The Application of Chopped Steel Wire Ropes into Curved and Twisted Fibers

A fiber wire and steel wire rope technology is applied in the field of vibration damping of metal porous materials, which can solve problems such as increasing process costs, and achieve the effects of reliable metallurgical bonding, easy aging, and good damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

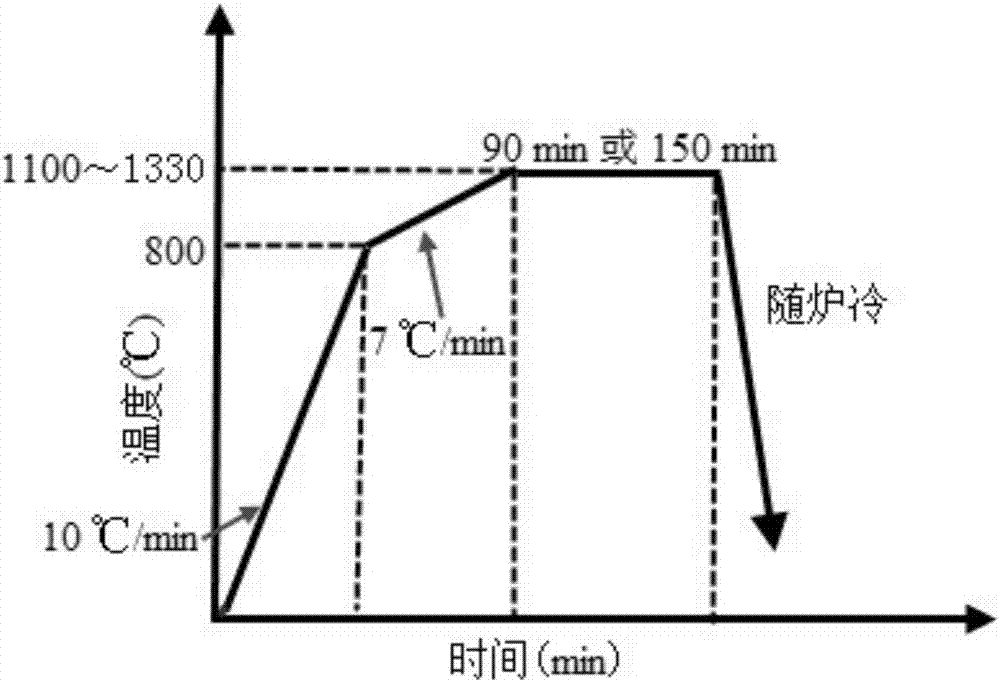

Method used

Image

Examples

Embodiment 1

[0054] The twisted and twisted fiber wire porous pad is inserted between the gear reducer transmission system and the base and fixed to achieve vibration reduction of the entire system.

[0055] Implementation results

[0056] 1) Comparison of the vibration velocity spectrum between the response point B1 plus the porous pad system and the original system is as follows: Figure 9 , Figure 10 with Figure 11 shown. Figure 9 The resonant vibration frequency is reduced from 10 to 4 after adding porous pads radially. In the original system, the maximum peak amplitude of 8.25mm / s corresponding to 99.38Hz decays to 0.83mm / s, and the vibration frequencies after this vibration frequency all disappear after adding porous spacers. The maximum peak value is generated at 89.38Hz, and its amplitude is 2.84mm / s, which is only 0.95mm / s higher than the amplitude of 1.89mm / s in the original system, but far smaller than the maximum amplitude of the original system's resonance peak. Figur...

Embodiment 2

[0069] Example 2 The porous ring of bent and twisted fiber filaments is assembled between the input shaft of the gearbox and the inner ring of the intermediate shaft bearing and the journal, and is tightly fitted and fixed, such as Figure 12 As shown, the vibration reduction of the whole system is realized.

[0070] Implementation results

[0071] 1) The vibration velocity spectrum comparison between the response point B1 plus the porous ring system and the original system is as follows Figure 13 , Figure 14 with Figure 15 shown.

[0072] Such as Figure 13 The radial original system shown has a maximum peak of 8.252mm / s at 99.37Hz. After the porous ring is added, the resonance here disappears, and a new maximum peak of 3.04mm / s occurs at 88.13Hz, which is about 37% of the original system. Figure 14 All the vibration frequencies after 174.36Hz of the original axial system shown in the figure almost disappear after the porous ring is added, and the amplitudes of very ...

Embodiment 3

[0087] The difference between this embodiment and Embodiment 2 is that the porous ring of twisted fiber filaments is assembled between the input shaft, the intermediate shaft, the inner ring of the output shaft bearing and the journal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com