Patents

Literature

37results about How to "Increased compressive yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength Al-Zn alloy and method for producing such an alloy product

The present invention relates to a high strength Al—Zn alloy product with an improved combination of corrosion resistance and toughness, the alloy including essentially (in weight percent): Zn: 6.0-9.5, Cu: 1.3-2.4, Mg: 1.5-2.6, Mn and Zr<0.25 but preferably in a range between 0.05 and 0.15 for higher Zn contents, other elements each less than 0.05 and less than 0.25 in total, balance aluminium, wherein (in weight percent): 0.1[Cu]+1.3<[Mg]<0.2[Cu]+2.15. The invention also relates to a method to produce these alloy products, and to some preferred applications thereof such as upper wing applications in aerospace.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Nano-ceramic particle reinforced aluminum foam matrix composite material and preparation method thereof

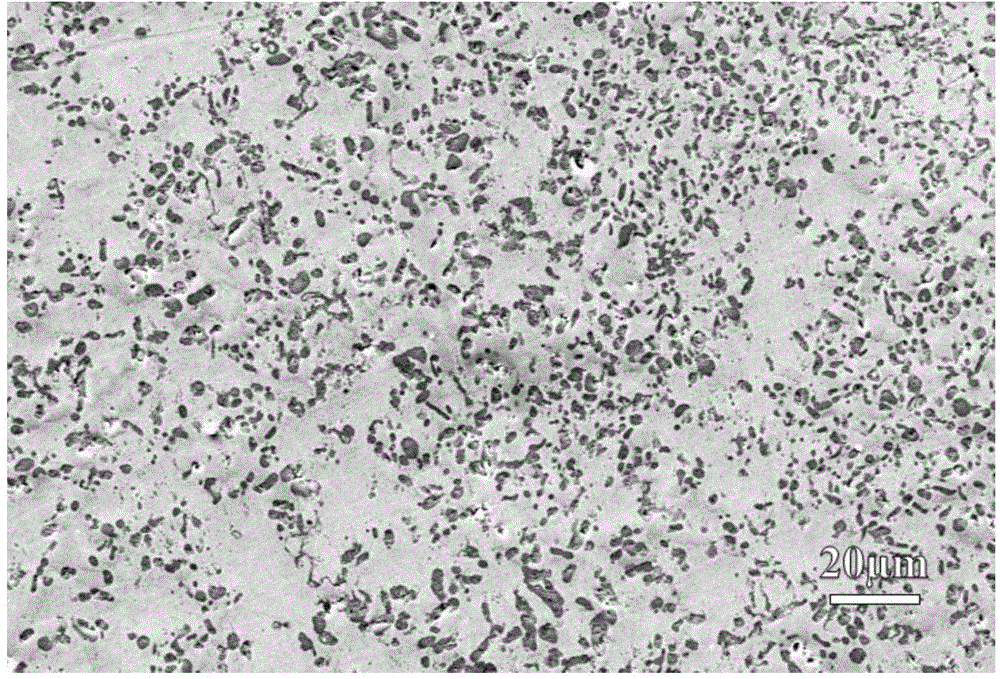

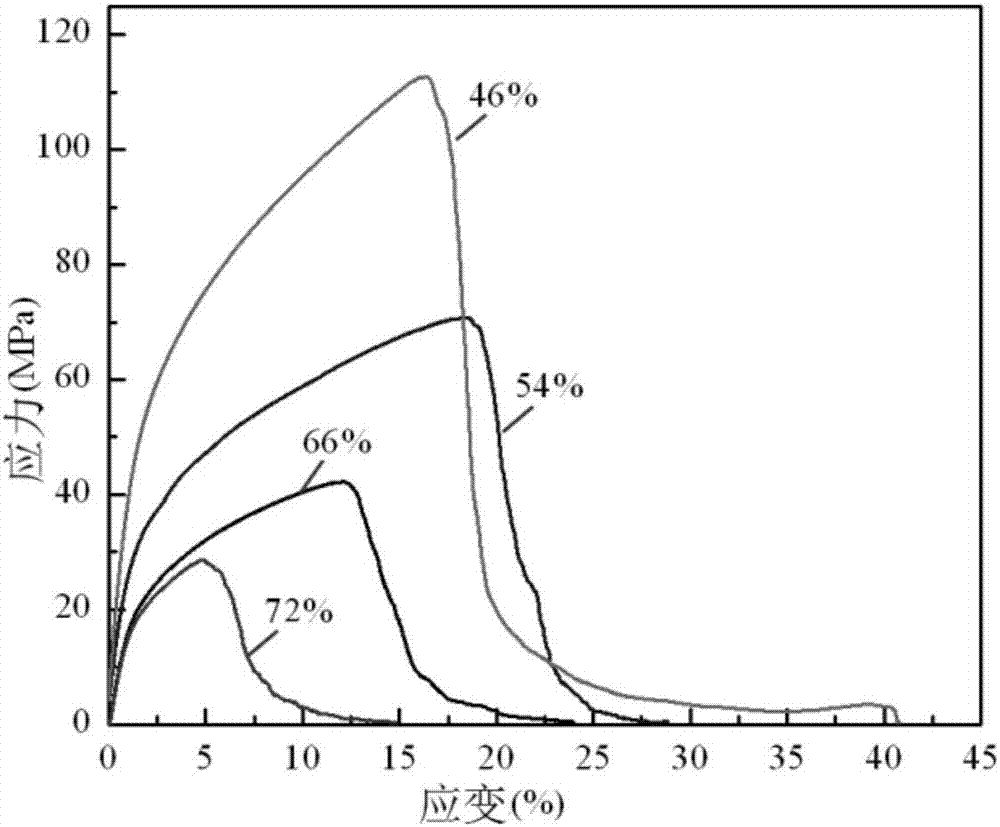

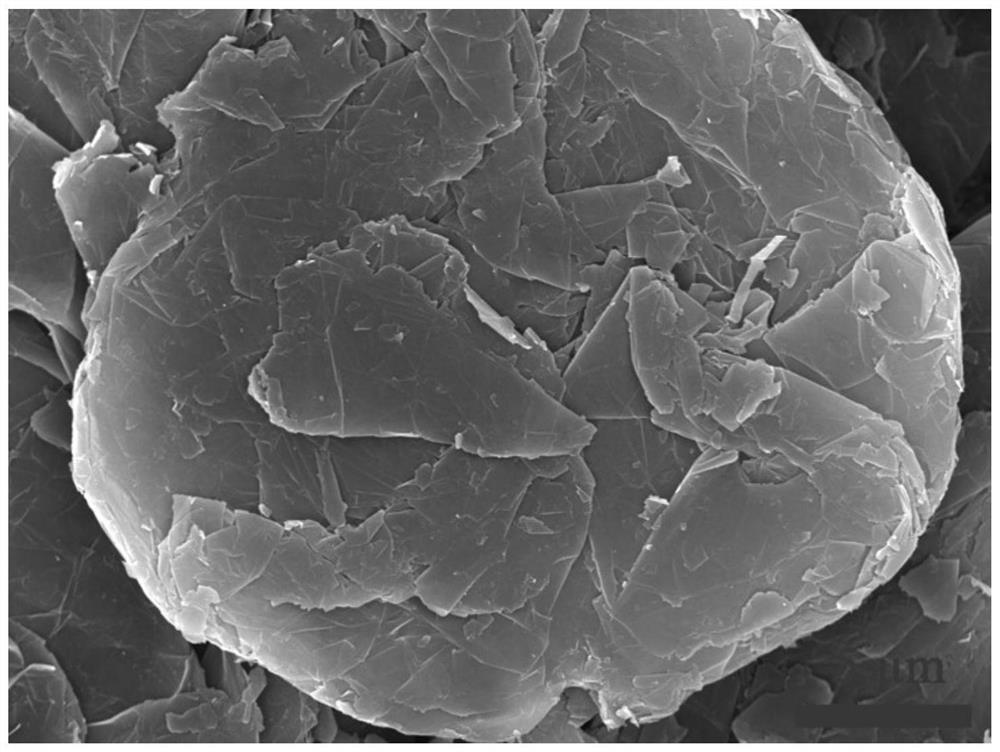

A nano-ceramic particle reinforced aluminum foam matrix composite material and a preparation method thereof relates to an aluminum foam matrix composite material and a preparation method thereof. The invention solves the problem that in the preparation method of the ceramic particle reinforced aluminum foam matrix composite material, ceramic particles are micron-sized, the uniform distribution of nano-ceramic particles can not be realized, and the existing ceramic particle reinforced aluminum foam matrix composite material has wide aperture and low compressive yield strength. The aluminum foam matrix composite material of the invention is prepared from aluminum or aluminum alloy powder, CaCO3 and nano-ceramic particles. The preparation method comprises the following steps: using a ball mill to process raw material powder and stearic acid, mixing powder, then placing the mixture in a graphite mould to perform vacuum hot press sintering and obtain a perform, performing forward extruding to obtain a semi-finished product, heating and foaming to obtain the finished product. The aperture of the aluminum foam matrix composite material is less than 1mm, and the compressive yield strength is 50-98MPa which is 2-20 times of that of the existing aluminum foam matrix composite material. By using the method of the invention, the nano-ceramic particles can be uniformly distributed in the aluminum foam matrix composite material.

Owner:HARBIN INST OF TECH

High-strength, high toughness Al-Zn alloy product and method for producing such product

Disclosed is a Al—Zn alloy wrought product, and a method of manufacturing such a product, with an improved combination of high toughness and high strength by maintaining good corrosion resistance, the alloy including (in weight percent): Zn 6.0-11.0, Cu 1.4-2.2, Mg 1.4-2.4, Zr 0.05-0.15, Ti<0.05, Hf and / or V<0.25, and optionally Sc and / or Ce 0.05-0.25, and Mn 0.05-0.12, other elements each less than 0.05 and less than 0.50 in total, balance aluminium, wherein such alloy has an essentially fully unrecrystallized microstructure at least at the position T / 10 of the finished product.

Owner:NOVELIS KOBLENZ GMBH

Method for preparing ceramic particle reinforced foamed aluminum-matrix composite material

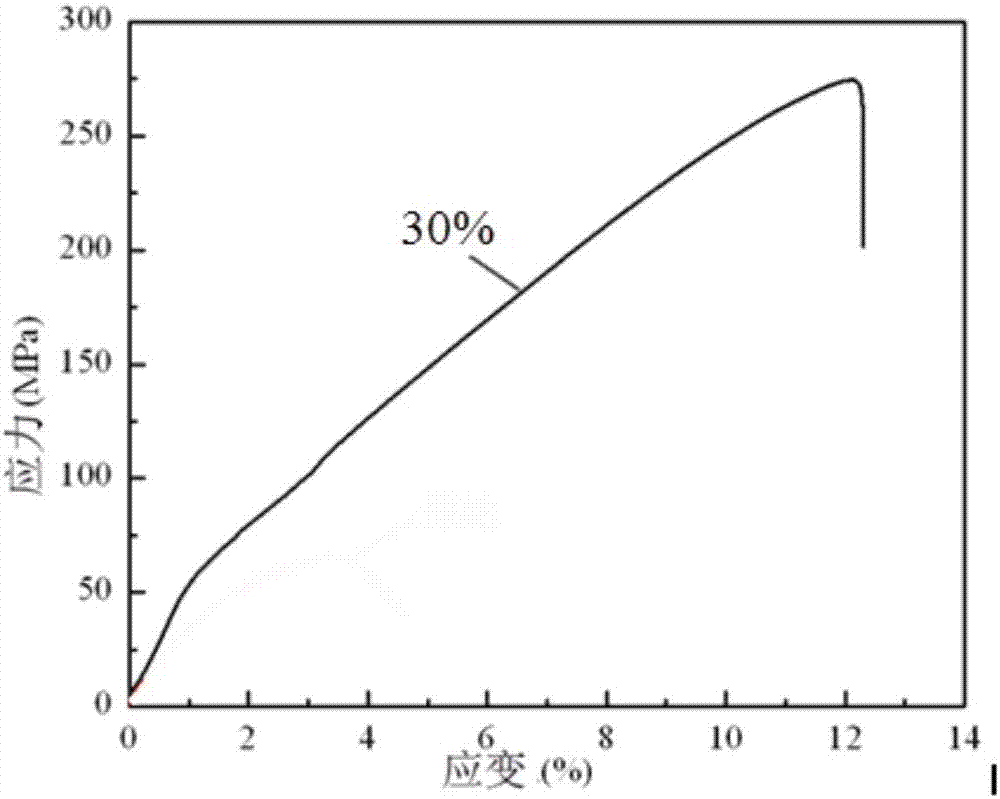

The invention relates to a method for preparing a ceramic particle reinforced foamed aluminum-matrix composite material, which relates to a method for preparing a foamed aluminum-matrix composite material. The method solves the problems of high production cost and nonuniform pore distribution of the obtained foamed aluminum-matrix composite material due to a foaming agent TiH2 adopted in a conventional melt-foaming method which is expensive, needs pretreatment and has a difficultly controlled decomposition rate. The method comprises the following steps of: mixing aluminum alloy powder, ceramic particles and calcium carbonate (CaCO3) powder and placing a mixture into a graphite mould; placing the graphite mould into a vacuum hotpressing sintering furnace to prepare a prefabricated body; and performing forward extrusion, heating and foaming on the prefabricated body to obtain the ceramic particle reinforced foamed aluminum-matrix composite material. By using a powder metallurgic method and taking the CaCO3 powder as a foaming agent, the method has the advantages of low price, no pretreatment, simple process, stable decomposition rate, convenience for industrial production and uniform pore distribution of the obtained composite material which has a pore diameter of 0.5 to 2 mm, a porosity of 40 to 82 percent and a compressive yield strength of 36 to 70 MPa.

Owner:HARBIN INST OF TECH

HIGH STENGTH Al-Zn ALLOY AND METHOD FOR PRODUCING SUCH AN ALLOY PRODUCT

The present invention relates to a high strength Al—Zn alloy product with an improved combination of corrosion resistance and toughness, the alloy including essentially (in weight percent): Zn: 6.0-9.5, Cu: 1.3-2.4, Mg: 1.5-2.6, Mn and Zr<0.25 but preferably in a range between 0.05 and 0.15 for higher Zn contents, other elements each less than 0.05 and less than 0.25 in total, balance aluminium, wherein (in weight percent): 0.1[Cu]+1.3<[Mg]<0.2[Cu]+2.15. The invention also relates to a method to produce these alloy products, and to some preferred applications thereof such as upper wing applications in aerospace.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

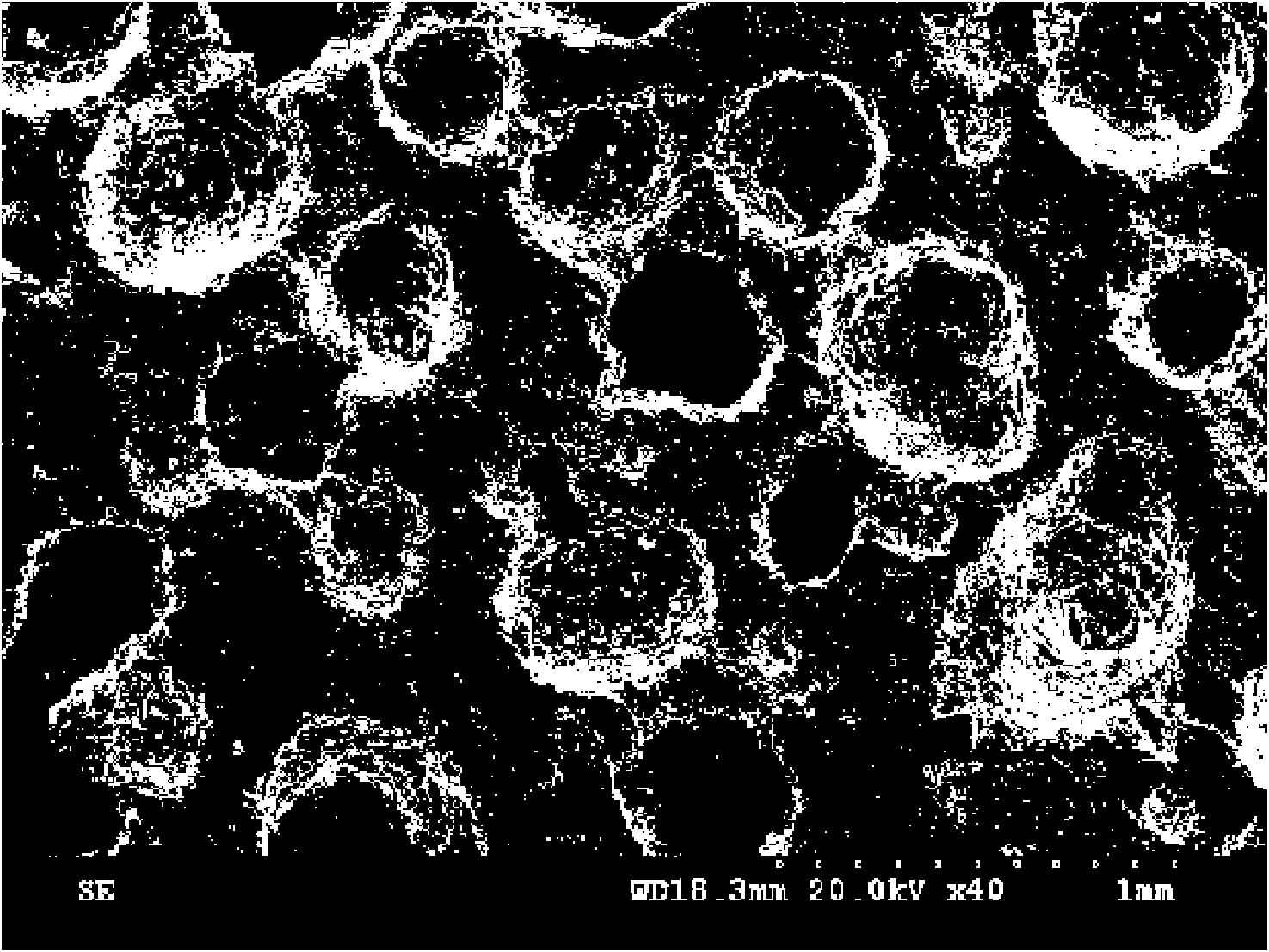

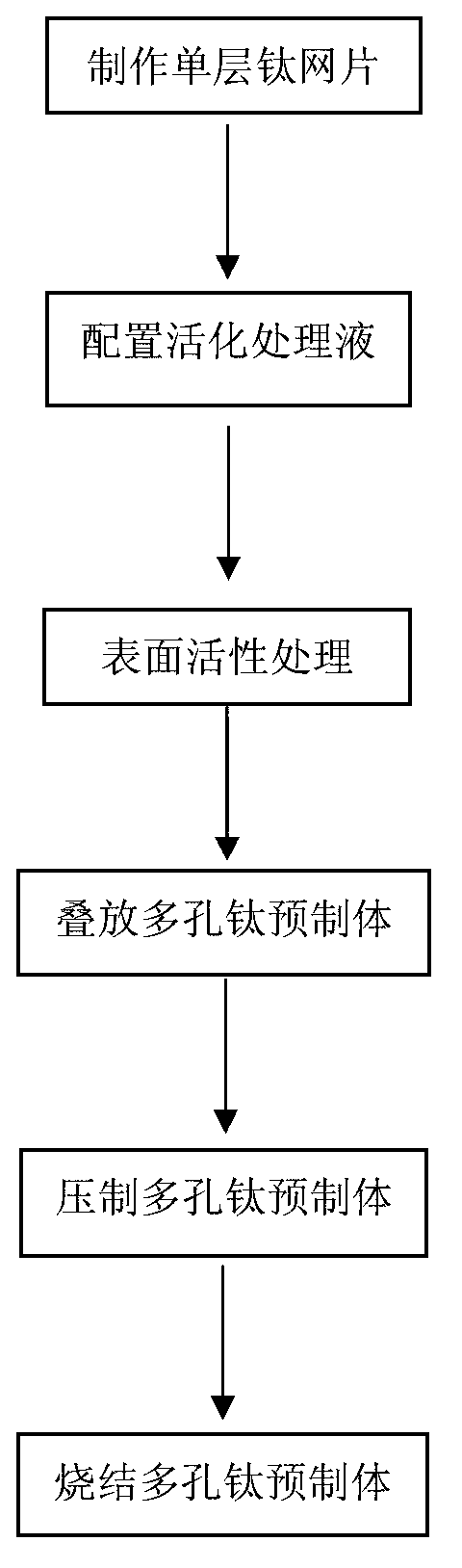

Preparation method of gradient porous titanium alloy

The invention relates to a preparation method of a gradient porous titanium alloy. The gradient porous titanium alloy is prepared through the titanium net aperture gradient superposing and vacuum sintering of a raw material regular-pore-form woven titanium or a titanium alloy net. In the invention, the pore form and the pore size of the porous body are controlled through adopting the single-layer titanium net, and the pore size gradient distribution is realized through superposing titanium alloy nets having different pore sizes, so the porous titanium pore size gradient distribution is realized. The elastic modulus and the comprehensive yield strength of the gradient porous titanium are in ranges of 0.66-12.8GPa and 27-364MPa respectively, so the gradient porous titanium is coupled with natural bone in elastic modulus; and the three-dimensional opened microstructure is in favor of the grow-in of bone tissues, so the application range of the porous titanium can be widened. The preparation method has the characteristics of easy control of the preparation technology, suitableness for the large-scale industrial production, and stable mechanical properties of the prepared porous body, and reduction of the pollution to the environment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

