Structural-performance-controllable high-elasticity-modulus titanium-based composite material and preparation method thereof

A technology of titanium-based composite materials and structural properties, applied in the field of high-elastic-modulus titanium-based composite materials and their preparation, can solve the problems of poor formability of TiC and other ceramics, difficult elastic modulus of titanium alloys, and poor processability, etc. The effects of increasing, speeding up molecular motion, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

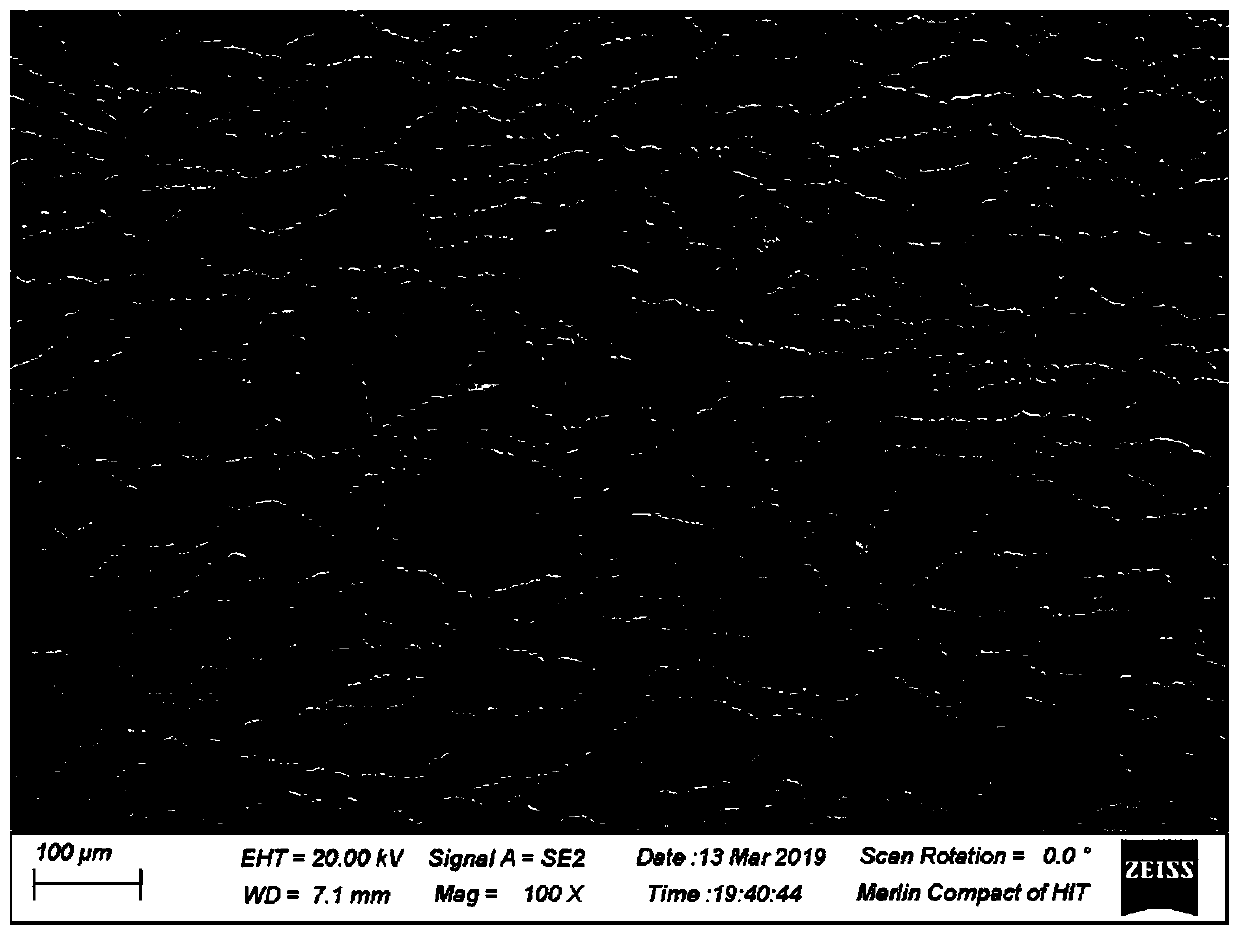

[0021] Specific Embodiment 1: In this embodiment, a high elastic modulus titanium-based composite material with controllable structural properties uses industrially pure titanium and diamond as raw materials, and introduces TiCp and diamond into the material as a reinforcing phase through powder metallurgy methods; The industrially pure titanium is titanium powder, and the diamond is diamond powder; the volume of the diamond powder accounts for 5-15% of the total volume of raw materials.

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: the diameter of the diamond powder is 2-10 μm; the titanium powder is spherical titanium powder with a diameter of 90-150 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the volume of the diamond powder accounts for 10% of the total volume of the raw material. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com