Method for detecting internal fault of SF6 electrical equipment by using gas chromatograph

A gas chromatograph and electrical equipment technology, applied in the field of electrical equipment failure detection, can solve the problems of unpredictable electrical equipment, whether there are hidden dangers, environmental pollution, unsuitable selection, etc., to avoid economic losses, low testing costs, and stable performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

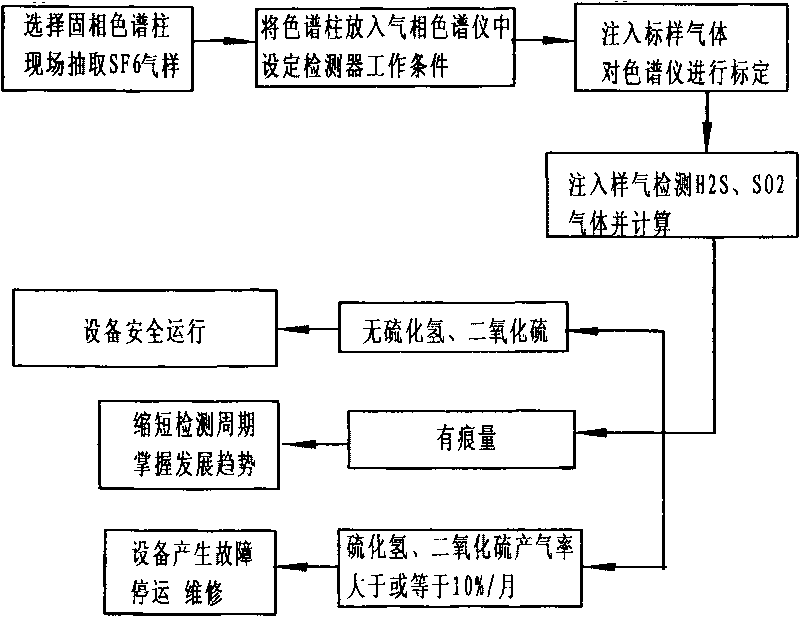

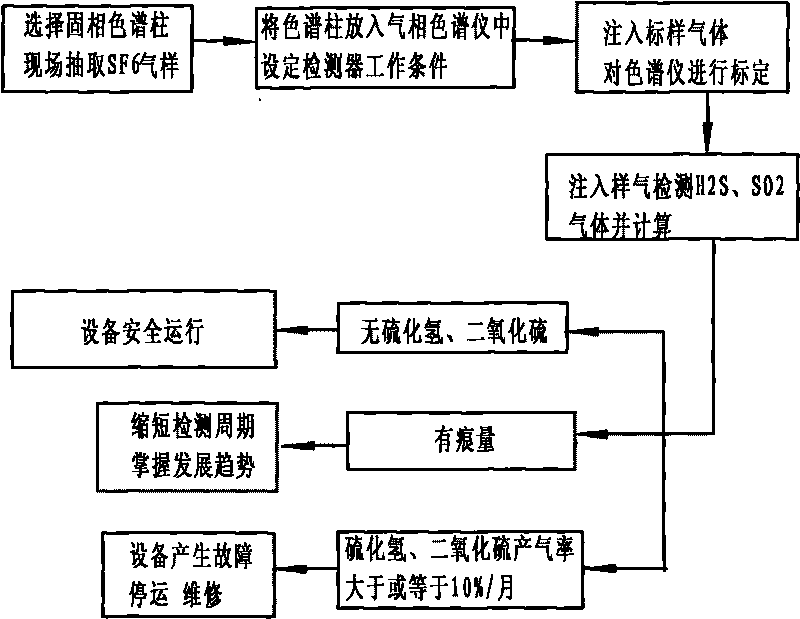

Method used

Image

Examples

Embodiment 1

[0045] On March 10, 2009, SF was extracted on-site from the electrical equipment of the 220kV substation built in 20086 SF in electrical equipment 6 The gas sample is 50mL, and a stainless steel tube with a length of 2m and an inner diameter of 3mm filled with a 60-80 mesh GDX-301 stationary phase is selected as the chromatographic column;