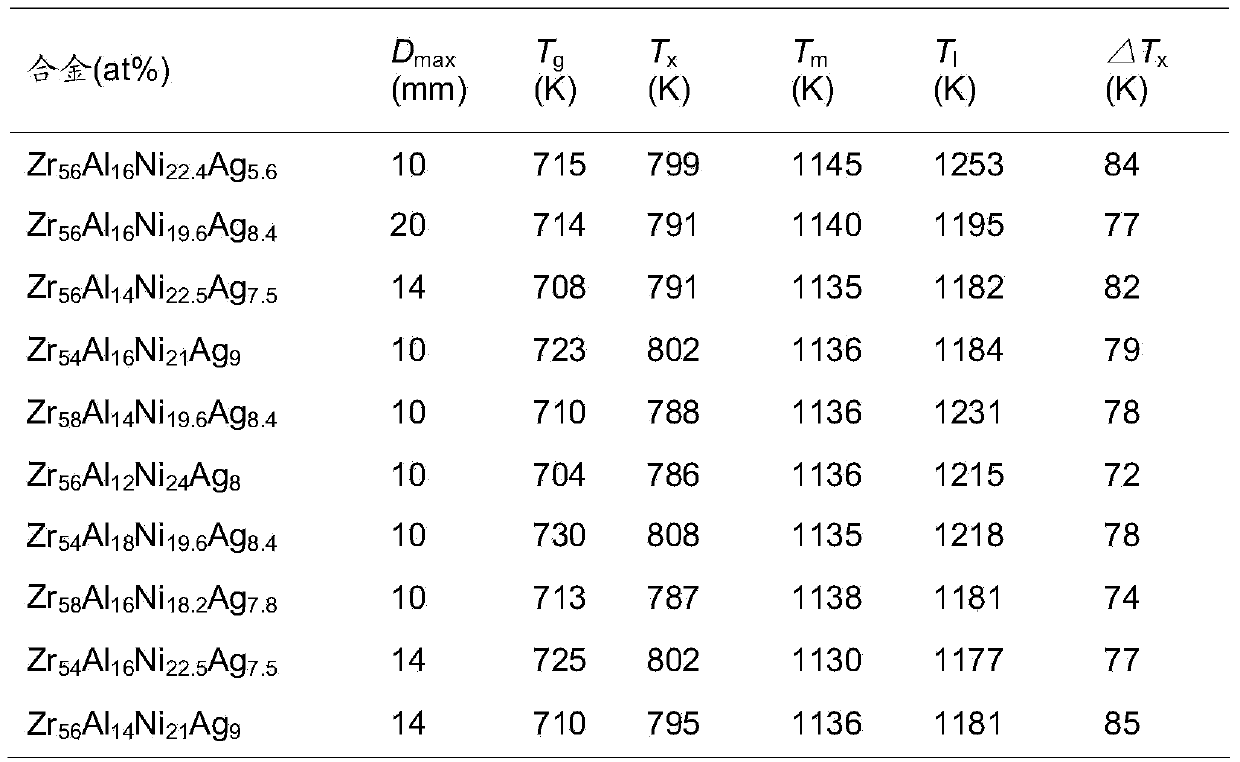

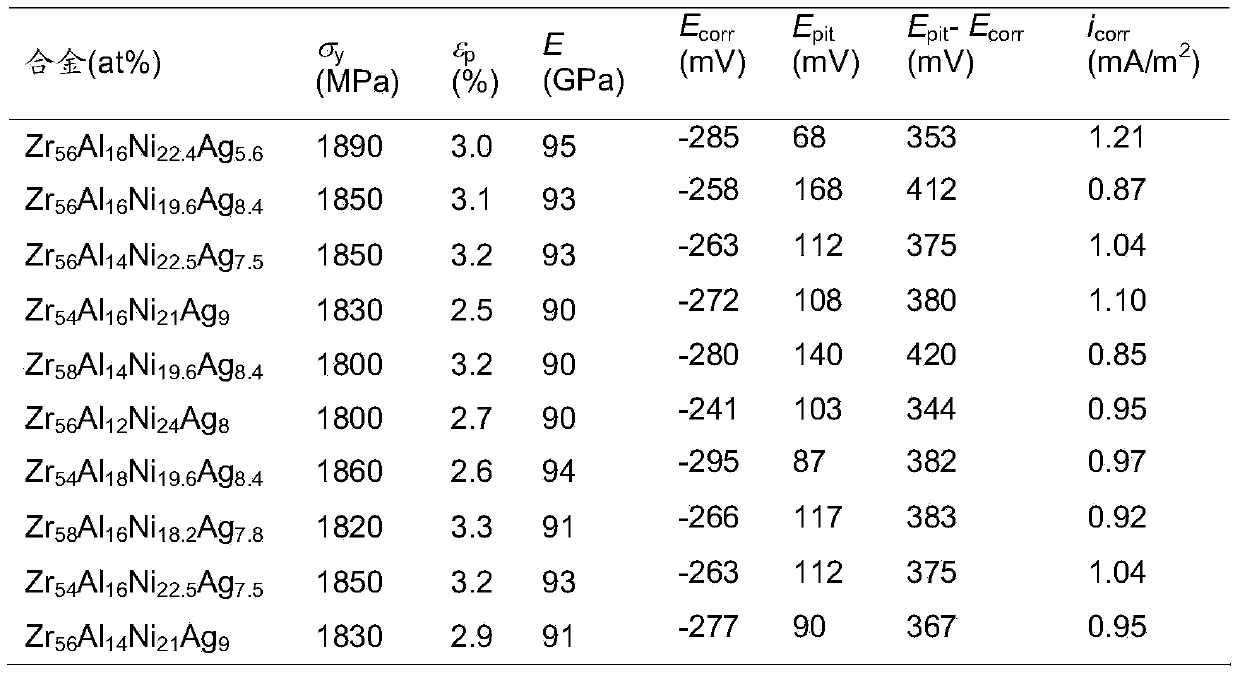

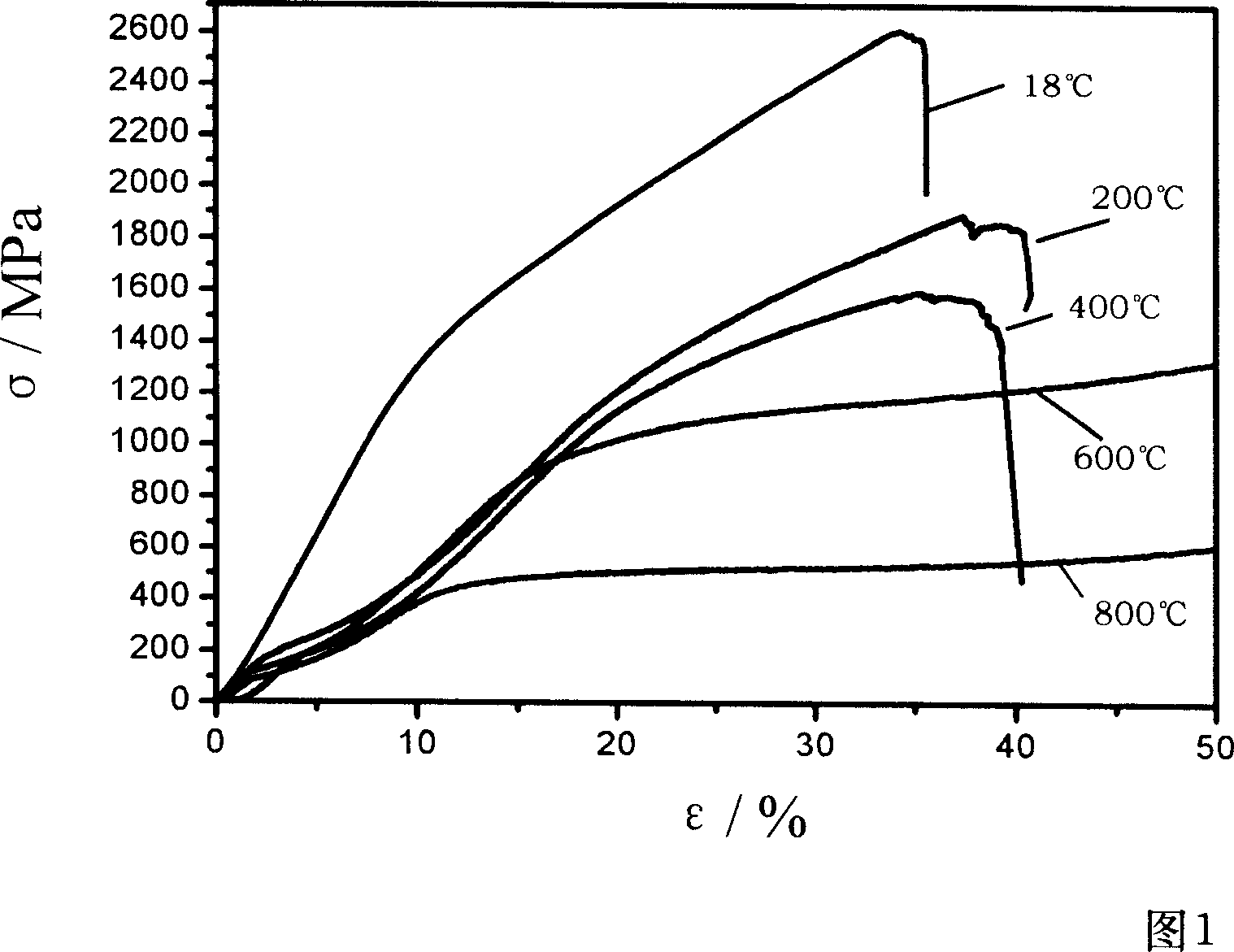

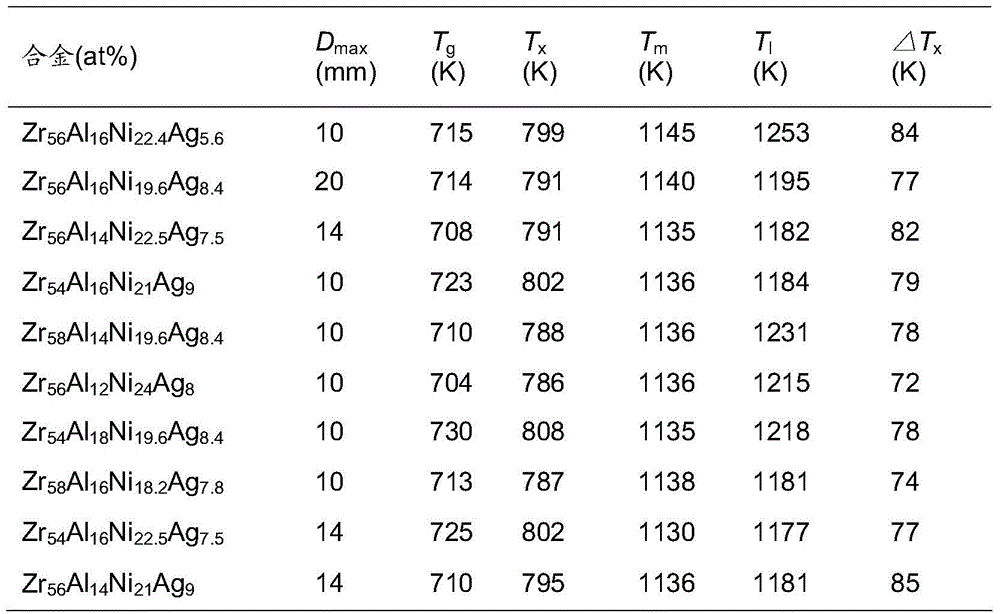

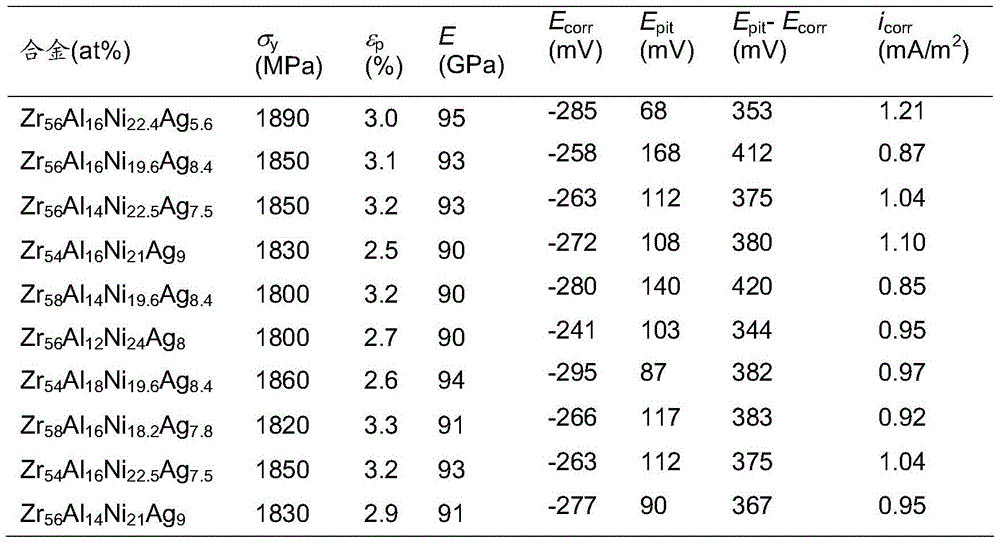

Centimeter-sized Zr-based bulk amorphous alloy, and preparation and application methods thereof

The invention discloses a centimeter-sized high-toughness and high-corrosion resistance Zr-based bulk amorphous alloy, which specifically has a chemical formula ZraAlbNicAgd, wherein a is more than 54 and less than 58 atomic percent, b is more than 12 and less than 18 atomic percent, c is more than 18.2 and less than 24 atomic percent, and d is more than 5.6 and less than 9 atomic percent, and a+b+c+d=100. The invention also discloses a preparation method for the Zr-based bulk amorphous alloy and a method for preparing a thin strip and a rod by utilizing the amorphous alloy. According to the Zr-based bulk amorphous alloy and the methods, elemental Ni and Ag are selected as components of the alloy, so that the corrosion resistance is greatly improved, the amorphous alloy formability of a Zr-Al-Ni alloy is improved, and the prepared bulk amorphous alloy is ultrahigh in formability; the Zr-based amorphous alloy also has the characteristics of high-amorphous alloy formability, high toughness and high corrosion resistance.

Owner:FUJIAN UNIV OF TECH

Ti-modified NiAl-Cr(Mo) polyphase eutectic intermetallic compound

The invention discloses a new-typed structure metal compound of Fe modified NiAl-Cr (Mo) polyphase eutectic crystal, which comprises the following parts: 33at% Ni,30at% Cr,4at% Mo,3-17at% Fe and Al, wherein the NiAl-Cr (Mo) polyphase alloy is modified by Fe, which induces plastic third phase gamma-phase and gamma'-phase to improve high-temperature strength and indoor temperature flexibility and plasticity.

Owner:BEIHANG UNIV

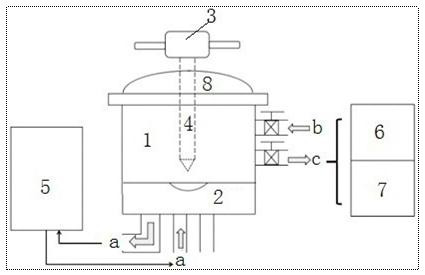

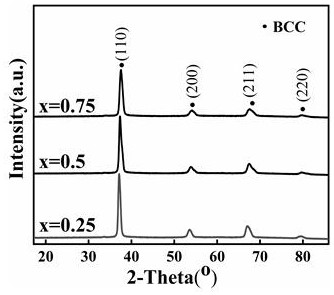

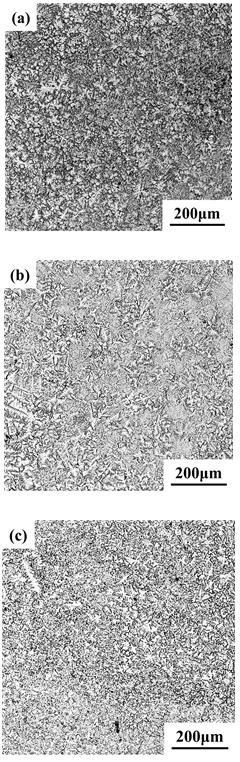

High-strength high-toughness TiZrHfNbTaWx refractory high-entropy alloy and preparation method thereof

The invention discloses a high-strength and high-toughness TiZrHfNbTaWx refractory high-entropy alloy and a preparation method thereof. The proportion of the elements is as follows: when x is equal to 0.25, the molar ratio of Ti to Zr to Hf to Nb to Ta to W is 19.05 to 19.05 to 19.05 to 19.05 to 19.05 to 4.76; when x is equal to 0.5, the molar ratio of the Ti to Zr to Hf to Nb to Ta to W is 18.18 to 18.18 to 18.18 to 18.18 to 18.18 to 9.09; and when x is equal to 0.75, the molar ratio of the elements of the Ti, Zr, Hf, Nb, Ta and W is 17.39 to 17.39 to 17.39 to 17.39 to 17.39 to 13.04. The TiZrHfNbTaWx single-phase refractory high-entropy alloy is prepared by adopting a non-consumable vacuum arc furnace technology, the method has the characteristics that the operation method is simple, elements of the alloy are fully compounded, the structure is uniform, the density is good, and the like.

