Zirconium-niobium alloy partitioned bone trabecula single-compartment femoral condyle containing oxide layer and preparation method

A technology of zirconium-niobium alloy and oxide layer, which is applied in the fields of medical science, prosthesis, additive processing, etc., can solve the problems of poor sintering of powder, uneven microstructure, poor mechanical properties, etc., and achieve Reduce stress shielding effect, improve initial stability and long-term stability, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

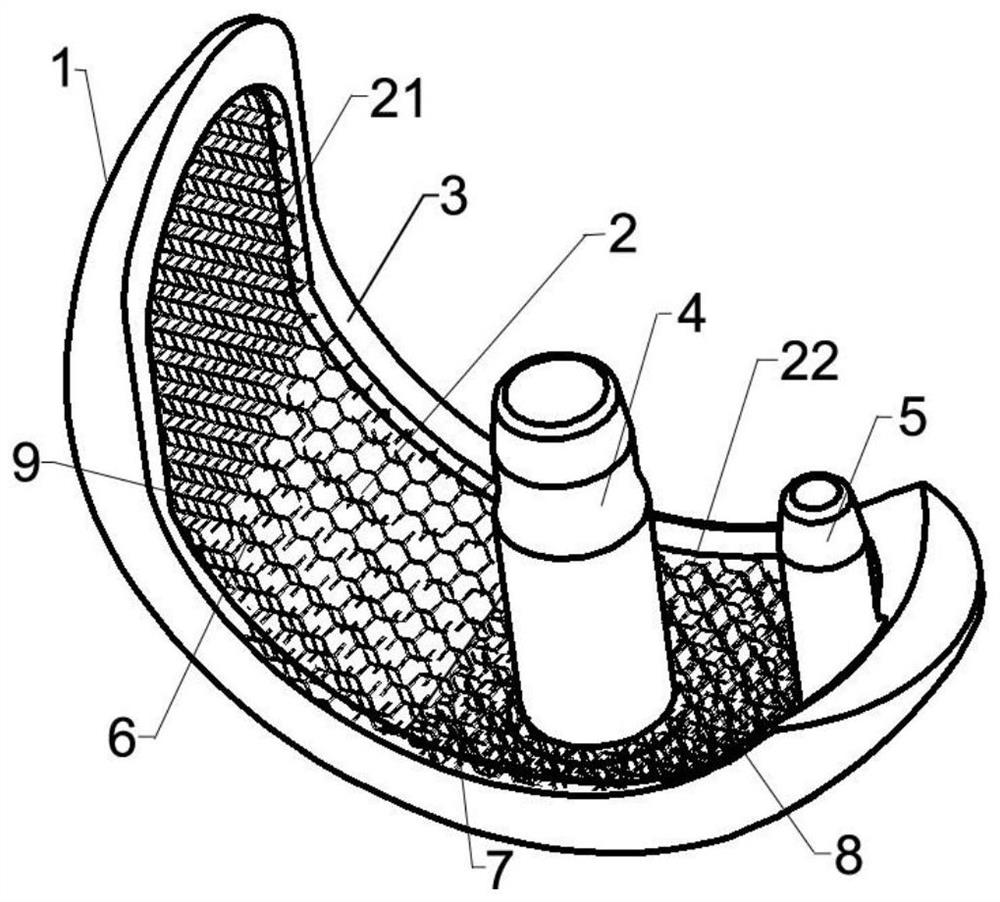

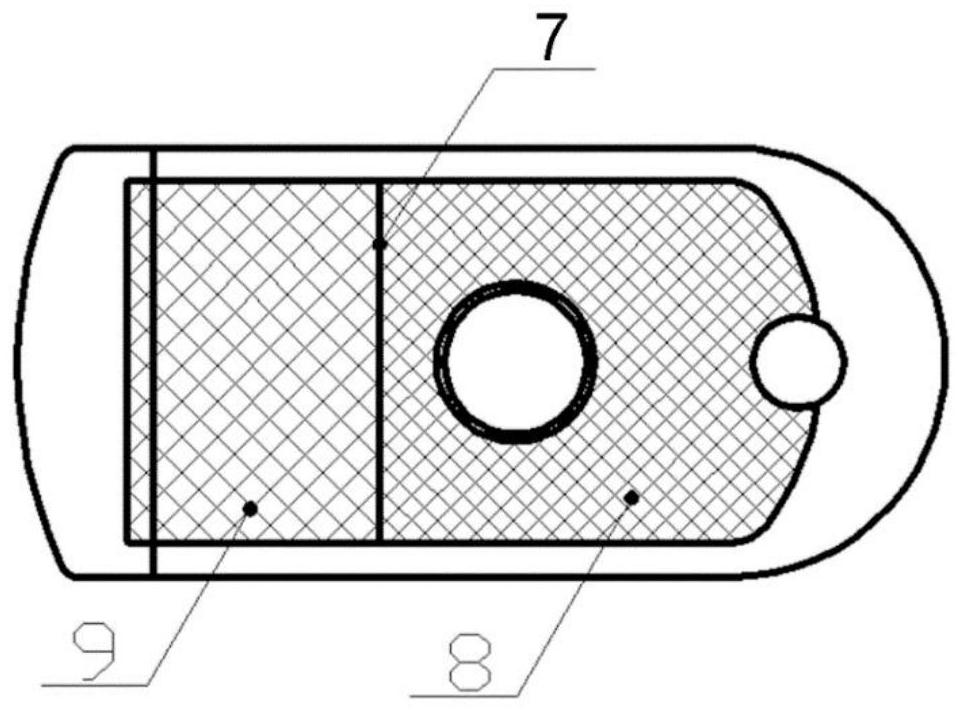

[0043] Oxide-containing zirconium-niobium alloy partitioned trabecular unicompartmental femoral condyle (see Figure 1-2 ) preparation method, comprising the steps of:

[0044] 1) Using zirconium-niobium alloy powder as the raw material, the first intermediate product of the femoral condyle with zirconium-niobium alloy partitioned trabecular unicompartment with oxide layer was obtained by 3D printing, and the first intermediate product was put into a hot isostatic pressing furnace. Under the protection of helium, raise the temperature to 1250°C, place it at a constant temperature of 180MPa for 3 hours, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain the second intermediate product;

[0045] 2) Place the second intermediate product in a programmed cooling box to cool down to -80°C at a rate of 1°C / min, place it at a constant temperature for 10 hours, and take it out of the programmed cooling box; place it in liquid nitrogen for another...

Embodiment 2

[0058] The preparation method of the single-compartment femoral condyle of the zirconium-niobium alloy partitioned trabecular bone comprising an oxide layer comprises the following steps:

