Low-temperature chemical Ni-Cu-P plating solution and chemical Ni-Cu-P plating method applying the solution

A low-temperature chemical, ni-cu-p technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem of not applying low-carbon steel substrate surface, etc., to improve the working environment conditions, Excellent hardness and wear resistance, the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

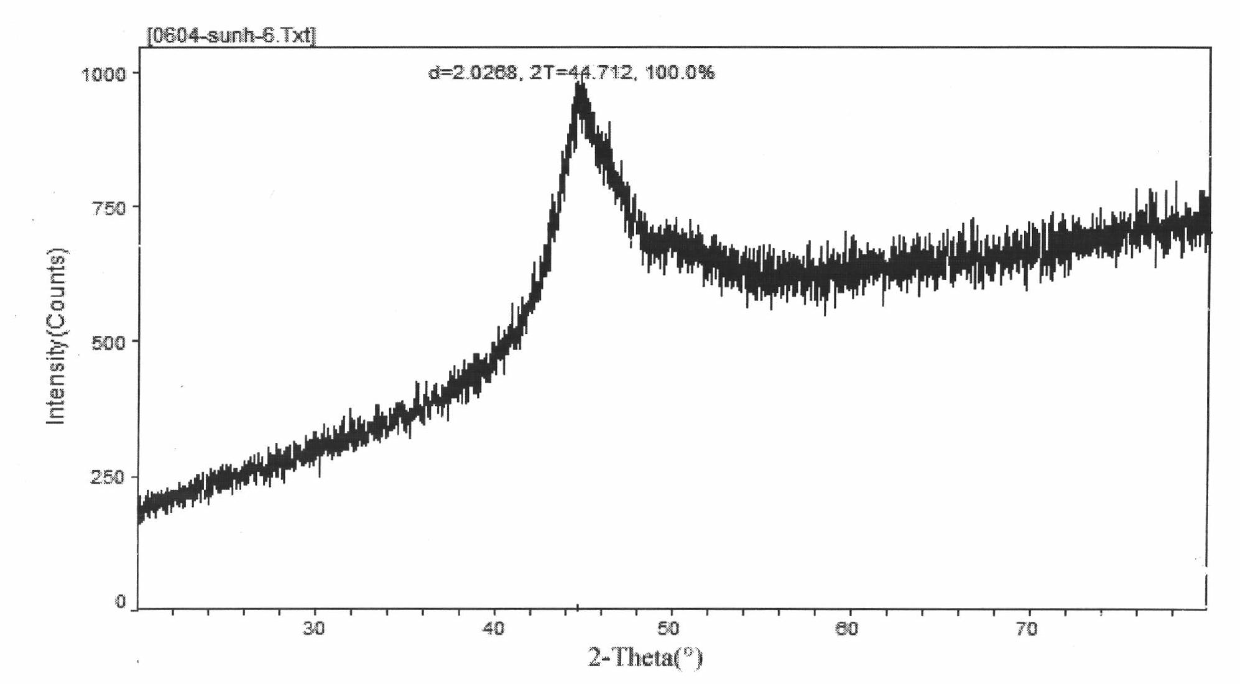

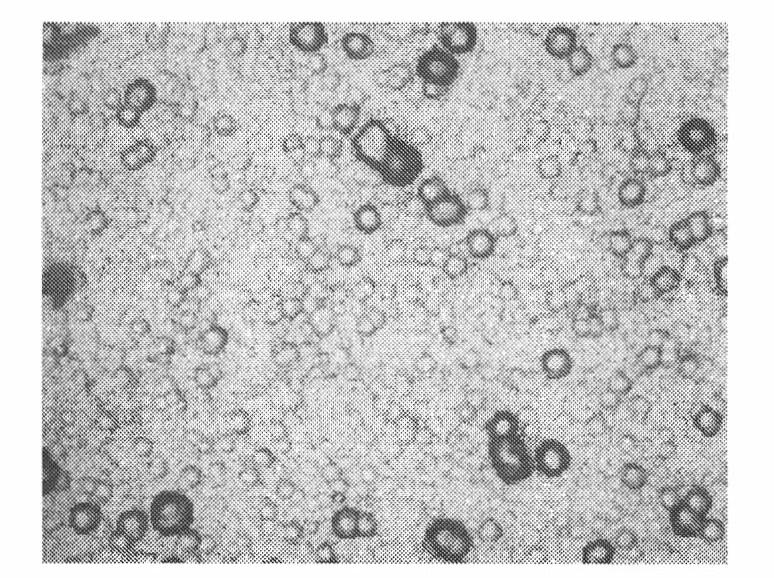

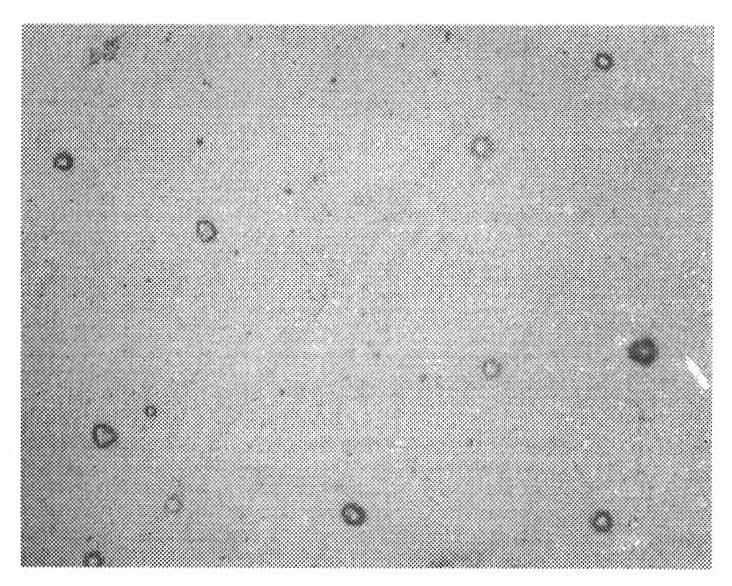

Image

Examples

Embodiment 1

[0065] A kind of low temperature chemical plating Ni-Cu-P solution, the prescription of this solution is: nickel sulfate 35g / L, copper sulfate 0.2g / L, sodium hypophosphite 25g / L, sodium acetate 8g / L, trisodium citrate 25g / L L, lactic acid 22ml / L, succinic acid 8g / L, glycine 0.01g / L, ammonium bifluoride 0.2g / L, potassium iodide 8mg / L, thiourea 1.5mg / L.

[0066] The specific configuration steps are:

[0067] (1) Accurately weigh each solid drug according to the above solution formula and dissolve it with a small amount of distilled water;

[0068] (2) the solution of nickel sulfate and copper sulfate is poured in the solution containing complex trisodium citrate, lactic acid, succinic acid and glycine under constant stirring;

[0069] (3) Add reducing agent sodium hypophosphite solution and stir and pour into (2) solution;

[0070] (4) Pour the stabilizing agent potassium iodide, thiourea and buffering agent sodium acetate solution into (3) solution under sufficient stirring r...

Embodiment 2

[0081] A kind of low temperature chemical plating Ni-Cu-P solution, the prescription of this solution is: nickel sulfate 35g / L, copper sulfate 0.2g / L, sodium hypophosphite 25g / L, sodium acetate 10g / L, trisodium citrate 30g / L L, lactic acid 28ml / L, succinic acid 10g / L, glycine 0.01g / L, ammonium bifluoride 0.2g / L, potassium iodide 8mg / L, thiourea 1.5mg / L.

