Modified organic ester for environment-friendly casting and preparation method

A technology of modification of organic esters, applied in casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of high price of organic esters, emphasis on environmental protection, and irritating odor, and achieve good hardness, low price, The effect of high sand mold strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

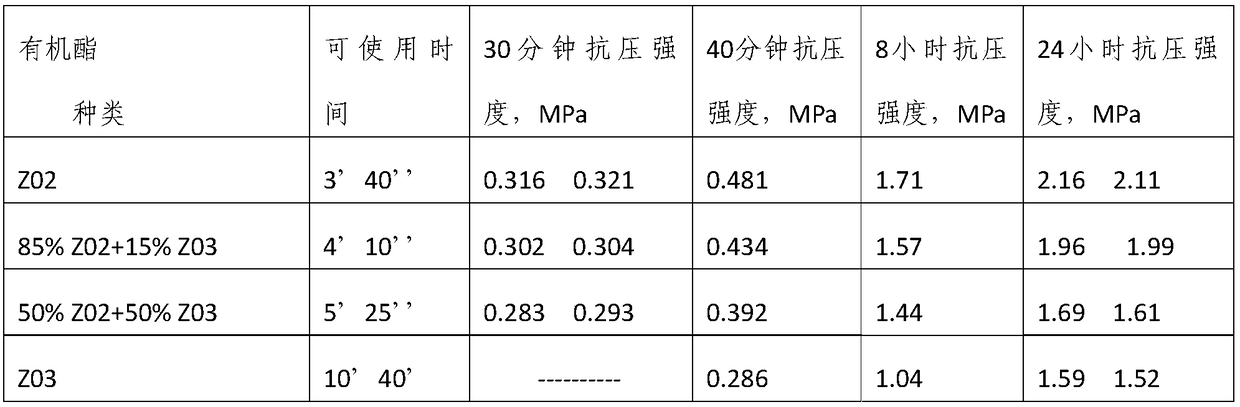

[0031] Example 1 Spring and Autumn Test: At the production site, the sand temperature is 16°C, and the sand temperature is 15°C. Take 2000g of the mixed sand sample and make it into a cylindrical standard sample.

[0032] Raw sand + 3% modified water glass + 20% organic ester Z01 glyceryl monoacetate Z02 glyceryl diacetate Z03 glyceryl triacetate Z04 citric acid ester

[0033] New sand (Inner Mongolia Daqi quartz sand)

[0034]

[0035] Note: All organic esters are added with 20% PPC and 5% with citric acid ester.

[0036] Mixed sand (20% new sand + 80% regenerated sand) residual Na in regenerated sand 2 O 0.53%

[0037]

[0038] Note: All organic esters are added with 20% PPC and 5% with citric acid ester.

