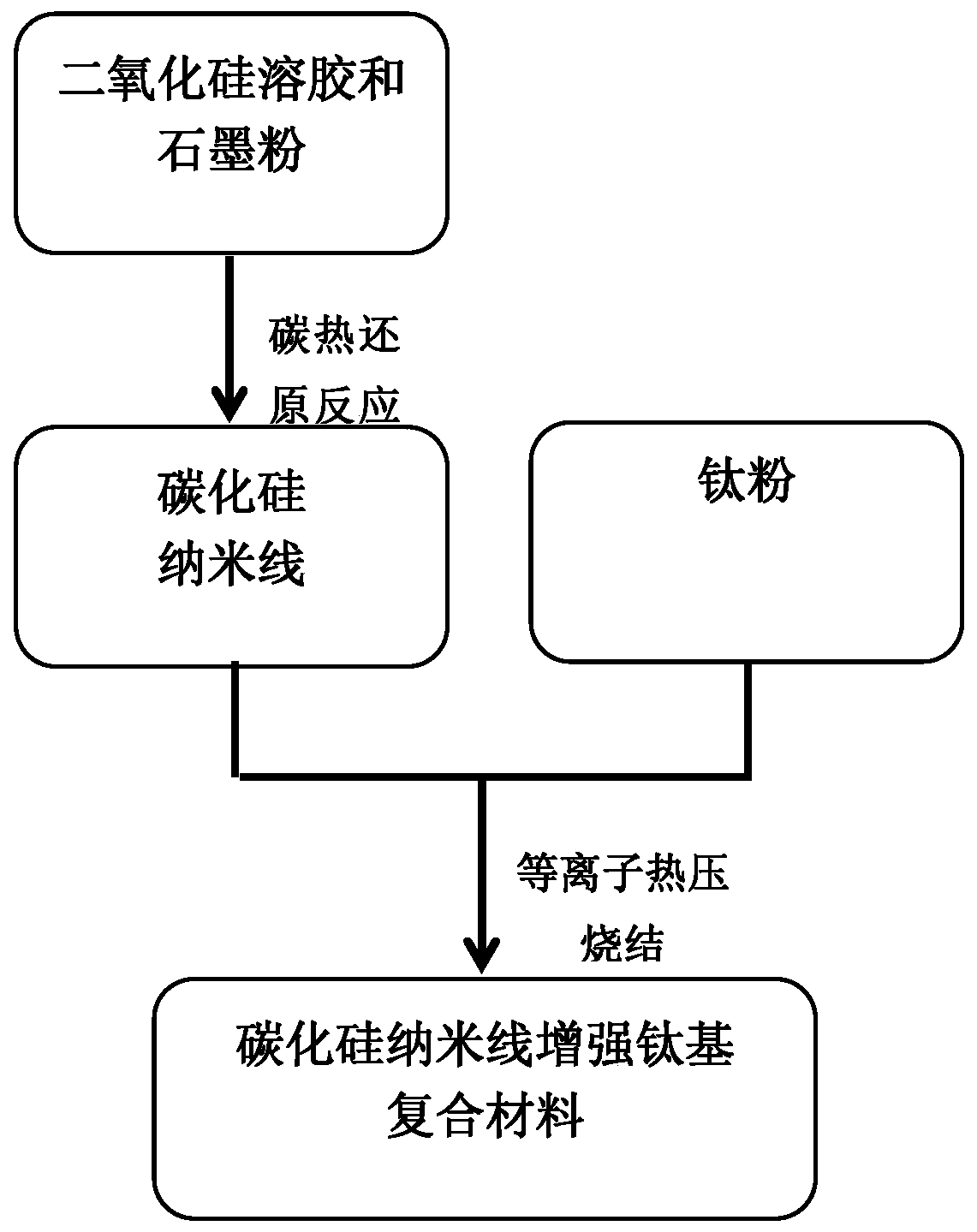

Method for low-temperature preparing of silicon carbide nanowire reinforced titanium matrix composite

A technology of silicon carbide nanowires and titanium-based composite materials, applied in the direction of silicon carbide, carbide, nanotechnology, etc., can solve the problems of weakening the strengthening and toughening effect of silicon carbide nanowires, losing the structural characteristics of silicon carbide nanowires, etc., to achieve Ensure the strengthening and toughening effect, improve the strengthening and toughening effect, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment includes the following steps:

