Centimeter-sized Zr-based bulk amorphous alloy, and preparation and application methods thereof

An amorphous alloy, centimeter-level technology, applied in the centimeter-level Zr-based bulk amorphous alloy and its preparation, application field, can solve problems such as poor corrosion resistance, achieve improved corrosion resistance, good thermal stability, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

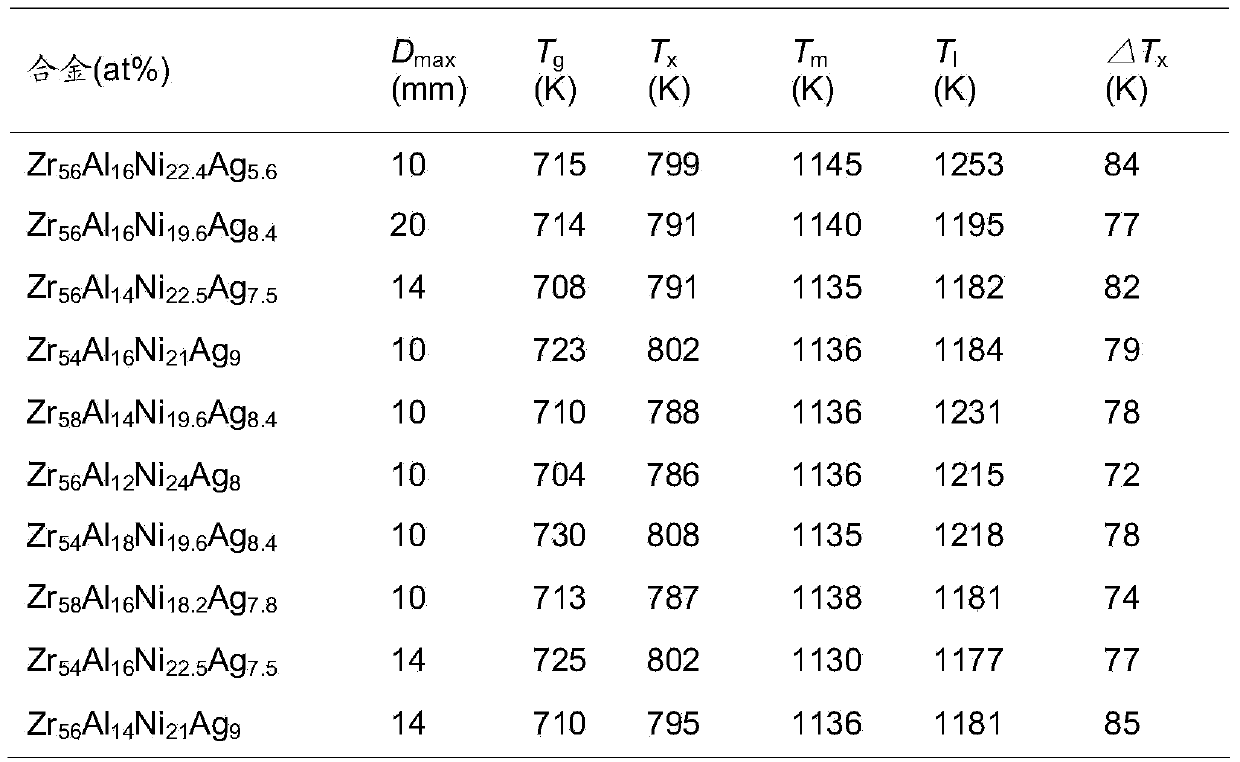

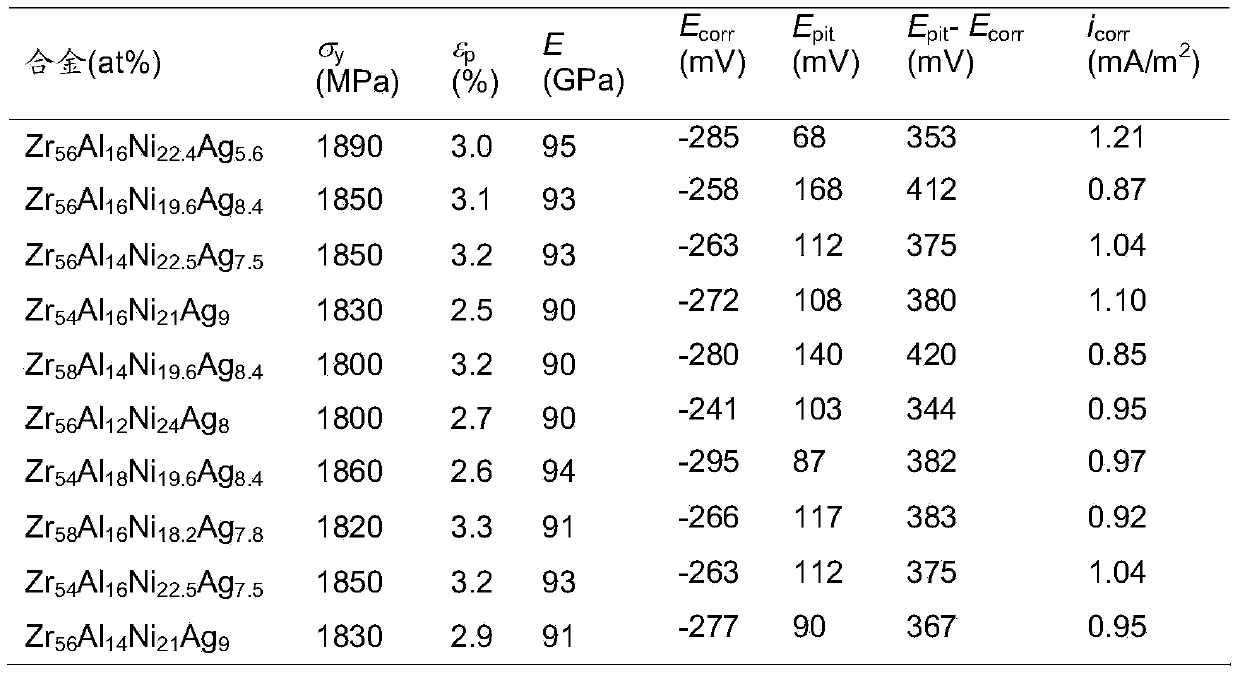

[0053] This embodiment adopts copper mold casting method to prepare the Zr that diameter is 10mm 58 Al 14 Ni 19.6 Ag 8.4 bulk amorphous alloy.

[0054] Step 1: Weigh each element

[0055] Calculate the weight of each element related to it according to the number of atoms required;

[0056] Step 2: Smelting Zr 58 Al 14 Ni 19.6 Ag 8.4 Master Alloy

[0057] Put the required raw materials weighed in step 1 into the vacuum smelting furnace, and adjust the vacuum degree to 5×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.05MPa; adjust the current 50-200A, melting temperature 1000-2000K; repeated smelting 4 times or more, after cooling with the furnace to get evenly mixed Zr-Al-Ni -Ag master alloy;

[0058] Step 3: Prepare Zr with a diameter of 10mm 58 Al 14 Ni 19.6 Ag 8.4 bulk amorphous alloy

[0059] Put the master alloy prepared in step 2 into the induction furnace of the rapid solidification device, and adjust the vacuum degree to 5×10 -3 Pa,...

Embodiment 2

[0067] This embodiment adopts copper mold casting method to prepare the Zr that diameter is 20mm 56 Al 16 Ni 19.6 Ag 8.4 bulk amorphous alloy.

[0068] Step 1: Weigh each element

[0069] Calculate the weight of each element related to it according to the number of atoms required;

