Closed-cell foam aluminum alloy and preparation method thereof

A technology of closed-cell foam and aluminum alloy, which is applied in the field of metal materials, can solve the problems of low strength of closed-cell foam aluminum, achieve strength improvement, keep compression yield strength stable, and solve the effects of uneven aging strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

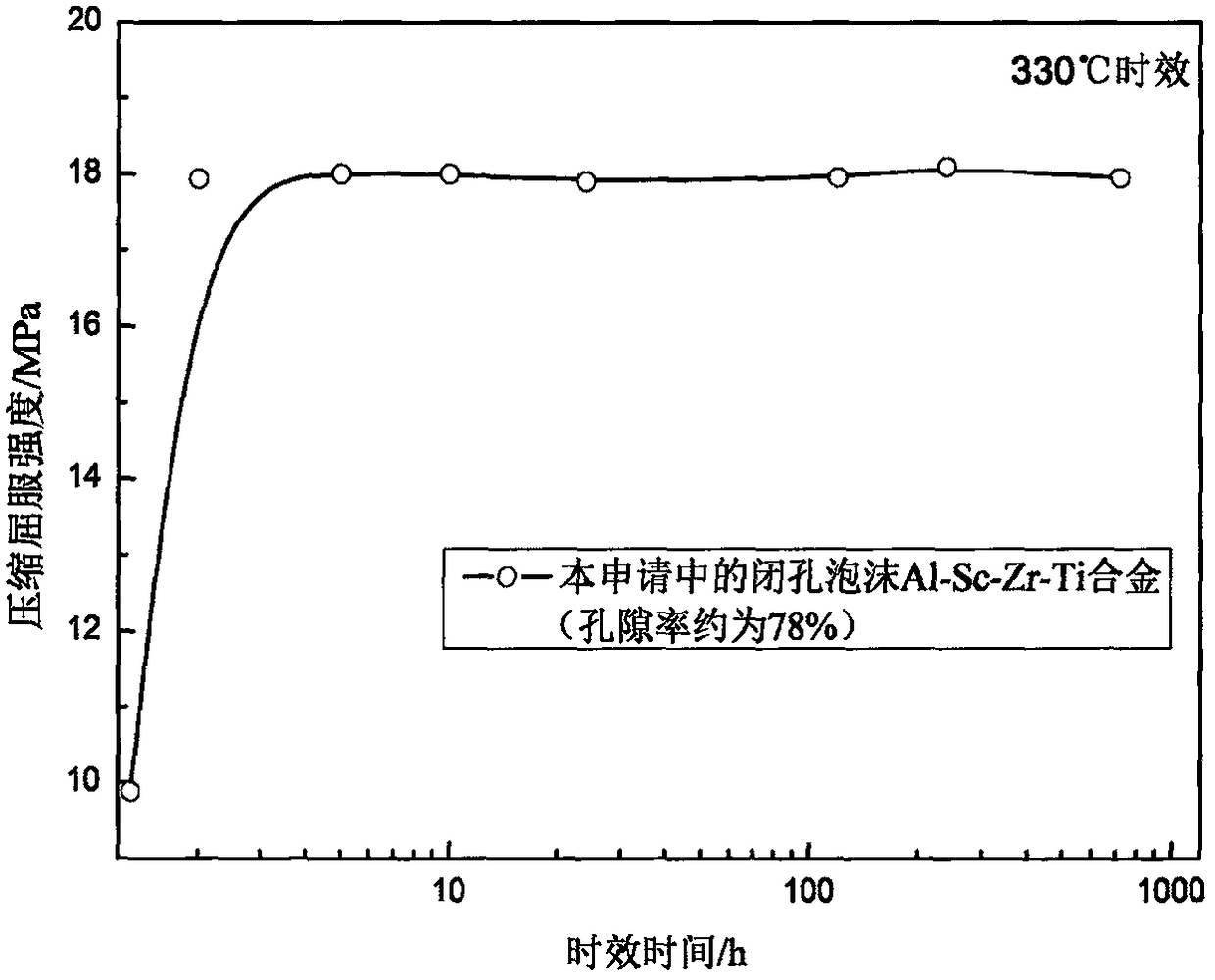

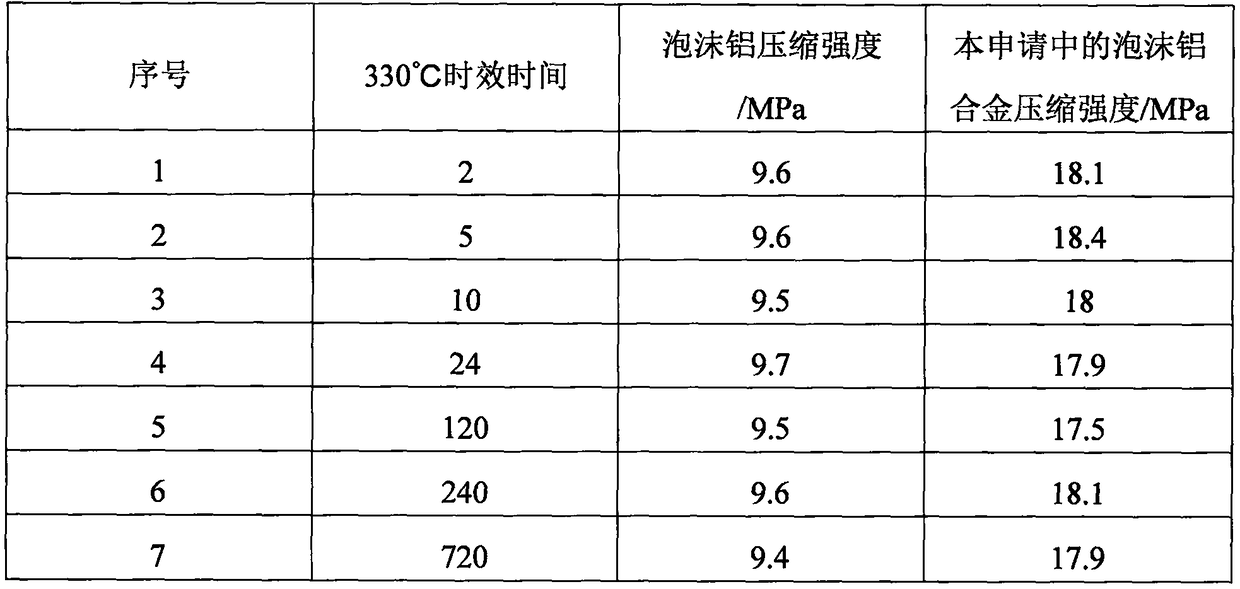

[0028] The present embodiment discloses a high-strength closed-cell foamed aluminum alloy that can be uniformly heat-treated and strengthened. The mass percentage of each component is Sc: 0.5%, Zr: 0.13%, Ti: 1.1%, and the balance is aluminum and a small amount of impurities.

[0029] The preparation method of the closed-cell foamed aluminum alloy described in Example 1 is as follows:

[0030] Step 1: Heat and melt pure aluminum and other alloy components Ti, Sc, Zr in a furnace according to mass percentage, and overheat to 860°C. After all the alloys are melted, stir for 10 minutes to cool the aluminum melt to 700°C , Adding 1.8% of the total weight of the melt (the mass ratio of hexachloroethane to sodium fluoride is 1:1.8), stirring for 10 minutes, and then vacuum degassing the aluminum melt and let it stand for 10 minutes; , Ti, Sc, Zr are added in the form of AlTi4, AlSc2, AlZr4 master alloy.