[0037]Step 1, mix absolute ethanol and tetraethyl orthosilicate and stir evenly, then add distilled water and a hydrochloric acid solution with a mass concentration of 37% and stir uniformly to obtain a silica sol; the absolute ethanol, tetraethyl orthosilicate , The molar ratio of hydrochloric acid in distilled water and hydrochloric acid solution is 3:0.5:3:0.1;

[0038] Step 2. Add graphite powder with a particle size of 60 mesh to 150 mesh to the silica sol obtained in step 1 and stir for 20 minutes, then place it in an oven, and dry it for 12 hours at a temperature of 100°C to obtain a coated silica sol. Graphite powder of silica sol; the mass ratio of graphite powder to silica sol with a particle size of 60 mesh to 150 mesh is 1:5;

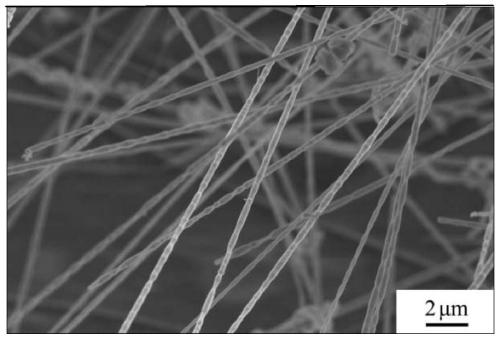

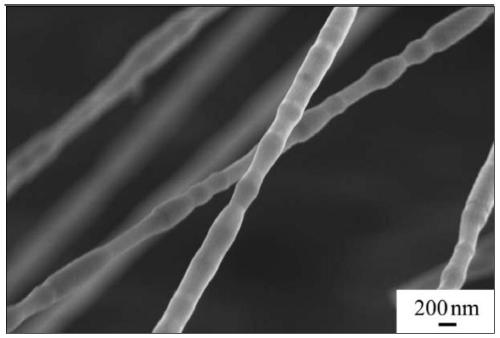

[0039] Step 3, placing the graphite powder coated with silica sol obtained in step 2 in a high-temperature tube furnace for carbothermal reduction reaction, and then undergoing an ultra...

Embodiment 2

[0059] This embodiment includes the following steps:

[0060] Step 1, mix absolute ethanol and tetraethyl orthosilicate and stir evenly, then add distilled water and a hydrochloric acid solution with a mass concentration of 37% and stir uniformly to obtain a silica sol; the absolute ethanol, tetraethyl orthosilicate , The molar ratio of hydrochloric acid in distilled water and hydrochloric acid solution is 5:2:8:0.5;

[0061] Step 2. Add graphite powder with a particle size of 60 mesh to 150 mesh into the silica sol obtained in step 1 and stir for 60 minutes, then place it in an oven, and dry it for 24 hours at a temperature of 100°C to obtain a coated silica sol. Graphite powder of silica sol; the mass ratio of graphite powder to silica sol with a particle size of 60 mesh to 150 mesh is 1:5;

[0062] Step 3, placing the graphite powder coated with silica sol obtained in step 2 in a high-temperature tube furnace for carbothermal reduction reaction, and then undergoing an ultr...

Embodiment 3

[0066] This embodiment includes the following steps:

[0067] Step 1, mix absolute ethanol and tetraethyl orthosilicate and stir evenly, then add distilled water and a hydrochloric acid solution with a mass concentration of 37% and stir uniformly to obtain a silica sol; the absolute ethanol, tetraethyl orthosilicate , The molar ratio of hydrochloric acid in distilled water and hydrochloric acid solution is 4:1.5:6:0.3;

[0068] Step 2. Add graphite powder with a particle size of 60 mesh to 150 mesh into the silica sol obtained in step 1 and stir for 40 minutes, then place it in an oven, and dry it for 20 hours at a temperature of 100°C to obtain a coated silica sol. Graphite powder of silica sol; the mass ratio of graphite powder to silica sol with a particle size of 60 mesh to 150 mesh is 1:5;

[0069] Step 3, placing the graphite powder coated with silica sol obtained in step 2 in a high-temperature tube furnace for carbothermal reduction reaction, and then undergoing an ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com