A kind of high-adhesion water-based waterproof primer and its preparation method and application

A waterproof primer and high adhesion technology, applied in the direction of primer, coating, etc., can solve the problems of poor adhesion of paint, peeling, scratches and cracks on the product surface, and toxicity, so as to improve the penetration and adhesion of the coating film. Efforts, resistance to overcome the phenomenon of back-alkali, good anti-alkali sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

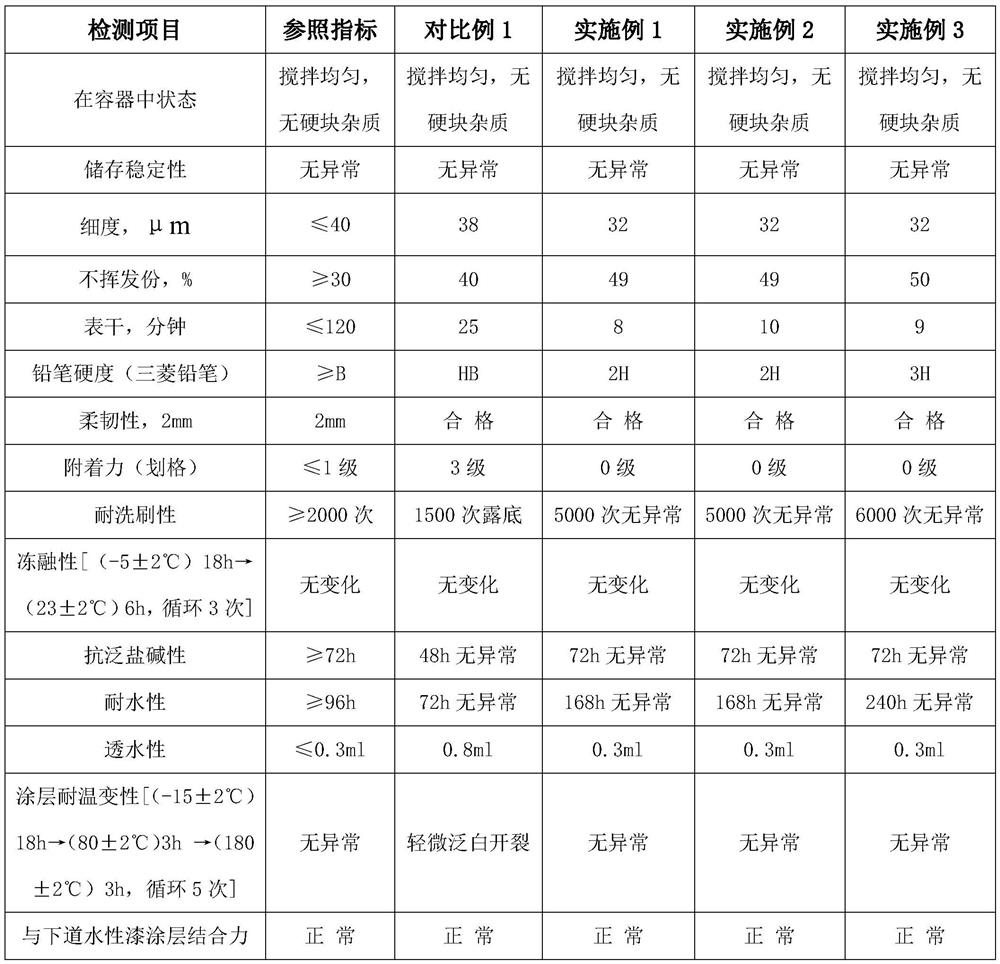

Examples

Embodiment 1

[0037] The present invention's high adhesion water-based waterproof primer weight percent is as follows each component:

[0038] Pure acrylic composite emulsified polymer emulsion 25, coupling film-forming aid 3.3, hydroxyethyl cellulose 1, titanium dioxide 18, barium sulfate 5.5, calcium carbonate 5.5, talcum powder 5.5, dispersant 1, wetting and leveling agent 0.8 , defoamer 0.4, preservative 0.2, antifreeze 2.2, rheological agent 0.2, pH regulator 0.2, thickener 0.6, tap water 30.6.

[0039] Its preparation method comprises the following steps:

[0040] Add water 30.6, hydroxyethyl cellulose 1 to the container and disperse evenly into a gel at a speed of 1200 rpm, then add dispersant 1, wetting and leveling agent 0.8, defoamer 0.4, preservative 0.2, antifreeze 2.2 Stir and mix evenly at a low speed of 600 rpm for 7 minutes; then add titanium dioxide 18, barium sulfate 5.5, calcium carbonate 5.5, and talc powder 5.5, stir and disperse at a high speed of 2000 rpm for 18 minu...

Embodiment 2

[0046] The present invention's high adhesion water-based waterproof primer weight percent is as follows each component:

[0047] Styrene-acrylic composite emulsified polymer emulsion 32, coupling film-forming aid 3.3, hydroxyethyl cellulose 0.6, titanium dioxide 18, barium sulfate 5.5, calcium carbonate 5.5, talcum powder 5.5, dispersant 1, wetting and leveling agent 0.8 , defoamer 0.4, preservative 0.2, antifreeze 2.2, rheological agent 0.2, pH regulator 0.2, thickener 0.6, tap water 24.

[0048] Its preparation method and construction method are identical with embodiment 1.

Embodiment 3

[0050] The present invention's high adhesion water-based waterproof primer weight percent is as follows each component:

[0051] Silicone acrylic composite emulsified polymer emulsion 28, coupling film-forming aid 3.3, hydroxyethyl cellulose 0.6, titanium dioxide 18, barium sulfate 5.5, calcium carbonate 5.5, talc 5.5, dispersant 1, wetting and leveling agent 0.8 , defoamer 0.4, preservative 0.2, antifreeze 2.2, rheological agent 0.2, pH regulator 0.2, thickener 0.6, tap water 28.

[0052] Its preparation method and construction method are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com