High-performance carbon ceramic friction welding stirring head and preparation method thereof

A friction welding and stirring head technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of insufficient toughness, poor wear resistance, and unsatisfactory characteristics, and achieve the retention of strength, toughness, and hardness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

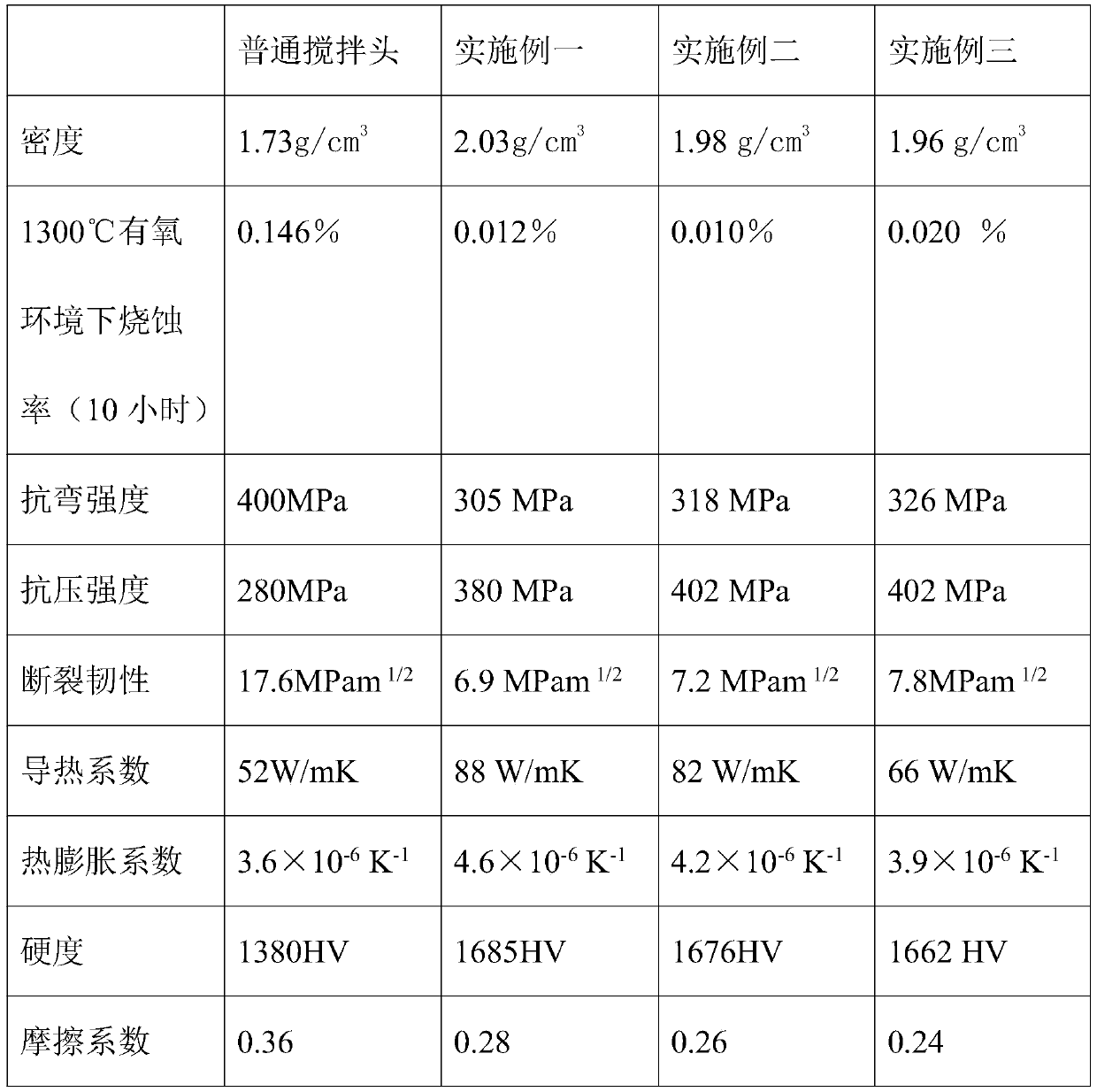

Examples

Embodiment 1

[0034] The impregnating agent used in this embodiment consists of the following composition ratios in parts by mass:

[0035] 80 parts of polycarbosilane, 30 parts of xylene, 10 parts of DVB (divinylbenzene). The average molecular weight of the polycarbosilane used is 1200, and the softening point is 175° C.; the content of DVB (divinylbenzene) used is 55%.

[0036] In this example, with Cf / C Composite material green body is the processing object; the volume density of its carbon fiber prefabricated body is 0.45g / cm 3 , C f / C Composite body density is 1.25g / cm 3 .

[0037] Its operation steps are:

[0038] Step 1. Polish C with sandpaper f On the surface of the / C composite material blank, the surface dust is sucked by a vacuum cleaner, then soaked in absolute ethanol, ultrasonically cleaned for 30-60 minutes, dried and placed in a pressure impregnation tank. After the pressure impregnation tank is sealed, it is vacuumed, Under the condition that the vacuum degree is l...

Embodiment 2

[0051] The impregnating agent used in this embodiment consists of the following composition ratios in parts by mass:

[0052] 80 parts of polycarbosilane, 30 parts of xylene, 10 parts of DVB (divinylbenzene). The average molecular weight of the polycarbosilane used is 1500, and the softening point is 185° C.; the content of DVB (divinylbenzene) used is 55%.

[0053] In this example, with C f / C composite body is the processing object; the volume density of its carbon fiber preform is 0.50g / cm 3 , C f / C composite body density is 1.30g / cm 3 .

[0054] Its operation steps are:

[0055] Step 1. Polish C with sandpaper f On the surface of the / C composite material blank, the surface dust is sucked by a vacuum cleaner, then soaked in absolute ethanol, ultrasonically cleaned for 30-60 minutes, dried and placed in a pressure impregnation tank. After the pressure impregnation tank is sealed, it is vacuumed, Under the condition that the vacuum degree is lower than 10Pa, suck the...

Embodiment 3

[0068] The impregnating agent used in this embodiment consists of the following composition ratios in parts by mass:

[0069] 80 parts of polycarbosilane, 30 parts of xylene, and 10 parts of DVB (divinylbenzene). The average molecular weight of the polycarbosilane used is 1800, the softening point is 195° C., and the content of DVB (divinylbenzene) used is 55%.

[0070] In this example, with C f / C Composite material green body is the processing object; the volume density of its carbon fiber prefabricated body is 0.55g / cm 3 , C f / C composite body density is 1.40g / cm 3 .

[0071] Its operation steps are:

[0072] Step 1. Polish C with sandpaper f On the surface of the / C composite material blank, the surface dust is sucked by a vacuum cleaner, then soaked in absolute ethanol, ultrasonically cleaned for 30-60 minutes, dried and placed in a pressure impregnation tank. After the pressure impregnation tank is sealed, it is vacuumed, Under the condition that the vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com