[0059] 1) Using zirconium-niobium alloy powder as the raw material, the first intermediate product of the femoral condyle with zirconium-niobium alloy partitioned trabecular unicompartment with oxide layer was obtained by 3D printing, and the first intermediate product was put into a hot isostatic pressing furnace. Under the protection of helium, raise the temperature to 1325°C, place it at a constant temperature of 160MPa for 2 hours, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain the second intermediate product;

[0060] 2) Place the second intermediate product in a programmed cooling box to cool down to -100°C at a rate of 1°C / min, place it at a constant temperature for 7 hours, and take it out of the programmed cooling box; place it in liquid n...

Embodiment 3

[0073] 1. The preparation method of trabecular unicompartmental femoral condyle containing oxide layer zirconium-niobium alloy partition, comprising the following steps:

[0074] (1) Using zirconium-niobium alloy powder as the raw material, the first intermediate product of the femoral condyle with zirconium-niobium alloy partitioned trabecular unicompartment containing the oxide layer was obtained through 3D printing, and the first intermediate product was placed in a hot isostatic pressing furnace. Under the protection of argon, raise the temperature to 1400°C, place it at a constant temperature of 140MPa for 1 hour, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain the second intermediate product;

[0075] (2) Place the second intermediate product in a programmed cooling box to cool down to -120°C at a rate of 1°C / min, place it at a constant temperature for 5 hours, and take it out of the programmed cooling box; place it in liquid nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com