Medical degradable fe-mn-ag alloy material and its preparation and application

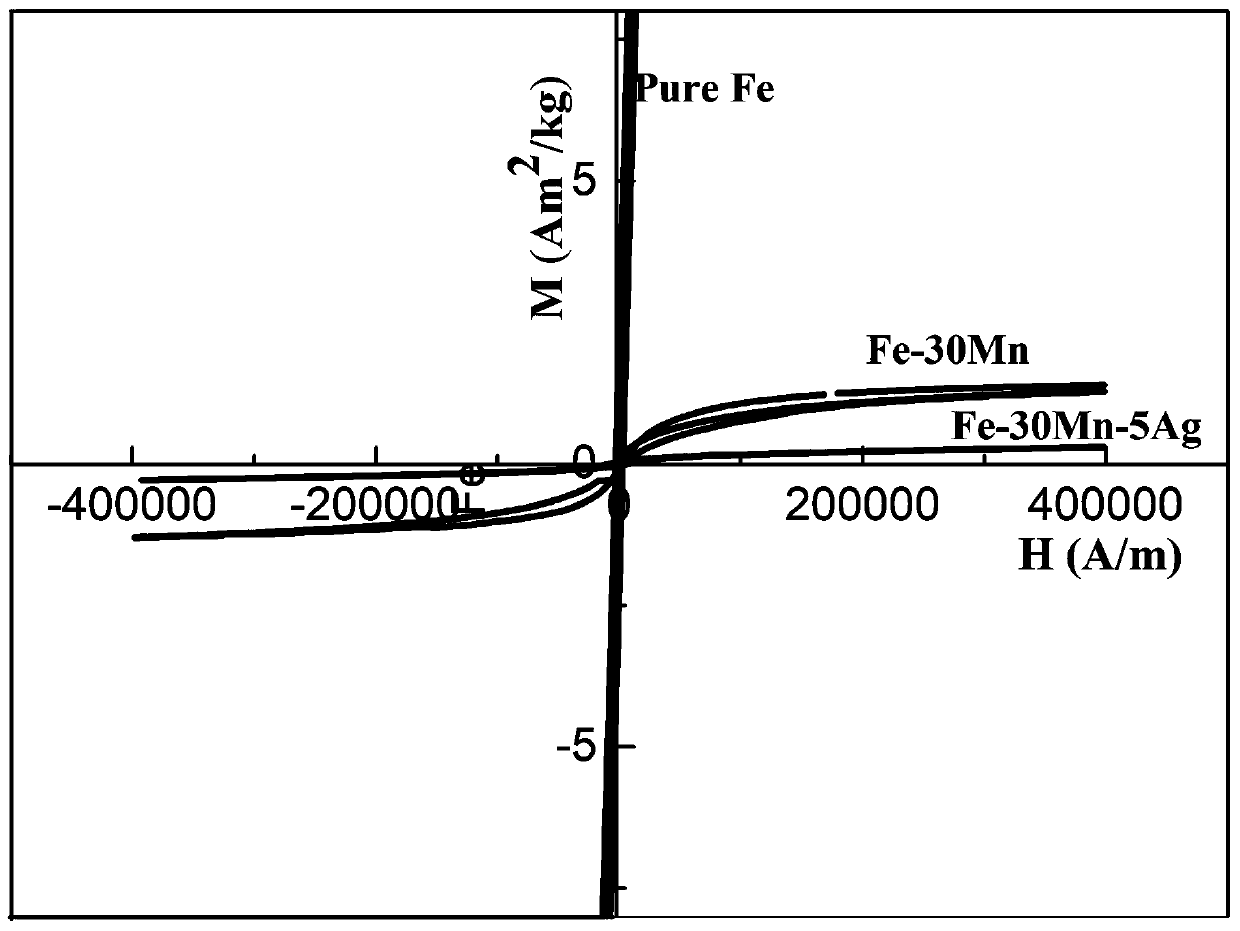

A technology of alloy material and biomedical material, which is applied in the field of medical degradable Fe-Mn-Ag ternary iron-based alloy material and its preparation and application, can solve the problems of low degradation rate of Fe-30Mn alloy, and achieve excellent mechanical properties, Effects of increased compressive yield strength, low magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Fe-Mn-Ag ternary iron-based alloy, the chemical composition of the components is: Mn: 30%, Ag: 5%, and the rest is iron; the purity of Mn and Ag is ≥99.9%, and the purity of Fe is ≥99.5%.

[0026] Weigh iron raw material, manganese raw material and silver raw material according to composition alloy ratio;

[0027] Heat and melt iron raw materials, manganese raw materials and silver raw materials, and repeatedly smelt them to form alloy melts;

[0028] The alloy melt is rapidly cooled and formed in a mold using a vacuum electric arc furnace.