Owner:TAIYUAN UNIV OF TECH

Non-pressure infiltration preparing method for Ti3AlC2/Fe-based composite material

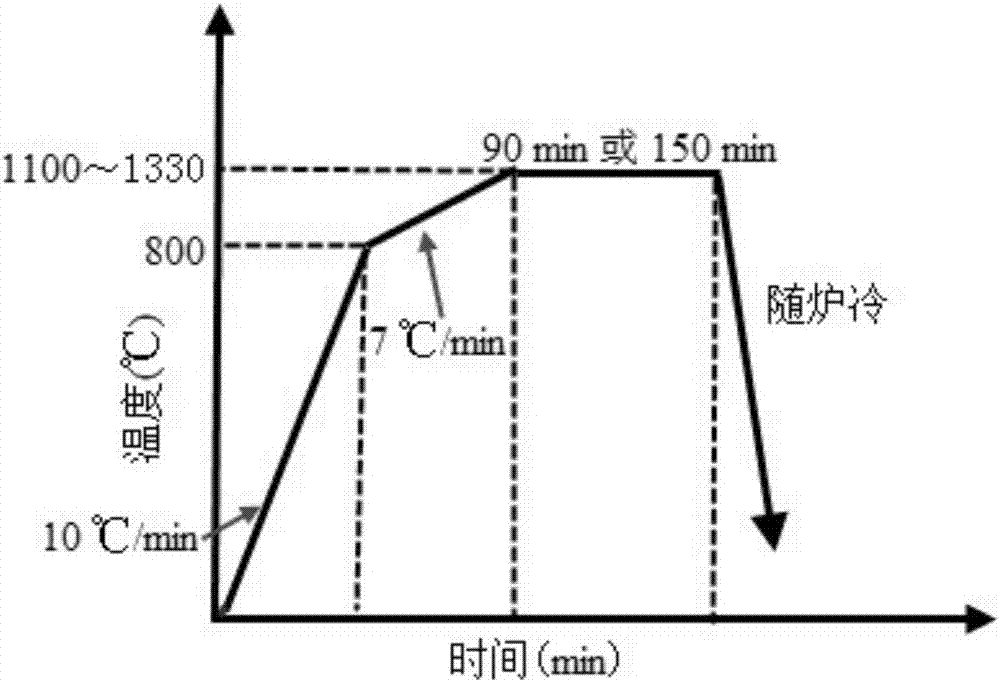

The invention discloses a non-pressure infiltration preparing method for a Ti3AlC2 / Fe-based composite material. The volume content of Ti3AlC2 in the composite material prepared through the method is 20-80 vol percent, and the rest is Fe-based alloy. According to the microstructure of the composite material, the ceramic phase Ti3AlC2 and the metal phase Fe-based alloy are each continuously distributed in the three-dimensional space and are of a network crossed structure in the space, and the interface of the ceramic phase Ti3AlC2 and the interface of the Fe-based alloy are firmly combined. The non-pressure infiltration preparing method includes the following steps that Ti3AlC2 prefabricated bodies with different porosities are put into an alumina crucible, an iron alloy ingot fired in advance is put above the Ti3AlC2 prefabricated bodies, heating is conducted in a high-temperature furnace with the heating rate of 10-30 DEG C / min to reach the temperature of 1200-1400 DEG C, the temperature is kept for 0.5-4 h, cooling is conducted at the cooling rate of 5-10 DEG C / min to reach the temperature of 800 DEG C, cooling is then conducted at the rate of 10-30 DEG C / min, and the Ti3AlC2 / Fe-based composite material is obtained after cooling. The Ti3AlC2 / Fe-based composite material has the advantages of being high in strength, hardness, wear resistance and the like and can be widely applied to key devices in the fields of transportation, the military industry, machine manufacturing and the like.

Owner:BEIJING JIAOTONG UNIV

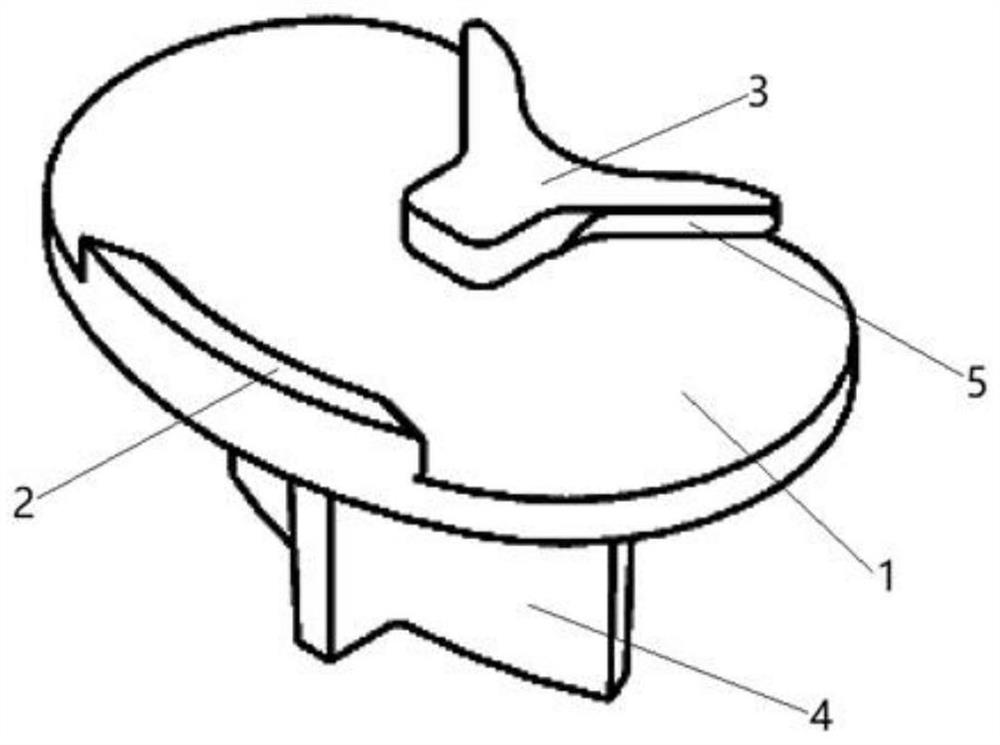

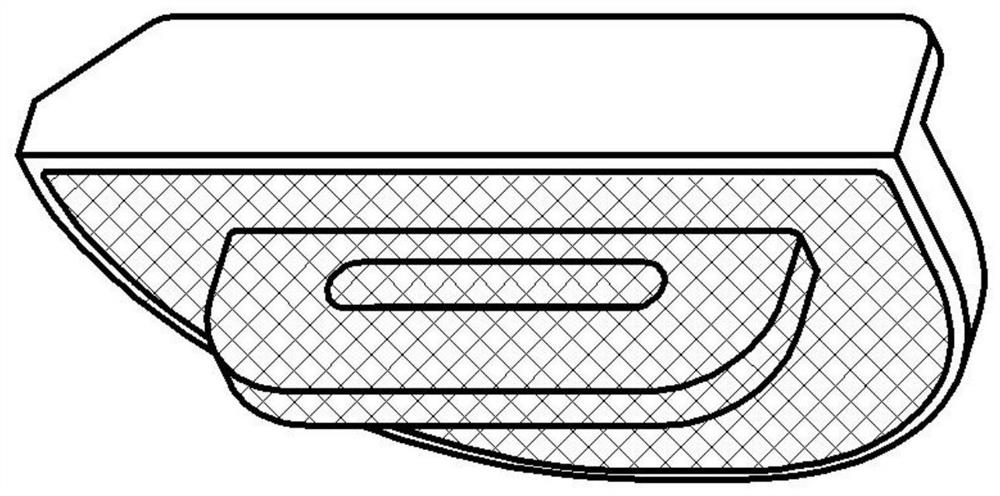

Zirconium-niobium alloy tibial plateau prosthesis containing oxide layer and provided with bone trabecula as well as preparation method

PendingCN112315627AImprove mechanical adaptabilityHigh bonding strengthAdditive manufacturing apparatusPharmaceutical delivery mechanismOsseointegrationElement model

The invention discloses a zirconium-niobium alloy tibial plateau prosthesis containing an oxide layer and provided with bone trabecula as well as a preparation method. According to the method, zirconium-niobium alloy powder is used as a raw material, an intermediate product is obtained through 3D printing integral forming, and then the tibial plateau prosthesis comprising a near-plateau support bone trabecula layer and a far-plateau support bone trabecula layer is prepared through hot isostatic pressing, cryogenic treatment and surface oxidation, the pore diameter and porosity of the near-plateau support bone trabecula layer are uniformly arranged, and the pore diameter and porosity of the far-plateau support bone trabecula layer are arranged in different areas; the bone trabecula topological structure of the tibial plateau prosthesis is in three-dimensional gradient distribution, the micro-strain of 64%-72% of a finite element model is between the lowest effective strain threshold value and the hyper-physiological strain threshold value, the mechanical adaptability of the prosthesis is improved, and the prosthesis has excellent bone ingrowth performance; and the oxide layer of thetibial plateau prosthesis can integrally realize excellent biocompatibility of an osseointegration interface and superhigh wear resistance and low wear rate of a friction interface.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

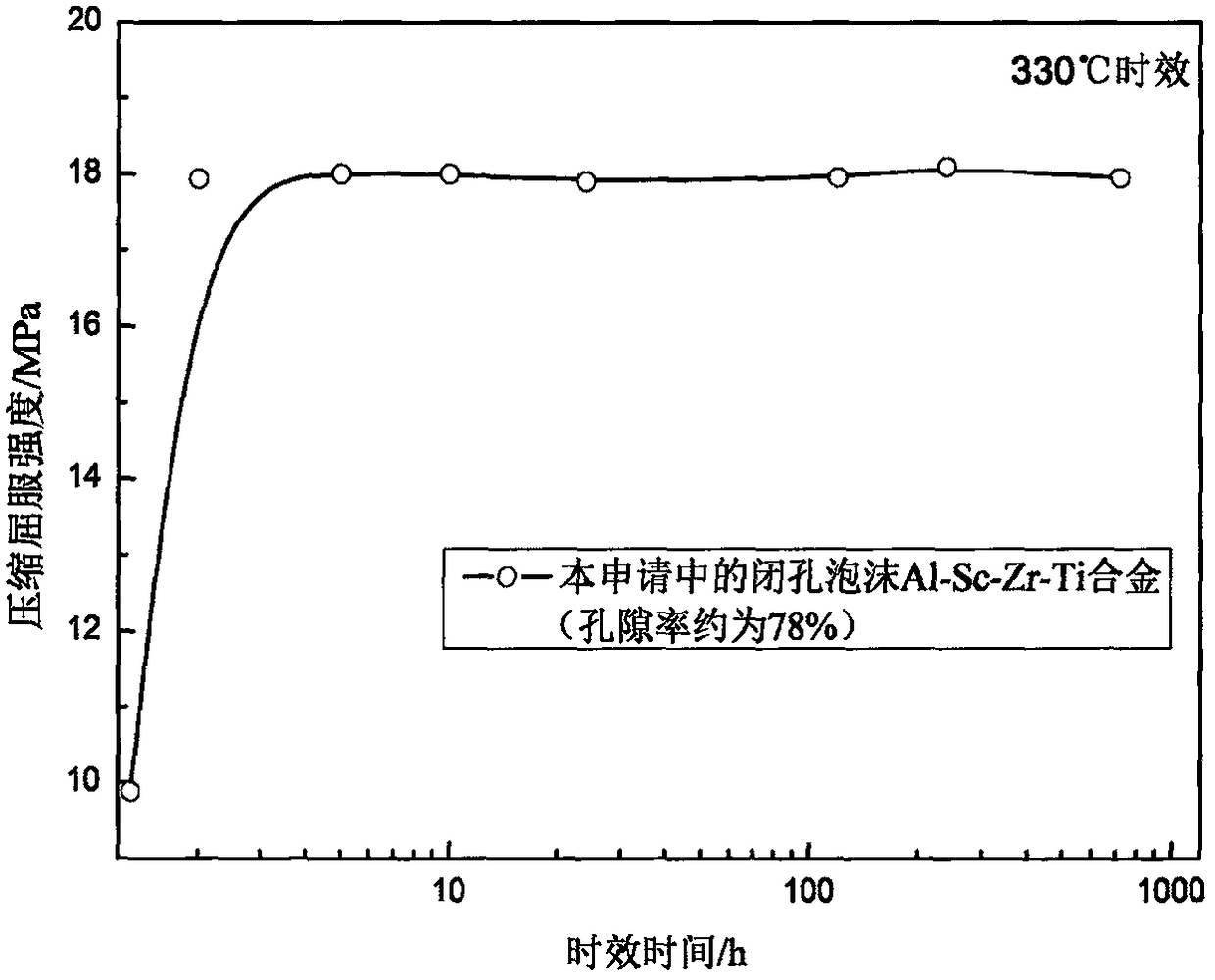

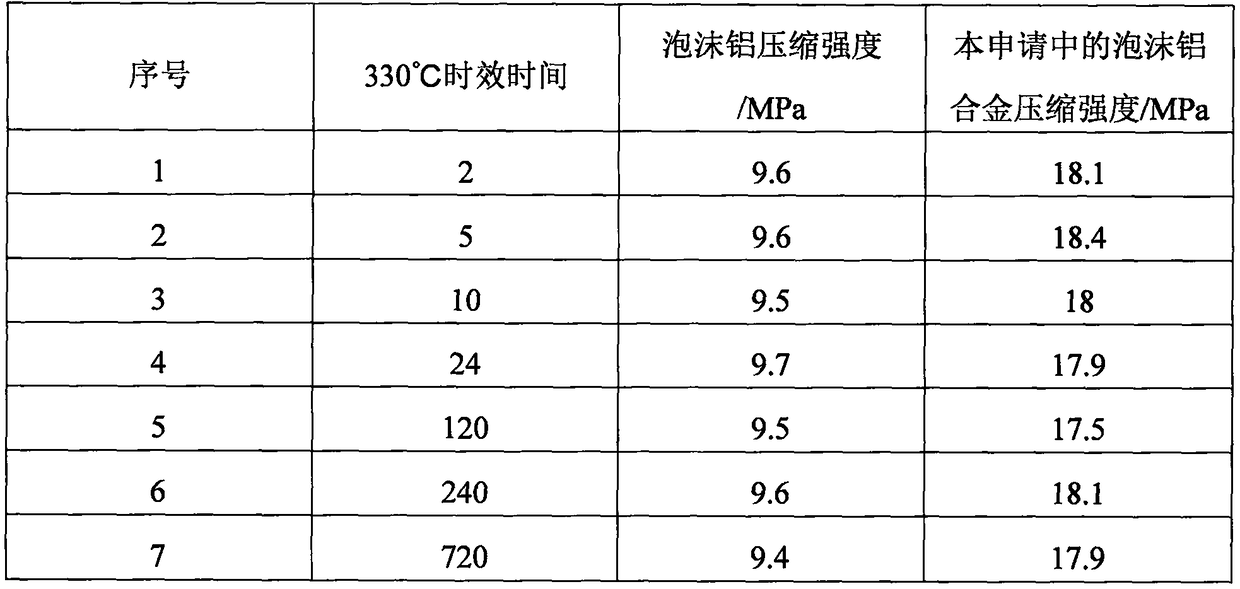

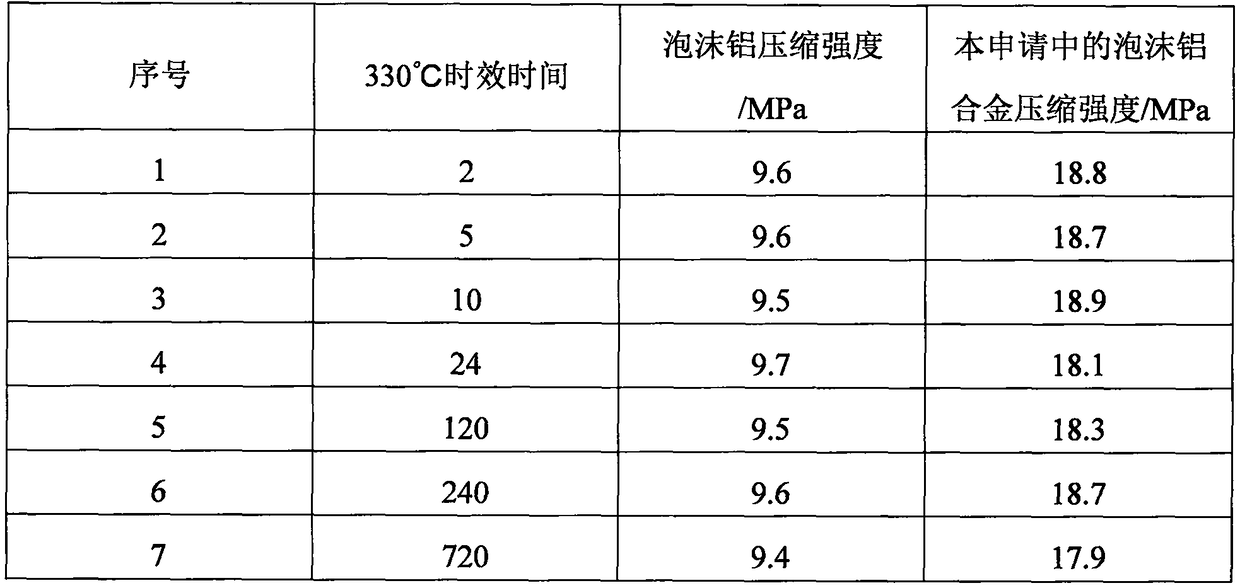

Closed-cell foam aluminum alloy and preparation method thereof

The invention relates to closed-cell foam aluminum alloy. The closed-cell foam aluminum alloy is prepared from aluminum, scandium, zirconium and titanium, wherein the mass of the scandium accounts for0.4-0.6% of that of the foam aluminum alloy, the mass of the zirconium accounts for 0.02-0.2% of that of the foam aluminum alloy, the mass of the titanium accounts for 0.5-2% of that of the foam aluminum alloy, and the content of other impurities does not exceed 0.8%. After being subjected to aging treatment, the closed-cell foamed aluminum alloy provided by the invention has the strength increased by nearly 88% compared with the conventional foamed aluminum, and can maintain the compressive yield strength to be stable for a long time at 330 DEG C, so that the problem that the performance aging enhancement of the surface and inside of the foamed aluminium is not uniform due to slow heat conduction of the closed-cell foam aluminum alloy can be effectively solved.

