Heat exchanger

A technology for heat exchangers and heat transfer surfaces, applied in the direction of heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., to achieve the effects of improving flow characteristics, improving support, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention with further improvements described below are merely regarded as examples, and are in no way intended to limit the scope of protection set by the claims.

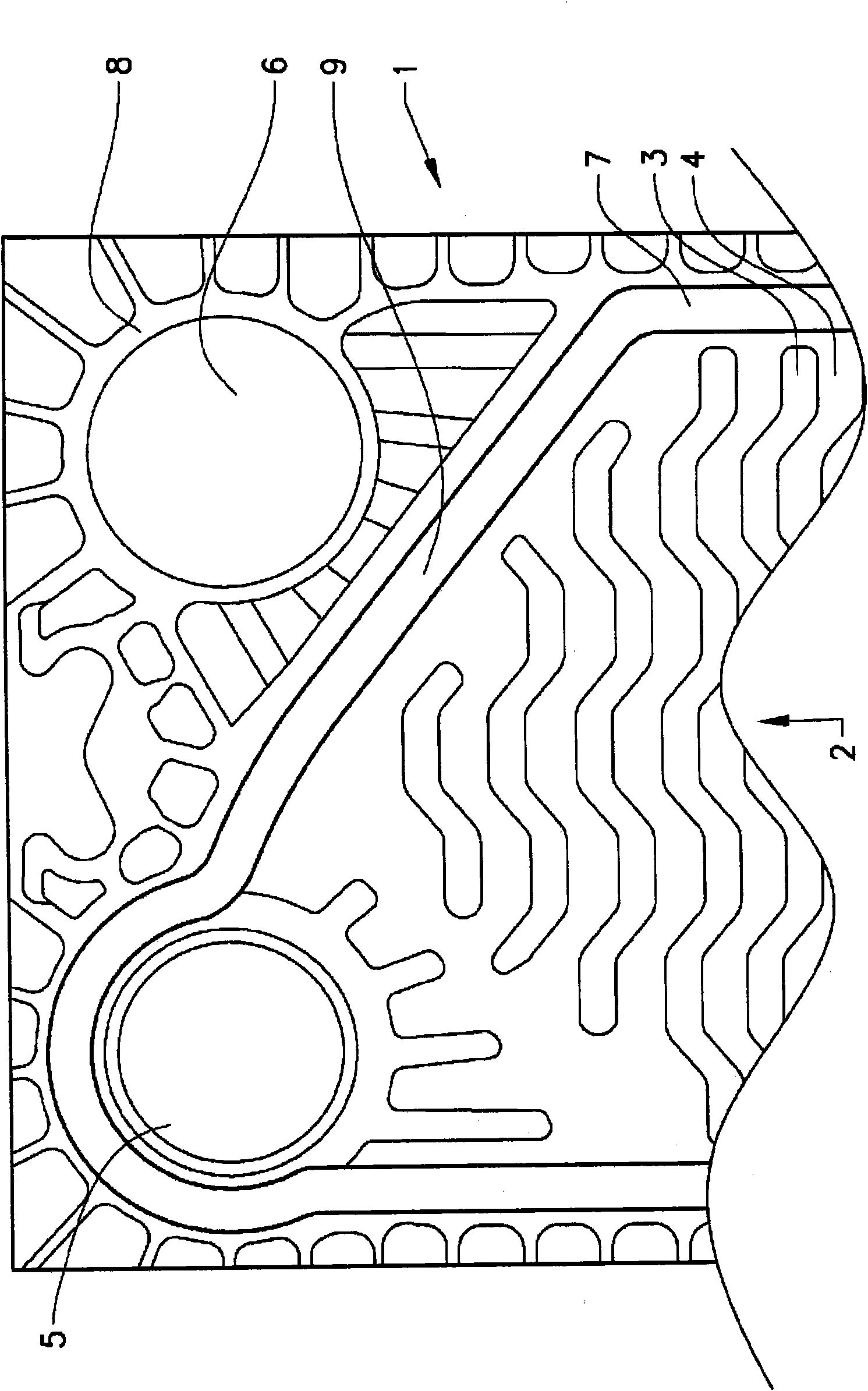

[0037] Figure 1 shows a part of a prior art contactless cassette for a heat exchanger disclosed in WO2006 / 080874. The heat exchanger cassette 1 includes two orifices constituting an inlet 5 and an outlet 6 and a heat transfer surface 2 having a ridge 3 and a valley 4. The plate also includes sealing gaskets suitable for sealing the fluid passages in the heat exchanger. The gasket 7 seals the contact-free product flow channel, and the annular gasket 8 seals the port for cooling / heating fluid. The liner 7 includes diagonal liner segments 9 which define the boundaries of the product channel at the distribution area of the inlet and outlet. The diagonal gasket section 9 is located in the diagonal gasket groove. Since the diagonal gasket groove is angled with respect to the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com