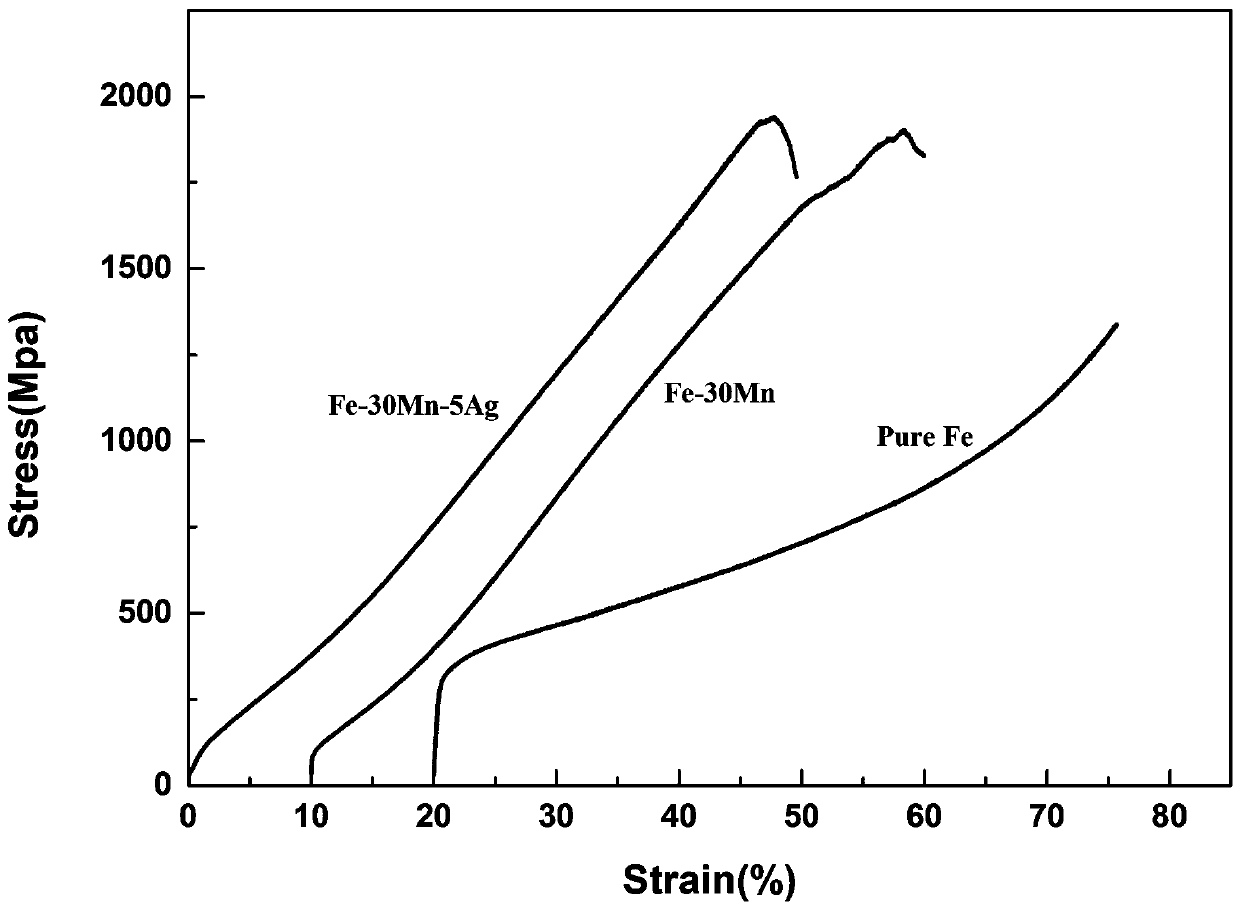

[0029] Process the ferroalloy after suction casting into a compression sample with a length of 6mm and a diameter of 3mm, and test the mechanical properties of the material on the RGM-4100 mechanical testing machine according to the GB / T 7314-2005 standard, such as figure 1 As shown, Fe-Mn-5Ag has better mechanical properties than Fe-30Mn, and its yield strength is 148MPa, and its plastic deformation is about 22%.

[0030] Such ...

Embodiment 2

[0036] Fe-Mn-Ag ternary iron-based alloy, the chemical composition of the components is: Mn: 30%, Ag: 2%, and the rest is iron; the purity of Mn and Ag is ≥99.9%, and the purity of Fe is ≥99.5%.

[0037] Weigh iron raw material, manganese raw material and silver raw material according to composition alloy ratio;

[0038] Heat and melt iron raw materials, manganese raw materials and silver raw materials, and repeatedly smelt them to form alloy melts;

[0039] The alloy melt is rapidly cooled and formed in a mold using a vacuum electric arc furnace.