Owner:北京世联信诺科技有限公司

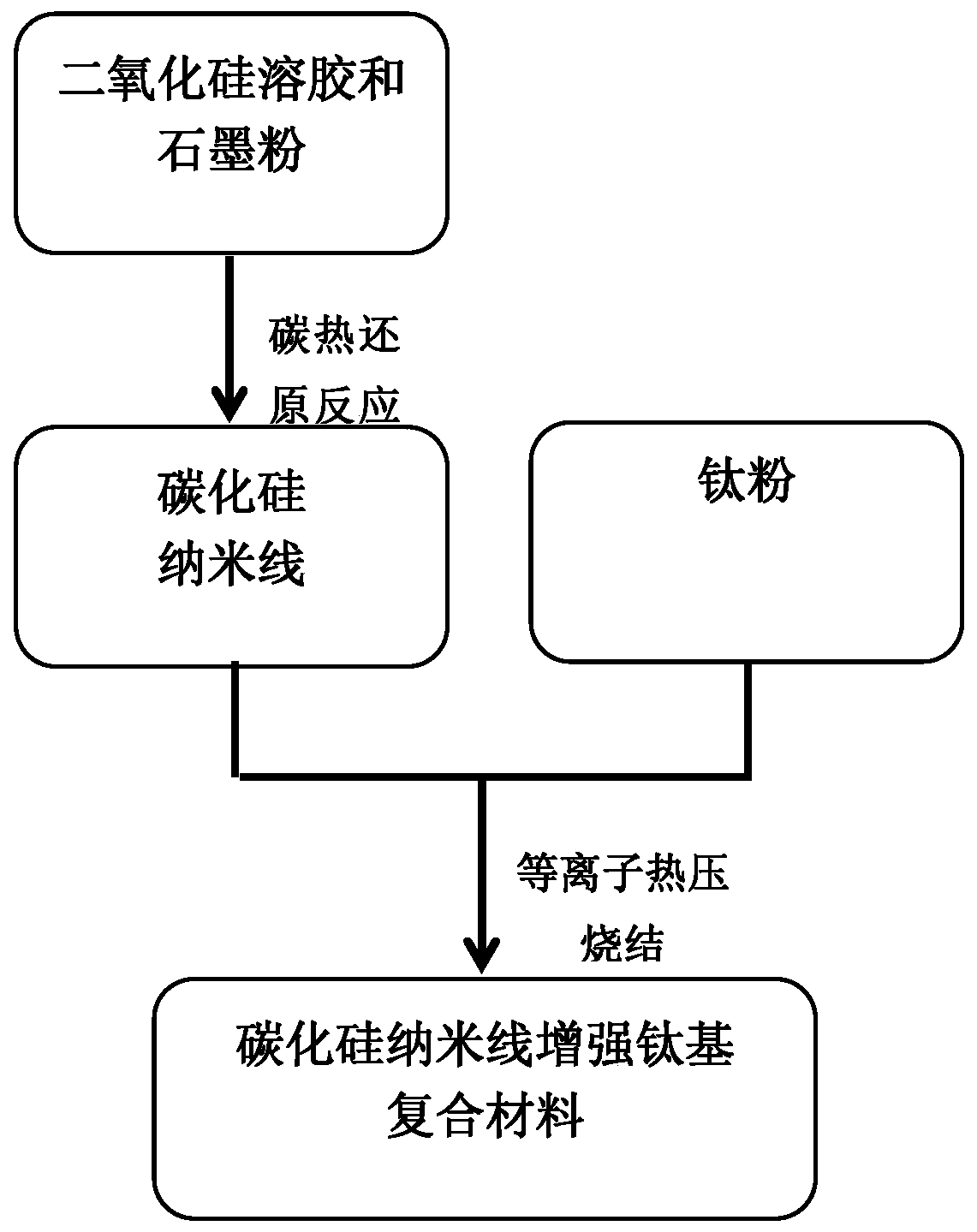

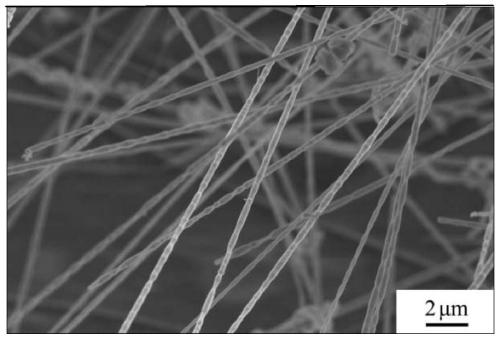

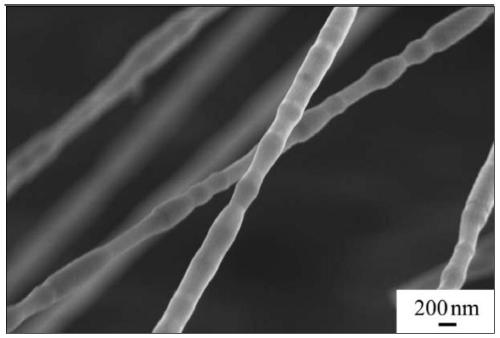

Method for low-temperature preparing of silicon carbide nanowire reinforced titanium matrix composite

ActiveCN110218958AEnhance the toughening effectImprove mechanical propertiesNanotechnologySilicon carbideGraphiteSilicon dioxide

The invention discloses a method for low-temperature preparing of a silicon carbide nanowire reinforced titanium matrix composite. According to the method, absolute ethyl alcohol, ethyl orthosilicate,distilled water and hydrochloric acid are evenly mixed, graphite powder is added, graphite powder wrapped with silicon dioxide sol is obtained, through the carbon thermal reduction reaction, a silicon carbide nanowire is obtained, the silicon carbide nanowire is subjected to ultrasonic dispersion, titanium powder is added, heat preservation and even stirring are carried out, through drying, silicon carbide nanowire and titanium powder mixed powder is obtained, discharge plasma hot pressed sintering is carried out, and the silicon carbide nanowire reinforced titanium matrix composite is obtained. Discharge plasma hot pressed sintering is carried out at the low temperature and high pressure, the phenomenon that in the high-temperature environment, the silicon carbide nanowire has a reactionwith the titanium to generate carbide and silicide is avoided, strengthening and toughening effects of the silicon carbide nanowire can be ensured, meanwhile, the silicon carbide nanowire and the titanium base are tightly combined, the multi-scale toughened structure is formed, the strengthening and toughening effects of the silicon carbide nanowire can be improved, and the mechanical property ofthe silicon carbide nanowire reinforced titanium matrix composite can be improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

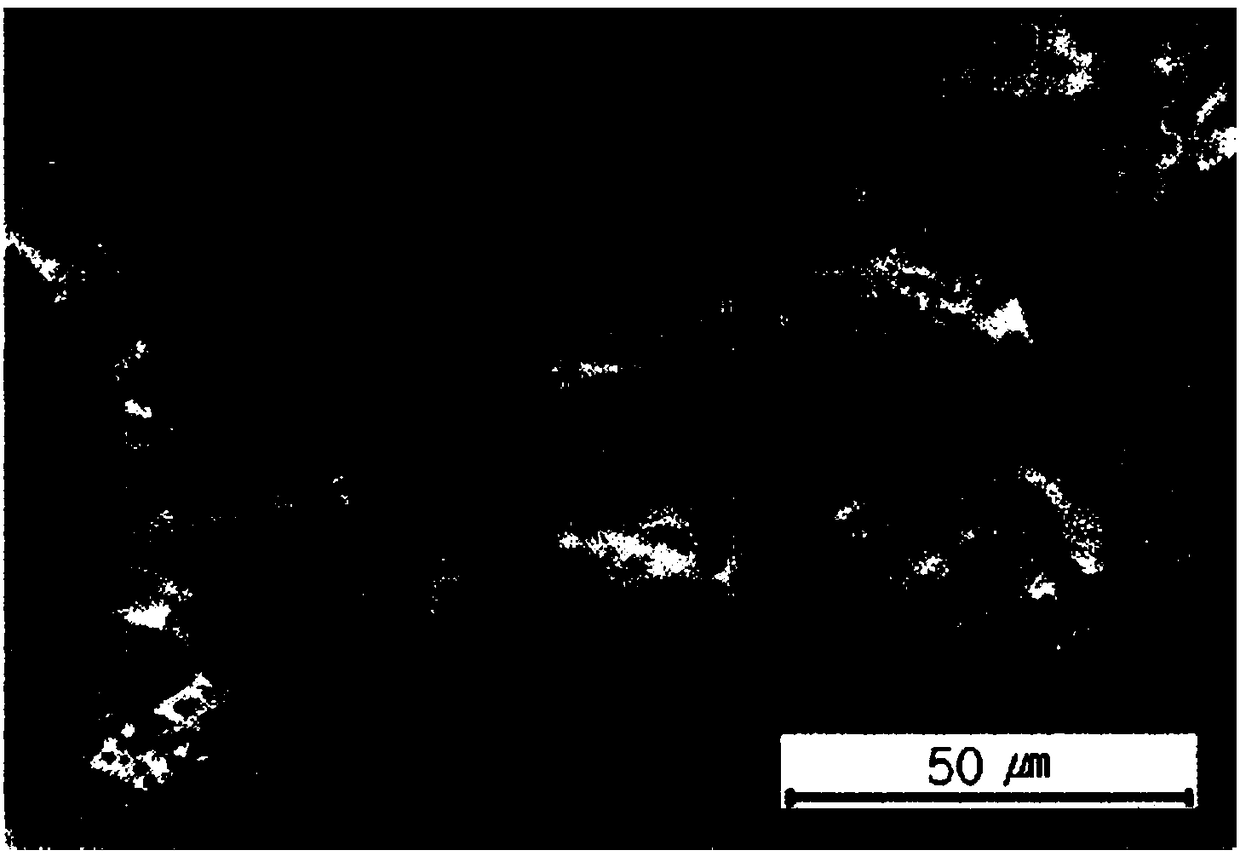

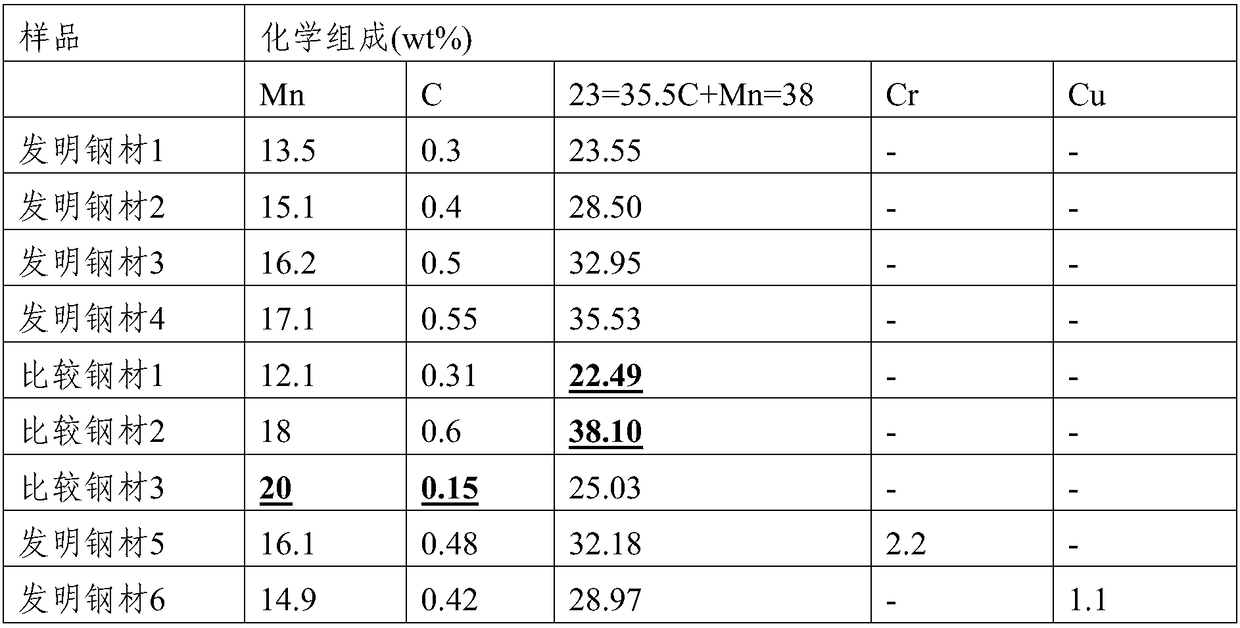

Expandable high-strength steel material and expanded high-strength steel pipe having superior expandability and collapse resistance, and methods for manufacturing thereof

InactiveCN106460124AGood expansion performanceUniform elongationFurnace typesRigid pipesSteel tubeSingle phase

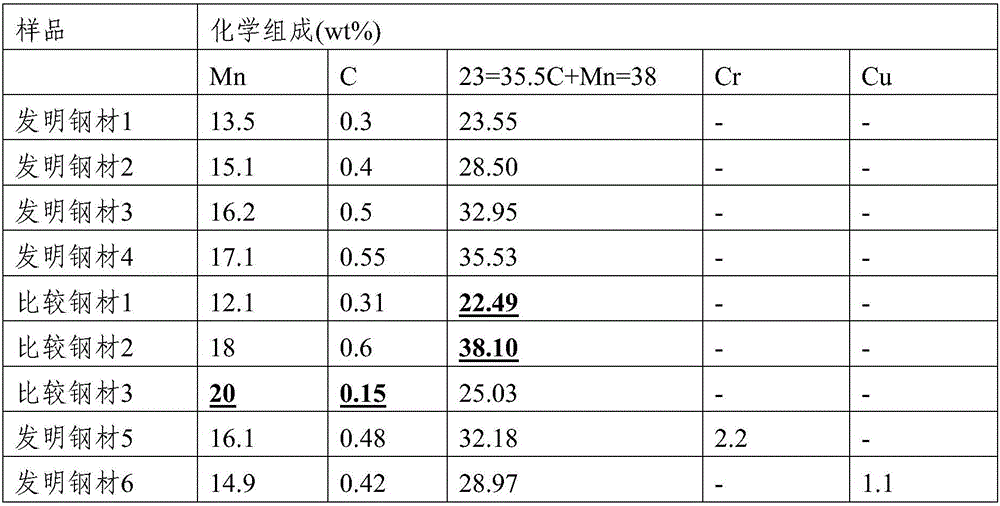

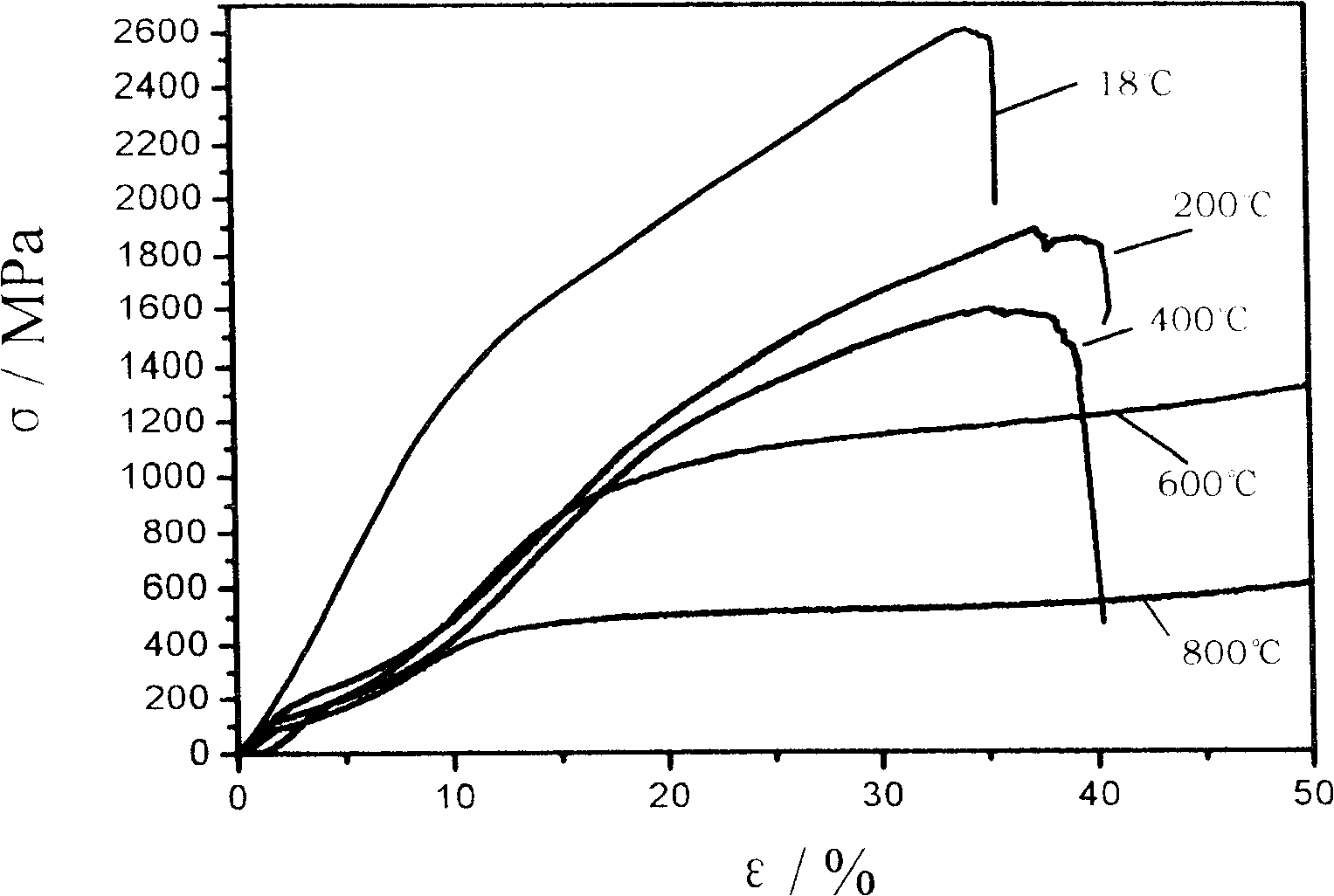

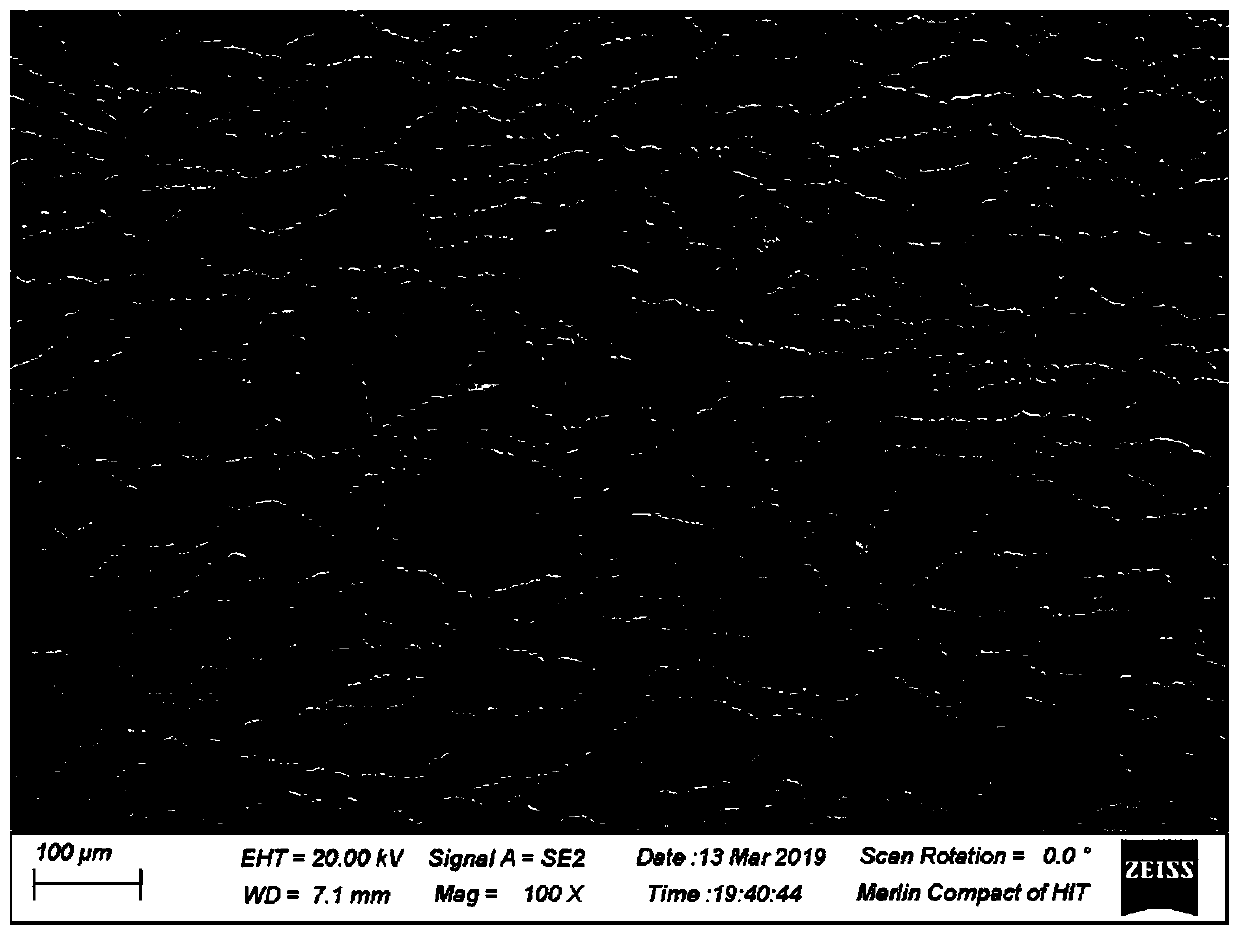

There are provided an expandable high-strength steel material and an expanded high-strength steel pipe having excellent expandability and collapse resistance, and methods for manufacturing the expandable high-strength steel material and the expanded high-strength steel pipe. The expandable high-strength steel material including, by weight, manganese (Mn): 12% to 18%, carbon (C): 0.3% to 0.6%, and a balance of iron (Fe) and inevitable impurities, wherein the carbon (C) and the manganese (Mn) satisfy the following condition: 23 <= 35.5C + Mn <= 38. Before being expanded, the expandable high-strength steel material has an austenite single phase microstructure, and after being expanded, the expandable high-strength steel material has a microstructure including 5 area% to 50 area% martensite and 50 area% to 95 area% austenite.