[0070] Step 2: Smelting Zr 56 Al 16 Ni 19.6 Ag 8.4 Master Alloy

[0071] Put the required raw materials weighed in step 1 into the vacuum smelting furnace, and adjust the vacuum degree to 5×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.05MPa; adjust the current 50-200A, melting temperature 1000-2000K; repeated smelting 4 times or more, after cooling with the furnace to get evenly mixed Zr-Al-Ni -Ag master alloy;

[0072] Step 3: Prepare Zr with a diameter of 20mm 56 Al 16 Ni 19.6 Ag 8.4 bulk amorphous alloy

[0073] Put the master alloy prepared in step 2 into the induction furnace of the rapid solidification device, and adjust the vacuum degree to 5×10 -3 Pa,...

Embodiment 3

[0081] This embodiment adopts copper mold casting method to prepare the Zr that diameter is 14mm 54 Al 16 Ni 22.5 Ag 7.5 bulk amorphous alloy.

[0082] Step 1: Weigh each element

[0083] Calculate the weight of each element related to it according to the number of atoms required;

[0084] Step 2: Smelting Zr 54 Al 16 Ni 22.5 Ag 7.5 Master Alloy

[0085] Put the required raw materials weighed in step 1 into the vacuum smelting furnace, and adjust the vacuum degree to 5×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.05MPa; adjust the current 50-200A, melting temperature 1000-2000K; repeated smelting for 4 times or more and then cooled with the furnace to obtain uniformly mixed Zr-Al-Ni -Ag master alloy;

[0086] Step 3: Prepare Zr with a diameter of 14mm 54 Al 16 Ni 22.5 Ag 7.5 bulk amorphous alloy

[0087] Put the master alloy prepared in step 2 into the induction furnace of the rapid solidification device, and adjust the vacuum degree to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Compression breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com