Embodiment 2

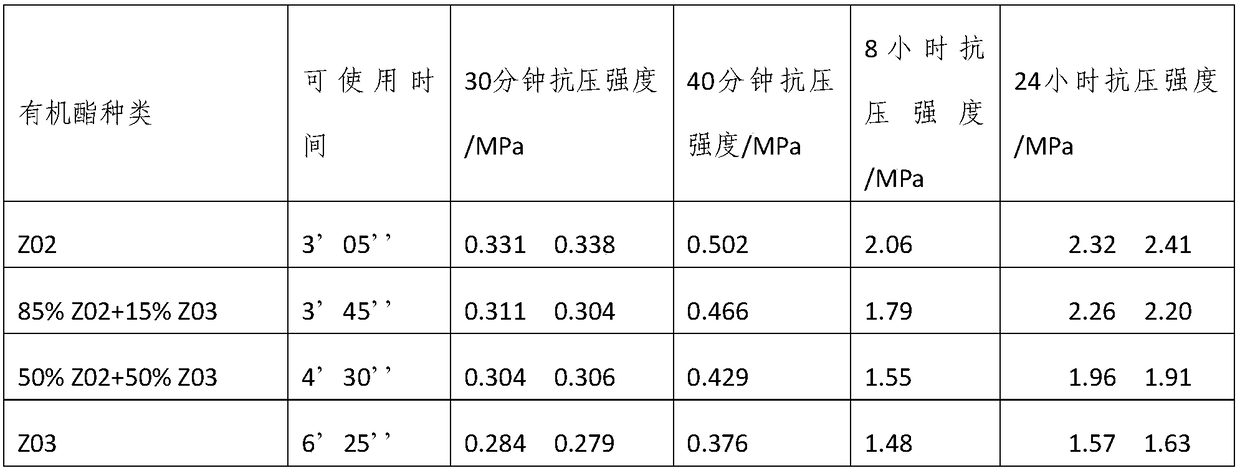

[0039] Example 2 Summer test: At the production site, the sand temperature is 30°C, and the sand temperature is 35°C. Take 2000g of the mixed sand sample and make it into a cylindrical standard sample.

[0040] Raw sand + 3% modified water glass + 20% organic ester Z01 glyceryl monoacetate Z02 glyceryl diacetate Z03 glyceryl triacetate Z04 citric acid ester

[0041] New sand (Inner Mongolia Daqi quartz sand)

[0042]

[0043] Note: All organic esters are added with 20% PPC and 5% with citric acid ester.

[0044] Mixed sand (20% new sand + 80% regenerated sand) regenerated sand residual Na2O 0.53%

[0045]

[0046] Note: All organic esters are added with 20% PPC and 5% with citric acid ester.

Embodiment 3

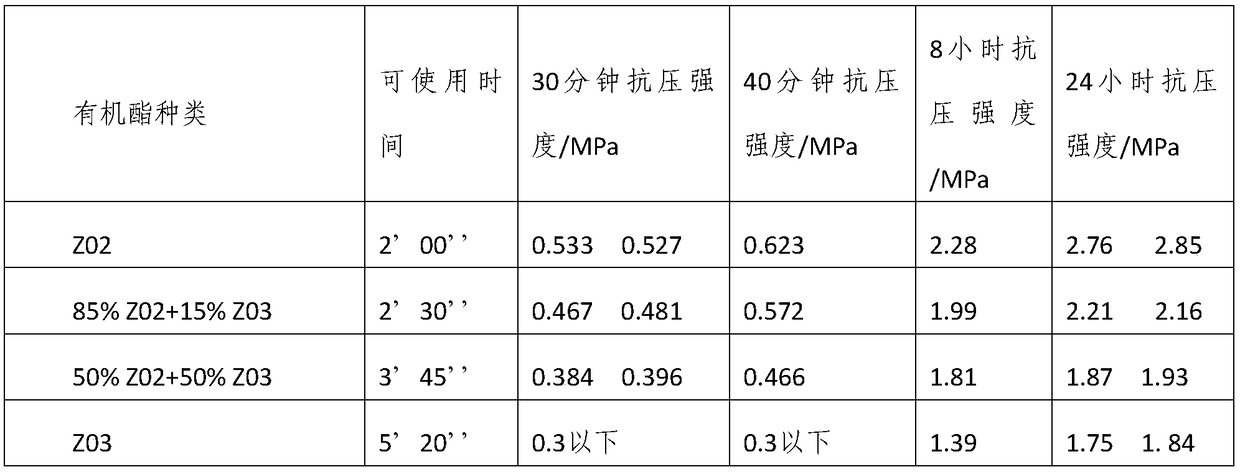

[0047] Example 3 Winter test: At the production site, the sand temperature is 8°C and the sand temperature is 16°C, take 2000g of the mixed sand sample, and make it into a cylindrical standard sample.

[0048] Raw sand + 3% modified water glass + 20% organic ester Z01 glyceryl monoacetate Z02 glyceryl diacetate Z03 glyceryl triacetate Z04 citric acid ester

[0049] New sand (Inner Mongolia Daqi quartz sand)

[0050]

[0051]

[0052] Note: All organic esters are added with 20% PPC and 5% with citric acid ester.

[0053] Mixed sand (20% new sand + 80% regenerated sand) regenerated sand residual Na2O 0.53%

[0054]

[0055] Note: All organic esters are added with 20% PPC and 5% with citric acid ester.

[0056] Compared with ordinary organic esters, the modified organic esters for environmentally friendly foundry of the present invention have the advantages of strong environmental adaptability, good fluidity of molding sand, good hardness and permeability of sand molds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com