Owner:POHANG IRON & STEEL CO LTD

Ti-modified NiAl-Cr(Mo) polyphase eutectic intermetallic compound

The invention discloses a new-typed structure metal compound of Fe modified NiAl-Cr (Mo) polyphase eutectic crystal, which comprises the following parts: 33at% Ni,30at% Cr,4at% Mo,3-17at% Fe and Al, wherein the NiAl-Cr (Mo) polyphase alloy is modified by Fe, which induces plastic third phase gamma-phase and gamma'-phase to improve high-temperature strength and indoor temperature flexibility and plasticity.

Owner:BEIHANG UNIV

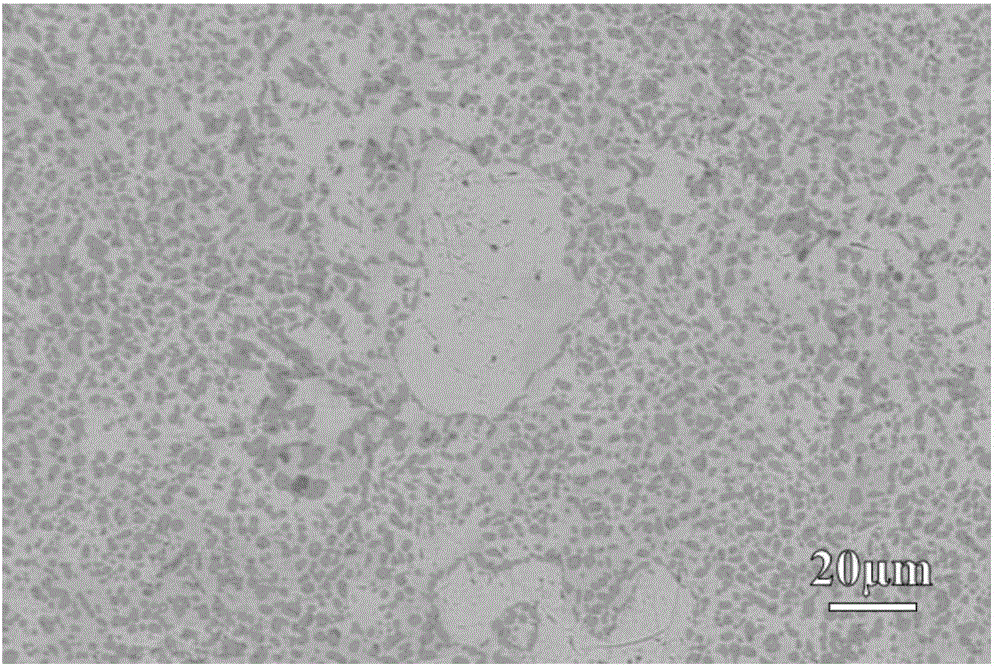

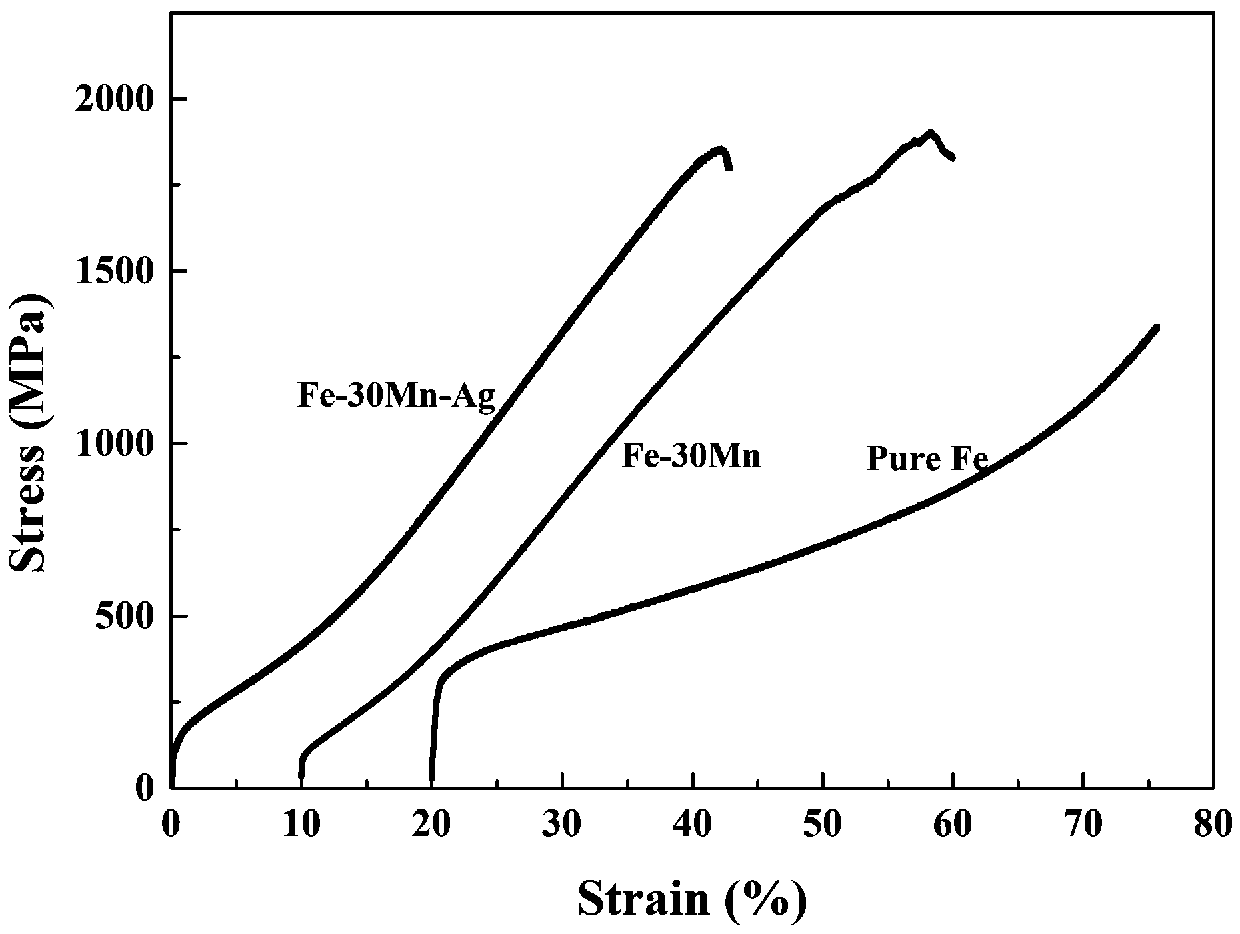

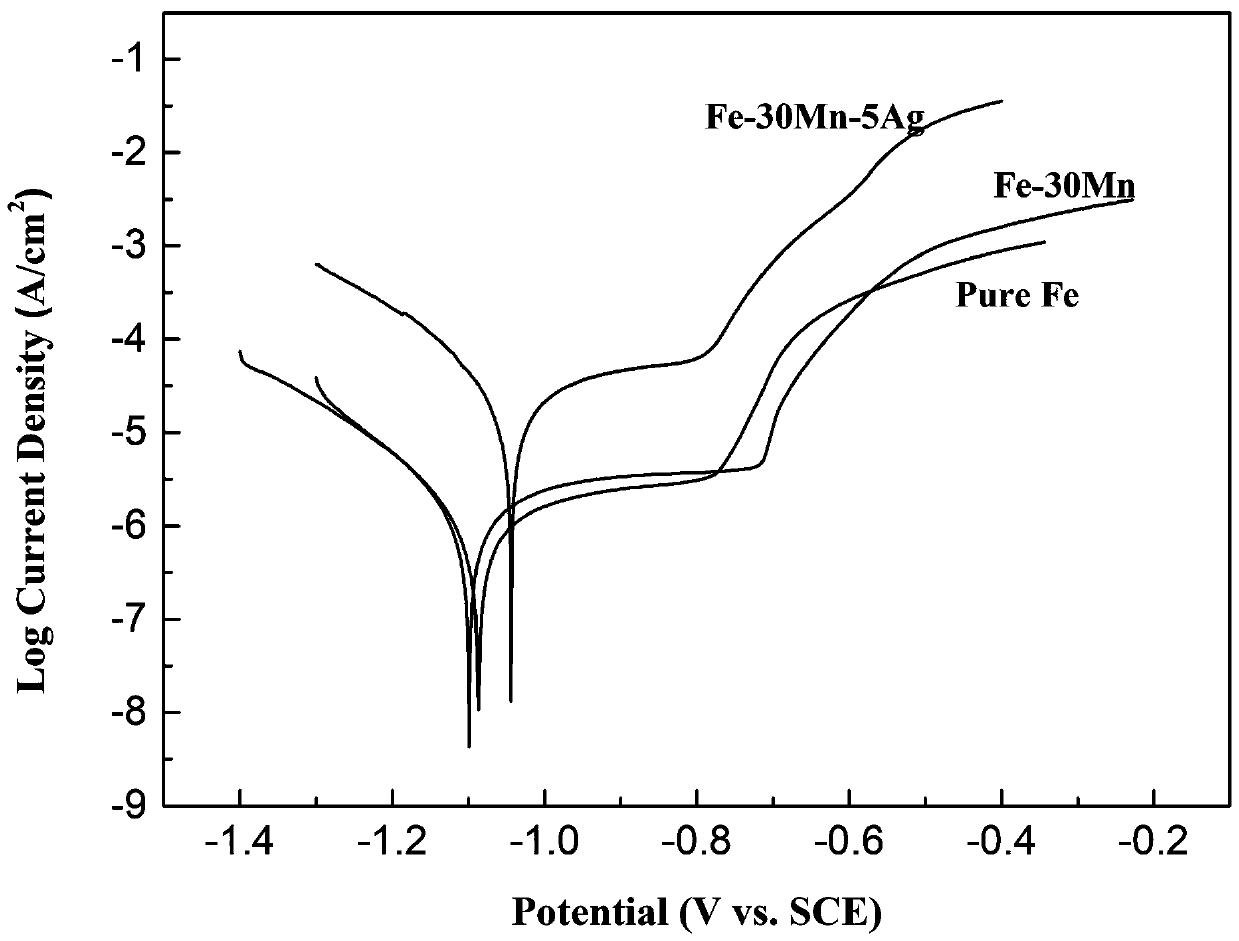

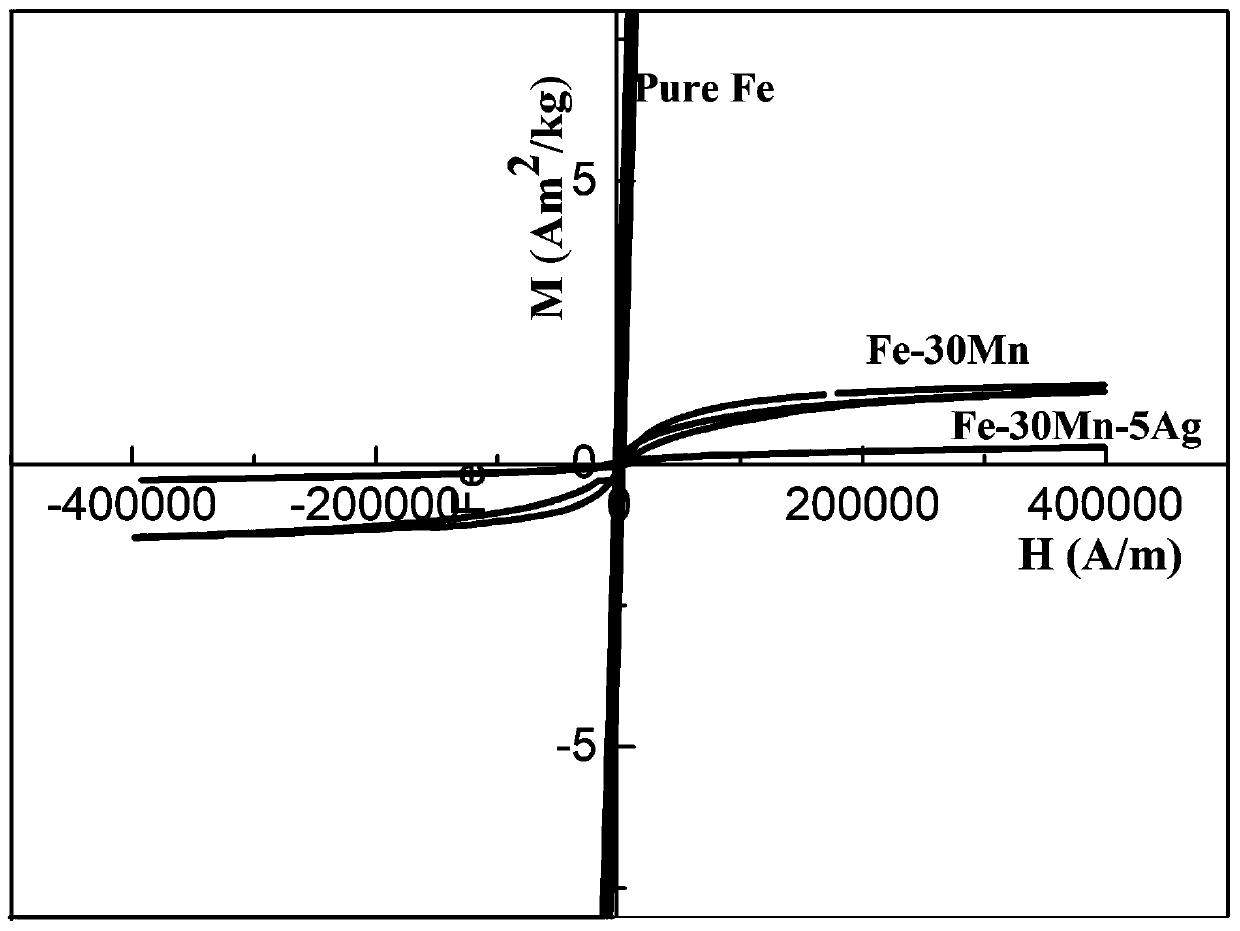

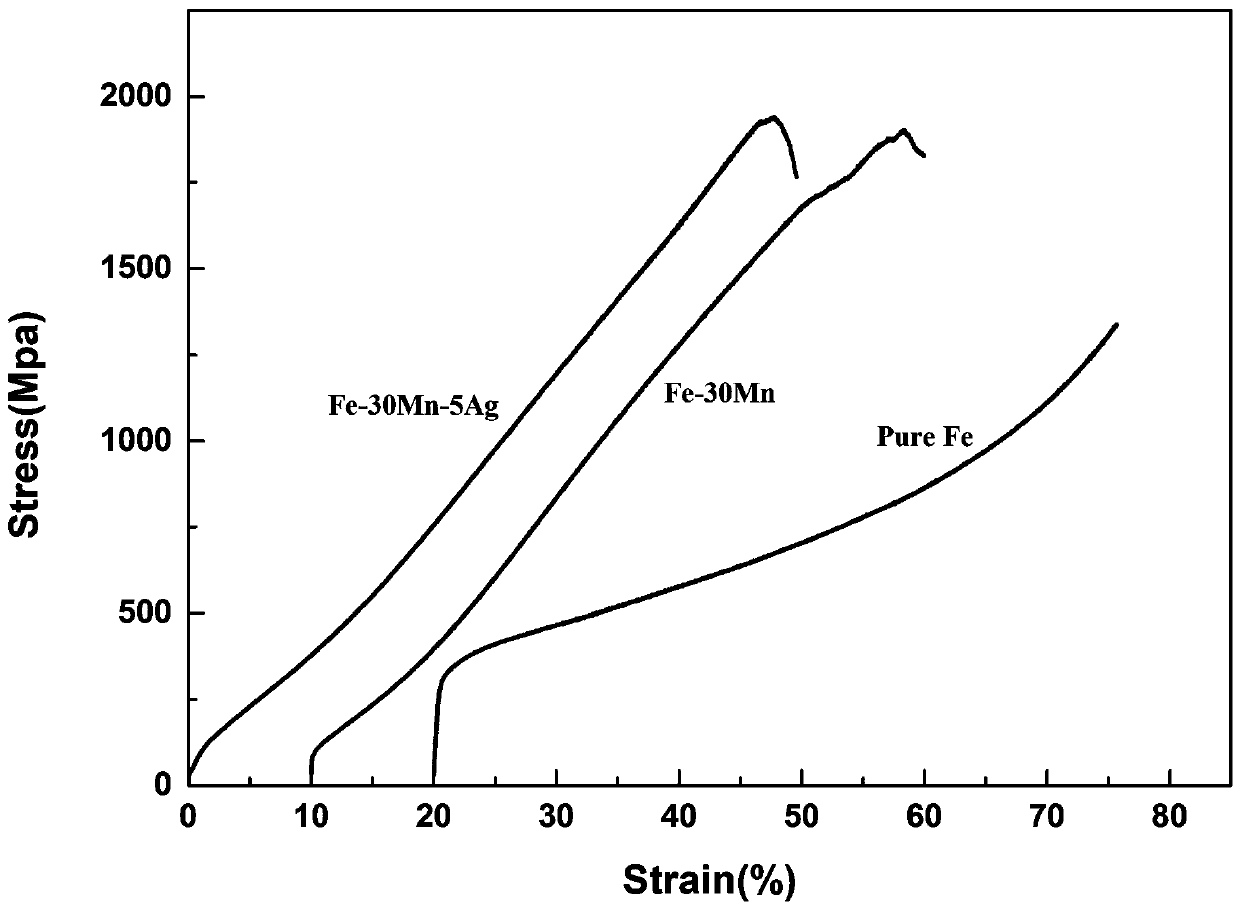

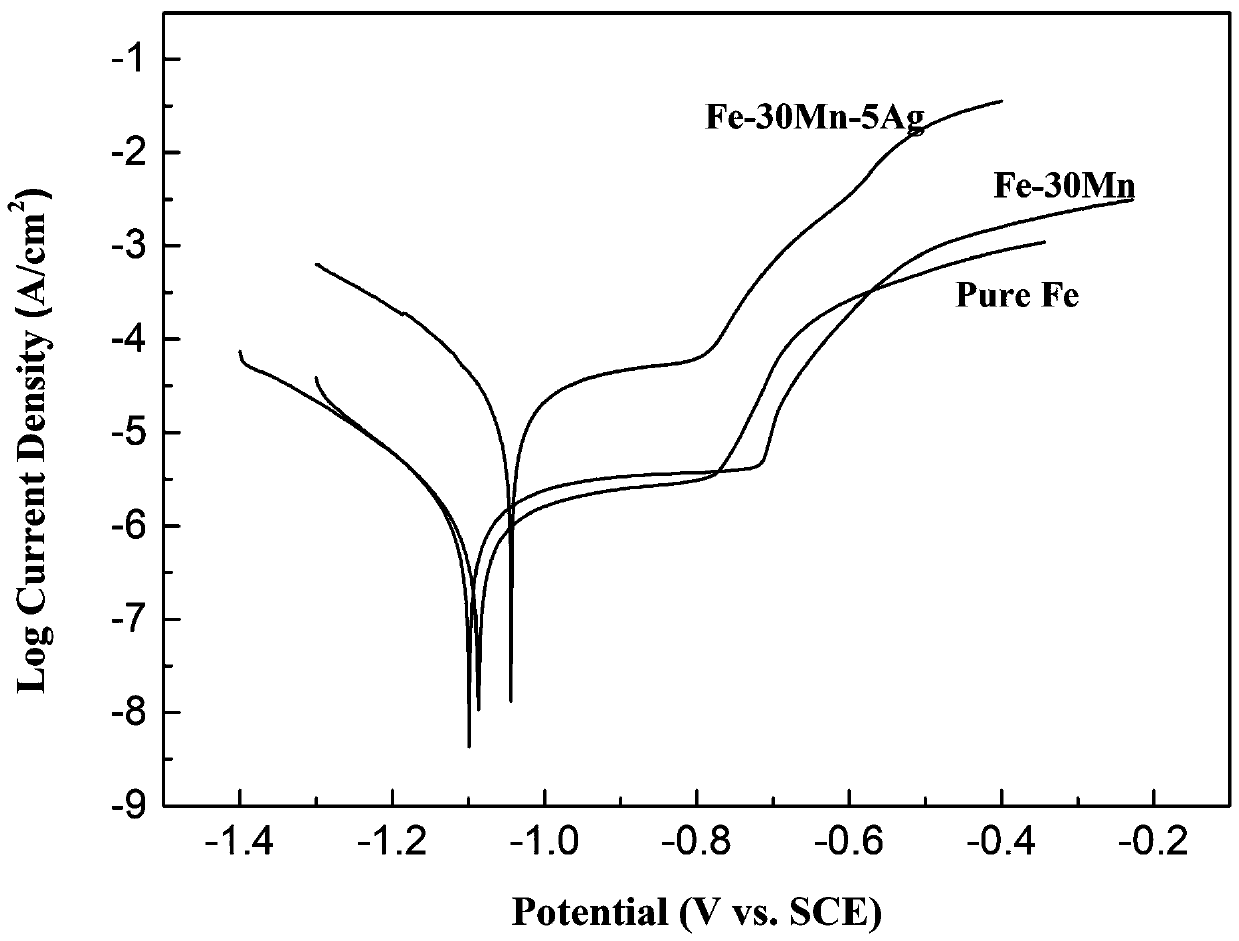

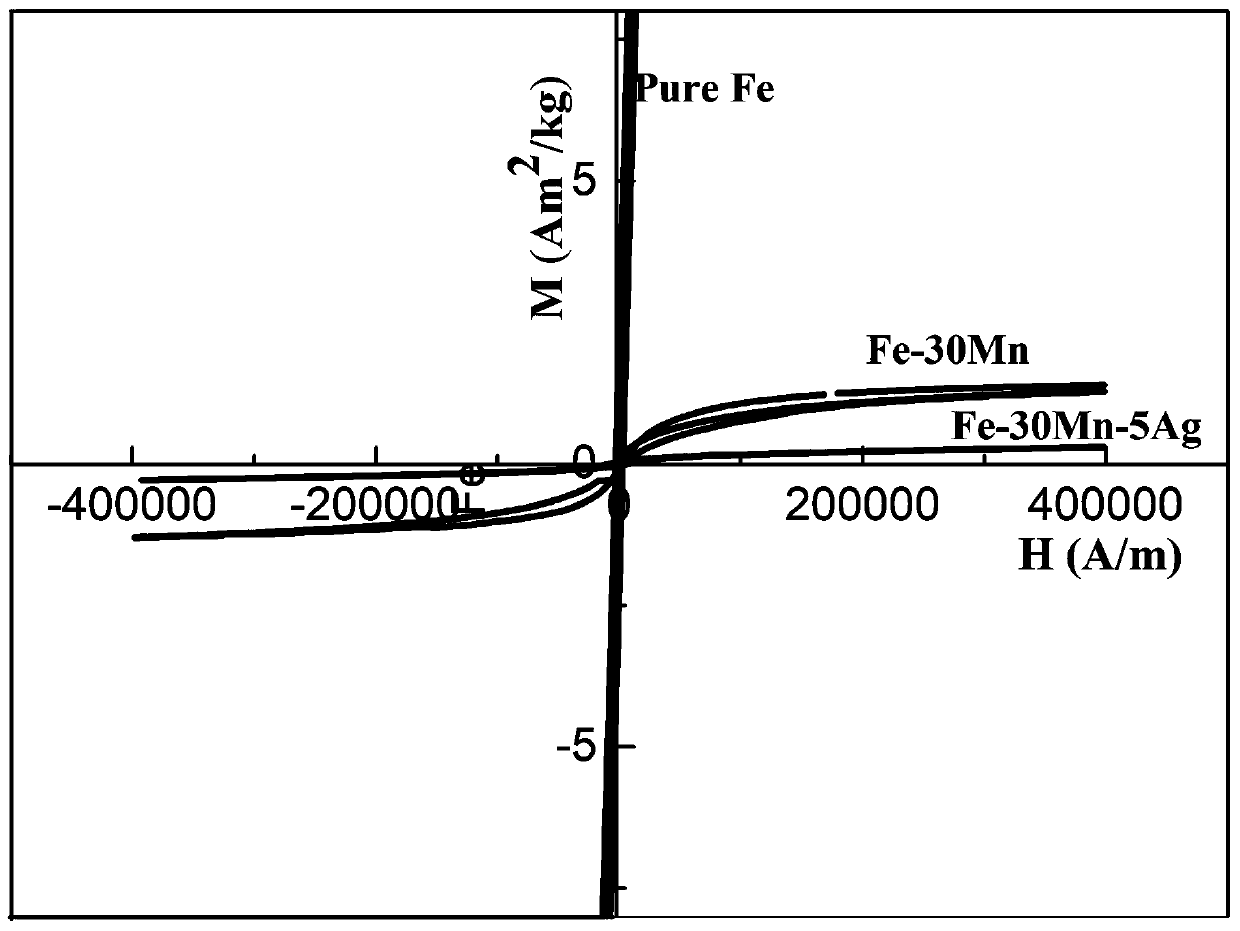

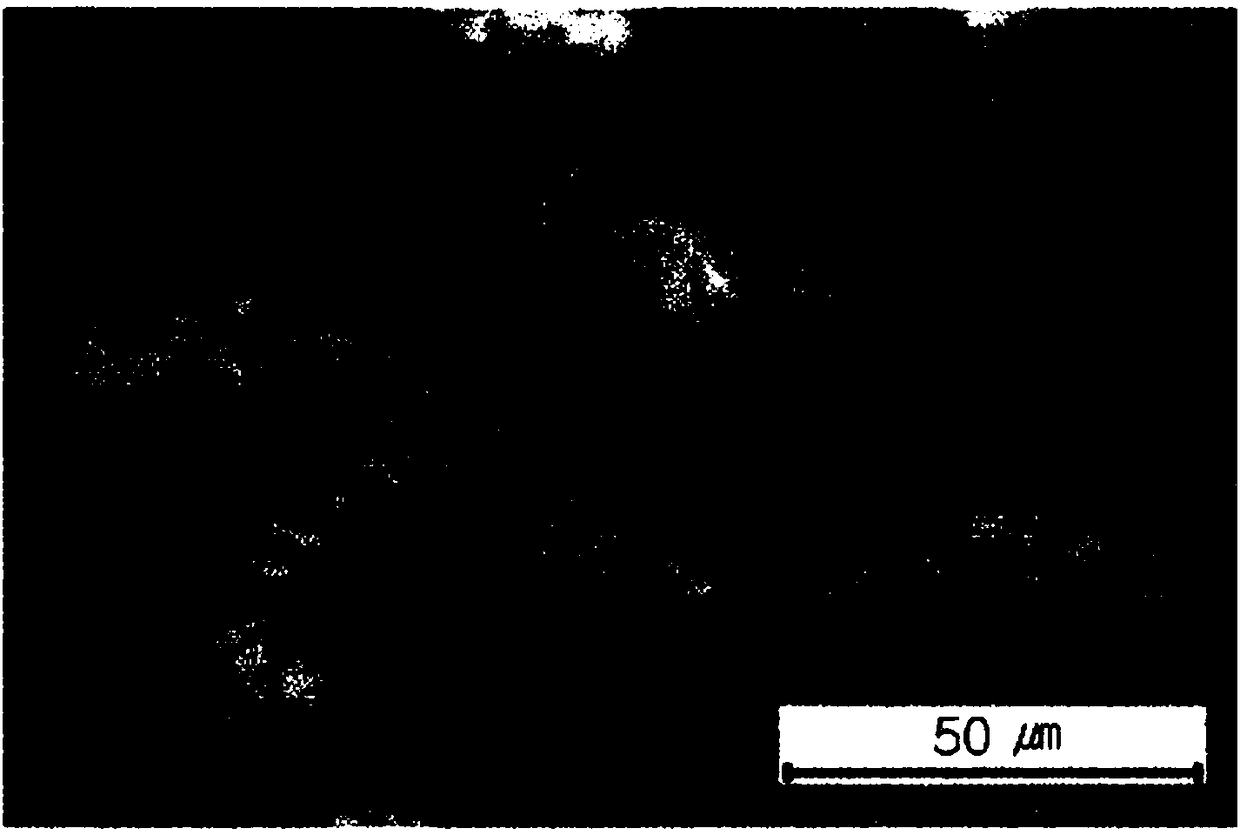

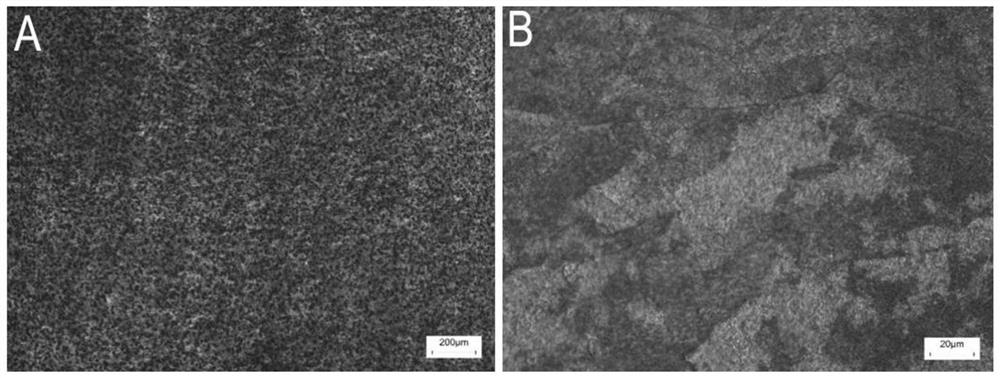

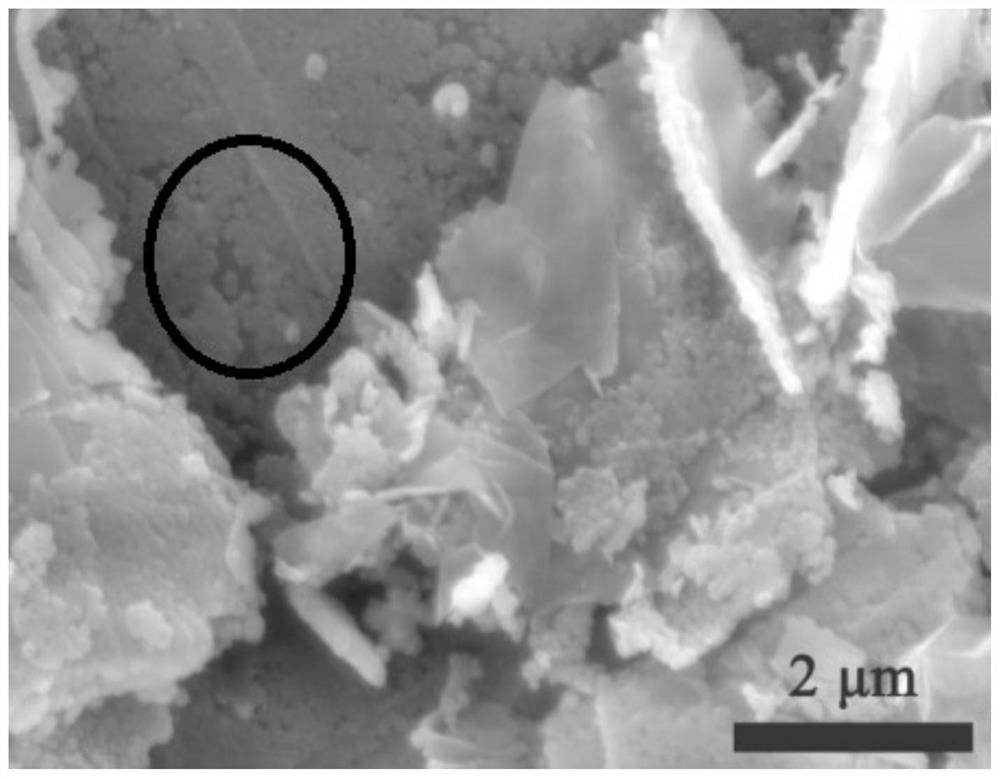

Medical degradable Fe-Mg-Ag alloy material, preparation and application

ActiveCN108677099AIncreased compressive yield strengthFast degradationSurgeryElectric arc furnaceBiocompatibility Testing

The invention relates to a medical degradable Fe-Mg-Ag alloy material and a preparation method thereof. The Fe-Mg-Ag alloy material comprises the following chemical components by weight percentage: 30% of Mn, 1-10% of Ag, and the balance iron. The invention utilizes the characteristic that Fe30Mn alloy can be corroded in the human environment so as to be biodegradable, the positive potential antibacterial element Ag is added into the alloy for smelting in a vacuum arc furnace, and rapid cooling is carried out to obtain the novel degradable iron-based alloy. The alloy has greatly increased degradation rate, is conducive to shortening the degradation time after implantation into the human body and reducing the stimulation of the implant to organisms, and later through release of Ag+, the implant has certain antibacterial properties, thus improving the therapeutic effect of medical devices. The material provided by the invention has good mechanical properties and biocompatibility, and hasmore excellent nuclear magnetic resonance compatibility.