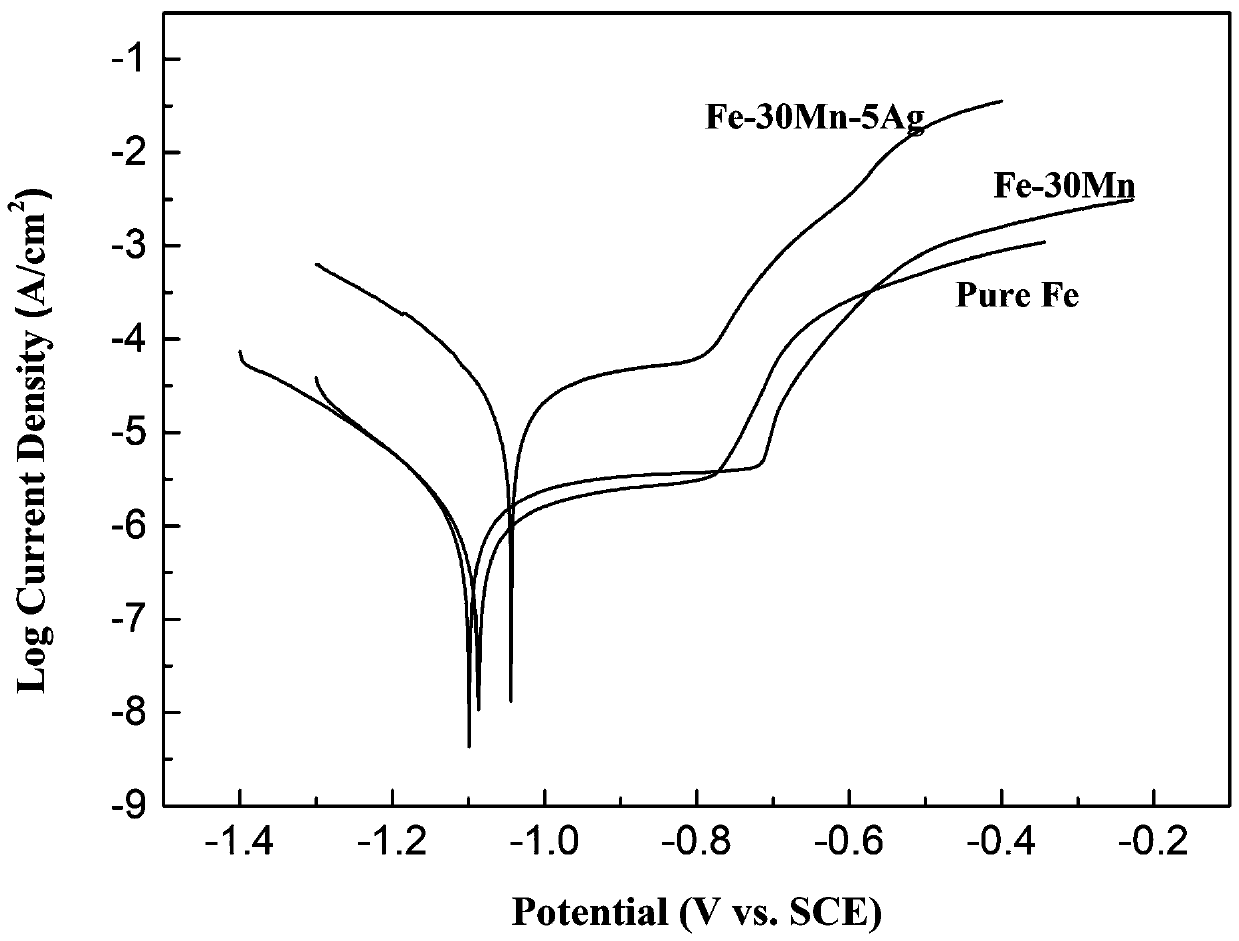

[0040]Process the ferroalloy after suction casting into a compression sample with a length of 6 mm and a diameter of 3 mm. According to the GB / T 7314-2005 standard, the mechanical properties of the material are tested on the RGM-4100 mechanical testing machine, and the yield strength is 126 MPa, and the plastic deformation is 27%. The corrosion rate obtained by electrochemical test in simulated body fluid SBF solution is 0.113mm...

Embodiment 3

[0042] Fe-Mn-Ag ternary iron-based alloy, the chemical composition of the components is: Mn: 30%, Ag: 10%, and the rest is iron; the purity of Mn and Ag is ≥99.9%, and the purity of Fe is ≥99.5%.

[0043] Weigh iron raw material, manganese raw material and silver raw material according to composition alloy ratio;

[0044] Heat and melt iron raw materials, manganese raw materials and silver raw materials, and repeatedly smelt them to form alloy melts;

[0045] The alloy melt is rapidly cooled and formed in a mold using a vacuum electric arc furnace.

[0046] The ferroalloy after suction casting is processed into a compression sample with a length of 6mm and a diameter of 3mm, and the mechanical properties of the material are tested on the RGM-4100 mechanical testing machine according to the GB / T 7314-2005 standard, and the yield strength is 194MPa, and the plastic deformation is 26%. The corrosion rate obtained by electrochemical test in simulated body fluid SBF solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com