Precise near-net forming technology and device for bevel gear shaft

A near-net-shape, bevel gear technology, used in metal processing equipment, metal extrusion dies, etc., can solve the problems of inability to meet market demand for large quantities and high quality, poor product size uniformity, and low material utilization. , to achieve the effect of facilitating the shunting of excess metal, significant economic and social benefits, and saving mold materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

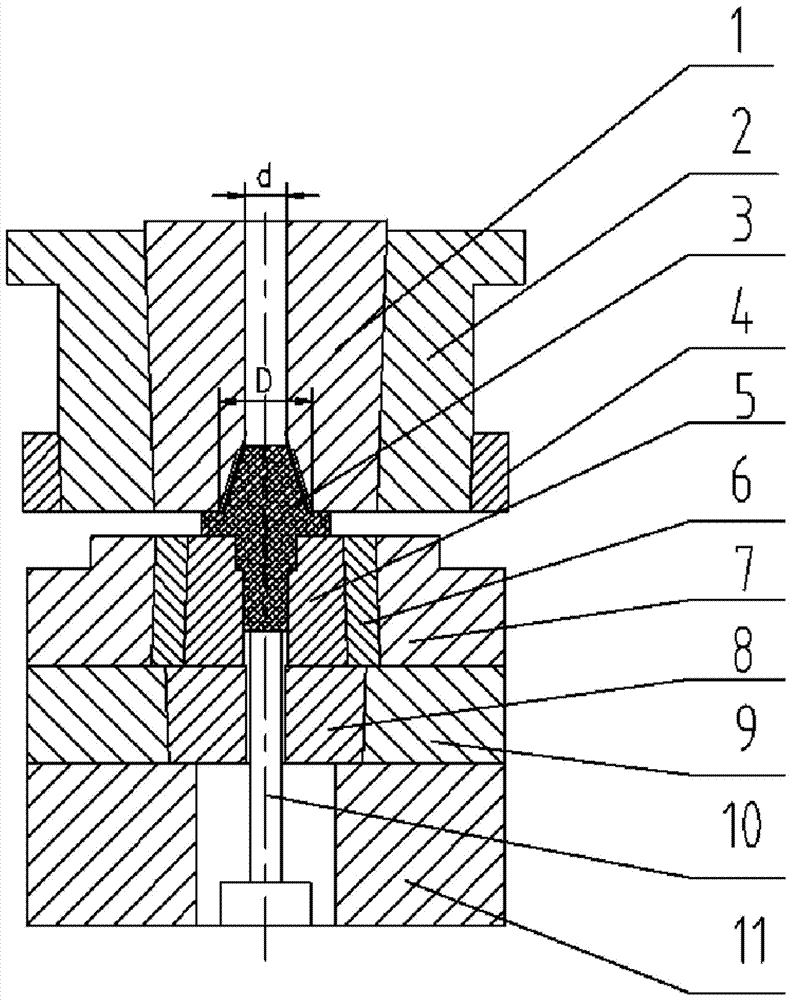

[0032] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0033] The purpose of the present invention is achieved through the following technical solutions:

[0034] The precision near-net shaping process of the bevel gear shaft of the present invention comprises the following steps:

[0035] a. Precise sawing and blanking of bar;

[0036] b. Annealing treatment;

[0037] c. Use high FM-4 molecular lubricant to lubricate the blank;

[0038] d. Cold heading preformed cone blank: use the method of cold heading at room temperature, preform the blank according to the bevel gear shaft's tooth cone angle and the shape of the shaft step, and lay the foundation for the next step of near-net shape bevel gear and step shaft;

[0039] e. Molybdenum disulfide lubrication: Stir molybdenum disulfide powder and engine oil according to the weight percentage of 30%-40%: 60%-70%, and then coat the prepared molybdenum disulfide on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com