Owner:SOUTHWEST UNIVERSITY

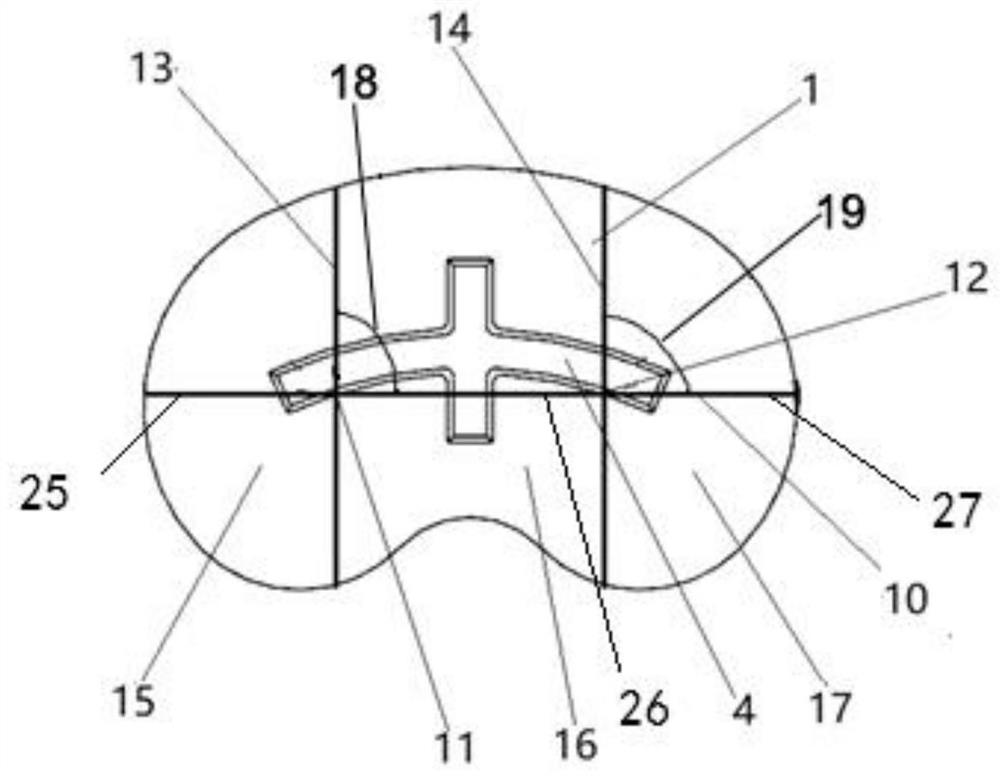

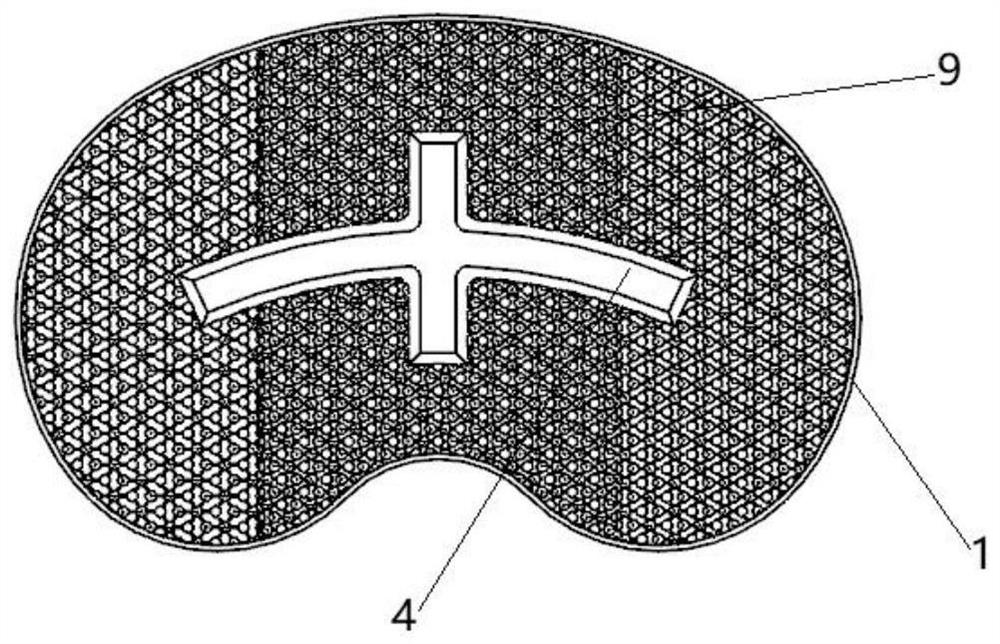

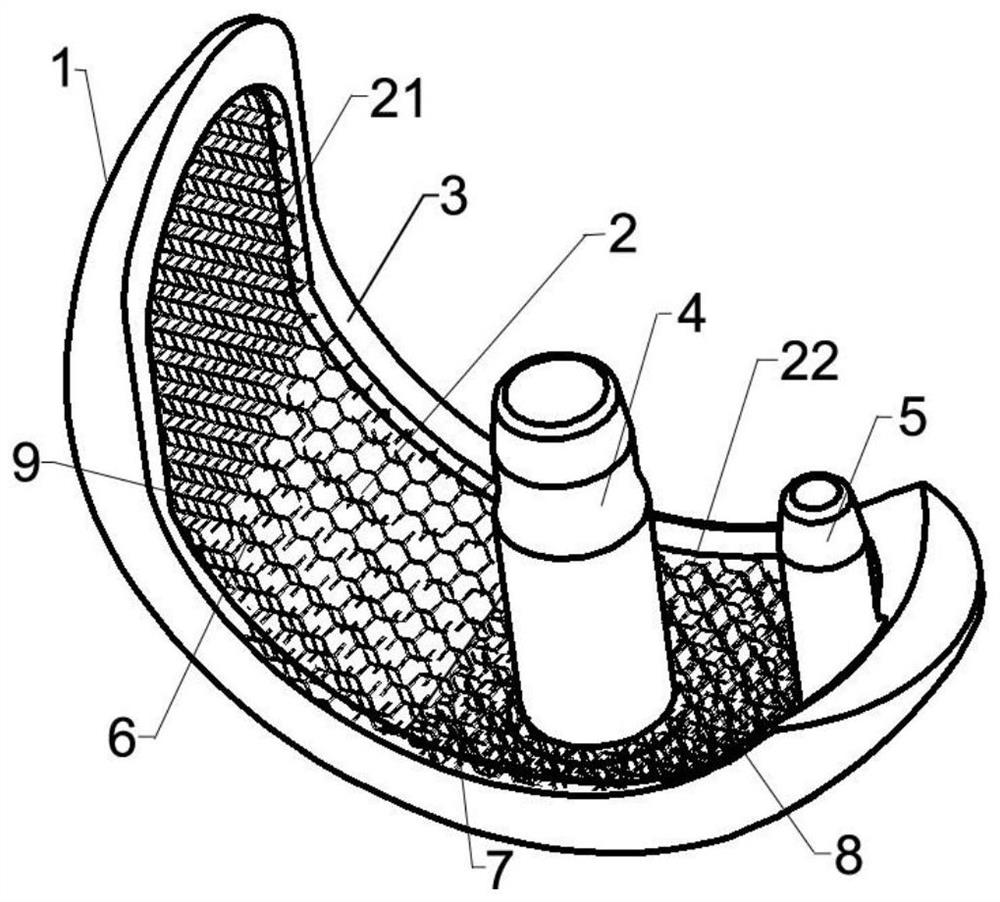

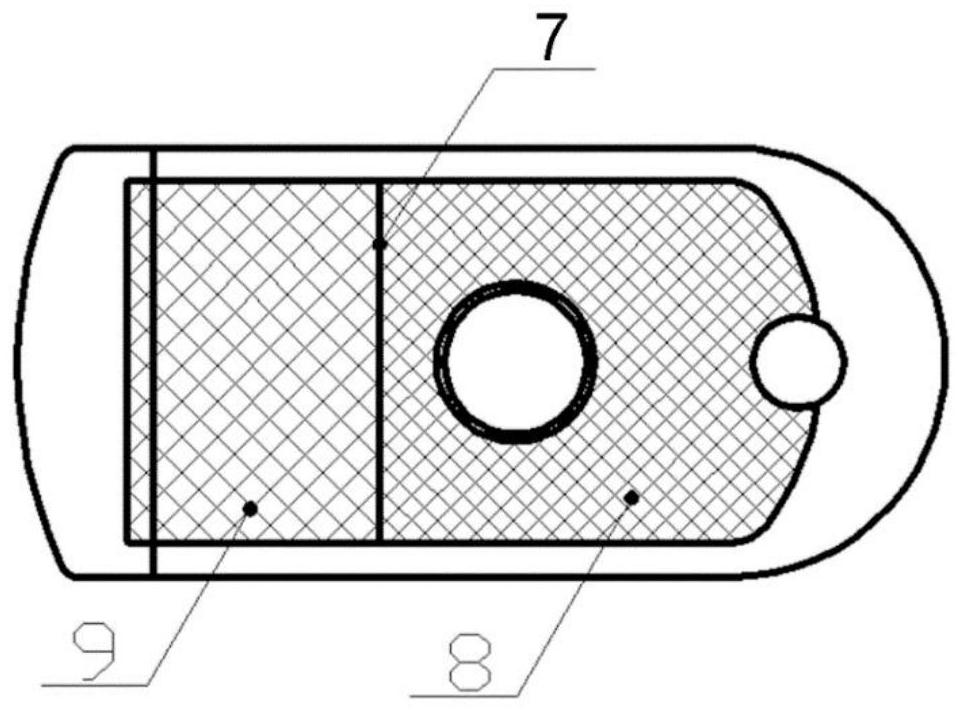

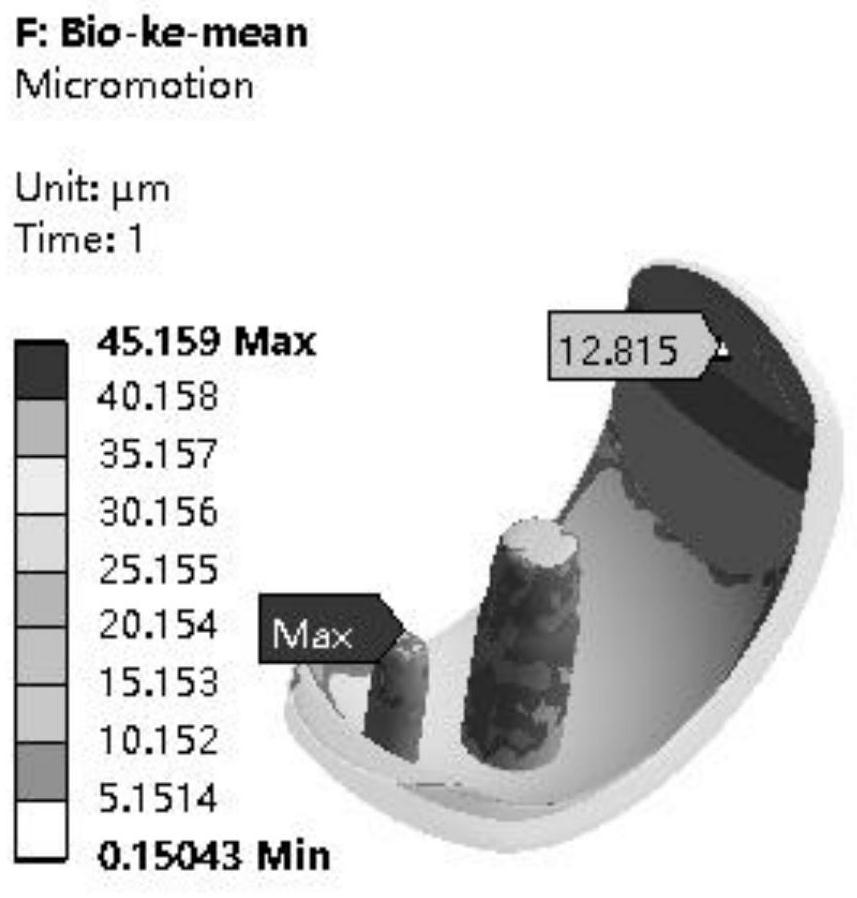

Zirconium-niobium alloy partitioned bone trabecula single-compartment femoral condyle containing oxide layer and preparation method

ActiveCN112296342ANot easy to fall offInhibit sheddingAdditive manufacturing apparatusIncreasing energy efficiencyArticular surfacesFacial bone

The invention discloses a zirconium-niobium alloy partitioned bone trabecula single-compartment femoral condyle containing an oxide layer and a preparation method. The preparation method comprises thesteps that zirconium-niobium alloy powder serves as a raw material, an intermediate product of the zirconium-niobium alloy partitioned bone trabecula single-compartment femoral condyle containing theoxide layer is obtained through 3D printing integral forming, then the zirconium-niobium alloy partitioned bone trabecula single-compartment femoral condyle containing the oxide layer is obtained through hot isostatic pressing, cryogenic treatment and surface oxidation, the femoral condyle comprises a femoral condyle articular surface and an osseointegration surface, and the osseointegration surface is provided with the bone trabecula in a partitioned manner. Micro-motion of the prosthesis and a bone interface can be reduced, the stress shielding effect of the prosthesis on bone tissue is reduced, the stress of the femoral condyle bone tissue is uniform, and the initial stability and long-term stability of the single-compartment femoral condyle are improved. According to the preparation method, excellent biocompatibility and bone ingrowth of the osseointegration interface and super-strong wear resistance and low wear rate of a friction interface are integrally realized; the femoral condyle bone trabecula has excellent compression resistance; and the compressive yield strength and plasticity of the solid part are enhanced.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

Zirconium-niobium alloy partitioned bone trabecula femoral condyle prosthesis containing oxide layer and preparation method

PendingCN112294499APromote ingrowthImprove long-term stabilityAdditive manufacturing apparatusJoint implantsOsseointegrationFEMORAL CONDYLE

The invention discloses a zirconium-niobium alloy partitioned bone trabecula femoral condyle prosthesis containing an oxide layer and a preparation method. The preparation method comprises the following steps: zirconium-niobium alloy powder serves as a raw material, an intermediate product of the zirconium-niobium alloy partitioned bone trabecula femoral condyle prosthesis containing the oxide layer is obtained through 3D printing integral forming, and then the zirconium-niobium alloy partitioned bone trabecula femoral condyle prosthesis containing the oxide layer is obtained through hot isostatic pressing, cryogenic treatment and surface oxidation; and partitioned bone trabecula is arranged at part of the zirconium-niobium alloy partitioned bone trabecula femoral condyle prosthesis containing the oxide layer. According to the invention, micro-strain of most areas of the femoral condyle bone tissue is between the minimum effective strain threshold value and the super-physiological strain threshold value, so that the bone ingrowth is facilitated, and the long-term stability is improved. Excellent biocompatibility and bone ingrowth of an osseointegration interface and super-strong wear resistance and low wear rate of a friction interface are integrally realized. The bone trabecula part has excellent compression resistance; and the compressive yield strength and plasticity of a solid part are enhanced.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

High-strength, high toughness Al-Zn alloy product and method for producing such product

Disclosed is a Al—Zn alloy wrought product, and a method of manufacturing such a product, with an improved combination of high toughness and high strength by maintaining good corrosion resistance, the alloy including (in weight percent): Zn 6.0-11.0, Cu 1.4-2.2, Mg 1.4-2.4, Zr 0.05-0.15, Ti <0.05, Hf and / or V <0.25, and optionally Sc and / or Ce 0.05-0.25, and Mn 0.05-0.12, other elements each less than 0.05 and less than 0.50 in total, balance aluminium, wherein such alloy has an essentially fully unrecrystallized microstructure at least at the position T / 10 of the finished product.

Owner:NOVELIS KOBLENZ GMBH

Uniform foaming and compositing technology for hard light composite material

The invention discloses a uniform foaming and compositing technology for a hard light composite material. According to the technical scheme of the uniform foaming and compositing technology, a traditional metal foaming structure is changed, through the characteristic that the thermal conductivity of ceramic balls is poor, the ceramic balls with the surface internal temperature subjected to differential treatment are uniformly added into foamed aluminum, the ceramic balls enter a foaming melt with the cooling capacity, internal cooling of the melt is accelerated, and the difficult problem of melt foaming layering is solved; the uniformity of a foaming material is improved, the finished product rate of the foaming material is increased, and the product cost and price are greatly reduced; andthe spatial structure and three-dimensional supporting of the composite material are reinforced, and the indexes such as energy absorption density, the compressive yield strength, the noise reductioncoefficient and the thermal-insulating property of the foaming material are improved, so that the developed hard light composite material can be more advantageously applied and popularized.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD

