Rotary forging die clamp and surface processing method thereof

A rotary forging and surface treatment technology, which is applied in the field of forging mold fixtures, can solve the problems of inability to clamp non-traditional square molds, deviate from the original requirements of processing molds, and the cumbersome process of centering and leveling, etc., to achieve surface and internal Effects of improved mechanical properties, increased efficiency, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

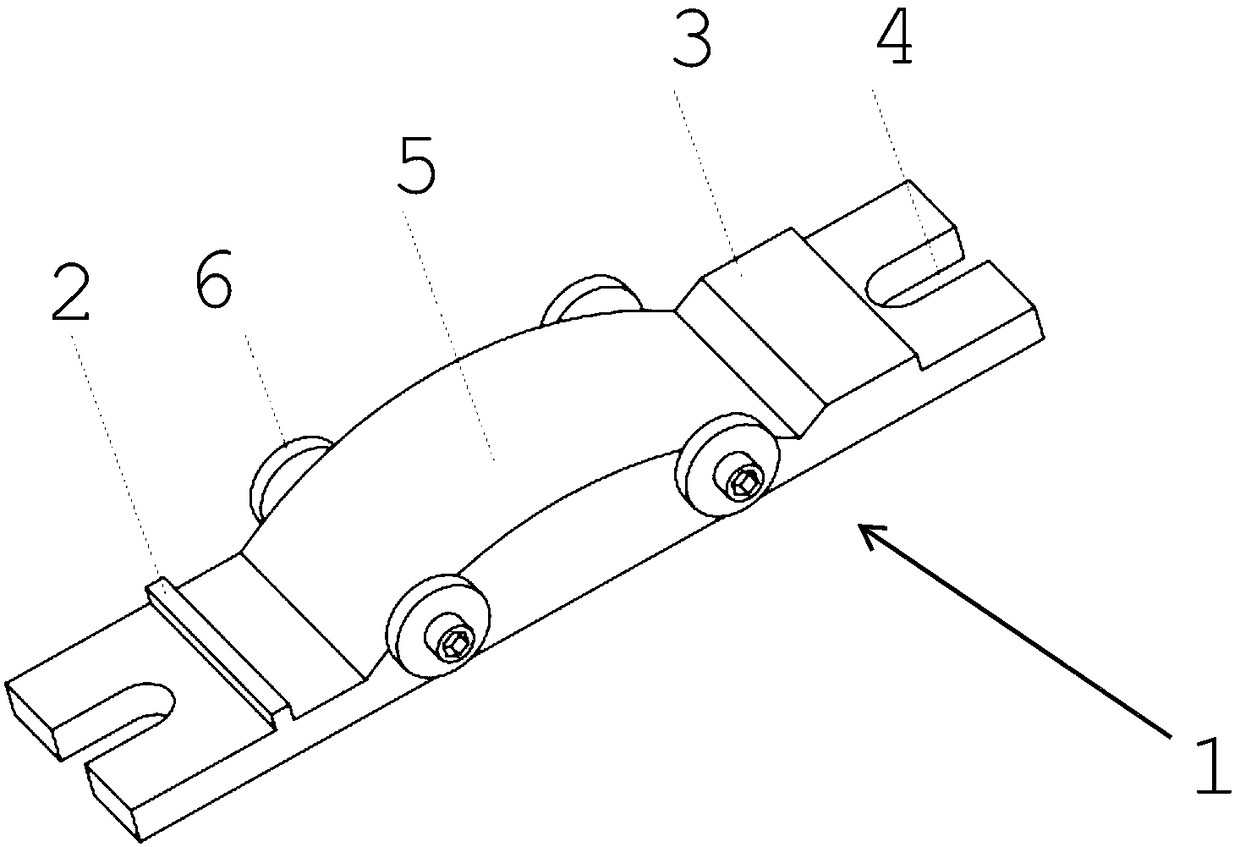

[0036] Such as figure 1 As shown in a rotary forging die fixture, the base body 1 is a cuboid, and a fixing slot 4 is provided at both ends of the long direction, which is used for fixing the processing machine tool. An arch bridge base 5 is provided on one side of the cuboid. The arch bridge base 5 fits the arc surface of the rotary forging die, and the fastening devices 6 on both sides of the arch bridge base 5 lock and fix the rotary forging die, which greatly improves the traditional furniture that cannot effectively and stably fix the rotary forging die. The disadvantage is that a positioning slope 3 and a positioning block 2 are oppositely provided at both ends of the arch bridge base 5 along the long direction of the main body 1, which can realize the rapid positioning of the rotary forging die and improve the processing efficiency.

[0037] The carburizing medium used in this example is SiC as carbon source with BaCO 3 As a solid carburizing medium composed of an infi...

Embodiment 2

[0039] Such as figure 1As shown in a rotary forging die fixture, the base body 1 is a cuboid, and a fixing slot 4 is provided at both ends of the long direction, which is used for fixing the processing machine tool. An arch bridge base 5 is provided on one side of the cuboid. The arch bridge base 5 fits the arc surface of the rotary forging die, and the fastening devices 6 on both sides of the arch bridge base 5 lock and fix the rotary forging die, which greatly improves the traditional furniture that cannot effectively and stably fix the rotary forging die. The disadvantage is that a positioning slope 3 and a positioning block 2 are oppositely provided at both ends of the arch bridge base 5 along the long direction of the main body 1, which can realize the rapid positioning of the rotary forging die and improve the processing efficiency.

[0040] The carburizing medium used in this embodiment is to use the charcoal of the embodiment as a carbon source in conjunction with CH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com