[0031] Step 2: Transfer the aluminum melt to the foaming furnace, control the temper...

Embodiment 2

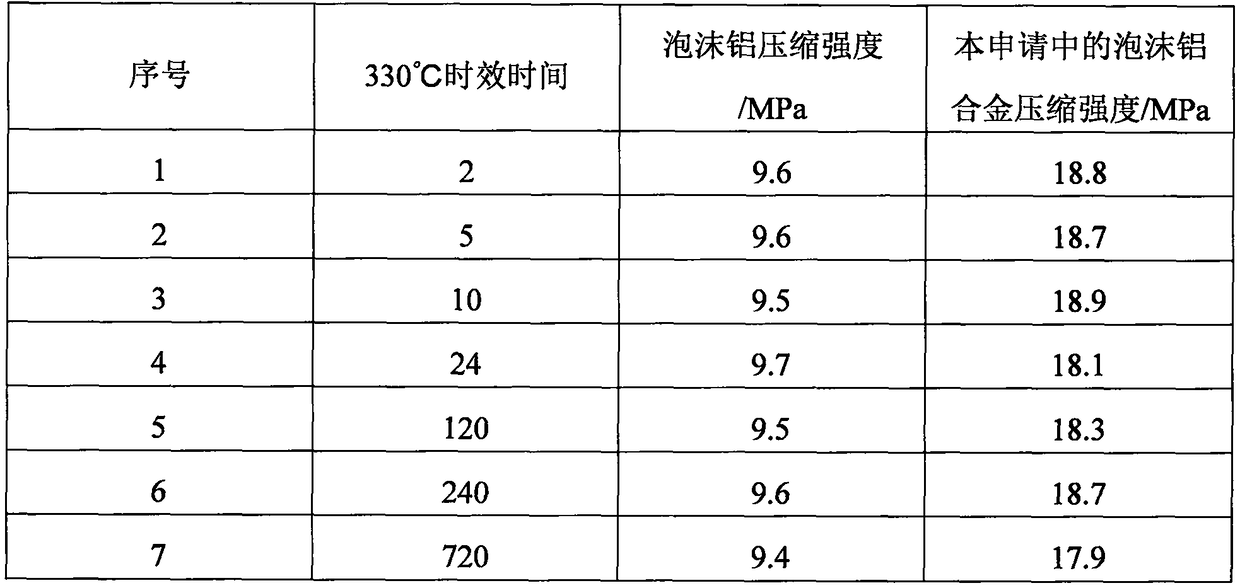

[0036] The present embodiment 2 discloses a high-strength closed-cell foamed aluminum alloy that can be uniformly heat-treated and strengthened. The mass percentages of each component are as follows: Sc: 0.58%, Zr: 0.18%, Ti: 1.6%, and the balance is aluminum.

[0037] The preparation method of the closed-cell foamed aluminum alloy described in embodiment 2 is as follows:

[0038] Step 1: Heat and melt pure aluminum, AlTi4, AlSc2, AlZr4 master alloy in a furnace, where the added pure aluminum, AlTi4, AlSc2, AlZr4 master alloy makes the content of Sc, Zr, Ti the same as the content of Example 2 After the alloy is completely melted into aluminum melt, stir for 12 minutes, cool the aluminum melt to 710°C, add 1.9% refining agent of the total weight of the melt, stir for 12 minutes, and then vacuum the aluminum melt Degassing treatment, let stand for 15min;

[0039] Step 2: Transfer the aluminum melt to the foaming furnace, control the aluminum melt temperature at 710°C, add 2.8% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com