[0046] Put the chromatographic column into the gas chromatograph, select hydrogen with a purity greater than or equal to 99.99% as the carrier gas, and set the working conditions of the TCD thermal conductivity detector of the gas chromatograph as follows: dry sound ≤ 0.02mv; drift ≤ 0.25mv / min , the temperature of column oven and injector is 80°C, the temperature of detector is 100°C, TCD attenuation×range: 1×0.05, the temperature of TCD hot wire is 180°C±10°C; the current of hot wire is: 100±2mA;

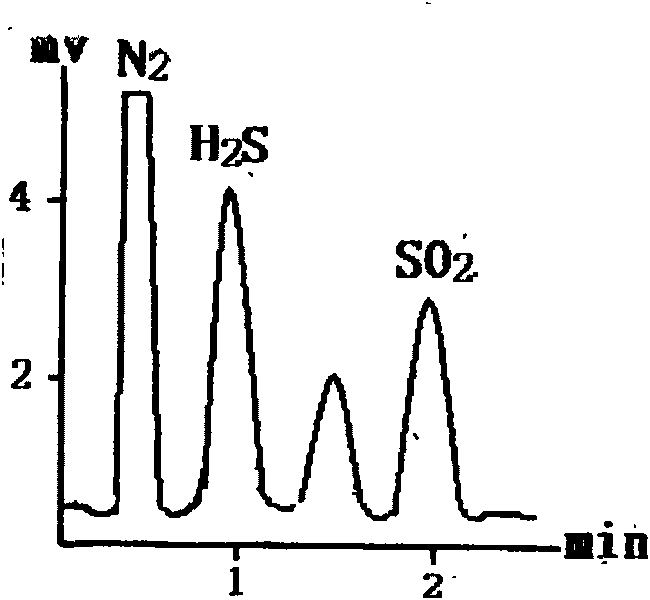

[0047] Use a syringe to inject H from the injection port of the chromatograph 2 S, SO 2 , N 2 Gas mixed standard sample gas 0.5mL to calib...

Embodiment 2

[0051] On April 6, 2009, when the operator was operating the 220 isolating switch, he heard an abnormal sound inside the equipment, suspected that there was an electrical fault, and extracted SF on-site from the electrical equipment of the 220kV substation. 6 The gas sample is 50mL; a stainless steel tube with a length of 2m and an inner diameter of 3mm filled with a 60-80 mesh GDX-301 stationary phase is selected as the chromatographic column.

[0052] Put the chromatographic column into the gas chromatograph, select hydrogen with a purity greater than or equal to 99.99% as the carrier gas, and set the working conditions of the TCD thermal conductivity detector of the gas chromatograph as follows: dry sound ≤ 0.02mv; drift ≤ 0.25mv / min , the temperature of column oven and injector is 80°C, the temperature of detector is 100°C, TCD attenuation×range: 1×0.05, the temperature of TCD hot wire is 180°C±10°C; the current of hot wire is: 100±2mA;

[0053] Use a syringe to inject H f...

Embodiment 3

[0057] On April 16, 2009, SF was extracted on-site in the electrical equipment of the 220kV substation 6 The gas sample is 50mL; a stainless steel tube with a length of 2m and an inner diameter of 3mm filled with a 60-80 mesh GDX-301 stationary phase is selected as the chromatographic column.

[0058] Put the chromatographic column into the gas chromatograph, select hydrogen with a purity greater than or equal to 99.99% as the carrier gas, and set the working conditions of the TCD thermal conductivity detector of the gas chromatograph as follows: dry sound ≤ 0.02mv; drift ≤ 0.25mv / min , the temperature of column oven and injector is 80°C, the temperature of detector is 100°C, TCD attenuation×range: 1×0.05, the temperature of TCD hot wire is 180°C±10°C; the current of hot wire is: 100±2mA;

[0059] Use a syringe to inject H from the injection port of the chromatograph 2 S, SO 2 , N 2 Gas mixed standard sample gas 0.5mL to calibrate the chromatograph;

[0060] After the chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com