in particular to an inorganic ceramic coating used for building walls or decorative panels. It contains 34-56% of water-based silica sol, 26-46% of alumina or hydrated alumina, 1-7% of water-soluble alcohol amine, 2-13% of calcium oxide or calcium hydroxide, and the rest for water. The invention can make a variety of building substrates (such as ceramics, glass, concrete, calcium silicate board, etc.) have good adhesion coating, and the obtained coating has excellent hardness, water resistance, stain resistance, Acid and alkali resistance, non-combustible, easy to use, can be widely used in building exterior walls and decorative panels.

Owner:高仁丽

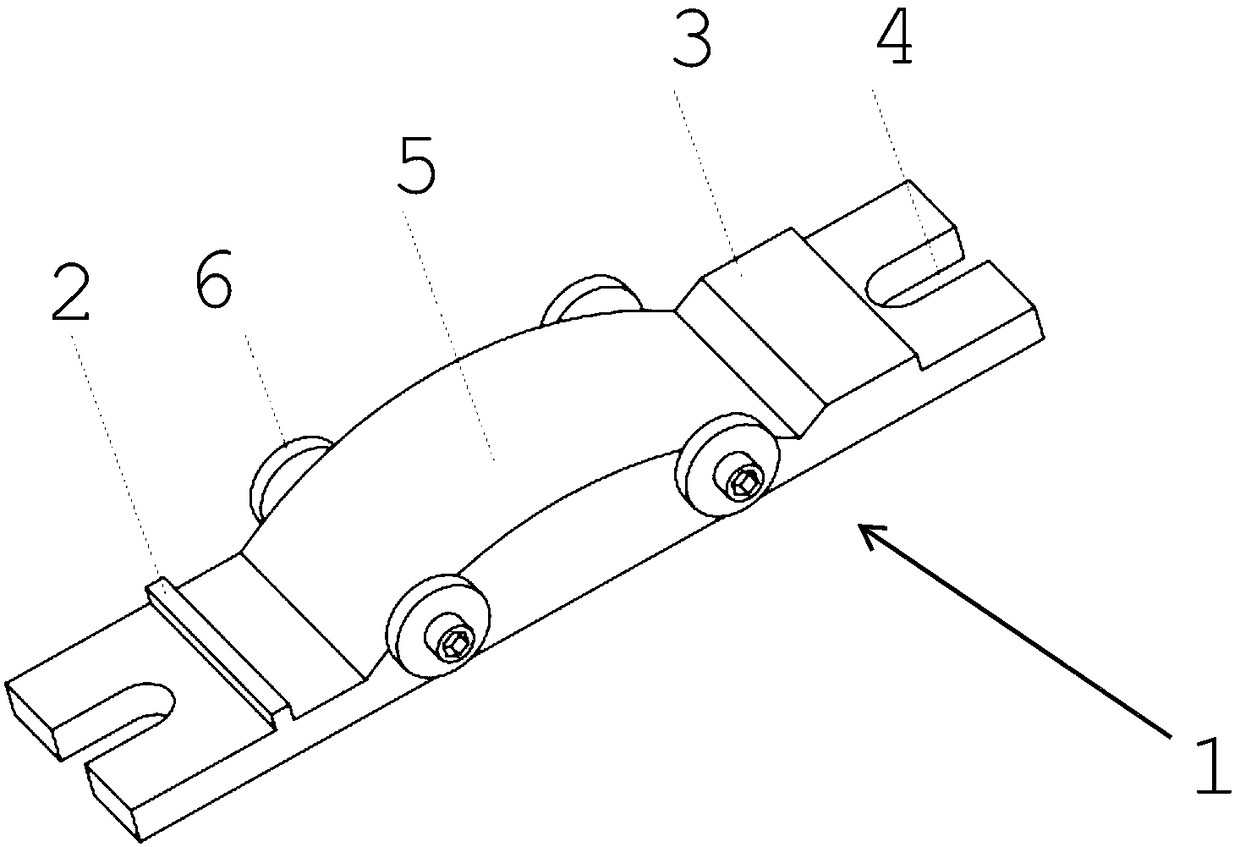

Rotary forging die clamp and surface processing method thereof

InactiveCN109226630AImprove clamping stabilityFit tightlyMolten spray coatingFurnace typesEngineeringMachining process

The invention relates to the field of forging die clamps, in particular to a rotary forging die clamp for clamping roller forging dies or other untraditional upright dies, and a surface processing method of the rotary forging die clamp. The problems that an existing clamp cannot effectively and stably clamp the untraditional upright dies, fixing and clamping are difficult, production efficiency isreduced, the dies bear uneven force, workpieces easily shake in the production and machining process, the machining dies deviate from the original requirements, the halving and leveling process is quite complicated for operators, and the quality cannot be ensured are solved. By means of the technical scheme, the rotary forging die clamp comprises a body and fixed clamping grooves. The fixed clamping grooves are formed in the two ends of the body in the length direction. An arch base is arranged on one bottom face of the body and provided with a curved surface. The curved surface is bent in the length direction of the body. At least two fastening devices are symmetrically arranged on the arch base. A positioning inclined surface is arranged at the end, extending in the length direction ofthe body, of the arch base, and a positioning block is oppositely arranged at the other end of the arch base.

Owner:ZHEJIANG YUEJIN MACHINERY

A kind of high-adhesion water-based waterproof primer and its preparation method and application

The invention discloses high-adhesion water-based waterproof primer as well as a preparation method thereof and application thereof. The high-adhesion water-based waterproof primer is prepared from the following components in parts by weight: 25-32 parts of composite emulsified polymer emulsion, 2.8-3.3 parts of coupling film-forming agent, 0.6-1 part of hydroxyethyl cellulose, 15-18 parts of titanium dioxide, 4-6 parts of barium sulfate, 4-6 parts of calcium carbonate, 4-6 parts of talcum powder, 1-2 parts of dispersing agent, 0.5-1 part of wetting leveling agent, 0.2-0.4 part of de-foaming agent, 0.2-0.3 part of preservative, 1.8-2.2 parts of anti-freezing agent, 0.1-0.3 part of rheological agent, 0.1-0.3 part of pH regulator, 0.4-0.8 part of thickening agent and 24-31 parts of water. The high-adhesion water-based primer has excellent film-forming property, hardness, flexibility, water resistance, chemical resistance, sealing property, seepage force and adhesion, can be effectively dissolved and permeated into an organic silicon mould release agent on novel material plates such as an art ware, a cement product, a glass magnesium board and a special cast sectional material, is inseamless engagement with the board, and achieves the practical effect of improving coating quality and field construction environment. Moreover, the preparation method is easy, is low in cost, is simple in construction way, and reduces production and construction cost.

Owner:ZHANG ZHOU SAN PAINTS

A kind of preparation method of skates for skates

The invention provides a preparation method for an ice skate blade of a skate. Heat treatment is carried out on an ice skate blade base blade slice so that different parts of the ice skate blade can acquire needed different hardnesses, and therefore it is guaranteed that after a coating is applied, an ice skate blade body has rigidity and toughness for resisting and transmitting ice pedaling strength, and meanwhile a blade edge can be enough to be resistant to abrasion and have surface roughness which is as small as possible. Moreover, the base body blade slice of the ice skate blade and the inner layer of the alloy coating are coated with powder, a specific alloy element component proportion is adopted, and therefore the hardness of the alloy coating is remarkably improved, and extremely-high abrasion resistance, good rockiness and resistance to oxidation are achieved.

Owner:凤阳精准模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com