Fiber-like composite phase ceramic and preparation method

A technology of multiphase ceramics and fibrous body, applied in the field of fibrous body multiphase ceramics and preparation, can solve the problems of complicated preparation process and limited improvement of the toughness of ceramic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

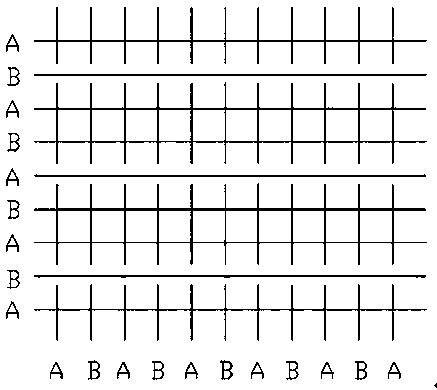

[0026] Slice and layer the fiber-like ceramic model to be prepared, and design it according to the composition of the composite ceramics as attached figure 1 The printing programs of the two complementary paths A and B are shown, and the program is imported into the printing device program; 74.5wt% silicon carbide powder, 0.5wt% boron carbide powder, 0.5wt% ammonium polyacrylate, 0.5wt% phenolic resin , 24wt% deionized water ball milling and mixing for 24 hours, then vacuum defoaming the slurry in a vacuum defoaming machine for 10 minutes to prepare the first ceramic slurry; according to step 2, select boron carbide powder to prepare the second ceramic slurry ;Add the first ceramic slurry to the first barrel, and the second ceramic slurry to the second barrel, and heat the printing nozzle to 50°C, choose a square nozzle with an aperture of 0.3mm, the nozzle of the 3D printer Under the control of the printing program, the ceramic slurry is extruded into a filamentous unit body,...

Embodiment 2

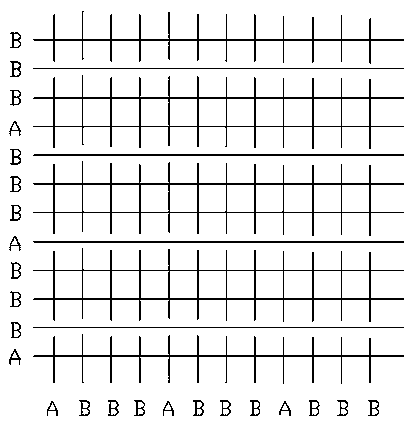

[0028] Slicing and layering the fiber-like ceramic model to be prepared, and designing the composite ceramic model as attached figure 2 The printing programs of the two complementary paths A and B are shown, and the program is imported into the printing device program; 84wt% alumina powder, 1wt% zirconia powder, 0.2wt% polyethylene glycol, 0.8wt% agarose, 14wt% deionized water was ball milled and mixed for 24 hours, and then the slurry was vacuum defoamed in a vacuum defoaming machine for 10 minutes to prepare the first ceramic slurry; according to step 2, the zirconia powder was selected to prepare the second ceramic slurry; Add the first ceramic slurry into the first barrel, add the second ceramic slurry into the second barrel, and heat the printing nozzle to 50°C. Choose a square nozzle with an aperture of 0.3mm. The nozzle of the 3D printer is in the Under the control of the printing program, the ceramic slurry is extruded into a filamentary unit body, and gradually piled...

Embodiment 3

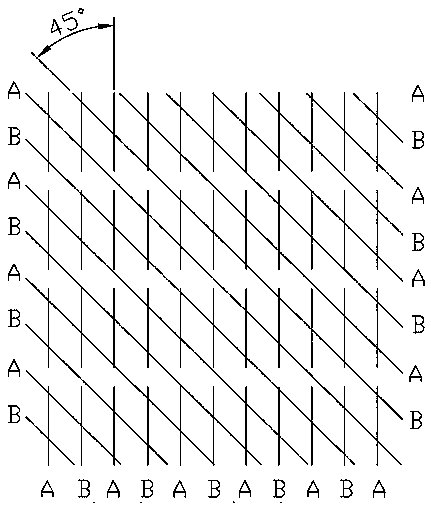

[0030] Slicing and layering the fiber-like ceramic model to be prepared, and designing the composite ceramic model as attached image 3The printing programs of the two complementary paths A and B are shown, and the program is imported into the printing device program; 84wt% alumina powder, 1wt% zirconia powder, 0.2wt% polyethylene glycol, 0.8wt% agarose, 14wt% deionized water was ball milled and mixed for 24 hours, and then the slurry was vacuum defoamed in a vacuum defoaming machine for 10 minutes to prepare the first ceramic slurry; according to step 2, the zirconia powder was selected to prepare the second ceramic slurry; Add the first ceramic slurry into the first barrel, add the second ceramic slurry into the second barrel, and heat the printing nozzle to 50°C. Choose a square nozzle with an aperture of 0.3mm. The nozzle of the 3D printer is in the Under the control of the printing program, the ceramic slurry is extruded into a filamentary unit body, and gradually piled u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com