Preparation method of gradient porous titanium alloy

A gradient porous, titanium alloy technology, applied in the field of porous titanium and titanium alloys, can solve the problems of difficult to achieve pore size gradient, difficult to control the pore size, difficult to control the pore shape, etc., to achieve easy control of the preparation process, stable mechanical properties, reduced The effect of small pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

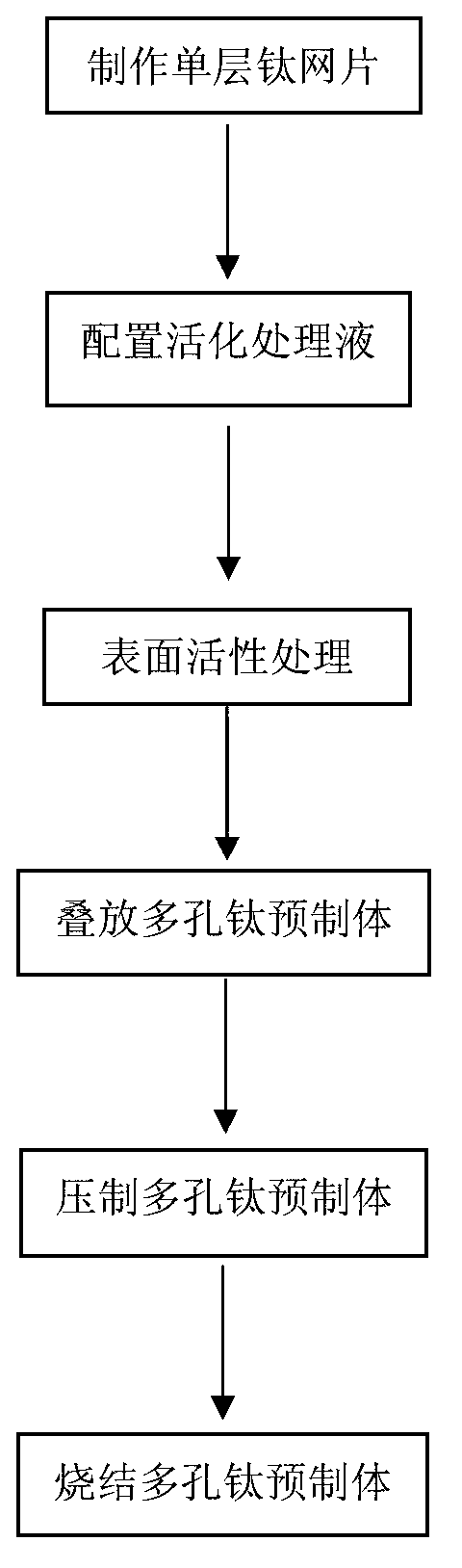

[0033] This embodiment is a method for preparing porous titanium with equal pore size, comprising the following steps:

[0034] Step 1. Make single-layer titanium mesh

[0035] A single-layer TA1 titanium mesh with a hole diameter of 100 mesh was punched into several discs of Φ15 mm using a punching machine to obtain several single-layer titanium mesh sheets. In this embodiment, the number of single-layer titanium meshes is 100.

[0036] Step 2. Configure activation treatment solution

[0037] The activation treatment liquid includes acidic solution and weak alkaline solution. Dissolve hydrofluoric acid and nitric acid in deionized water and stir evenly to obtain an acidic solution; the volume percentages of the hydrofluoric acid and nitric acid are 5% respectively. Dissolve 5.0 g of sodium bicarbonate in 100 ml of deionized water and stir evenly to obtain a weak alkaline solution.

[0038] Step 3. Surfactant treatment

[0039] Put the single-layer titanium mesh prepared ...

Embodiment 2

[0047] A method for preparing porous titanium with equal pore size, comprising the following steps:

[0048] Step 1. Make single-layer titanium mesh

[0049] A single-layer TA1 titanium mesh with a hole diameter of 30 mesh was punched into several discs of Φ20 mm by a punching machine. Several single-layer titanium meshes were obtained. In this embodiment, the number of single-layer titanium meshes is 80.

[0050] Step 2. Configure activation treatment solution

[0051] The activation treatment liquid includes acidic solution and weak alkaline solution. Hydrofluoric acid and nitric acid are dissolved in deionized water and stirred uniformly to obtain an acidic solution; the volume percentage of said hydrofluoric acid and nitric acid is respectively 10%; 5.0g sodium bicarbonate is dissolved in 100ml deionized water and stirred uniformly to obtain Weak alkaline solution.

[0052] Step 3. Surfactant treatment

[0053] Put the single-layer titanium mesh prepared in step 1 in...

Embodiment 3

[0061] A preparation method of an equal-aperture porous titanium alloy, comprising the following steps:

[0062] Step 1. Make single-layer titanium mesh

[0063] A single-layer Ti6Al4V titanium alloy mesh with a hole diameter of 50 mesh was punched into several Φ20mm discs by a punching machine to obtain several single-layer titanium meshes. The number of single-layer titanium mesh is 100.

[0064] Step 2. Configure activation treatment solution

[0065] The activation treatment liquid includes acidic solution and weak alkaline solution. Dissolve hydrofluoric acid and nitric acid in deionized water and stir evenly to obtain an acidic solution; the volume percentages of hydrofluoric acid and nitric acid are respectively 10%, 30%; 10.0g sodium bicarbonate is dissolved in 100ml deionized water and stirred Evenly, a weakly alkaline solution is obtained.

[0066] Step 3. Surfactant treatment

[0067] Put the single-layer titanium mesh prepared in step 1 into the obtained acidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com