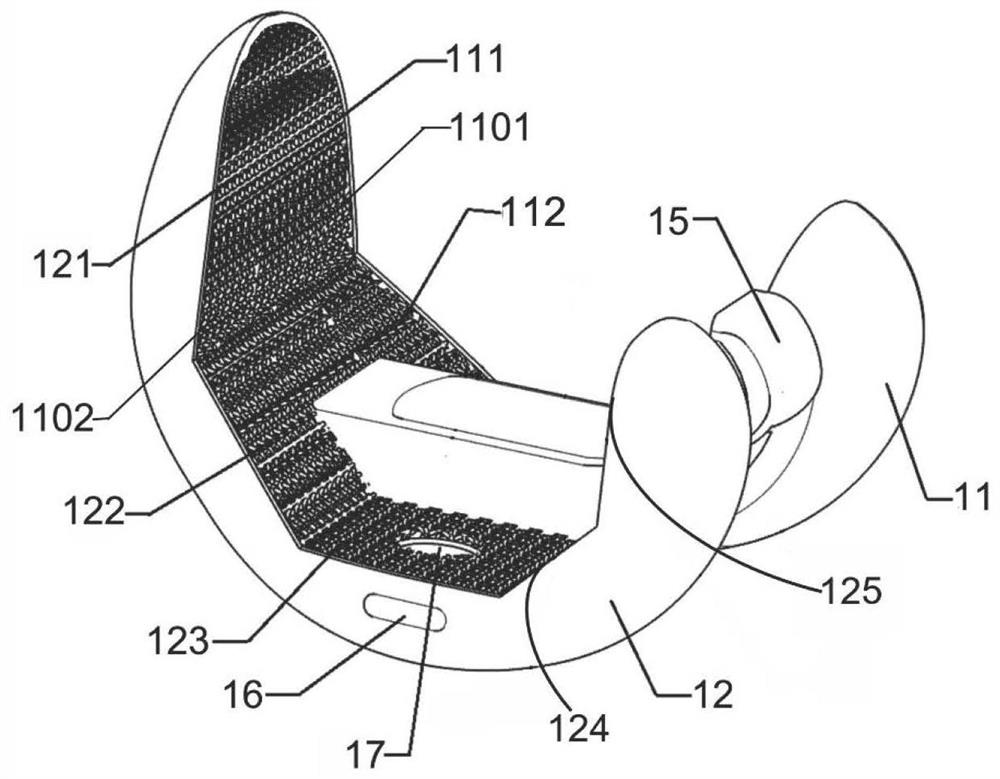

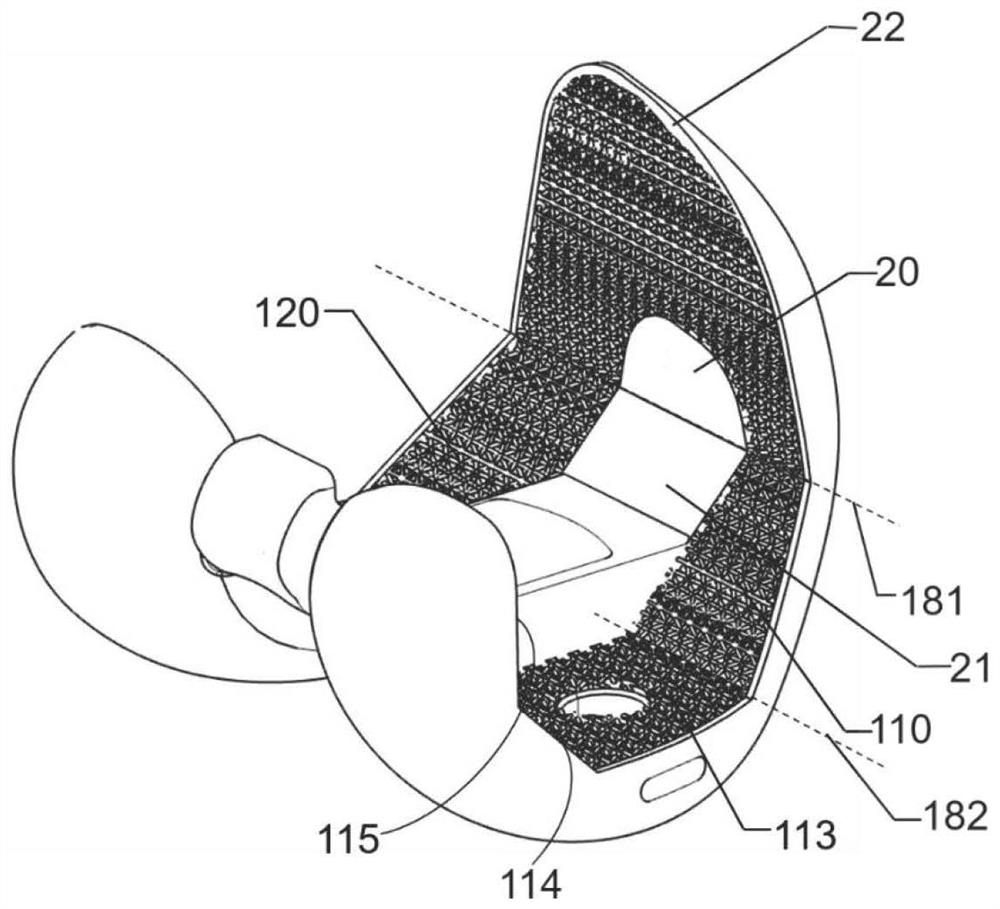

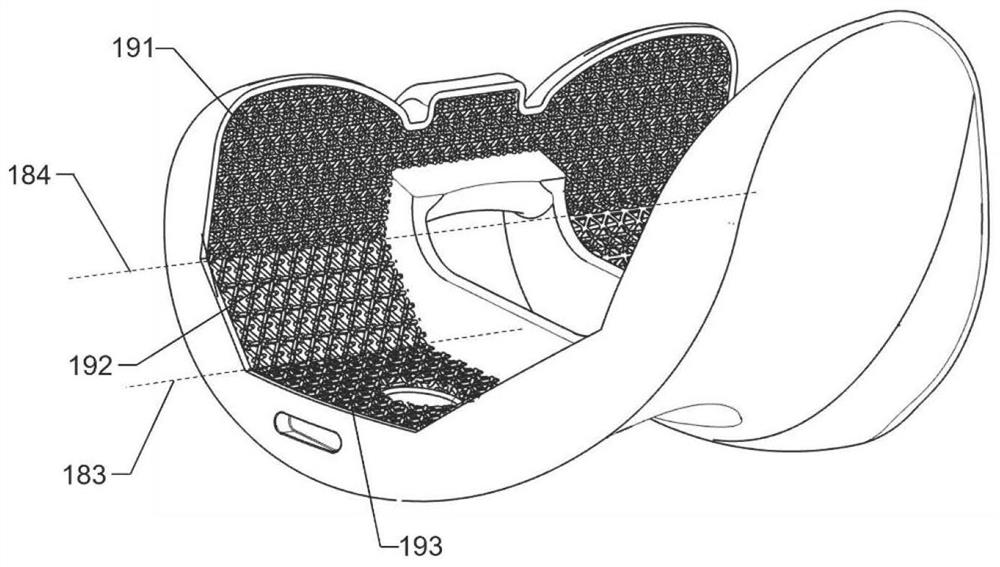

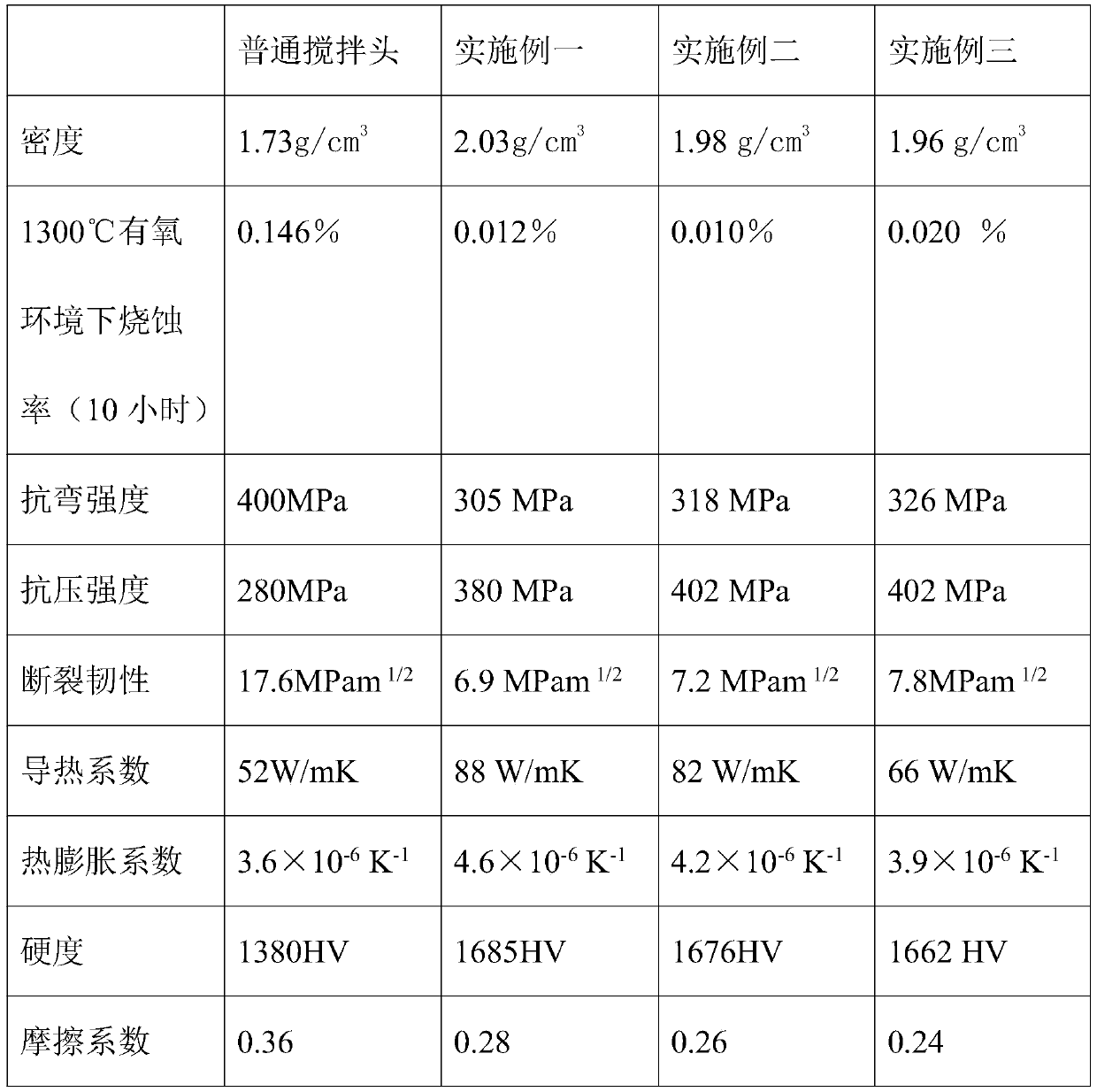

High-performance carbon ceramic friction welding stirring head and preparation method thereof

ActiveCN109824376AExcellent hardnessExcellent mechanicsNon-electric welding apparatusMaterials preparationFriction welding

The invention discloses a high-performance carbon ceramic friction welding stirring head and a preparation method thereof. The preparation method comprises the following steps: manufacturing a friction welding stirring head primary blank; pretreating the Cf / C composite friction welding stirring head primary blank; densifying the Cf / C composite friction welding stirring head primary blank; and preparing a SiC coating of a Cf / C-SiC composite friction welding stirring head pre-finished product.The high-performance carbon ceramic friction welding stirring head and a preparation method thereof belongs to the technical field of ceramic-based composite material preparation, and the high-performance carbon ceramic friction welding stirring head and the preparation method thereof ensure that residual free carbon and free silicon in the material fully react, and simultaneously remove other impurities, so that the hardness and the wear resistance of the Cf / C-SiC composite material friction welding stirring head are greatly improved; a layer of compact SiC coating can be prepared on the surface of the material through further SiC deposition treatment, the oxidation resistance of the stirring head at high temperature is greatly improved; meanwhile, the purity of surface silicon carbide is more than 99%, the surface hardness is further improved, and the service life of the stirring headis greatly prolonged.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

Medical degradable fe-mn-ag alloy material and its preparation and application

ActiveCN108677099BIncreased compressive yield strengthFast degradationSurgeryHuman bodyTherapeutic effect

The invention relates to a medical degradable Fe-Mg-Ag alloy material and a preparation method thereof. The Fe-Mg-Ag alloy material comprises the following chemical components by weight percentage: 30% of Mn, 1-10% of Ag, and the balance iron. The invention utilizes the characteristic that Fe30Mn alloy can be corroded in the human environment so as to be biodegradable, the positive potential antibacterial element Ag is added into the alloy for smelting in a vacuum arc furnace, and rapid cooling is carried out to obtain the novel degradable iron-based alloy. The alloy has greatly increased degradation rate, is conducive to shortening the degradation time after implantation into the human body and reducing the stimulation of the implant to organisms, and later through release of Ag+, the implant has certain antibacterial properties, thus improving the therapeutic effect of medical devices. The material provided by the invention has good mechanical properties and biocompatibility, and hasmore excellent nuclear magnetic resonance compatibility.

Owner:SOUTHWEST UNIV

Submerged arc surfacing manufacturing process for looper rolls used in rolling mills

ActiveCN104785895BHigh hardnessParticlesArc welding apparatusWelding/cutting media/materialsManufacturing technologyStrip mill

The invention discloses a submerged arc surfacing manufacturing process for a looper roll used in a rolling mill. The specific steps are as follows: rough machining the parent material until the outer diameter is 6mm less than the finished product size, using hard material welding wire, and matching HJ107 flux, and reverse welding The variable DC welding machine is surfacing until the outer diameter is 3-5mm thicker than the finished product; the base metal is subjected to post-heat treatment, kept at 600°C for 3 hours, then cooled with the furnace, and then air cooled after the furnace temperature drops to 300°C , to obtain surfacing products, and after finishing the surfacing products to the specified specifications according to the process drawings, the looper rolls for rolling mills are obtained. The invention has the advantages of wear resistance, long service life and the like.

Owner:安徽东方新材料有限公司

Expandable high-strength steel material and expanded high-strength steel pipe having excellent expansibility and crush strength, and manufacturing method thereof

InactiveCN106460124BGood expansion performanceUniform elongationFurnace typesRigid pipesManganeseHigh intensity

Owner:POHANG IRON & STEEL CO LTD

A centimeter-level Zr-based bulk amorphous alloy and its preparation and application methods

The invention discloses a centimeter-sized high-toughness and high-corrosion resistance Zr-based bulk amorphous alloy, which specifically has a chemical formula ZraAlbNicAgd, wherein a is more than 54 and less than 58 atomic percent, b is more than 12 and less than 18 atomic percent, c is more than 18.2 and less than 24 atomic percent, and d is more than 5.6 and less than 9 atomic percent, and a+b+c+d=100. The invention also discloses a preparation method for the Zr-based bulk amorphous alloy and a method for preparing a thin strip and a rod by utilizing the amorphous alloy. According to the Zr-based bulk amorphous alloy and the methods, elemental Ni and Ag are selected as components of the alloy, so that the corrosion resistance is greatly improved, the amorphous alloy formability of a Zr-Al-Ni alloy is improved, and the prepared bulk amorphous alloy is ultrahigh in formability; the Zr-based amorphous alloy also has the characteristics of high-amorphous alloy formability, high toughness and high corrosion resistance.

Owner:FUJIAN UNIV OF TECH

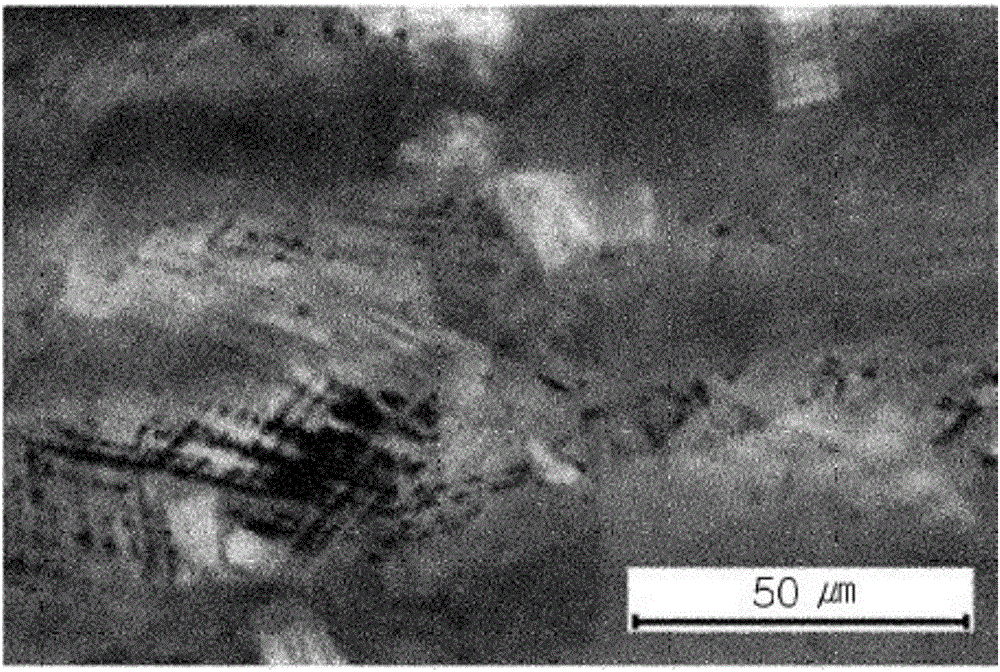

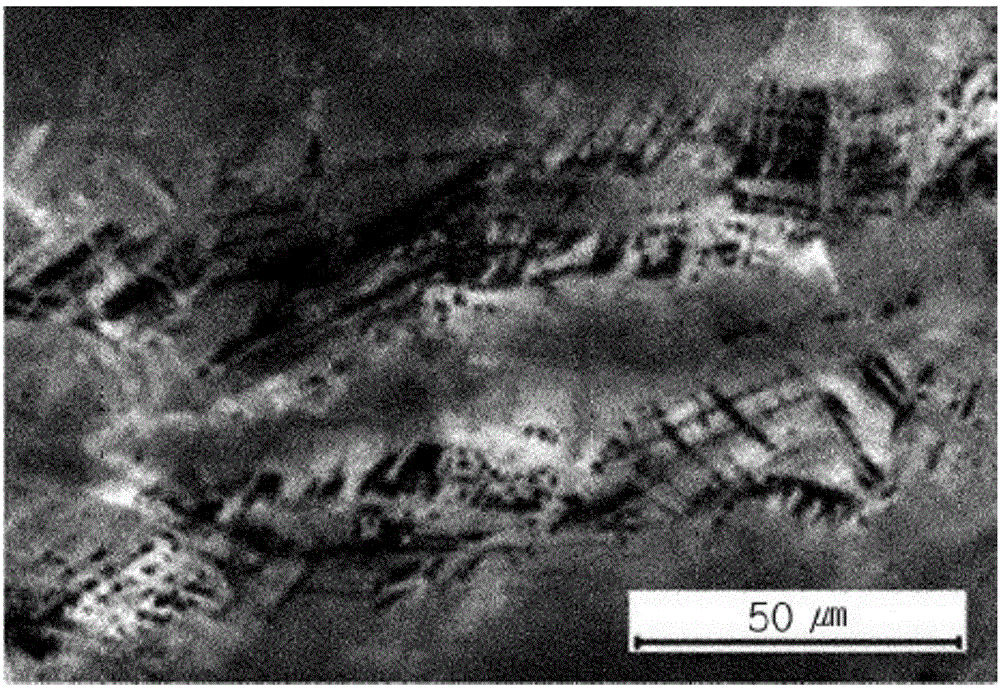

The Application of Chopped Steel Wire Ropes into Curved and Twisted Fibers

ActiveCN105880596BRealize large-scale productionContinuation of high mechanical strength characteristicsPorosityFiber

The invention discloses application of bending torsion filaments obtained by chopping a steel wire rope, and particularly relates to application of a mechanical structure part made from a metal porous material formed by pressing and sintering bending torsion filaments obtained by chopping a steel wire rope in directly achieving porous rigid vibration attenuation. According to different using conditions, the porosity of the metal porous material which is formed by pressing and sintering bending torsion filaments obtained by chopping the steel wire rope is adjustable, the porosity mainly ranges from 20% to 75%, and the loss factor ranges from 0.01 to 0.06. The sintered bending torsion filament metal porous material is machined into a part to be applied to a mechanical structure for rigid vibration attenuation, the porosity of the filament porous material ranges from 20% to 50%, and the loss factor ranges from 0.01 to 0.04. The metal porous material can be directly machined into the bearing structural part, and mechanical system porous light rigid vibration attenuation is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Structural-performance-controllable high-elasticity-modulus titanium-based composite material and preparation method thereof

The invention provides a structural-performance-controllable high-elasticity-modulus titanium-based composite material and a preparation method of the structural-performance-controllable high-elasticity-modulus titanium-based composite material and relates to the structural-performance-controllable high-elasticity-modulus titanium-based composite material and the preparation method of the structural-performance-controllable high-elasticity-modulus titanium-based composite material. The structural-performance-controllable high-elasticity-modulus titanium-based composite material and the preparation method of the structural-performance-controllable high-elasticity-modulus titanium-based composite material aim to solve the problems that it is difficult for the elastic modulus of a titanium alloy to exceed 120 GPa, it is difficult for the elastic modulus of the titanium-based composite material to exceed 170 GPa, and the formability and processability of ceramic such as TiC are poor are solved. According to the structural-performance-controllable high-elasticity-modulus titanium-based composite material and the preparation method, industrial pure titanium and diamond are taken as raw materials, and TiCp and diamond reinforced phases are introduced into the material in a target manner through a powder metallurgy method. The blank of the titanium material with the elastic modulus being higher than 170 GPa is filled, the shape of the net structure is achieved by changing the ball milling process, and the diamond reacting dose is controlled by changing the sintering process. The preparation method is used for preparing the high-elasticity-modulus titanium-based composite material.

Owner:HARBIN INST OF TECH

Iron-base amorphous alloy material with high saturation magnetic induction density

InactiveCN100529146CGood soft magneticStrong Amorphous Formation AbilityChemical compositionVolumetric Mass Density

The invention discloses an iron-based amorphous alloy material with high saturation magnetic induction. The chemical composition of the iron-based amorphous alloy material is FeaMobSicPdCeBf, and a+b+c+d+e+f=100%, the atoms of b The percentage range is 0-2, the atomic percentage range of c is 2-5, the atomic percentage range of d is 8-10, the atomic percentage range of e is 5-8, the atomic percentage range of f is 3-5, a is the rest quantity. The FeaMobSicPdCeBf alloy material of the invention has a high saturation magnetic induction of 1.30-1.55T and good amorphous forming ability, and can be widely used in structural materials and soft magnetic materials. The preparation method of the alloy material is simple and the production cost is low.

Owner:BEIHANG UNIV

Zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis containing oxide layer and preparation method

PendingCN112155801AHigh bonding strengthNot easy to fall offAdditive manufacturing apparatusJoint implantsOsseointegrationProsthesis

The invention discloses a zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis containing an oxide layer and a preparation method. The preparation method includes the stepsthat zirconium-niobium alloy powder is taken as a raw material; a zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis intermediate product containing the oxide layer is integrally formed and obtained through 3D printing; and the zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis containing the oxide layer is obtained through hot isostatic pressing, cryogenic treatment, and surface oxidation. The zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis containing the oxide layer comprises a tibial plateau support body, a side wall is arranged on the upper surface of the straight line edge of the tibial plateau support body, a semi-oval keel with a long circular hole is arranged at the position, close to the sidewall, of the lower surface of the tibial plateau support body, and a bone trabecula is arranged on the lower surface of the tibial plateau support body and the semi-oval keel. According to the zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis containing the oxide layer and the preparation method, excellent biocompatibility and bone ingrowth of an osseointegration interface and super-strong wear resistance and low wear rate of a friction interface are integrally realized; the bone trabecula part has excellent compression resistance; and the compressive yield strength and the plasticity of a solid part are enhanced.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

Surface nickel-phosphorus plated graphene reinforced titanium-based composite material and preparation method thereof

ActiveCN114523104AGuaranteed performanceGuaranteed retouching effectIncreasing energy efficiencyLiquid/solution decomposition chemical coatingTitanium matrix compositesGraphite

The invention discloses a surface nickel-phosphorus plated graphene reinforced titanium-based composite material, the surface of graphene in the composite material is coated with a nickel-phosphorus layer, and the surface nickel-phosphorus plated graphene is dispersively distributed on the surface of a titanium ball; wherein the graphene is distributed at the grain boundary of the titanium matrix, and the composite material only has diffraction peaks corresponding to the alpha phase and the beta phase of titanium. The invention further discloses a preparation method of the surface nickel-phosphorus plated graphene reinforced titanium-based composite material. According to the composite material, the problem that graphene and titanium easily generate TiC is solved, meanwhile, the dispersity of the graphene is better, the graphene is not prone to damage in the ball milling and sintering process, and therefore the performance of the composite material is improved to the maximum extent.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com