[0082] The specific configuration steps are:

[0083] (1) Accurately weigh each solid drug according to the above solution formula and dissolve it with a small amount of distilled water;

[0084] (2) the solution of nickel sulfate and copper sulfate is poured in the solution containing complex trisodium citrate, lactic acid and succinic acid under constant stirring;

[0085] (3) Add reducing agent sodium hypophosphite solution and stir and pour into (2) solution;

[0086] (4) Pour the stabilizing agent potassium iodide, thiourea and buffering agent sodium acetate solution into (3) solution under sufficient stirring respecti...

Embodiment 3

[0097] A kind of low temperature chemical plating Ni-Cu-P solution, the formula of this solution is: nickel sulfate 35g / L, copper sulfate 0.4g / L, sodium hypophosphite 30g / L, sodium acetate 8g / L, trisodium citrate 25g / L L, lactic acid 28ml / L, succinic acid 10g / L, glycine 0.01g / L, ammonium bifluoride 0.2g / L, potassium iodide 8mg / L, thiourea 1.5mg / L.

[0098] The specific configuration steps are:

[0099] (1) Accurately weigh each solid drug according to the above solution formula and dissolve it with a small amount of distilled water;

[0100] (2) the solution of nickel sulfate and copper sulfate is poured in the solution containing complex trisodium citrate, lactic acid and succinic acid under constant stirring;

[0101] (3) Add reducing agent sodium hypophosphite solution and stir and pour into (2) solution;

[0102] (4) Pour the stabilizing agent potassium iodide, thiourea and buffering agent sodium acetate solution into (3) solution under sufficient stirring respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com